The discussion of poultry focuses primarily on chicken meat, but the principles also apply to the meat of turkey, geese, ducks, and squab.

Contents

Contamination of Poultry

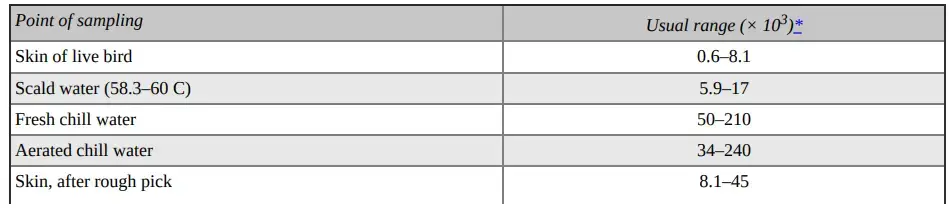

- The contamination sources outlined for meats also apply to fowl. The skin of living birds may carry an average of 1,500 microorganisms per square centimetre.

- These numbers likely reflect the natural flora of the skin in addition to other creatures that may have originated from the feet, feathers, and faeces.

- Washing, plucking, and evisceration all result in contamination of the skin and the lining of the bodily cavity.

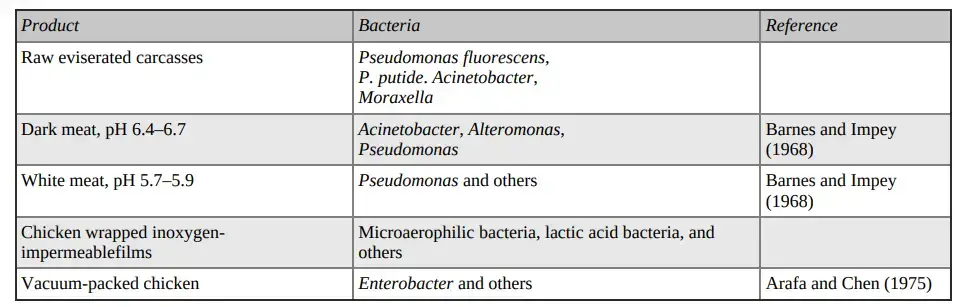

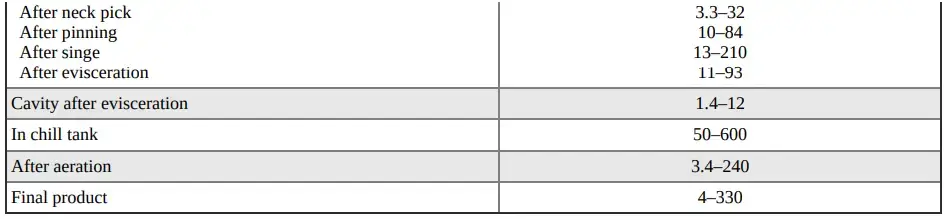

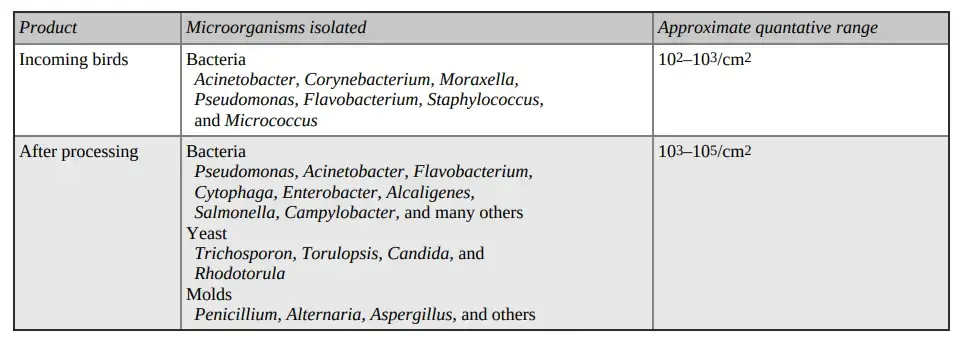

- The table displays microbiological counts measured at various processing stages. Comparing Table 17.1 with Table 17.2 reveals that the microbial loads of the final product are comparable.

- Clearly, processing methods have evolved since 1956. Currently, chickens are processed using a completely automated conveyor or track line with vacuum evisceration.

- The quantity of bacteria on the surface of chickens varies substantially. However, this diversity is greater between birds than between regions of the same bird.

- The types of organisms recovered depend on sample collection location and processing stage. Numerous genera are represented by isolates from poultry and poultry products (Table 17.3), The giblets (gizzards, hearts, and livers) are processed separately from the carcass, and the amount and types of microorganisms present may vary from those of the carcass.

