- Vortex Mixer can define as a small laboratory device which mainly used for mixing liquid samples quickly.

- In this equipment, the liquid is agitated by circular motion that produced when the tube pressed against a rotating cup-shaped rubber piece.

- Usually the speed of rotation is adjustable (from about 1000–3000 rpm), and the vortex formed help in thorough mixing without spilling.

- The motion causes the liquid to spin rapidly, forming a funnel shape in center, that’s why it’s called vortex.

- These mixers are widely used in biological, chemical, and biochemical labs for mixing reagents, suspensions, or small samples etc.

- Some vortex mixers have automatic or touch mode, where mixing starts only when the tube is pressed down on the cup.

- It is compact, easy to handle and cleaning of it are simple, so it’s very convenient device for routine lab use.

- After that, safety precautions must be followed, because at high speed, splashing or tube breaking may occur.

- The main principle based on the transfer of circular motion from motor to liquid via frictional contact between rubber cup and tube bottom.

- Thus, vortex mixer plays a vital role in achieving homogeneous solutions rapidly and uniformly.

Definition of Vortex Mixer

A vortex mixer is a laboratory device that uses rapid circular oscillations to create a swirling motion, or vortex, in small volumes of liquid samples for efficient mixing and blending.

Principle of Vortex Mixer

- The working principle of a vortex mixer mainly based on the creation of a vortex motion by rotational movement of motor shaft.

- Inside the device, a small electric motor is present which connected to an off-center drive shaft that attached with rubber cup or pad.

- When the motor turned on, the rubber cup start oscillating in circular motion (usually very fast), and this motion transfer to the liquid container placed on it.

- Due to friction between the bottom of the test tube and rubber cup, the liquid inside begin to spin rapidly forming a whirlpool-like pattern.

- This whirlpool is actually the vortex, which help in complete mixing of solution or suspension within very short time.

- As speed increased, stronger vortex formed, and mixing becomes more uniform, but sometimes bubbles also formed which may affect sensitive samples.

- The energy from the rotating shaft converted into kinetic energy in the liquid, causing random motion of particles that result thorough mixing.

- In some models, the vibration amplitude and speed can be adjusted, so control of mixing intensity possible easily by user.

- Thus the mechanical energy of motor transmitted through rubber head into the container, and circular fluid motion achieved continuously.

- Overall, vortex mixer works on principle of converting rotary motion into rapid turbulent flow, that makes homogeneous mixing of small volumes very efficient.

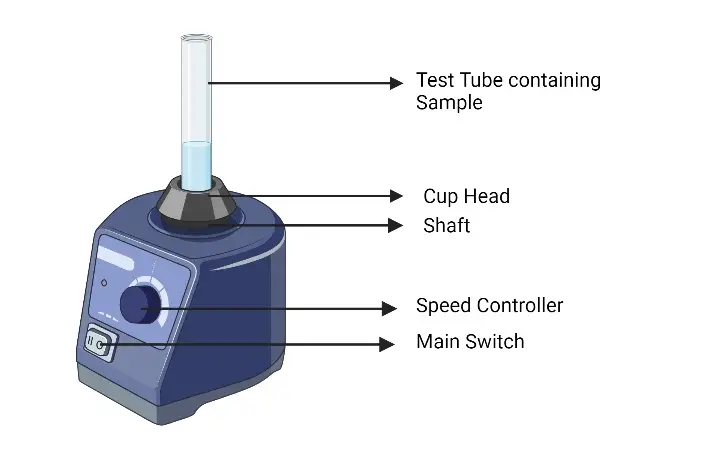

Parts of Vortex Mixer

- Base/Body – It made from sturdy metal or plastic, which hold all internal components firmly. Sometimes rubber pads are fixed below it to avoid vibration or slipping during operation.

- Electric Motor – The heart of the device that provides rotary motion. When powered, it rotate the shaft connected to mixing head, generating the circular vibration needed for vortex formation.

- Drive Shaft – A small metal rod linked between motor and mixing cup; it transmit the motion. The shaft usually placed slightly off-center, so that it creates circular oscillation instead of simple rotation.

- Rubber Cup (or Mixing Head) – This soft rubber pad is the part where test tube or container pressed. Its flexibility allow smooth transmission of motion without damaging the glass surface.

