What is Centrifuge?

- By quickly rotating a sample, a centrifuge—a mechanical device—generates centrifugal force that separates particles with varying densities according to mass and size.

- It works on the sedimentation principle, in which lighter substances stay closer to the center of the rotating container while denser materials are driven outward to the periphery.

- Centrifuges are essential in laboratories for isolating cells, separating blood components, purifying proteins, and fractionating subcellular organelles, so accelerating activities that would take far longer under normal gravity.

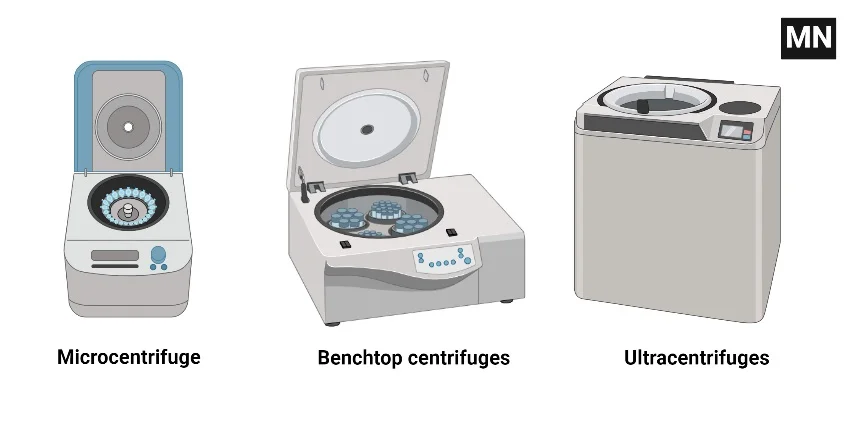

- Microcentrifuges for small volume samples, high-speed centrifuges for quick separations, and ultracentrifuges capable of producing extreme g-forces for molecular-level studies are among the several kinds of centrifuges available.

- Rotational speed (RPM) and relative centrifugal force (RCF) define a centrifuge’s performance in terms of multiples of Earth’s gravity, so quantifying the acceleration applied to the sample.

- Various rotor designs—such as fixed-angle, swinging bucket, and continuous-flow rotors—are customized to particular uses, therefore affecting the way the separated materials form pellets or layers within the container.

- Centrifuges are used in industrial operations for dewatering sludge, clarifying liquids such as milk by separating cream, and even for specific uses such gas centrifuges in uranium enrichment, where isotopes are separated depending on minute mass variations.

- Gas centrifuges are essential in nuclear fuel processing as they particularly employ high-speed spinning to separate isotopes in gaseous compounds, therefore effectively enriching uranium with significantly lower energy consumption than more conventional techniques.

- Safety is vital with centrifuges as uneven loads or rotor breakdowns can lead to catastrophic mechanical damage and pose major dangers; consequently, careful balancing, frequent maintenance, and attention to safety regulations are necessary

- Modern centrifuges sometimes include automated balancing systems, temperature control, and computerized controls that improve the repeatability of experimental results as well as separation efficiency.

- Factors like sample amount, sensitivity to temperature, desired separation efficiency, and the particular kind of the materials involved determine the choice of a centrifuge so that the equipment is flexible in several scientific and commercial uses.

- From biotechnology and clinical diagnostics to chemical processing and nuclear technology, centrifuges are a basic instrument in both research and industry allowing quick, effective, scalable separation procedures supporting developments in sectors ranging from biotechnology and clinical diagnostics to chemical processing and nuclear technology.

Types of Centrifuges

There are many different types of centrifuges available, and the appropriate type depends on the specific application and the characteristics of the sample being processed. Some common types of centrifuges include:

1. Benchtop centrifuges

- Perfect for research, therapeutic, and biochemical uses, benchtop centrifuges are tiny laboratory tools used to do centrifugation on small- volume materials.

- They are engineered to fit on a standard laboratory bench, offering a space-saving solution compared to larger, floor-standing models

- By spinning materials at great speeds to create centrifugal force, these machines separate elements like cells, proteins, nucleic acids, and other biomolecules.

- Benchtop centrifuges generally support a range of sample containers including microcentrifuge tubes and tiny conical tubes, offering adaptability for diverse experimental techniques

- Many versions have a variety of rotating speeds—from moderate to high RPM—along with exact digital controls that let users select spin duration, speed, and occasionally even temperature.

