Laboratory incubators are essential equipment in research laboratories, providing a controlled environment for various experiments and cell culture processes. They are designed to maintain precise temperature, humidity, and atmospheric conditions within an enclosed chamber, enabling the optimal growth and development of microorganisms, cell lines, and other biological samples.

These incubators play a crucial role in DNA replication, a fundamental process in molecular biology. DNA replication is the process by which a DNA molecule is copied, ensuring that genetic information is accurately passed on to daughter cells during cell division.

Accurate temperature control is crucial for the success of DNA replication experiments. Incubators that are not properly

What is Laboratory Incubator?

- A laboratory incubator is basically a heated box used to grow and maintain cell or microbiological cultures. Think of it as a controlled environment where you can tweak the temperature, humidity, and CO2 levels to create the perfect conditions for your samples.

- These incubators are key in various fields like pharmaceuticals, agriculture, environmental science, and food safety. They’re used for everything from growing bacteria to working with cell and tissue cultures. Whether it’s for basic research or industrial applications, an incubator provides a contaminant-free space to support the growth and preservation of your samples.

- Temperature monitoring is crucial, so data loggers with sensors are often used during calibration to keep everything in check. Lab incubators ensure that your research or production processes can proceed without a hitch, supporting tasks from bacterial culture and cell research to pharmaceutical testing and food analysis.

Incubator definition

A laboratory incubator is a heated, insulated device used to grow and maintain cell or microbiological cultures by controlling temperature, humidity, and CO2 levels.

Principle of Incubator / Working of Incubator

- A lab incubator works on the principle of thermoelectricity. It maintains a stable temperature using a thermostat to create a thermal gradient. When exposed to a heat gradient, any conductor generates voltage—this is the thermoelectric effect.

- Here’s the breakdown: power is applied to the circuit, heating the incubator to a set temperature, typically around 37°C. The temperature sensor, controller, and contactor work together to keep things steady. When the switch is turned on, current flows through the system, energizing the contactor, which powers the heating elements (like bulbs). A fan then circulates the hot air throughout the incubator.

- When the desired temperature is reached, the digital controller sends a signal to the contactor, which shuts off the heaters temporarily. If the temperature drops, the contactor re-energizes, turning the heaters back on.

- Incubators also control other factors like humidity and airflow. They create an isolated environment to support microbial growth by maintaining optimal conditions. Some incubators, like shaking incubators, even provide continuous movement for cell aeration and solubility studies.

- In short, an incubator’s job is to create and maintain the perfect environment for microorganisms to grow by balancing temperature, humidity, and airflow.

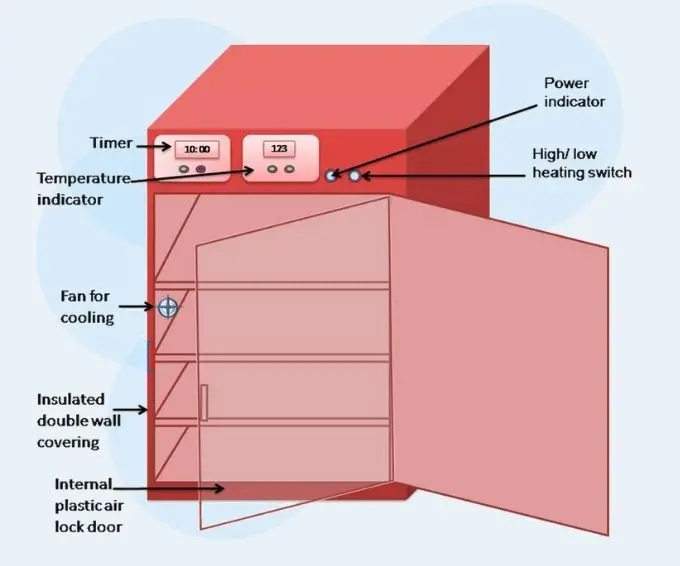

Parts/Components of Incubator

- Cabinet – The cabinet is the main structure of the incubator. It’s a double-walled box, typically ranging from 20 to 800 liters in capacity. The outer wall is stainless steel, while the inner wall is aluminum. The space between these walls is filled with glass wool for insulation, preventing heat loss and saving energy. Inside, there are projections to hold the shelves.