- Control Knob / Speed Regulator – Used to adjust the rotation speed or mixing intensity. Some mixers also have dual-mode (continuous / touch) switch for controlling operation style.

- Power Switch – It used for starting or stopping the device; usually located on front or side of mixer body.

- Electrical Cord – Provide connection with main supply, often detachable for safety purpose.

- Housing Cover – It protects inner motor and wiring from dust or chemical spills, ensuring long life of device.

- Fuse / Safety Unit – Added in some models to prevent overheating or current overload which may damage the instrument.

Operating Procedure of Vortex Mixer

To operate a vortex mixer, follow these steps:

- The vortex mixer must placed on a flat and stable surface before operation to avoid shaking or sliding during use.

- Check that power supply connected properly and switch of the mixer turned OFF initially.

- The desired speed control knob adjusted to low or medium setting at first to prevent sudden splashing of liquids.

- A test tube or small container having sample solution is held vertically and gently pressed against the rubber cup located on top of mixer.

- When the tube pressed down, the contact activates the motor (in touch mode) and circular motion starts immediately, forming vortex in the liquid.

- The sample allowed to mix for few seconds only, because mixing occur very fast by vortex movement.

- After desired mixing time, the tube slowly lifted away from rubber cup, and the motor will automatically stop in touch mode.

- If mixer is in continuous mode, then the switch must be turned OFF manually after mixing completed.

- The test tube should be checked for uniformity of mixture; if not homogeneous, the step can be repeated again briefly.

- After that, disconnect the power cord when not in use, and clean the top surface with dry cloth to remove any spilled material.

- Care must be taken not to apply too much pressure on the cup, as it may cause tube cracking or vibration imbalance.

- Thus by simple pressing action and circular motion, quick and thorough mixing of solutions achieved effectively and safely.

Difference Between Vortex Mixer and Centrifuge

- Vortex Mixer is used mainly for mixing liquids or suspensions quickly, it works by creating a circular vortex motion in tube or flask.

- Centrifuge, on the other side, is employed for separating components of mixture (like cells, plasma, etc.) by spinning at high speed.

- In vortex mixer, motion occurs horizontally, the liquid spins around its center forming a small whirlpool, thus mixing happens rapidly but not separation.

- While in centrifuge, centrifugal force acts outward; particles with higher density settle down, lighter ones remain up.

- Mixing by vortex is instant and uniform, though it’s mainly for small volumes (usually microtubes or small bottles).

- Centrifugation is used for both small and large samples, depending on rotor size & speed (measured in rpm or ×g).

- Principle of vortex relies on rotational agitation, but centrifuge works on centrifugal acceleration; that’s the main physics difference.

- After operation, in vortex, all components remain together, but after centrifugation, fractions or layers appear (like supernatant & pellet).

- Temperature control is usually provided in centrifuges (especially refrigerated type), not in simple vortex machines.

- Thus, both are laboratory tools, but they serve different purpose, one for mixing, another for separation, etc.

| Aspect | Vortex Mixer | Centrifuge |

|---|---|---|

| Sample Types and Accessories | Applicable for single and multiple samples using various accessories | Primarily used for multiple samples with varying volumes and requires specialized rotors and tubes |

| Application | Mixing liquids | Separating components in fluids |

| Size and Placement | Compact, fits on a benchtop | Larger size, requires dedicated space |

| Operation Time | Quick operation time | Longer operation time |

| Centrifugal Force | Smaller centrifugal force | Higher centrifugal force |

| Movement of Samples | Movement occurs within the tube/container contents | Tubes/containers remain in a fixed position, while the rotor rotates |

| Temperature Control | No temperature control options | Temperature control features available |

| Rotation Speed | Range: 100-3200 rpm | Range: 300-15000 rpm |

Safety Precautions

- Before using vortex mixer, device should be checked properly for loose parts or damaged cord.

- It must be placed on stable surface, vibration or movement during operation can cause spilling or falling.

- Glass tubes/flasks must be held tightly but not forced, otherwise breakage may happen causing injuries.

- Always wear lab coat, gloves and goggles, it’s important for protection from chemical splash or broken glass.

- Liquid samples should never be overfilled, about 2/3 full is safer limit to avoid overflow during mixing.

- Do not touch the top cup or sample holder while machine running, as strong vibration may cause skin irritation or accidents.

