What is Centrifuge?

- A centrifuge is a laboratory device that is used to separate particles from a solution according to their size, shape, density, viscosity of the medium, and rotor speed. The principle of centrifugation involves the application of centrifugal force, which is the force exerted on a body moving in a circular path, directed away from the center around which the body is rotating. This force is used to accelerate the settling rate of particles within a liquid suspension.

- In a centrifuge, samples are placed in tubes that are inserted into the rotor, the rotating component of the machine. When the centrifuge is powered on, the rotor spins at high speeds, creating a strong centrifugal force. This force causes denser particles or substances within the suspension to move outward to the bottom of the tube, while less dense substances rise to the top. The result is the separation of components based on their density, with the formation of a solid pellet at the bottom of the tube and a supernatant (the liquid above the pellet) that can be removed.

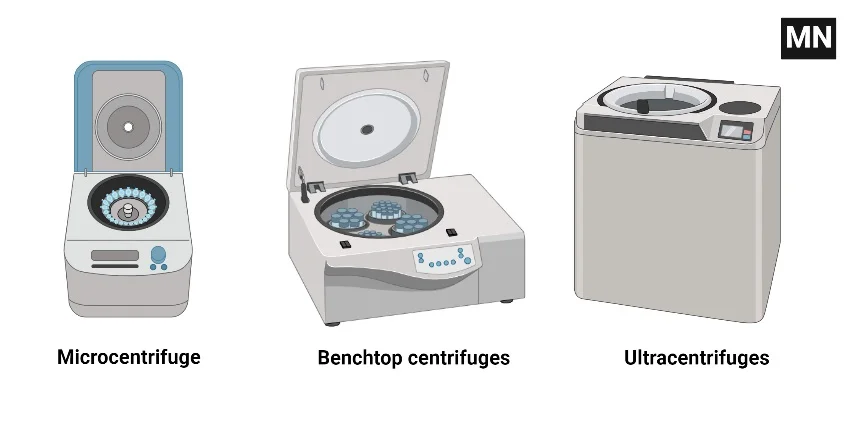

- Centrifuges come in various sizes and designs, ranging from small benchtop units to larger floor-standing models, and are equipped with different types of rotors and operational speeds to accommodate a wide range of applications. These applications include blood component separation, purification of cells, viruses, proteins, and nucleic acids, as well as the clarification of suspensions and emulsions in both research and industrial settings.

Types of Centrifuges

There are many different types of centrifuges available, and the appropriate type depends on the specific application and the characteristics of the sample being processed. Some common types of centrifuges include:

1. Benchtop centrifuges

These are small, portable centrifuges that are designed to be used on a laboratory bench or tabletop. They are commonly used for routine separations and for processing small samples.

Operating procedure Benchtop centrifuges

The operating procedure for a benchtop centrifuge may vary depending on the specific model and its intended use, but there are some general steps that are common to most benchtop centrifuges. Here is a basic outline of the operating procedure for a benchtop centrifuge:

- Familiarize yourself with the centrifuge and its controls: Before using the centrifuge, make sure you understand how to operate it and are familiar with the controls and safety features.

- Prepare the sample: Depending on the specific application, you may need to prepare the sample in a specific way before placing it in the rotor. This may involve diluting the sample, adding a precipitating agent, or performing other preparatory steps.

- Load the sample: Carefully load the sample into the rotor, making sure not to overfill it or exceed the maximum capacity of the rotor. Follow the manufacturer’s guidelines for loading the sample.

- Close the lid: Securely close the lid of the centrifuge, making sure that it is properly sealed to contain the sample and protect the user from the spinning rotor.

- Set the speed and duration: Use the control panel to set the desired speed and duration of the centrifugation process. Follow the manufacturer’s guidelines for selecting the appropriate speed and duration for your specific application.

- Start the centrifuge: Press the start button on the control panel to begin the centrifugation process. Make sure to keep your hands and other objects away from the rotor while it is spinning.

- Monitor the centrifuge: Keep an eye on the centrifuge while it is running to ensure that it is operating properly. If you notice any problems or abnormalities, stop the centrifuge immediately and troubleshoot the issue.

- Unload the sample: When the centrifugation process is complete, carefully unload the sample from the rotor. Follow the manufacturer’s guidelines for unloading the sample safely.

- Clean the centrifuge: After use, be sure to clean the rotor, the control panel, and any other parts of the centrifuge that may have come into contact with the sample. This will help to prevent contamination and ensure that the centrifuge is ready for use in the future.

Overall, it is important to follow the manufacturer’s guidelines and take proper precautions when operating a benchtop centrifuge to ensure the safety of the user and the accuracy of the results.

Applications of Benchtop centrifuges

Benchtop centrifuges are small, portable centrifuges that are designed to be used on a laboratory bench or tabletop. They are commonly used for routine separations and for processing small samples. Some specific applications of benchtop centrifuges include:

- Separating cells: Benchtop centrifuges can be used to separate cells, such as red blood cells or white blood cells, based on their density or size.

- Purifying proteins: Benchtop centrifuges can be used to purify proteins by precipitating them out of solution and collecting the precipitate after centrifugation.

- Separating particles: Benchtop centrifuges can be used to separate particles, such as viruses or bacteria, based on their density or size.

- Preparing samples for analysis: Benchtop centrifuges can be used to prepare samples for analysis by separating or concentrating the components of the sample.

- Isolating DNA or RNA: Benchtop centrifuges can be used to isolate DNA or RNA from biological samples by using techniques such as density gradient centrifugation.

Overall, benchtop centrifuges are useful tools for separating, purifying, and concentrating a wide range of substances in the laboratory. They are particularly useful for processing small samples and for routine separations.

Advantages of Benchtop centrifuges

They have several advantages over larger centrifuges, including:

- Compact size: Benchtop centrifuges are much smaller and more portable than larger centrifuges, making them easier to store and transport.

- Low cost: Benchtop centrifuges are generally less expensive than larger centrifuges, making them a more cost-effective option for many labs.

- Easy to use: Benchtop centrifuges are generally simpler to operate than larger centrifuges, making them a good choice for labs that do not have a lot of experience with centrifugation.

- Versatility: Benchtop centrifuges are versatile and can be used for a wide range of applications, including separating cells, purifying proteins, and preparing samples for analysis.

- Small sample size: Benchtop centrifuges are well-suited for processing small samples, making them a good choice for labs that do not have a lot of sample material available.

Overall, benchtop centrifuges are an important tool in many labs due to their compact size, low cost, ease of use, versatility, and ability to process small samples. They are an essential piece of equipment for many scientific and industrial applications.

Limitations of Benchtop centrifuges

Although benchtop centrifuges are useful tools for many scientific and industrial applications, they do have some limitations. Some of the main limitations of benchtop centrifuges include:

- Low maximum speed: Benchtop centrifuges generally have a lower maximum speed than larger centrifuges, which can limit their separation efficiency for denser samples.

- Small capacity: Benchtop centrifuges generally have a smaller capacity than larger centrifuges, which can be limiting for applications that require the processing of large quantities of sample material.

- Limited rotor options: Benchtop centrifuges generally have fewer rotor options than larger centrifuges, which can limit their versatility for certain applications.

- Less robust construction: Benchtop centrifuges are typically not as robustly constructed as larger centrifuges, which can make them less durable and more prone to failure.

- Limited temperature control: Some benchtop centrifuges do not have the ability to control the temperature of the sample during the centrifugation process, which can be a limitation for certain applications.

Overall, while benchtop centrifuges are useful tools for many applications, they are not suitable for all purposes and may be limited by their low maximum speed, small capacity, limited rotor options, less robust construction, and limited temperature control.

2. Floor-standing centrifuges

- These are larger centrifuges that are designed to be used on the floor or on a dedicated stand. They are commonly used for larger samples or for higher-throughput applications.

- A floor-standing centrifuge is a type of laboratory equipment that is used to separate different components of a liquid mixture based on their densities. It consists of a spinning rotor that holds the sample tubes or bottles, and a drive motor that provides the power to spin the rotor at high speeds. The rotor is surrounded by a hinged lid, which helps to contain the samples during centrifugation and may have a safety interlock to prevent the rotor from spinning if the lid is open.

- The control panel allows the user to set the desired speed and time for the centrifuge to run, and may also include displays for monitoring the status of the machine and any error messages. Some floor-standing centrifuges may have removable buckets that can be used to hold the sample tubes or bottles in place within the rotor. The brake system is used to bring the rotor to a stop after the centrifugation process is complete, and the base of the machine provides support and stability during operation.

- Floor-standing centrifuges are typically used in research laboratories and industrial settings, and are suitable for handling larger volumes of samples. They are generally more powerful and can operate at higher speeds than benchtop centrifuges, which are smaller and more compact.

Applications of Floor-standing centrifuges

Floor-standing centrifuges are widely used in a variety of scientific and industrial applications, including:

- Separating blood components: Floor-standing centrifuges are commonly used in medical and clinical settings to separate different components of blood, such as red blood cells, white blood cells, and plasma.

- Purifying proteins: Centrifugation is often used to purify and concentrate proteins from complex mixtures, such as those found in cell lysates or fermentation broths.