- Door – Every incubator has a door to close off the insulated cabinet. This door is also insulated and features a glass pane, allowing you to check on the contents without opening it. A handle on the exterior makes it easy to open and close.

- Control Panel – On the outer wall, there’s a control panel with switches and indicators to manage the incubator’s settings. This includes a switch for controlling the thermostat.

- Thermostat – The thermostat is crucial for setting and maintaining the desired temperature inside the incubator. Once set, it keeps the temperature stable until you decide to change it.

- Perforated Shelves – Inside the incubator, perforated shelves hold the culture media plates. The perforations allow hot air to circulate freely. Some incubators have removable shelves for easy cleaning.

- Asbestos Door Gasket – The asbestos door gasket creates an almost airtight seal between the door and the cabinet, preventing outside air from entering and ensuring a stable internal environment.

- L-shaped Thermometer – A thermometer is mounted on the outer wall, with one end outside for easy reading and the other end inside to monitor the internal temperature.

- HEPA Filters – Advanced incubators may include HEPA filters to reduce contamination from airflow. An air pump with filters creates a closed-loop system to maintain a clean internal atmosphere.

- Humidity and Gas Controllers – CO2 incubators have a water reservoir to maintain relative humidity and gas chambers to control CO2 concentration, ensuring the right conditions for microbial growth.

| Component | Description |

|---|---|

| Cabinet | Double-walled container (20-800L) with stainless steel outer wall and aluminum inner wall. Glass wool insulation between walls reduces heat loss and electricity consumption. Shelves are supported by inward extensions on the inner wall. |

| Door | Insulated door with a glass pane for viewing inside without opening. Handle on the exterior for easy maneuvering. |

| Control Panel | Located on the outer wall, it includes switches and indicators for controlling incubator settings, including the thermostat. |

| Thermostat | Sets and maintains the desired temperature inside the incubator. Keeps the temperature stable once set. |

| Perforated Shelves | Shelves with perforations allow hot air circulation. Removable shelves in some models for easy cleaning. |

| Asbestos Door Gasket | Provides an airtight seal between the door and the cabinet, preventing external air from entering and maintaining a stable internal environment. |

| L-Shaped Thermometer | Mounted on the outer wall, with one end inside the incubator for temperature monitoring and the other outside for easy reading. |

| HEPA Filters | Advanced models feature HEPA filters to reduce contamination from airflow. An air pump with filters creates a closed-loop system for cleaner air inside. |

| Humidity and Gas Controllers | CO2 incubators include a water reservoir for maintaining humidity and gas chambers to regulate CO2 levels. |

Types of Incubator in laboratory

Laboratory incubators come in various types, each suited to specific needs and conditions:

- Cooled/Refrigerated Incubator: These units feature internal refrigeration systems that maintain temperatures lower than the surrounding environment. Air circulation fans ensure uniform temperature distribution and precise control, making them ideal for biological and microbiological research.

- Shaking Incubator: Designed to promote cell growth by agitating culture media, shaking incubators integrate oxygen and nutrients efficiently. They are used extensively in microbiology for cultivating bacterial cultures, tissue cultures, and yeast.

- Portable Incubator: Compact and versatile, portable incubators facilitate microbiological testing in remote locations. They are crucial for fieldwork where transporting samples is challenging.

- CO2 Incubator: These specialized units mimic human body conditions with controlled levels of CO2, temperature, and humidity. They are essential for growing biological cell cultures under precise conditions.

- BOD Incubator: Known for maintaining low temperatures suitable for yeast and mold growth, BOD incubators are used in environmental and biological oxygen demand testing.

- Light Incubator: Specifically designed for replicating growth conditions for plants, seeds, and photostability testing of materials, these incubators promote plant development and enhance disease resistance.