- Electrical connection should be dry and free from chemical residues, short circuit can prevail safe working.

- The speed knob must be adjusted gradually, sudden high speed can throw the tube out.

- After use, surface must be cleaned properly with mild disinfectant; avoid strong acids/base which may corrode body.

- Machine should be turned off & unplugged when not in use, also during maintenance or cleaning.

- Avoid using flammable solvents near it, because motor may generate heat or spark sometimes.

- Always ensure operator’s hand is dry before operation, it prevent accidental electric shock.

Types of Vortex Mixer

- Fixed-Speed Vortex Mixer – This type operates at a constant rpm (usually full speed). Mixing starts immediately when the tube pressed against the rubber head. It’s simple in use but not suitable when delicate agitation required.

- Variable-Speed Vortex Mixer – Speed can be regulated by the user. Low rpm used for gentle mixing while higher rpm for strong agitation. This give flexibility for different sample types and volumes.

- Digital Vortex Mixer – It features digital display of time/speed and offers both continuous and pulsing mode. Range usually 300–4200 rpm; allows very accurate control of mixing force.

- Analog Vortex Mixer – A traditional model having manual speed control knob. It can start at low rpm for mild mixing or increase for vigorous vortexing. Operates in either touch or continuous mode.

- Mini Vortex Mixer – Compact and portable device used mainly for small test tubes. It contains a suction base for stability and low noise. Shaking begins automatically when tube inserted into soft rubber cup.

- Multi-Tube Vortex Mixer – Designed for mixing several tubes or flasks simultaneously. Speed range 300–2500 rpm; platform fitted with foam inserts to hold tubes/flasks securely. Used for batch processing in labs.

- Pulsing Vortex Mixer – Works on principle of intermittent (on–off) vortexing, producing strong pulsing motion. It gives excellent cell disruption for glass bead treatments and reduces overheating during operation.

- Microplate Vortex Mixer – Made for mixing microplates at adjustable speed. Used for assays and enzyme reactions. Available in both digital and non-digital versions; non-digital ones are cost-effective for routine work.

- Heavy-Duty Industrial Vortex Mixer – Built with powerful motor and solid body for large volume or viscous samples. It runs smoothly for long time without overheating.

- Touch-Mode Mixer – Motor runs only when the tube touches the cup, then stop automatically when released. It’s energy-saving and ideal for quick mix of small samples.

- Continuous-Mode Mixer – Operates constantly after power switched ON; mostly used when multiple samples need mixing in sequence.

- Micro Vortex Mixer – Smaller than mini type, used for very low-volume samples like micro-centrifuge tubes (0.5–2.0 mL). Provide gentle yet effective agitation.

- Dual-Mode Vortex Mixer – Combines both touch and continuous operation; mode selected by switch depending on user need.

- Orbital Vortex Mixer – Has an orbital movement rather than strict circular vibration, used when slower, even mixing desired for sensitive biological samples.

- Programmable Vortex Mixer – Advanced model that allows setting of rpm, duration, and pulse pattern. Used mostly in research labs for reproducible experimental protocols.

Applications of Vortex Mixer

- Vortex mixer is mainly used for mixing small liquid samples in test tubes, flasks, or microtubes.

- It’s applied in biological labs for mixing cell suspensions, enzymes, or reagents before analysis.

- In chemical experiments, vortexing helps dissolve powders, crystals, or salts quickly in solvent.

- Used during DNA/RNA extraction, to homogenize solution and break minor clumps in sample.

- In clinical laboratories, it’s applied for mixing blood, serum or reagent before testing.

- Helps in preparing bacterial cultures by evenly dispersing cells in nutrient broth.

- Useful for protein assays, ensuring uniform distribution of color reagent and sample.

- Often employed in pharmaceutical labs for drug formulation studies, where components need thorough mixing.

- In analytical chemistry, vortex mixer assists before centrifugation, to ensure proper sample uniformity.

- It’s also used for resuspending pellets after centrifuge or settling, by quick agitation.

- Sometimes it applied in environmental studies for mixing soil or water extracts before measurement.

Advantages of Vortex Mixer

- Vortex mixer provides quick and efficient mixing of small liquid samples within few seconds only.

- It requires very less effort and no manual shaking, so fatigue of operator is reduced a lot.