- Analyzing chemical compounds: Centrifugation can be used to separate and isolate different chemical compounds in a mixture based on their densities, which can be useful for analysis and characterization.

- Industrial processes: Centrifuges are also used in a variety of industrial processes, such as the separation of oil and water in the petroleum industry, or the separation of solid particles from liquids in the food processing industry.

- Environmental testing: Centrifuges are often used to separate and analyze different components of environmental samples, such as water or soil, for the purpose of testing and monitoring.

- Quality control: Centrifugation is often used as a quality control measure to ensure the purity and consistency of products, such as pharmaceuticals or industrial chemicals.

Advantages of Floor-standing centrifuges

There are several advantages to using floor-standing centrifuges in a laboratory or industrial setting:

- High-speed operation: Floor-standing centrifuges are generally more powerful and can operate at higher speeds than benchtop centrifuges, which allows them to separate mixtures more efficiently and quickly.

- Large sample capacity: Floor-standing centrifuges typically have a larger capacity for samples than benchtop centrifuges, which makes them more suitable for handling larger volumes of samples.

- High-capacity rotors: Many floor-standing centrifuges have high-capacity rotors that can hold a larger number of sample tubes or bottles, which reduces the need for multiple runs and saves time.

- Wide range of rotors available: There is a wide range of rotors available for floor-standing centrifuges, including fixed angle, swing-out, and vertical rotors, which allows them to be used for a variety of applications and sample types.

- Durability: Floor-standing centrifuges are generally more durable and have a longer lifespan than benchtop centrifuges due to their larger size and heavier construction.

- Safety features: Many floor-standing centrifuges have built-in safety features, such as interlocks on the lid and emergency stop buttons, to ensure the safety of the operator and the samples.

- Versatility: Floor-standing centrifuges can be used for a wide range of applications, from medical and clinical settings to industrial processes, and can handle a variety of sample types and volumes.

Limitations of Floor-standing centrifuges

There are a few limitations to using floor-standing centrifuges in a laboratory or industrial setting:

- Size and weight: Floor-standing centrifuges are generally larger and heavier than benchtop centrifuges, which can make them difficult to move or transport.

- Cost: Floor-standing centrifuges are typically more expensive to purchase and maintain than benchtop centrifuges due to their larger size and higher capacity.

- Complexity: Some floor-standing centrifuges may have more complex control panels and require more training to operate than benchtop centrifuges.

- Power requirements: Floor-standing centrifuges typically require a higher power supply and may need to be plugged into a dedicated outlet to operate properly.

- Sample size limitations: Some floor-standing centrifuges may have limitations on the size or shape of the samples that can be processed, which may restrict their use for certain applications.

- Vibration: Some floor-standing centrifuges may generate more vibration during operation than benchtop centrifuges, which may affect the accuracy of some measurements or experiments.

- Noise: Floor-standing centrifuges can generate more noise during operation than benchtop centrifuges, which may be a concern in some laboratory or industrial settings.

3. High-speed centrifuges

- These centrifuges are designed to spin the rotor at very high speeds, typically in excess of 10,000 rpm.

- They are commonly used for denser samples or for applications that require high levels of separation efficiency.

- High-speed centrifuges are a type of laboratory equipment that are designed to spin samples at very high speeds, typically in the range of 20,000 to 100,000 revolutions per minute (rpm). They are used to separate different components of a liquid mixture based on their densities, and can be either floor-standing or benchtop models.

- High-speed centrifuges typically have a spinning rotor that holds the sample tubes or bottles, and a drive motor that provides the power to spin the rotor.

- They may also have a control panel that allows the user to set the desired speed and time for the centrifuge to run, as well as displays for monitoring the status of the machine and any error messages. Some high-speed centrifuges may have removable buckets or other accessories to hold the sample tubes or bottles in place within the rotor.

- High-speed centrifuges are used in a variety of applications, including the separation of blood components, purification of proteins, and analysis of chemical compounds. They are particularly useful for separating small volumes of samples or for separating samples at very high speeds, which may be required for certain applications.

- However, they may be more expensive to purchase and maintain than lower-speed centrifuges, and may have higher power requirements and generate more vibration and noise during operation.

Applications of High-speed centrifuges

High-speed centrifuges are used in a variety of applications, including:

- Separating blood components: High-speed centrifuges are commonly used in medical and clinical settings to separate different components of blood, such as red blood cells, white blood cells, and plasma.

- Purifying proteins: Centrifugation is often used to purify and concentrate proteins from complex mixtures, such as those found in cell lysates or fermentation broths. High-speed centrifuges may be particularly useful for separating small volumes of samples or for separating samples at very high speeds, which may be required for certain applications.

- Analyzing chemical compounds: Centrifugation can be used to separate and isolate different chemical compounds in a mixture based on their densities, which can be useful for analysis and characterization. High-speed centrifuges may be particularly useful for separating small volumes of samples or for separating samples at very high speeds, which may be required for certain applications.

- Industrial processes: Centrifuges are also used in a variety of industrial processes, such as the separation of oil and water in the petroleum industry, or the separation of solid particles from liquids in the food processing industry. High-speed centrifuges may be used for these applications if very high separation speeds are required.

- Environmental testing: Centrifuges are often used to separate and analyze different components of environmental samples, such as water or soil, for the purpose of testing and monitoring. High-speed centrifuges may be used for these applications if very high separation speeds are required.

- Quality control: Centrifugation is often used as a quality control measure to ensure the purity and consistency of products, such as pharmaceuticals or industrial chemicals. High-speed centrifuges may be used for these applications if very high separation speeds are required.

Advantages of High-speed centrifuges

There are several advantages to using high-speed centrifuges in a laboratory or industrial setting:

- High separation speeds: High-speed centrifuges are designed to spin samples at very high speeds, typically in the range of 20,000 to 100,000 rpm, which allows them to separate mixtures more efficiently and quickly.

- Small sample volumes: High-speed centrifuges are particularly useful for separating small volumes of samples, as they can achieve high separation speeds even with small amounts of sample material.

- High-capacity rotors: Many high-speed centrifuges have high-capacity rotors that can hold a large number of sample tubes or bottles, which reduces the need for multiple runs and saves time.

- Wide range of rotors available: There is a wide range of rotors available for high-speed centrifuges, including fixed angle, swing-out, and vertical rotors, which allows them to be used for a variety of applications and sample types.

- Safety features: Many high-speed centrifuges have built-in safety features, such as interlocks on the lid and emergency stop buttons, to ensure the safety of the operator and the samples.

- Versatility: High-speed centrifuges can be used for a wide range of applications, from medical and clinical settings to industrial processes, and can handle a variety of sample types and volumes.

- High precision: High-speed centrifuges can achieve high levels of separation precision, which is important for certain applications such as the purification of proteins or the analysis of chemical compounds.

Limitations of High-speed centrifuges

There are a few limitations to using high-speed centrifuges in a laboratory or industrial setting:

- Cost: High-speed centrifuges are generally more expensive to purchase and maintain than lower-speed centrifuges due to their high-speed capabilities and specialized rotors.

- Complexity: Some high-speed centrifuges may have more complex control panels and require more training to operate than lower-speed centrifuges.

- Power requirements: High-speed centrifuges typically require a higher power supply and may need to be plugged into a dedicated outlet to operate properly.

- Sample size limitations: Some high-speed centrifuges may have limitations on the size or shape of the samples that can be processed, which may restrict their use for certain applications.

- Vibration: High-speed centrifuges may generate more vibration during operation than lower-speed centrifuges, which may affect the accuracy of some measurements or experiments.

- Noise: High-speed centrifuges can generate more noise during operation than lower-speed centrifuges, which may be a concern in some laboratory or industrial settings.

- Safety concerns: High-speed centrifuges can pose safety risks due to the high speeds at which they operate, and proper precautions must be taken to ensure the safety of the operator and the samples.

4. Refrigerated centrifuges

- These centrifuges are equipped with a refrigeration system that allows for the cooling of the sample during the centrifugation process.

- They are commonly used for samples that are sensitive to temperature changes or for applications that require the separation of temperature-sensitive samples.

- A refrigerated centrifuge is a type of laboratory equipment that is used to separate different components of a liquid mixture based on their densities. It consists of a spinning rotor that holds the sample tubes or bottles, and a drive motor that provides the power to spin the rotor at high speeds. The rotor is surrounded by a hinged lid, which helps to contain the samples during centrifugation and may have a safety interlock to prevent the rotor from spinning if the lid is open.

- In addition to the standard components of a centrifuge, a refrigerated centrifuge also includes a cooling system that maintains the temperature of the samples at a predetermined level during centrifugation. The cooling system may consist of a refrigeration unit, a cooling chamber, and a temperature control system.

- Refrigerated centrifuges are used in a variety of applications, including the separation of blood components, purification of proteins, and analysis of chemical compounds. They are particularly useful for separating temperature-sensitive samples or for maintaining the integrity of samples that require cold storage during the centrifugation process. However, they may be more expensive to purchase and maintain than non-refrigerated centrifuges, and may have higher power requirements and generate more vibration and noise during operation.