- Anaerobic Incubator: Creating oxygen-free environments, anaerobic incubators support the growth of anaerobic organisms, which are sensitive to oxygen exposure.

- Constant Temperature and Humidity Incubator: These units simulate diverse environmental conditions needed for industrial research and biotechnology testing, ensuring precise control over temperature and humidity.

- Analog and Digital Incubators: Differentiated by their control mechanisms, analog incubators are simpler and cost-effective, while digital ones offer enhanced accuracy and real-time monitoring capabilities.

Operating Procedure of an incubator

Operating an incubator involves a straightforward procedure to ensure optimal conditions for biological experiments:

- Power Connection: Ensure the incubator is securely plugged into the power source.

- Power On: Switch on the main power supply to activate the incubator.

- Temperature Adjustment: Adjust the red power knob from 0 to 1 to initiate the heating process. For cooling incubators, adjust the cooling knob similarly to activate the refrigeration system.

- Setting Temperature: Set the desired temperature using the control panel. For instance, to set it at 22°C, adjust the temperature settings incrementally using the set point adjustments with a screwdriver. Lower the temperature to 21°C by adjusting “SET POINT -1” and raise it to 23°C with “SET POINT -2.”

- Specific Temperatures: Customize the temperature settings as needed. For temperatures like 37°C, 44°C, and 55°C, adjust the lower settings to 36°C, 43°C, and 54°C, respectively, and the upper settings to 38°C, 45°C, and 56°C, respectively.

- Temperature Monitoring: Maintain a temperature log twice daily—morning and night—to ensure consistency. A variance of up to 2°C from the set temperature is generally acceptable.

Application of Incubator

In laboratories incubator is used for different purpose such as;

- Microbial Culture: Used extensively in microbiology to cultivate bacteria, fungi, and other microorganisms.

- Cell and Tissue Culture: Supports the growth of cell cultures for biomedical research and pharmaceutical development.

- Crystal Growth: Facilitates the growth of crystals and protein crystals crucial for structural biology and drug development.

- Biochemical Oxygen Demand: Determines wastewater quality by incubating samples to measure biochemical oxygen demand.

- Food Analysis: Assists in food microbiology for testing and analysis purposes.

- Haematological Research: Provides controlled conditions for blood-related research.

- Pharmaceutical Work: Used in drug development processes requiring controlled temperature and humidity.

- Zoological Applications: Helps in hatching eggs and breeding insects, birds, and other oviparous organisms in zoology laboratories.

- Sample Storage: Maintains biological specimens under controlled conditions before analysis in medical laboratories.

Advantages of Incubator

Advantages of laboratory incubators include:

- Energy Efficiency: Lower energy consumption leads to cost savings.

- Customizable Parameters: Parameters can be adjusted based on the specific needs of cell cultures.

- Stable Environment: Provides a stable environment essential for the growth and survival of cultures and microorganisms, utilizing natural and forced convection.

Limitations of Incubator

Limitations of laboratory incubators include:

- Risk of Contamination: Leaving the incubator door open for extended periods can lead to sample contamination.

- Single Environmental Conditions: Incubators support cultures at specific settings for temperature, humidity, pH, and CO2, necessitating separate setups for different cultures.

- Cost and Maintenance: Incubators are expensive to purchase and maintain, requiring skilled personnel for operation and upkeep.

Precautions

Precautions to follow when using laboratory incubators:

- Place sterile water beneath the shelves during prolonged operation to prevent culture media from drying out.

- Ensure culture plates meet growth parameters before storing them in the incubator.

- Position plates upside down to prevent condensation on the media.

- Clean the interior regularly to prevent organism buildup on shelves and corners.

- Minimize door openings to avoid temperature fluctuations.

- Maintain stable incubator temperature.

- Clean the incubator regularly to maintain sterility.

- For prolonged incubation of Petri plates, use a moist chamber with damp sterile cotton wool.

- Use cotton plugs in test tube necks for extended incubation at higher temperatures to prevent medium drying out.