- Uniform mixing is obtained, ensuring homogeneous solution or suspension each time.

- The machine design is compact and portable, so it can be easily moved or placed anywhere in lab bench.

- Speed control is adjustable; therefore, mixing intensity can be varied according to type of sample.

- Works well with different tube sizes (test tube, microtube, flask etc.) without any complex attachment.

- Maintenance is minimal since mechanical parts are simple, mostly motor and rubber cup.

- Contamination risk is low because sample remain closed inside the tube while mixing.

- Temperature rise is negligible, so sensitive samples like enzymes or proteins can be safely mixed.

- It’s highly reliable for repetitive task—gives consistent results over long period.

- Operation is easy; even non-technical user can handle it after short demonstration.

Limitation of Vortex Mixer

- Vortex mixer can handle only small volume samples, usually few milliliters, not suitable for large batch mixing.

- It is not effective for thick or viscous liquids, because vortex motion fails to reach deep inside.

- Mixing uniformity depends on operator handling; if tube not held properly, splashing or uneven blending occur.

- No temperature control is available, so can’t be used when heat-sensitive reactions need strict conditions.

- Prolonged operation may cause wear of rubber cup or vibration noise in the device.

- Glass tubes sometimes break if excessive pressure applied on top plate while vortexing.

- It cannot perform separation or purification like centrifuge, only agitation is possible.

- The speed is limited; too high rpm can throw out tube or spill sample.

- Power fluctuations affect motor performance, leading to inconsistent mixing result.

- Continuous use for long time may generate small heat or vibration that disturb nearby instruments.

- It’s less suitable for samples producing foam or bubbles; vortex motion increases aeration.

FAQ

What is a vortex mixer?

A vortex mixer is a laboratory instrument used to mix or blend liquids by creating a vortex or whirlpool motion.

How does a vortex mixer work?

A vortex mixer works by applying a circular shaking motion to a sample or container, causing the liquid to spin rapidly in a vortex pattern.

What are the main applications of a vortex mixer?

Vortex mixers are commonly used in various applications such as mixing reagents, suspending cells, blending samples, DNA extraction, and protein analysis.

Can a vortex mixer handle multiple samples simultaneously?

Yes, many vortex mixers come with accessories like tube racks or plate holders that allow for simultaneous mixing of multiple samples.

What is the speed range of a vortex mixer?

The speed range of a vortex mixer typically varies from 100 to 3200 revolutions per minute (rpm), although this may vary depending on the specific model.

Can I control the speed of a vortex mixer?

Yes, most vortex mixers have adjustable speed controls, allowing users to set the desired speed for their mixing requirements.

Is a vortex mixer suitable for mixing solid materials?

No, vortex mixers are primarily designed for liquid mixing applications and are not suitable for mixing solid materials.

Are there any safety precautions to consider when using a vortex mixer?

Yes, it is important to securely fasten the shaking head, wear protective eyewear, avoid using flammable substances, and use proper containment vessels for hazardous samples.

Can a vortex mixer control the temperature of the sample?

Generally, vortex mixers do not have temperature control capabilities. They are mainly used for mixing at ambient temperature.

How does a vortex mixer differ from a centrifuge?

While both instruments utilize centrifugal force, a vortex mixer is used for mixing liquids, while a centrifuge is used for separating components in fluids through spinning at high speeds.

- https://www.gilson.com/pub/media/docs/VORTEX_UG_LT318403-01.pdf

- https://www.tillquist.se/wp-content/uploads/2017/09/Vortex-Mixers-Data-Sheet_AP_EN_Tillquist.pdf

- https://www.labnetinternational.com/sites/www.labnetinternational.com/files/product-documents/RY%20929929%20Vortex%20Mixer%20S0200.pdf

- https://www.fishersci.com/content/dam/fishersci/en_US/documents/programs/scientific/brochures-and-catalogs/catalogs/fisher-scientific-vortex-mixer-catalog.pdf

- https://camblab.info/what-does-a-vortex-mixer-do/

- https://ijrat.org/downloads/Vol-6/dec-2018/Paper%20ID-612201848.pdf

- https://microbeonline.com/vortex-mixer-principle-types-and-uses/

- https://www.mrclab.com/vortex

- https://www.azom.com/article.aspx?ArticleID=17282