Applications of Refrigerated centrifuges

Refrigerated centrifuges are used in a variety of applications, including:

- Separating blood components: Refrigerated centrifuges are commonly used in medical and clinical settings to separate different components of blood, such as red blood cells, white blood cells, and plasma. They are particularly useful for separating temperature-sensitive samples or for maintaining the integrity of samples that require cold storage during the centrifugation process.

- Purifying proteins: Centrifugation is often used to purify and concentrate proteins from complex mixtures, such as those found in cell lysates or fermentation broths. Refrigerated centrifuges may be particularly useful for separating temperature-sensitive samples or for maintaining the integrity of samples that require cold storage during the centrifugation process.

- Analyzing chemical compounds: Centrifugation can be used to separate and isolate different chemical compounds in a mixture based on their densities, which can be useful for analysis and characterization. Refrigerated centrifuges may be particularly useful for separating temperature-sensitive samples or for maintaining the integrity of samples that require cold storage during the centrifugation process.

- Industrial processes: Centrifuges are also used in a variety of industrial processes, such as the separation of oil and water in the petroleum industry, or the separation of solid particles from liquids in the food processing industry. Refrigerated centrifuges may be used for these applications if temperature-sensitive samples are involved or if cold storage is required during the centrifugation process.

- Environmental testing: Centrifuges are often used to separate and analyze different components of environmental samples, such as water or soil, for the purpose of testing and monitoring. Refrigerated centrifuges may be used for these applications if temperature-sensitive samples are involved or if cold storage is required during the centrifugation process.

- Quality control: Centrifugation is often used as a quality control measure to ensure the purity and consistency of products, such as pharmaceuticals or industrial chemicals. Refrigerated centrifuges may be used for these applications if temperature-sensitive samples are involved or if cold storage is required during the centrifug

Advantages of Refrigerated centrifuges

Refrigerated centrifuges have several advantages over non-refrigerated centrifuges:

- Temperature control: Refrigerated centrifuges are equipped with cooling systems that allow the temperature of the samples being spun to be controlled. This is especially useful for temperature-sensitive samples or for reducing the risk of sample degradation during the spinning process.

- Increased sample stability: The ability to control the temperature of the samples being spun can also increase the stability of the samples. For example, some enzymes are more stable at lower temperatures and can be preserved for longer periods of time if stored in a refrigerated centrifuge.

- Improved separation efficiency: Refrigerated centrifuges can also improve the efficiency of separations, particularly when dealing with samples that contain large amounts of insoluble material. The cooler temperature can help to reduce the risk of sample clogging or fouling, which can occur when samples are heated up during the spinning process.

- Increased sample throughput: Refrigerated centrifuges can also increase the sample throughput of a laboratory by allowing multiple samples to be processed simultaneously. This is because the cooling system helps to dissipate the heat generated during the spinning process, which can allow the centrifuge to run for longer periods of time without overheating.

Overall, refrigerated centrifuges offer improved sample stability, increased separation efficiency, and increased sample throughput, making them an important tool for many laboratory applications.

Limitations of Refrigerated centrifuges

There are several limitations to using refrigerated centrifuges:

- Cost: Refrigerated centrifuges are generally more expensive than non-refrigerated centrifuges due to the additional cost of the cooling system and the need for regular maintenance of that system.

- Size and weight: Refrigerated centrifuges are generally larger and heavier than non-refrigerated centrifuges due to the added cooling system and the need for additional insulation. This can make them more difficult to move or transport.

- Limited temperature range: The temperature range of refrigerated centrifuges is typically limited to between 4°C and 40°C, which may not be suitable for all samples. In some cases, a wider temperature range may be required, in which case a non-refrigerated centrifuge may be more suitable.

- Risk of sample contamination: If the refrigerated centrifuge is not properly maintained and cleaned, there is a risk of sample contamination. This can occur if bacteria or other contaminants enter the centrifuge and come into contact with the samples being spun.

Overall, refrigerated centrifuges are a valuable tool for many laboratory applications, but they can be costly and may have some limitations in terms of temperature range and risk of sample contamination. It is important to carefully consider the specific needs of your laboratory and the types of samples you will be working with before deciding whether a refrigerated centrifuge is the right choice.

5. Microcentrifuges

- Microcentrifuges are small, high-speed centrifuges that are used to separate small volumes of liquid samples in the laboratory. They are commonly used to isolate DNA, RNA, and proteins, and to purify samples for downstream applications such as PCR, western blotting, and chromatography.

- Microcentrifuges are typically smaller and more compact than standard benchtop centrifuges, making them suitable for use in small laboratories or in field settings. They are also lightweight and portable, making them easy to transport to different locations.

- Microcentrifuges typically have a maximum speed of around 15,000 to 20,000 rpm, and are equipped with a rotor that can hold a range of different tube sizes, such as microtubes, PCR tubes, and Eppendorf tubes. Some microcentrifuges also have refrigeration capabilities, which can be useful for temperature-sensitive samples.

- Overall, microcentrifuges are a useful tool for separating small volumes of liquid samples in the laboratory and are commonly used in molecular biology and biochemistry research.

Applications of Microcentrifuges

Microcentrifuges are widely used in the laboratory for a variety of applications, including:

- Isolation of DNA, RNA, and proteins: Microcentrifuges are commonly used to isolate DNA, RNA, and proteins from cell or tissue samples. This is typically done by lysing the cells and then spinning the lysate in a microcentrifuge to separate the cellular components.

- Purification of samples: Microcentrifuges can also be used to purify samples for downstream applications such as PCR, western blotting, and chromatography. For example, microcentrifuges can be used to remove contaminants from a sample, or to concentrate a sample by spinning it down to a smaller volume.

- Pellet preparation: Microcentrifuges can also be used to prepare pellets of cells or other biological materials. This is typically done by spinning the cells in a microcentrifuge at high speed, which causes the cells to sediment to the bottom of the tube.

- Centrifugation of microtubes: Microcentrifuges are specifically designed to spin small tubes, such as microtubes and PCR tubes, at high speeds. This makes them an ideal tool for applications such as DNA purification and protein separation, where small volumes of sample are used.

Overall, microcentrifuges are an essential tool for many laboratory applications, particularly in molecular biology and biochemistry research.

Advantages of Microcentrifuges

There are several advantages to using microcentrifuges in the laboratory:

- Small size and compact design: Microcentrifuges are smaller and more compact than standard benchtop centrifuges, making them suitable for use in small laboratories or in field settings.

- Lightweight and portable: Microcentrifuges are lightweight and portable, making them easy to transport to different locations.

- Suitable for small volumes: Microcentrifuges are specifically designed to spin small tubes, such as microtubes and PCR tubes, at high speeds. This makes them an ideal tool for applications such as DNA purification and protein separation, where small volumes of sample are used.

- High speed: Microcentrifuges can reach speeds of up to 20,000 rpm, making them suitable for fast separations of small volumes of liquid.

- Wide range of rotor options: Microcentrifuges are equipped with a variety of rotors that can hold different tube sizes, including microtubes, PCR tubes, and Eppendorf tubes.

Overall, microcentrifuges offer a convenient and efficient way to separate small volumes of liquid samples in the laboratory, making them an important tool for many applications in molecular biology and biochemistry research.

Limitations of Microcentrifuges

There are a few limitations to using microcentrifuges in the laboratory:

- Limited sample volume: Microcentrifuges are designed to spin small volumes of liquid, typically up to 2 mL. If larger volumes of sample are needed, a larger centrifuge may be required.

- Limited capacity: Microcentrifuges typically have a limited capacity and can only hold a few tubes at a time. If more samples need to be processed simultaneously, a larger centrifuge may be required.

- Limited speed range: Microcentrifuges typically have a limited speed range of up to 20,000 rpm. If higher speeds are required, a larger centrifuge may be necessary.

- Limited temperature control: Some microcentrifuges may have limited or no temperature control, which can be a limitation for temperature-sensitive samples.

- Risk of sample loss: There is a risk of sample loss if the tubes are not properly sealed or if the rotor becomes unbalanced during the spinning process.

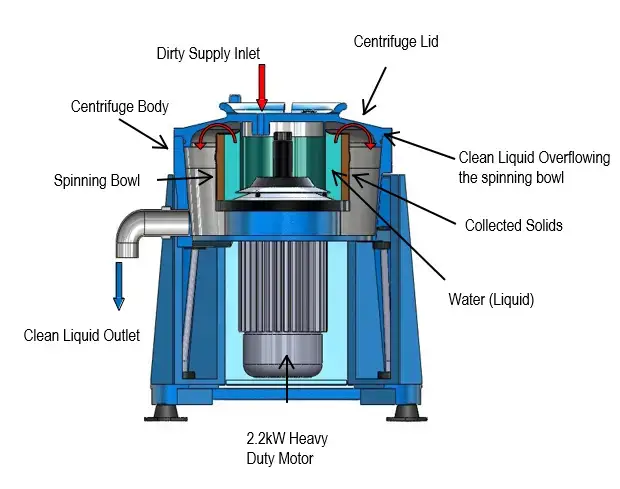

6. Industrial centrifuges

- These are large, heavy-duty centrifuges that are designed for use in industrial settings. They are commonly used for separating large quantities of samples or for processing highly viscous or abrasive materials.