Examples of Incubators

Here is a list of top 10 incubators for laboratories:

- Thermo Fisher Scientific Forma Series II Water-Jacketed CO2 Incubator

- BINDER CB Series CO2 Incubator

- NuAire NU-5700 CO2 Incubator

- VWR In-Line HEPA Filtered CO2 Incubator

- Sanyo MCO-19AIC CO2 Incubator

- Eppendorf Incubator e CO2

- Panasonic MCO-170M CO2 Incubator

- Thermo Scientific Heracell VIOS 160i CO2 Incubator

- Panasonic MCO-20MPC CO2 Incubator

- BINDER FD Series CO2 Incubator

It’s important to note that the best incubator for a laboratory will depend on the specific needs and requirements of the laboratory. Factors to consider when choosing an incubator include the size and capacity of the incubator, the type of samples being incubated, the temperature and humidity range required, and the type of CO2 control system needed.

What are the five incubation problems?

There are several common incubation problems that may arise in a laboratory setting:

- Temperature fluctuations: Incubators should be set to a specific temperature, and fluctuations in temperature can affect the growth and development of the samples being incubated.

- Humidity issues: Incubators should be set to a specific humidity level, and deviations from this level can affect the growth and development of the samples being incubated.

- Contamination: Incubators should be kept clean to prevent contamination of the samples being incubated.

- CO2 levels: Incubators that use CO2 as a gas for incubation should maintain a specific level of CO2 in the incubator, and deviations from this level can affect the growth and development of the samples being incubated.

- Power failures: Incubators rely on a constant power supply, and power failures can affect the temperature and humidity of the incubator, potentially leading to problems with sample growth and development.

It’s important to carefully monitor incubation conditions and address any issues that may arise to ensure the success of the incubation process.

Why do incubators need CO2?

Incubators, which are devices used to incubate and hatch eggs, often include a system for maintaining a specific concentration of carbon dioxide (CO2) in the air inside the incubator. This is typically done for two main reasons:

- To regulate the humidity inside the incubator: The amount of CO2 in the air can affect the humidity inside the incubator, as CO2 can be absorbed and released by water. By maintaining a specific concentration of CO2, incubator operators can better control the humidity inside the incubator, which is important for the proper development of the eggs.

- To regulate the temperature inside the incubator: The presence of CO2 in the air can also affect the temperature inside the incubator, as CO2 is a greenhouse gas that traps heat. By controlling the concentration of CO2, incubator operators can fine-tune the temperature inside the incubator to ensure that it is optimal for the eggs being incubated.

Overall, the main goal of controlling CO2 in an incubator is to create a stable, controlled environment that is suitable for the eggs being incubated, as this can help improve the chances of successful hatching.

FAQ

Do all incubators need CO2?

Not all incubators include a system for controlling the concentration of carbon dioxide (CO2) in the air inside the incubator. Some incubators rely on other methods to regulate the humidity and temperature inside the incubator.

However, many incubators, particularly those used for incubating eggs from certain species, do include a CO2 control system. This is because the concentration of CO2 in the air can affect the humidity and temperature inside the incubator, and by controlling the CO2 concentration, incubator operators can better regulate these variables. Maintaining a stable and controlled environment inside the incubator is important for the proper development of the eggs being incubated, as it can improve the chances of successful hatching.

Ultimately, whether or not an incubator needs a CO2 control system depends on the specific requirements of the eggs being incubated and the goals of the incubator operator. Some eggs may require a specific humidity or temperature range to develop properly, and a CO2 control system may be necessary to achieve these conditions.

Why are incubators kept at 37 degrees?

Incubators are often kept at a temperature of around 37 degrees Celsius (98.6 degrees Fahrenheit) because this is the temperature that is optimal for the development of many types of eggs, including chicken eggs. This temperature is close to the body temperature of the parent bird, and it is believed to be the temperature that provides the best environment for the embryo to grow and develop.