- Considerable emphasis has been paid to the prevalence of salmonellae on poultry carcasses and the function of poultry processing in the transmission of salmonellosis.

- The reported incidence of salmonella-positive birds ranges from 0 to 50 percent.

- Campylobacter jejuni is also prevalent in poultry processing plants and on the processed bird.

Preservation of Poultry

- As with the slaughter of animals for meat, the manner in which poultry is killed and bled has a significant impact on the quality of the final product.

- Modern techniques involve serving the jugular vein and draining the blood while the bird is supported by its feet.

- Trachea preservation is referred to as an outside cut, whereas trachea severing is a kosher cut.

- When birds are scalded, they may gasp and pull scalding water into their air sacs. Because the cut end of the trachea is dragged under the skin, the kosher cut appears to decrease breathing of scalding water.

- The manner of picking or plucking has some effect on the quality of the bird’s preservation. Dry-plucked birds are more resistant to decomposition than semiscalded or scalded birds because the skin is less likely to be ruptured and there are more pinfeathers remaining.

- The semiscald method, in which birds are submerged in water at around 55 degrees Celsius for two minutes, is the most common method for plucking birds.

- Experiments have demonstrated that if sufficient measures are adopted, the water used in the semiscald technique is not a significant source of contaminating microorganisms.

- Although the total number of bacteria in the scald water may rise during processing, contamination to birds is avoided due to (1) the temperature of the scald water, (2) the low initial count on certain birds, and (3) the dilution effect of adding new water to the scald tank (Brune and Cunningham, 1971).

- The USDA mandates a minimum of 1 quart each minute per bird. Birds scalded with steam are more effective than those scalded with hot water at reducing the quantity of bacteria, including coliforms and salmonella.

1. Asepsis

- It is rather difficult to prevent bacteria from infecting the prepared poultry.

- The cleanliness of the birds’ habitat before to slaughter has some effect on the number of microorganisms on the skin during dressing, but even under ideal conditions, enough spoilage organisms contaminate the skin to permit microbial decay if handling and storage conditions are inadequate.

- If the fowl is not eviscerated until it is sold on the retail market, contamination of the lining of the body cavity can be avoided, although visceral taints may occur if the birds are not appropriately refrigerated.

- The shackles that restrain the feet and head of the chickens may be a major source of infection. When equipment is cleaned and sterilised on a periodic basis, contamination can be reduced.

2. Use of Heat

- Dressed chicken and other poultry may be preserved in their own juices or in jelly, either whole or in pieces.

- Similar thermal techniques are used to preserve canned meats.

- Before being packaged in glass jars or cans, the chicken or other poultry may be salted in a weak brine.

3. Use of Low Temperatures

- The majority of poultry is kept by chilling or freezing. Priority number one in either mode of storage is a rapid cooling process immediately following the evisceration and drawing of the birds (if that is done).

- There are various commercial ways for submerging birds in cold water, ice water, or ice slush.

- Variations include counterflow vat-type, counterflow tumbler-type, and oscillating vat-type chillers, agitated ice and water, and blasts of cold air or CO2 or refrigerant sprays or solid CO2.

- The chill tanks might be a source of contamination if they are not adequately managed. Fresh potable water injected to the chiller would flow against the movement of the carcasses in a counterflow system, so inhibiting the growth of microorganisms more effectively.

- To lower the quantity of organisms, chlorine can be added to chill-tank water. However, the effect of chlorine on the carcasses’ shelf life is questionable.

- Birds chilled by blasts of cold air would be relatively drier than those chilled in chill tanks. The extra moisture may not only introduce organisms to the carcasses, but also promote their growth.

a. Chilling

- Chilling storage of poultry is limited to a brief term, typically less than a month; birds that need to be preserved for a longer duration must be frozen.

- Packing the dressed birds in ice has been utilised for short-term storage and in the absence of mechanical refrigeration.

- The lower the storage temperature, the longer the birds can be kept without undergoing adverse alterations.

- Ayres (1959) discovered that, relative to room temperature, the storage life of cut-up chicken was two days longer at 10 degrees Celsius, six days longer at 4.4 degrees Celsius, and fourteen days longer at 0 degrees Celsius.

b. Freezing

- If frozen quickly and stored at a low temperature, poultry can be kept in excellent condition for months.

- As a result of the formation of fine ice crystals within the fibres, quick freezing is preferable since it produces feathers with a light appearance.

- Slow freezing, on the other hand, causes the accumulation of big crystals outside the fibres, which darkens the flesh.

- A chicken frozen quickly while still fresh will have smaller crystals than one frozen slowly. Most commercially frozen chickens are packaged ten to a box lined with moisture- and airtight paper and are dressed but not drawn.