- An industrial centrifuge is a machine that uses centrifugal force to separate substances of different densities or to remove water or other solvents from a substance. Centrifuges are used in a wide variety of industries, including pharmaceuticals, chemical processing, food and beverage production, and waste management.

Types of Industrial centrifuges

There are several types of industrial centrifuges, including:

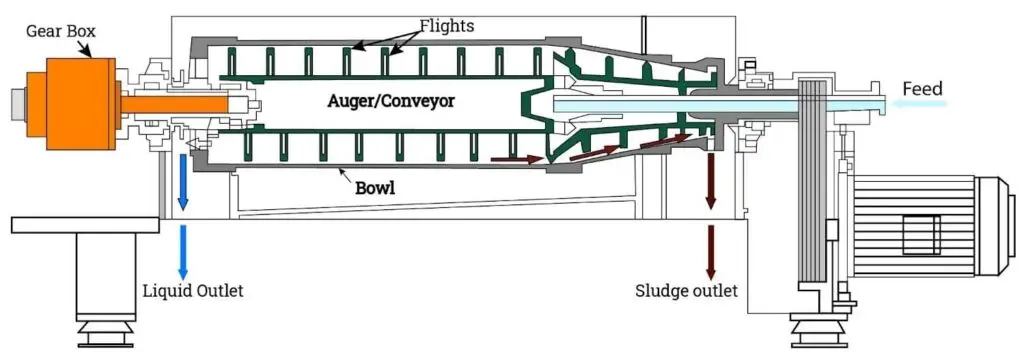

- Decanter centrifuges: These are used to separate solid particles from a liquid by spinning the mixture at high speeds. They consist of a horizontal, cylindrical drum that rotates around a central axis, and a screw conveyor that helps to move the solids through the drum.

- Disk stack centrifuges: These are used to separate suspended solids from a liquid by spinning the mixture at high speeds. They consist of a vertical, cylindrical drum that rotates around a central axis, and a series of disks mounted on the drum that create a series of compartments.

- Basket centrifuges: These are used to separate solid particles from a liquid by spinning the mixture at high speeds. They consist of a basket that rotates around a central axis and is partially submerged in the liquid.

- Peeler centrifuges: These are used to separate solid particles from a liquid by spinning the mixture at high speeds. They consist of a horizontal, cylindrical drum that rotates around a central axis, and a series of blades mounted on the drum that scrape the solids off the inner surface of the drum as it rotates.

- Pusher centrifuges: These are used to separate solid particles from a liquid by spinning the mixture at high speeds. They consist of a horizontal, cylindrical drum that rotates around a central axis, and a series of paddles mounted on the drum that push the solids through the drum as it rotates.

- Sedimentation centrifuges: These are used to separate solid particles from a liquid by spinning the mixture at high speeds. They consist of a horizontal, cylindrical drum that rotates around a central axis, and a series of blades mounted on the drum that scrape the solids off the inner surface of the drum as it rotates.

Applications of Industrial centrifuges

Industrial centrifuges are used in a variety of industries for a wide range of applications, including:

- Pharmaceuticals: Centrifuges are used in the production of drugs and other pharmaceutical products to purify and concentrate raw materials, as well as to separate solid particles from liquids.

- Chemical processing: Centrifuges are used in chemical processing to separate and purify various substances, such as oil, water, and other solvents.

- Food and beverage production: Centrifuges are used in the production of food and beverages to separate solid particles from liquids, such as in the production of milk, cream, and other dairy products.

- Waste management: Centrifuges are used in waste management to separate solid particles from liquids in order to reduce the volume of waste that needs to be disposed of.

- Oil and gas: Centrifuges are used in the oil and gas industry to separate solid particles from liquids, such as in the production of crude oil and natural gas.

- Water treatment: Centrifuges are used in water treatment to remove solid particles and other contaminants from water.

- Mining and minerals: Centrifuges are used in the mining and minerals industry to separate and purify various substances, such as minerals, ore, and coal.

Overall, industrial centrifuges are valuable tools for separating and purifying substances in a variety of industries.

Advantages of Industrial centrifuges

Some advantages of industrial centrifuges include:

- High efficiency: Centrifuges are able to separate and purify substances quickly and efficiently, making them a valuable tool for many industries.

- Can handle a wide range of materials: Centrifuges can be used to separate and purify a wide range of materials, including liquids, gases, and solids.

- Can handle large volumes: Centrifuges are able to process large volumes of material at one time, making them an efficient choice for large-scale operations.

- Can be automated: Many modern centrifuges are equipped with automation and control systems, which allows them to run with minimal supervision.

- Can be customized: Centrifuges can be customized to meet the specific needs of a given application, such as by using different sizes or types of rotors or by adding specialized equipment or features.

- Can be used for multiple applications: Centrifuges can be used for a variety of applications, including separating solid particles from liquids, purifying substances, and removing water or other solvents from a substance.

Overall, industrial centrifuges are valuable tools for separating and purifying substances in a variety of industries due to their high efficiency, versatility, and ability to handle large volumes of material.

Limitations of Industrial centrifuges

Some limitations of industrial centrifuges include:

- High energy consumption: Centrifuges require a lot of energy to operate, which can be costly and may not be environmentally friendly.

- Limited capacity: Centrifuges have a limited capacity for the amount of material they can process at one time. This means that large batches may need to be processed in multiple runs, which can be time-consuming and inefficient.

- Requires skilled operators: Centrifuges require trained operators to set them up and run them properly. This can be a challenge if trained personnel are not available.

- Can be noisy: Centrifuges can be noisy when they are operating, which can be a problem in some environments.

- Can be expensive: Centrifuges can be expensive to purchase and maintain, which may not be feasible for some businesses or organizations.

- May not be suitable for all materials: Centrifuges may not be suitable for all materials, as some materials may be too fragile or may not withstand the high centrifugal forces.

Overall, while industrial centrifuges can be effective tools for separating and purifying substances, they have some limitations that should be taken into consideration when determining whether they are the best choice for a given application.

7. Haematocrit centrifuge

- A haematocrit centrifuge is a specialized type of centrifuge that is used to separate red blood cells from other components of blood, such as plasma and white blood cells. It is often used in medical laboratories to measure the haematocrit, which is the percentage of red blood cells in a sample of blood.

- Haematocrit centrifuges typically consist of a small, portable machine that can hold a number of blood samples at once. The samples are placed in capillary tubes, which are then inserted into the machine. The machine spins the tubes at high speeds, using centrifugal force to separate the red blood cells from the other components of the blood.

- Haematocrit centrifuges are commonly used in hospitals, clinics, and other medical facilities to perform routine blood tests, such as complete blood counts (CBCs). They are also used in research laboratories to study blood and blood disorders.

- Overall, haematocrit centrifuges are important tools for separating and analyzing the components of blood, and are used in a wide range of medical and research settings.

Applications of Haematocrit centrifuge

Some applications of haematocrit centrifuges include:

- Determining the haematocrit: Haematocrit centrifuges are used to determine the haematocrit, which is the percentage of red blood cells in a sample of blood. This measurement is used to assess an individual’s overall health and to diagnose and monitor a variety of medical conditions, such as anemia and dehydration.

- Performing complete blood counts (CBCs): Haematocrit centrifuges are used in the process of performing complete blood counts (CBCs), which are routine blood tests that are used to evaluate an individual’s overall health. CBCs measure the number of red blood cells, white blood cells, and platelets in a sample of blood, as well as other important parameters, such as hemoglobin and hematocrit.

- Studying blood disorders: Haematocrit centrifuges are used in research laboratories to study blood disorders and other conditions that affect the blood. For example, they may be used to study the effects of different medications on the blood or to investigate the underlying causes of blood disorders.

- Monitoring medical treatment: Haematocrit centrifuges are used to monitor the effectiveness of medical treatment for conditions that affect the blood, such as anemia or blood loss. They can help to determine whether the treatment is working and whether any adjustments are needed.

Overall, haematocrit centrifuges are important tools for separating and analyzing the components of blood, and are used in a wide range of medical and research settings.

Advantages of Haematocrit centrifuge

Some advantages of haematocrit centrifuges include:

- Quick and accurate: Haematocrit centrifuges are able to separate and analyze the components of blood quickly and accurately, making them an efficient and reliable tool for medical and research purposes.

- Portable: Haematocrit centrifuges are typically small and portable, which makes them easy to transport and use in a variety of settings, including hospitals, clinics, and research laboratories.

- Can handle multiple samples at once: Haematocrit centrifuges are able to process multiple samples at the same time, which makes them an efficient choice for busy medical and research environments.

- Easy to use: Haematocrit centrifuges are relatively easy to operate, and do not require special training or expertise to use.

- Non-invasive: Haematocrit centrifuges do not require any invasive procedures or needles, which makes them a safe and convenient option for analyzing blood samples.