Maintaining a stable and consistent temperature inside the incubator is important for the proper development of the eggs being incubated. If the temperature fluctuates too much or is too high or too low, it can disrupt the development of the embryo and may result in abnormal or unsuccessful hatching.

It’s worth noting that the optimal temperature for incubating eggs may vary depending on the species of the eggs being incubated. For example, some species of reptiles and birds may require slightly higher or lower temperatures than chicken eggs. Incubator operators should carefully research the specific temperature requirements of the eggs they are incubating to ensure that the incubator is set to the appropriate temperature.

How long can an incubator stay without electricity?

The length of time that an incubator can stay without electricity will depend on a variety of factors, including the type of incubator, the stage of development of the eggs being incubated, and the ambient temperature.

In general, incubators that are designed for incubating chicken eggs can usually stay without electricity for a few hours without harming the eggs, as long as the ambient temperature is not too hot or cold. However, if the incubator is without electricity for an extended period of time, the eggs may start to lose moisture and the embryos may begin to dry out, which can lead to abnormal or unsuccessful hatching.

If the eggs being incubated are at a more advanced stage of development, they may be more sensitive to changes in temperature and humidity and may be more likely to be affected by a power outage. In this case, it may be necessary to try to restore power to the incubator as soon as possible in order to maintain the optimal environment for the eggs.

It’s important to note that if the incubator is without electricity for an extended period of time, it may be necessary to discard the eggs and start again with fresh eggs. This is because the eggs may have been exposed to conditions that are not suitable for their development, which can result in abnormal or unsuccessful hatching.

Is oxygen necessary for incubator?

Oxygen is necessary for the proper development of eggs being incubated in an incubator. The embryo inside the egg uses oxygen as a source of energy for growth and development. Without an adequate supply of oxygen, the embryo may not develop properly and may be more likely to experience abnormal or unsuccessful hatching.

Incubators are designed to provide a controlled environment for the eggs being incubated, and this includes regulating the amount of oxygen in the air inside the incubator. Most incubators include a ventilation system that helps to circulate fresh air and maintain a proper oxygen level inside the incubator.

It’s worth noting that the specific oxygen requirements for incubating eggs may vary depending on the species of the eggs being incubated. Some eggs may require higher or lower levels of oxygen than others in order to develop properly. Incubator operators should carefully research the specific oxygen requirements of the eggs they are incubating to ensure that the incubator is providing an optimal environment for the eggs.

Does incubator need water?

Incubators typically do not require a direct water supply, as the eggs being incubated are not directly in contact with water. However, the air inside the incubator may need to be humidified in order to maintain a suitable environment for the eggs being incubated.

One way that incubators maintain humidity is by controlling the concentration of carbon dioxide (CO2) in the air. CO2 can be absorbed and released by water, and by controlling the concentration of CO2, incubator operators can regulate the humidity inside the incubator.

Another way that incubators maintain humidity is by using a water pan or tray. This is a container that holds water and is placed inside the incubator. As the water evaporates, it helps to increase the humidity inside the incubator. The water pan or tray should be kept full in order to maintain a sufficient level of humidity inside the incubator.

Overall, while incubators do not typically require a direct water supply, they may require a source of water in order to maintain the proper humidity inside the incubator, which is important for the proper development of the eggs being incubated.

Why do you put water in an incubator?

The water in an incubator is used to help maintain the humidity inside the incubator at a suitable level for the eggs being incubated. The eggs need a certain level of humidity in order to develop properly, as the eggs absorb and release moisture during the incubation process.

One way that incubators maintain humidity is by using a water pan or tray. This is a container that holds water and is placed inside the incubator. As the water evaporates, it helps to increase the humidity inside the incubator. The water pan or tray should be kept full in order to maintain a sufficient level of humidity inside the incubator.

It’s worth noting that the specific humidity requirements for incubating eggs may vary depending on the species of the eggs being incubated. Some eggs may require higher or lower levels of humidity than others in order to develop properly. Incubator operators should carefully research the specific humidity requirements of the eggs they are incubating to ensure that the incubator is providing an optimal environment for the eggs.