- Poultry must be frozen quickly enough to preserve the majority of its natural bloom or outward appearance of a freshly dressed bird.

- To prevent surface drying, the storage temperature should be below 17.8 C and the relative humidity should be above 95%.

- The majority of poultry is flash-frozen at 29 degrees Celsius or lower in circulating air or on a moving conveyor belt in a freezing tunnel.

- For rapid freezing, a smaller packaging is required, typically a full, halved, or deboned bird wrapped in a special watertight and almost airtight wrapper.

- Although some germs are destroyed by the freezing process and the amount decreases slowly throughout storage, plenty bacteria remain to cause spoiling when the bird is thawed.

- During harvesting, dressing, drawing, and chilling, as well as during the freezing process until the bird’s temperature reaches 0 degrees Celsius, bacteria might multiply.

- Before freezing, deterioration caused by bacterial development, diffusion of taints from the viscera, and activity of the bird’s enzymes will be transferred to the frozen product.

- Although bacterial growth has ceased, some enzymatic activity will persist unless the storage temperature is extremely low.

- Unless sufficient sanitary precautions are performed, the removal of cooked poultry bones for later canning or rapid freezing will result in a significant increase in bacteria.

- Numerous Proteus and Alcaligenes bacteria, as well as coliform bacteria, have been discovered at low temperatures. Canning will kill them, but rapid freezing allows for their survival.

4. Use of Preservatives

- Although minimal doses of antibiotic may be deposited in the flesh, feeding antibiotics to birds may increase the proportion of resistant germs in their faeces and, consequently, on their bodies.

- The majority of the antibiotics present in the flesh of treated chickens are eliminated by cooking. It has also been reported that soaking cut-up poultry in solutions of organic acids (acetic, adipic, etc.) at pH 2.5 extends shelf life.

- Occasionally, turkey is cured in a solution of salt, sugar, and sodium nitrate for several weeks at approximately 3.3 degrees Celsius, then washed, dried, and smoked.

- Typically, a light smoking technique is employed for flavour rather than preservation.

- The recommended smoking temperatures and times range from 43.3 to 60 degrees Celsius and a few hours to several days, respectively.

5. Carbon Dioxide Atmosphere

- The growth of psychrotrophs is inhibited by increasing carbon dioxide concentrations (10 to 20 percent) in the environment of stored chickens.

- Dry ice containing the corpses may act as the carbon dioxide source.

- In combination with a carbon dioxide atmosphere, the usage of films with both high and low gas permeability is the key component in lowering microbial counts.

6. Use of Irradiation

- Irradiation of poultry with cathode or gamma rays could be a viable way of food preservation because the rays generate a less undesirable change in appearance and flavour than they do in other foods, but the practise has not yet been implemented commercially.

- Radiation doses between 1 and 10 kilograys would diminish the microbial flora and increase the refrigerated shelf life of the product.

- The carcasses of chickens have been treated with 2.5 kilograys to eliminate salmonellae.

Spoilage of Poultry

- Enzymes of the bird contribute to the deterioration of the dressed bird, while bacteria in the intestines are the principal cause of spoiling.

- According to research on the bacterial spoilage of poultry, the majority of bacterial growth occurs on the surfaces, such as the skin, the lining of the body cavity, and any cut surfaces, and decomposition products permeate slowly into the meat.

- When the bacterial population on the skin was approximately 2.5 million per square centimetre, a surface odour was detected.

- In one series of trials, this took roughly 4 weeks at 0 degrees Celsius and 5 weeks at 1,1 degrees Celsius. Pseudomonas and, to a lesser extent, yeasts, such as Torulopsis and Rhodotorula, decompose eviscerated poultry stored at 10 degrees Celsius or below.

- Above 10 degrees Celsius, micrococci often predominate, with Alcaligenes and Flavobacterium also growing.

- Typically, the surface of meat turns slimy over time. Small levels of iron in the wash water (1 to 5 ppm) may promote bacterial growth on the surface and pseudomonad synthesis of the luminous pigment pyoverdine; higher concentrations of iron will inhibit pigmentation.

- The ideal magnesium concentration for pigment synthesis by P. fluorescens is around 100 ppm.

- Frequently, iced, cut-up poultry develops a slime along with an odour characterised as “tainted,” “acidic,” “sour,” or “dishraggish.”

- This deficiency is primarily caused by Pseudomonas species, while Alcaligenes may also be involved.

- Similar bacteria thrive at temperatures as low as 0 C and as high as 10 C, and massive quantities, approximately 10 8 per square centimetre, must be present before the stench is detectable.

- Table 17.4 provides a summary of the principal species responsible for spoiling. During refrigerated storage, chemical changes in poultry meat other than those produced by bacteria occur and eventually degrade the product’s quality.