Overall, haematocrit centrifuges are valuable tools for separating and analyzing the components of blood, and offer a number of advantages over other methods of blood analysis.

Limitation of Haematocrit centrifuge

Some limitations of haematocrit centrifuges include:

- Limited to analyzing blood: Haematocrit centrifuges are only able to analyze blood samples, so they may not be suitable for studying other types of samples or substances.

- Requires skilled operators: Haematocrit centrifuges require trained operators to set them up and run them properly. This can be a challenge if trained personnel are not available.

- Can be expensive: Haematocrit centrifuges can be expensive to purchase and maintain, which may not be feasible for some organizations or facilities.

- Can be noisy: Haematocrit centrifuges can be noisy when they are operating, which can be a problem in some environments.

- May not be suitable for all samples: Haematocrit centrifuges may not be suitable for all blood samples, as some samples may contain substances that interfere with the analysis or that may not withstand the high centrifugal forces.

Overall, while haematocrit centrifuges are useful tools for separating and analyzing the components of blood, they have some limitations that should be taken into consideration when determining whether they are the best choice for a given application.

8. Low-speed centrifuges

- Low-speed centrifuges are machines that use centrifugal force to separate substances of different densities or to remove water or other solvents from a substance. They are called “low-speed” centrifuges because they operate at relatively low rotational speeds, typically in the range of 500 to 10,000 revolutions per minute (RPM).

- Low-speed centrifuges are used in a variety of industries, including pharmaceuticals, chemical processing, food and beverage production, and waste management. They are often used for applications that require gentle separation or for samples that are sensitive to high centrifugal forces.

- Low-speed centrifuges come in a range of sizes and configurations, including tabletop models for small-scale applications and larger, floor-standing models for larger volumes of material. They may be equipped with a variety of rotor types, such as fixed-angle rotors or swing-out rotors, to accommodate different types of samples.

- Overall, low-speed centrifuges are important tools for separating and purifying substances in a variety of industries, and are particularly useful for applications that require gentle separation or for samples that are sensitive to high centrifugal forces.

Applications of Low-speed centrifuges

Low-speed centrifuges are used in a variety of industries for a wide range of applications, including:

- Pharmaceuticals: Low-speed centrifuges are used in the production of drugs and other pharmaceutical products to purify and concentrate raw materials, as well as to separate solid particles from liquids.

- Chemical processing: Low-speed centrifuges are used in chemical processing to separate and purify various substances, such as oil, water, and other solvents.

- Food and beverage production: Low-speed centrifuges are used in the production of food and beverages to separate solid particles from liquids, such as in the production of milk, cream, and other dairy products.

- Waste management: Low-speed centrifuges are used in waste management to separate solid particles from liquids in order to reduce the volume of waste that needs to be disposed of.

- Oil and gas: Low-speed centrifuges are used in the oil and gas industry to separate solid particles from liquids, such as in the production of crude oil and natural gas.

- Water treatment: Low-speed centrifuges are used in water treatment to remove solid particles and other contaminants from water.

- Mining and minerals: Low-speed centrifuges are used in the mining and minerals industry to separate and purify various substances, such as minerals, ore, and coal.

Overall, low-speed centrifuges are valuable tools for separating and purifying substances in a variety of industries. They are particularly useful for applications that require gentle separation or for samples that are sensitive to high centrifugal forces.

Advantages of Low-speed centrifuges

Some advantages of low-speed centrifuges include:

- Gentle separation: Low-speed centrifuges operate at relatively low rotational speeds, which makes them suitable for applications that require gentle separation or for samples that are sensitive to high centrifugal forces.

- Can handle a wide range of materials: Low-speed centrifuges can be used to separate and purify a wide range of materials, including liquids, gases, and solids.

- Can be customized: Low-speed centrifuges can be customized to meet the specific needs of a given application, such as by using different sizes or types of rotors or by adding specialized equipment or features.

- Can be used for multiple applications: Low-speed centrifuges can be used for a variety of applications, including separating solid particles from liquids, purifying substances, and removing water or other solvents from a substance.

- Can be automated: Many modern low-speed centrifuges are equipped with automation and control systems, which allows them to run with minimal supervision.

- Can be portable: Some low-speed centrifuges are designed to be portable, which makes them easy to transport and use in a variety of settings.

Overall, low-speed centrifuges are valuable tools for separating and purifying substances in a variety of industries due to their ability to handle a wide range of materials, their customization options, and their suitability for applications that require gentle separation.

Limitation of Low-speed centrifuges

There are several disadvantages to using low-speed centrifuges:

- Limited separation capabilities: Low-speed centrifuges are not able to generate the high centrifugal forces required for the efficient separation of particles with a large size or density difference.

- Low capacity: Low-speed centrifuges can only hold a small amount of sample at a time, making them less suitable for large-scale sample processing or for handling a high volume of samples.

- Lower precision and reliability: Low-speed centrifuges are generally less precise and less reliable than higher-speed centrifuges, as they are more susceptible to vibration and imbalance. This can lead to inaccurate or inconsistent results, especially when separating delicate or sensitive samples.

- Longer separation times: Low-speed centrifuges operate at relatively low rotational speeds, so they may take longer to separate samples compared to higher-speed centrifuges.

- Higher risk of contamination: Low-speed centrifuges are more prone to contamination due to their lower rotational speeds and the fact that they do not generate as high of a force to remove contaminants.

Overall, low-speed centrifuges are best suited for relatively simple separations that do not require high levels of precision or the separation of particles with a large size or density difference. They are often used for tasks such as the sedimentation of cells or the separation of small particles from a liquid.

9. Continuous flow centrifuges

- Continuous flow centrifuges, also known as tubular or scroll centrifuges, are a type of mechanical separation device that uses centrifugal force to separate solids from liquids or to separate different types of liquids. They are called “continuous flow” centrifuges because they are designed to process a continuous flow of material, rather than batch processing like many other types of centrifuges.

- Continuous flow centrifuges consist of a cylindrical tube or “scroll” that is mounted on a horizontal axis and rotated at high speeds. The material to be separated is introduced into the scroll through a feed pipe, and as it rotates, the centrifugal force causes the denser components to move outward towards the walls of the scroll, while the lighter components remain near the center.

- The separated components are then discharged from the centrifuge through separate outlets, with the solids or denser liquids being discharged from the outer wall of the scroll and the lighter liquids being discharged from the center.

- Continuous flow centrifuges are widely used in a variety of industries, including chemical, pharmaceutical, food and beverage, and oil and gas, for tasks such as solid-liquid separation, liquid-liquid separation, and clarification of liquids. They are known for their high separation efficiency, low energy consumption, and low maintenance requirements.

Applications of Continuous flow centrifuges

Continuous flow centrifuges are widely used in a variety of industries for tasks such as solid-liquid separation, liquid-liquid separation, and clarification of liquids. Some specific applications of continuous flow centrifuges include:

- Chemical industry: Continuous flow centrifuges are used to separate various chemicals and chemical mixtures, such as pigments, dyes, and catalysts, as well as to purify and clarify chemicals.

- Pharmaceutical industry: Continuous flow centrifuges are used to separate and purify various types of pharmaceutical products, including antibiotics, hormones, and vaccines.

- Food and beverage industry: Continuous flow centrifuges are used to separate solids from liquids in the production of various food and beverage products, such as milk, juices, and beer. They are also used to clarify and purify various types of liquids, such as wine and vegetable oils.

- Oil and gas industry: Continuous flow centrifuges are used to separate and purify various types of oil and gas products, including crude oil, diesel fuel, and natural gas liquids.

- Environmental industry: Continuous flow centrifuges are used to separate and purify water and wastewater, as well as to remove solids and contaminants from water and other liquids.

Overall, continuous flow centrifuges are known for their high separation efficiency, low energy consumption, and low maintenance requirements, making them an attractive choice for a wide range of separation and purification applications.

Advantages of Continuous flow centrifuges

There are several advantages to using continuous flow centrifuges:

- High separation efficiency: Continuous flow centrifuges are known for their high separation efficiency, as they are able to effectively separate a wide range of particles based on size, density, and other physical properties.

- Low energy consumption: Continuous flow centrifuges are relatively energy-efficient, as they operate at relatively low rotational speeds compared to other types of centrifuges.

- Low maintenance requirements: Continuous flow centrifuges have few moving parts and are generally easy to maintain, with a long service life.

- High processing capacity: Continuous flow centrifuges are designed to process a continuous flow of material, rather than batch processing like many other types of centrifuges. This allows them to handle a high volume of material with a relatively small footprint.

- Flexibility: Continuous flow centrifuges can be easily adapted to different separation requirements by adjusting the rotational speed, feed rate, and other process variables.

- Gentle on delicate materials: Continuous flow centrifuges operate at relatively low rotational speeds, which makes them gentle on delicate materials and less likely to damage or degrade them.

Overall, continuous flow centrifuges are a popular choice for a wide range of separation and purification applications due to their high separation efficiency, low energy consumption, low maintenance requirements, and flexibility.