- Certain benchtop centrifuges provide chilling choices, therefore guaranteeing that heat-sensitive samples are kept at ideal settings throughout centrifugation.

- Though they have limited capability for processing greater sample numbers, they are typically more cost-effective and simpler to run for low-to medium-volume applications.

- Safety features such as tight lid-locking mechanisms and automated imbalance detection are typically implemented, helping to prevent rotor failure and assure operator safety

- Benchtop centrifuges are a common option in university labs, healthcare settings, and small biotech facilities for regular sample preparation and separation procedures thanks in part to their simple design and compact footprint.

- Without the large size, power, and maintenance needs of industrial-scale equipment, tabletop centrifuges offer an effective, flexible, and reasonably priced answer for laboratory centrifugation needs overall.

Applications of Benchtop centrifuges

- Separation of blood components for clinical tests

- Isolation of cells for culture and analysis

- Purification of proteins and nucleic acids

- Removal of precipitates and debris from solutions

- Clarification of liquid samples in research labs

- Concentration of small-volume samples for assays

- Routine sample preparation in diagnostic procedures

- Quick sedimentation of particles in biochemical studies

2. Floor-standing centrifuges

- Floor-standing centrifuges are huge, durable equipment meant to be installed directly on the laboratory or industrial floor

- Compared to benchtop models, they provide more capacity and manage higher sample volumes.

- Built for fast running, these centrifuges may produce rather strong relative centrifugal forces.

- Often including sophisticated controls, several rotor configurations, and even integrated refrigeration systems, they

- Floor-standing centrifuges are often employed in industrial and large-scale laboratory applications such as dewatering, large-scale cell processing, and bulk chemical separations

- Given the great weight and vibration during operation, their design need for sturdy installation and dedicated floor area.

3. High-speed centrifuges

- High-speed centrifuges are specialized laboratory tools designed to separate mixture components depending on density variations via fast rotation.

- They work by spinning samples in a rotor at very high speeds to produce a strong centrifugal force that drives heavier particles outward while lighter molecules stay at the center.

- The design guarantees that the produced forces lead to effective and uniform separation without compromising sample integrity by carefully balanced rotors and sample holders.

- The varied centrifugal forces as the rotor accelerates enable components with differing densities to stratify into separate layers, therefore enabling the separation of certain chemicals, cells, or subcellular organelles.

- High-speed centrifuges have one main benefit in that they can quickly and consistently separate complicated mixtures—a necessary step for time-sensitive research and diagnostic uses.

- By giving users exact control over operational variables like speed, duration, and temperature, they enable users to modify procedures for various samples and experimental requirements.

- These devices are perfect for clinical laboratories and industrial operations where uniformity and efficiency are crucial as they are designed for automation and great throughput.

- Among the limitations are great energy consumption and the need for constant maintenance to guarantee rotor balance and mechanical integrity, particularly considering the stresses produced at high speeds.

- The great spinning speeds can produce a lot of heat, which usually calls for integrated cooling systems to preserve delicate samples and extend the lifetime of equipment.

- In research, high-speed centrifuges are used to separate biological components, purify proteins, and isolate nucleic acids, therefore rendering them vital in biochemistry and molecular biology.

- Clinically, they are extensively utilized for separating blood components like plasma and serum, which are essential for diagnostic tests and treatment uses.

- Reflecting their adaptability in processing a range of materials, industrial uses include the treatment of wastewater, chemical purification, and particle matter removal.

- Advanced digital interfaces and programmable settings on the instruments allow for exact control over experimental conditions and guarantees of repeatability across several runs.

- In both research and industry settings where high-quality separation is crucial, fast centrifuges offer a vital mix of efficiency, accuracy, and adaptability.

4. Refrigerated centrifuges

- Refrigerated centrifuges are specialist laboratory tools combining high-speed centrifugation with an integrated cooling system to preserve a carefully regulated low-temperature environment throughout operation.

- Designed to treat temperature-sensitive samples, they chill the centrifuge chamber using a refrigeration system—usually including compressor, condenser, evaporator, and digital control panel—while the rotor spins rapidly.

- Samples are loaded into balanced tubes inside the rotor during operation; the refrigeration system is turned on to lower the chamber’s temperature; and high-speed rotation produces centrifugal force that stratifies sample components by density without sacrificing the integrity of heat-sensitive molecules.