Limitation of Continuous flow centrifuges

There are a few disadvantages to using continuous flow centrifuges:

- Limited separation capabilities: Continuous flow centrifuges are not able to generate the high centrifugal forces required for the efficient separation of particles with a large size or density difference.

- Complexity: Continuous flow centrifuges are more complex than some other types of centrifuges, with many moving parts and a relatively high number of process variables to control. This can make them more difficult to operate and maintain.

- Higher cost: Continuous flow centrifuges are generally more expensive to purchase and operate than some other types of centrifuges, such as low-speed centrifuges.

- Limited applicability: Continuous flow centrifuges are not suitable for all types of separation and purification tasks, and may not be the best choice for certain applications.

Overall, while continuous flow centrifuges have many advantages, they may not be the best choice for every separation and purification task, and it is important to carefully evaluate their suitability for a particular application.

10. Ultracentrifuges

- Ultracentrifuges are a type of high-speed centrifuge that is used to separate and purify a wide range of materials, including proteins, nucleic acids, viruses, cells, and other biological samples. They operate at very high rotational speeds, typically in the range of 50,000 to 200,000 rpm, and are able to generate extremely high centrifugal forces, up to several hundred thousand times the force of gravity.

- Ultracentrifuges consist of a rotor, which holds the sample, and a drive motor, which rotates the rotor at high speeds. The sample is placed in a centrifuge tube or other container, which is then placed in the rotor. As the rotor rotates, the centrifugal force causes the denser components of the sample to sediment out, while the lighter components remain in solution.

- Ultracentrifuges are widely used in various fields, including biology, chemistry, and materials science, for tasks such as protein purification, virus isolation, and the characterization of biomolecules. They are known for their high separation efficiency and precision, as well as their ability to handle a wide range of sample types and sizes.

Types of Ultracentrifuges

There are several types of ultracentrifuges, including:

- Analytical ultracentrifuges: Analytical ultracentrifuges are used to measure the size, shape, and molecular weight of small particles, such as proteins and viruses, as well as to study the properties of solutions and mixtures. They are equipped with a variety of detection systems, such as UV-Vis spectrometers, refractometers, and interferometers, which allow for the precise measurement of sample properties.

- Preparative ultracentrifuges: Preparative ultracentrifuges are used to purify and isolate large quantities of biological samples, such as proteins, cells, and viruses. They are typically equipped with a large rotor and are able to handle a wide range of sample sizes and volumes.

- High-resolution ultracentrifuges: High-resolution ultracentrifuges are used to study the structure and function of complex biological systems, such as cells and tissues. They are equipped with advanced detection systems and are able to resolve very small differences in sample properties.

- Air-driven ultracentrifuges: Air-driven ultracentrifuges are a type of ultracentrifuge that uses pressurized air to drive the rotor, rather than an electric motor. They are often used in situations where an electrical power source is not available or is not suitable, such as in field research or on-board aircraft.

Overall, the type of ultracentrifuge used depends on the specific separation and analysis needs of the application.

Applications of Ultracentrifuges

Ultracentrifuges are widely used in various fields for tasks such as protein purification, virus isolation, and the characterization of biomolecules. Some specific applications of ultracentrifuges include:

- Biology: Ultracentrifuges are widely used in biology for tasks such as the purification and isolation of proteins, nucleic acids, cells, and viruses, as well as the characterization of biomolecules and the study of cell structure and function.

- Chemistry: Ultracentrifuges are used in chemistry to study the properties of solutions and mixtures, including the size, shape, and molecular weight of small particles.

- Materials science: Ultracentrifuges are used in materials science to study the properties of materials at the molecular level, including their structure, composition, and stability.

- Environmental science: Ultracentrifuges are used in environmental science to study the properties of natural and anthropogenic substances, such as water, soil, and air.

- Medicine: Ultracentrifuges are used in medicine for tasks such as the diagnosis of diseases, the preparation of vaccines, and the development of new drugs.

Overall, ultracentrifuges are an important tool for a wide range of scientific and industrial applications, due to their high separation efficiency and precision, as well as their ability to handle a wide range of sample types and sizes.

Advantages of Ultracentrifuges

There are several advantages to using ultracentrifuges:

- High separation efficiency: Ultracentrifuges are able to generate extremely high centrifugal forces, which allows them to effectively separate and purify a wide range of materials based on size, density, and other physical properties.

- High precision: Ultracentrifuges are equipped with advanced detection systems, such as UV-Vis spectrometers and refractometers, which allow for the precise measurement of sample properties.

- Wide range of sample types and sizes: Ultracentrifuges are able to handle a wide range of sample types and sizes, from small molecules to large cells and tissues.

- Versatility: Ultracentrifuges can be used for a wide range of separation and purification tasks, including the isolation of proteins, nucleic acids, cells, and viruses, as well as the characterization of biomolecules and the study of solutions and mixtures.

- High speed: Ultracentrifuges operate at very high rotational speeds, which allows for the rapid separation of samples.

Overall, ultracentrifuges are an important tool for a wide range of scientific and industrial applications, due to their high separation efficiency, precision, and versatility.

Limitation of Ultracentrifuges

There are a few disadvantages to using ultracentrifuges:

- High cost: Ultracentrifuges are generally more expensive to purchase and operate than other types of centrifuges, such as low-speed or continuous flow centrifuges.

- Complexity: Ultracentrifuges are more complex than some other types of centrifuges, with many moving parts and a high number of process variables to control. This can make them more difficult to operate and maintain.

- Risk of sample damage: The high centrifugal forces generated by ultracentrifuges can be damaging to some types of samples, such as fragile cells or delicate biomolecules. Care must be taken to ensure that the sample is properly protected during the separation process.

- Limited applicability: Ultracentrifuges may not be suitable for all types of separation and purification tasks, and may not be the best choice for certain applications.

Overall, while ultracentrifuges have many advantages, they may not be the best choice for every separation and purification task, and it is important to carefully evaluate their suitability for a particular application.

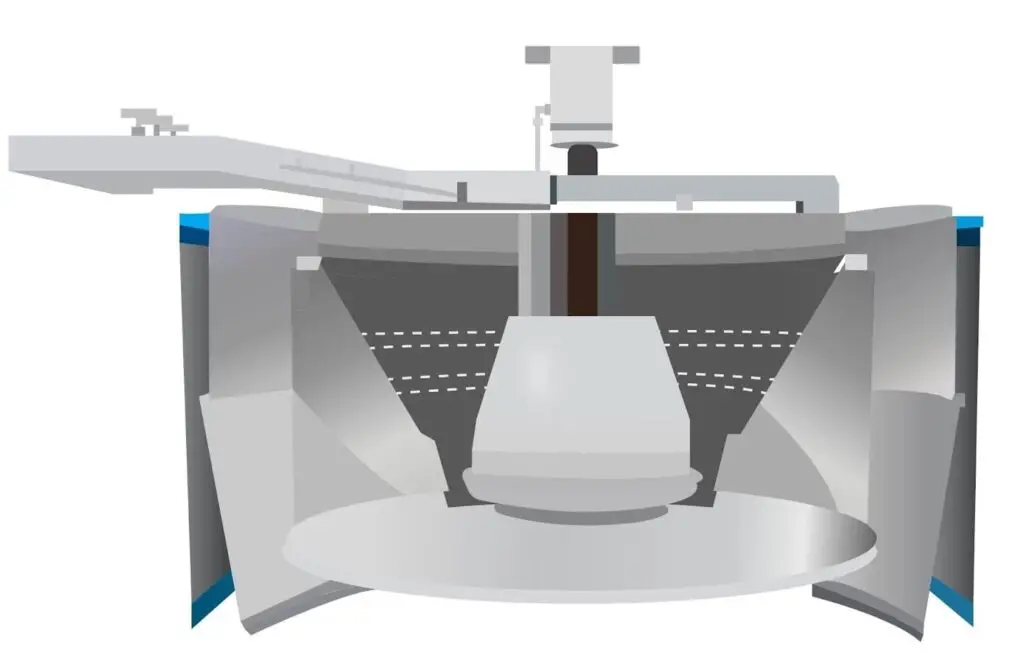

11. Basket Centrifuge

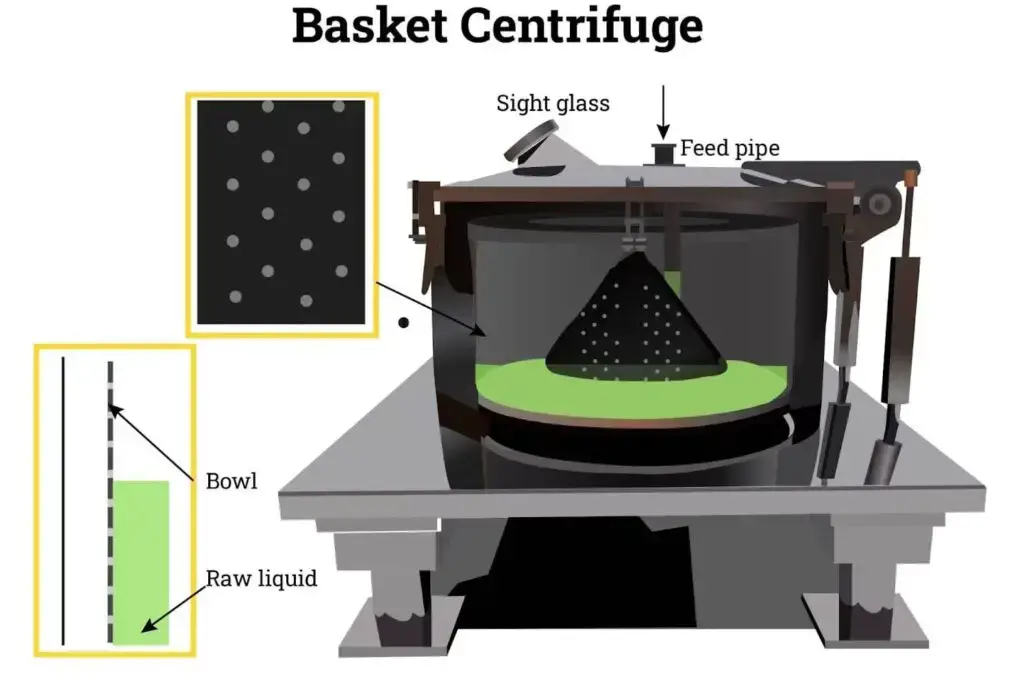

- A basket centrifuge is a type of centrifuge that separates substances by using a spinning motion. It consists of a cylindrical basket that is mounted on a rotating shaft. The basket is usually made of metal or other durable material and has perforations or openings to allow the substances being separated to pass through.

- The basket centrifuge works by spinning the basket at high speeds, typically in the range of 3,000 to 5,000 revolutions per minute (rpm). As the basket spins, the substances being separated are subjected to a force known as the centrifugal force. This force causes the heavier substances to be forced outward towards the walls of the basket, while the lighter substances are forced towards the center.

- The basket centrifuge is commonly used in a variety of industries, including pharmaceutical, chemical, food processing, and waste treatment. It is particularly useful for separating solid particles from liquids, such as in the production of milk or beer. It can also be used to separate emulsions, or mixtures of two or more liquids that are immiscible (do not mix).

- Overall, the basket centrifuge is a useful tool for separating substances based on their weight or density, and is widely used in many different applications.

Basket Centrifuge Applications

Basket centrifuges are used in a wide range of applications, including:

- Separation of solids from liquids: Basket centrifuges are commonly used to separate solid particles from liquids, such as in the production of milk or beer.

- Separation of emulsions: Basket centrifuges can be used to separate emulsions, or mixtures of two or more immiscible liquids.

- Clarification: Basket centrifuges can be used to clarify liquids by removing impurities or suspended solids.

- Separation of cells and cell components: Basket centrifuges are used in laboratories to separate cells and cell components for various purposes, such as purifying proteins or isolating DNA.

- Separation of waste products: Basket centrifuges are used in waste treatment plants to separate solid and liquid waste products, such as sewage sludge.

- Separation of metal particles: Basket centrifuges are used in the mining and metallurgical industries to separate metal particles from ore or other materials.

- Separation of oil and water: Basket centrifuges are used in the oil and gas industry to separate oil and water, which can be useful in the cleanup of oil spills or in the production of oil and gas.

- Separation of other substances: Basket centrifuges are used to separate a wide range of other substances, such as pigments, fibers, and abrasives, in various industries.

Advantages of Basket Centrifuge

There are several advantages to using a basket centrifuge:

- High separation efficiency: Basket centrifuges are highly efficient at separating substances based on their weight or density. They are able to achieve high levels of separation in a short amount of time, making them a fast and effective method for separating substances.

- Versatility: Basket centrifuges can be used to separate a wide range of substances, including solids, liquids, and emulsions. They can also be used in a variety of industries, including pharmaceutical, chemical, food processing, and waste treatment.

- Low operating costs: Basket centrifuges have low operating costs, as they do not require any consumables and have low energy requirements. They are also easy to maintain, with minimal downtime required for maintenance or repair.

- High capacity: Basket centrifuges have a large capacity and can process large quantities of material in a single batch. This makes them suitable for use in high-volume production environments.

- Compact size: Basket centrifuges are relatively small and compact, making them easy to install and operate in a variety of settings.

- Safety: Basket centrifuges are designed with safety in mind, with features such as interlocks and alarms to ensure safe operation. They are also relatively easy to operate, which reduces the risk of accidents or injuries.

Disadvantages of Basket Centrifuge

There are also some disadvantages to using a basket centrifuge:

- Limited separation capabilities: Basket centrifuges are only able to separate substances based on their weight or density, so they may not be suitable for separating substances that are not significantly different in these properties.

- Sensitivity to temperature: Basket centrifuges are sensitive to temperature changes, which can affect the separation process. This may require the use of temperature-controlled environments or the addition of cooling or heating mechanisms.

- Sensitivity to moisture: Basket centrifuges are sensitive to moisture, as the presence of water can affect the separation process. This may require the use of drying or dehumidifying equipment to remove excess moisture.

- High initial cost: Basket centrifuges can be expensive to purchase and install, especially for larger or more complex systems.

- Noise: Basket centrifuges can be noisy during operation, which may be a concern in certain environments.

- Waste disposal: The substances being separated in a basket centrifuge may need to be properly disposed of, which can be an issue in some cases. This may require the use of specialized equipment or procedures to ensure safe and environmentally-friendly disposal.

12. Decanter Centrifuge

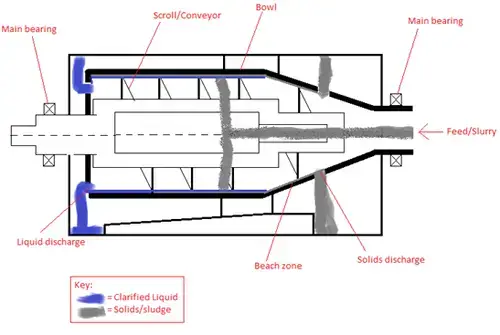

- A decanter centrifuge is a type of centrifuge that separates substances by using a spinning motion. It consists of a cylindrical drum that is mounted on a rotating shaft. The drum is usually made of metal or other durable material and has perforations or openings to allow the substances being separated to pass through.

- The decanter centrifuge works by spinning the drum at high speeds, typically in the range of 3,000 to 5,000 revolutions per minute (rpm). As the drum spins, the substances being separated are subjected to a force known as the centrifugal force. This force causes the heavier substances to be forced outward towards the walls of the drum, while the lighter substances are forced towards the center.

- The decanter centrifuge is commonly used in a variety of industries, including pharmaceutical, chemical, food processing, and waste treatment. It is particularly useful for separating solid particles from liquids, such as in the production of milk or beer. It can also be used to separate emulsions, or mixtures of two or more liquids that are immiscible (do not mix).

- Overall, the decanter centrifuge is a useful tool for separating substances based on their weight or density, and is widely used in many different applications.

Applications of Decanter Centrifuge

Decanter centrifuges are used in a wide range of applications, including:

- Separation of solids from liquids: Decanter centrifuges are commonly used to separate solid particles from liquids, such as in the production of milk or beer.

- Separation of emulsions: Decanter centrifuges can be used to separate emulsions, or mixtures of two or more immiscible liquids.

- Clarification: Decanter centrifuges can be used to clarify liquids by removing impurities or suspended solids.

- Separation of cells and cell components: Decanter centrifuges are used in laboratories to separate cells and cell components for various purposes, such as purifying proteins or isolating DNA.

- Separation of waste products: Decanter centrifuges are used in waste treatment plants to separate solid and liquid waste products, such as sewage sludge.

- Separation of metal particles: Decanter centrifuges are used in the mining and metallurgical industries to separate metal particles from ore or other materials.

- Separation of oil and water: Decanter centrifuges are used in the oil and gas industry to separate oil and water, which can be useful in the cleanup of oil spills or in the production of oil and gas.

- Separation of other substances: Decanter centrifuges are used to separate a wide range of other substances, such as pigments, fibers, and abrasives, in various industries.

Advantages of Decanter Centrifuge

There are several advantages to using a decanter centrifuge:

- High separation efficiency: Decanter centrifuges are highly efficient at separating substances based on their weight or density. They are able to achieve high levels of separation in a short amount of time, making them a fast and effective method for separating substances.

- Versatility: Decanter centrifuges can be used to separate a wide range of substances, including solids, liquids, and emulsions. They can also be used in a variety of industries, including pharmaceutical, chemical, food processing, and waste treatment.

- Continuous operation: Decanter centrifuges can operate continuously, making them suitable for use in high-volume production environments.

- High capacity: Decanter centrifuges have a large capacity and can process large quantities of material in a single batch.

- Compact size: Decanter centrifuges are relatively small and compact, making them easy to install and operate in a variety of settings.

- Safety: Decanter centrifuges are designed with safety in mind, with features such as interlocks and alarms to ensure safe operation. They are also relatively easy to operate, which reduces the risk of accidents or injuries.

- Low operating costs: Decanter centrifuges have low operating costs, as they do not require any consumables and have low energy requirements. They are also easy to maintain, with minimal downtime required for maintenance or repair.

Disadvantages of Decanter Centrifuge

There are also some disadvantages to using a decanter centrifuge:

- Limited separation capabilities: Decanter centrifuges are only able to separate substances based on their weight or density, so they may not be suitable for separating substances that are not significantly different in these properties.

- Sensitivity to temperature: Decanter centrifuges are sensitive to temperature changes, which can affect the separation process. This may require the use of temperature-controlled environments or the addition of cooling or heating mechanisms.

- Sensitivity to moisture: Decanter centrifuges are sensitive to moisture, as the presence of water can affect the separation process. This may require the use of drying or dehumidifying equipment to remove excess moisture.

- High initial cost: Decanter centrifuges can be expensive to purchase and install, especially for larger or more complex systems.

- Noise: Decanter centrifuges can be noisy during operation, which may be a concern in certain environments.

- Waste disposal: The substances being separated in a decanter centrifuge may need to be properly disposed of, which can be an issue in some cases. This may require the use of specialized equipment or procedures to ensure safe and environmentally-friendly disposal.

13. Other Types of Centrifuge

a. Inverting Filter Centrifuge

The objective of the design of an inverted filter centrifuge is to remove all cake material without leaving any heel. An inverting filter centrifuge, like a horizontal peeler centrifuge, features a revolving drum. Instead of using peeler blades to remove the cake, the cake is pushed out of the bottom of the drum. The pushing action extends so far that the filter fabric is inverted, hence eliminating the need for any type of mechanical cleaning.

Inverting filter centrifuges ensures the highest level of product purity achievable. They are utilised with difficult-to-filter items and in situations when operator interaction with the product must be avoided.

b. Vertical Solid Bowl Centrifuge

Solid bowl vertical centrifuges are clarity centrifuges that separate mixed materials using centrifugal force. The slurry is placed within the rotating bowl. As the bowl’s speed increases, the g forces remove dense and solid items from the liquid and deposit them on the bowl’s inner wall.

Since there are no apertures in a solid bowl vertical centrifuge, it must be routinely opened and cleaned away. This is carried out throughout the scrape cycle. Solid bowl vertical centrifuges are not continuous flow centrifuges since they must be regularly stopped and scraped out.

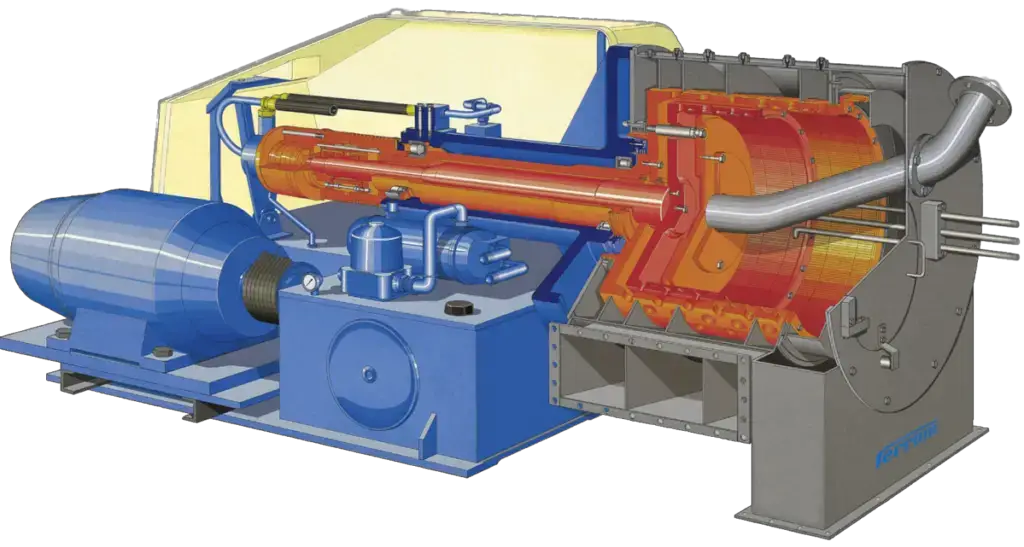

c. Pusher Centrifuge

Pusher centrifuges, also known as horizontal basket centrifuges, have a hydraulic piston with metal screening sheets or slotted sieves. They can filter liquids to create filter cakes utilising an oscillating pushing motion from the hydraulic piston to move the cakes out of the bowl or have them washed away. Pusher centrifuges are continuous-operation centrifuges developed for high-volume solids with purity and residual moisture requirements.

The pusher centrifuge’s basket generates the centrifugal force necessary to separate particles from slurry. Each forward stroke of a hydraulically driven piston that rotates with the basket expels solids from the basket. Liquids drain through the basket’s metal screen or slotted sieve, while solids are deposited on the screen.

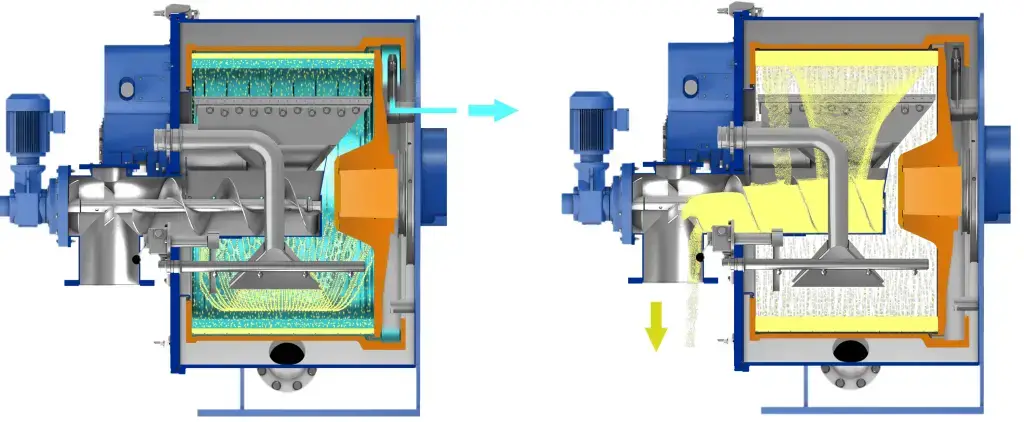

d. Horizontal Peeler Centrifuge

Peeler centrifuges are batch centrifuges with cloth filters and perforated bowls. Liquids are centrifuged at high speeds to create cakes of solids on the filter cloth. The cakes are dried by a spinning method. After the cakes have dried, peeler knives are used to scrape them off. After the heel has been scraped, remaining heel must be removed. Changes are made to the position of the scraper, and high-pressure nitrogen is utilised to eliminate the residual.

A horizontal peeler centrifuge is a filtration machine with continuous flow that may be toggled between automatic and manual control.

e. Oil Centrifuge

The oil centrifuge is also known as a centrifugal oil filter since it is utilised in places where oils must be filtered. The machine’s dirty lubricating oil circulates through the centrifuge oil filter. The oil is then forced under pressure through a filter and into a bowl. The bowl is then spun at extremely high rates of 5,000 to 8,000 rpm, depending on the oil inlet pump pressure. The resulting gravitational force attracts any particles to the bowl walls, while the clean, purified oil returns to the machine for use. During normal engine operation, soot and other impurities are eliminated frequently.

Importantly, the oil filter is not a barrier-type filtration mechanism, therefore it does not rely on filtration media to remove hydraulic or lubricant oil-contaminated particles.

References

- Moran, S. (2017). Centrifuges. Process Plant Layout, 389–397. doi:10.1016/b978-0-12-803355-5.00027-5

- Bridges, S., & Robinson, L. (2020). Centrifuges. A Practical Handbook for Drilling Fluids Processing, 475–488. doi:10.1016/b978-0-12-821341-4.00021-x

- Berk, Z. (2009). Centrifugation. Food Process Engineering and Technology, 217–232. doi:10.1016/b978-0-12-373660-4.00009-0

- https://www.ehs.uci.edu/sop/hazardous-operations/centrifuge-sop.pdf

- https://www.mls.be/en/p/lab-apparatus/centrifuges/centrifuges-hettich/hematocrit-centrifuges/

- https://www.sigmaaldrich.com/IN/en/technical-documents/technical-article/protein-biology/protein-pulldown/centrifugation-separations

- https://www.iqsdirectory.com/articles/centrifuge.html

- https://www.tec2med.com/centrifuge-rotor-rcf-rpm/

- https://www.toppr.com/guides/chemistry/is-matter-around-us-pure/centrifugation/

- https://www.biocompare.com/Lab-Equipment/Laboratory-Centrifuges/

- https://druckerdiagnostics.com/knowledge/how-a-centrifuge-works/

- https://study.com/academy/lesson/what-is-centrifugation-definition-process-uses.html

- https://www.genfollower.com/centrifuges-types-uses-in-laboratories/

- https://www.labmanager.com/product-focus/the-basics-of-centrifuge-operation-and-maintenance-1433

- https://www.coleparmer.in/c/centrifuges

- https://microbenotes.com/centrifuge-principle-parts-types-uses-examples

- https://www.labtron.com/centrifuge