- Refrigerated centrifuges have several benefits for maintaining the viability of proteins, nucleic acids, and cells: better reproducibility of separation techniques, precise control over parameters including speed, time, and temperature, which is essential; prevention of thermal degradation will help to preserve samples.

- In applications needing strict temperature control, they are especially helpful since the low temperatures preserve the structural and functional integrity of sensitive biological materials and increase the efficiency of separations in clinical, biochemical, and molecular biology studies.

- Higher expense and complexity compared to conventional centrifuges, more maintenance needs resulting from the refrigeration components—such as controlling frost buildup and compressor wear—and a bigger physical footprint that can call for more laboratory space are among the limitations.

- Common applications of chilled centrifuges encompass the separation of blood components (including plasma and serum), purification of proteins and nucleic acids, cell culture processing, pharmaceutical research, and even environmental monitoring, where effective analysis depends on exact temperature control.

- In chemical synthesis and freeze-drying applications, these devices also assist eliminate solvents and swiftly solidify samples, therefore boosting product purity and experimental efficiency

- Because they provide high-speed, high-accuracy separations while maintaining the integrity of temperature-sensitive samples, refrigerated centrifuges are essentially essential in modern labs as they guarantees reliability and dependability of experimental results.

5. Microcentrifuges

- Microcentrifuges are tiny, bench-top laboratory tools particularly intended for processing extremely small amounts of liquid, often accommodating tubes of 0.5, 1.5, or 2.0 mL capacity

- Usually ranging from 10,000 to 15,000 rpm, they quickly spin the sample tubes in a rotor at high speeds to provide considerable centrifugal force that separates components depending on density, therefore allowing heavy particles to settle at the bottom while lighter materials remain above.

- Once turned on, the balanced microcentrifuge tubes are loaded into a fixed-angle or swinging bucket rotor; once activated, the rotor accelerates to the set speed and the resultant force drives the sedimentation process using a tightly enclosed lid preventing contamination and aerosol generation.

- Microcentrifuges are perfect for labs with limited space because of their small footprint and simplicity of operation; their design allows quick separation of small-volume samples, so conserving valuable biological material and lowering reagent consumption; they are also reasonably cost-effective compared to more powerful centrifugation systems.

- Applications in molecular biology, biochemistry, and clinical diagnostics where exact separation of nucleic acids, proteins, and cell components is vital depend on their fast processing times and great repeatability.

- Limitations include a limited capacity that confines their use to small-volume samples, making them unsuitable for large-scale or high-throughput processing; additionally, prolonged high-speed operation may lead to heat buildup, perhaps affecting temperature-sensitive samples unless a refrigerated model is used.

- In research and clinical laboratories, microcentrifuges are extensively used for DNA, RNA, and protein extraction, cell pelleting, and sample clarity as well as in forensic analysis and diagnostic processes where handling low sample quantities with great efficiency is critical.

- Microcentrifuges are a vital tool for many modern laboratory uses as they offer an accurate, quick, and easily available way to separate and purify small-volume materials.

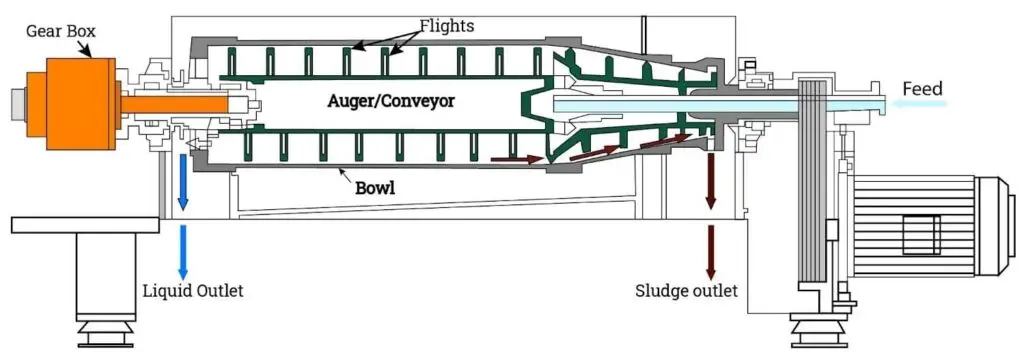

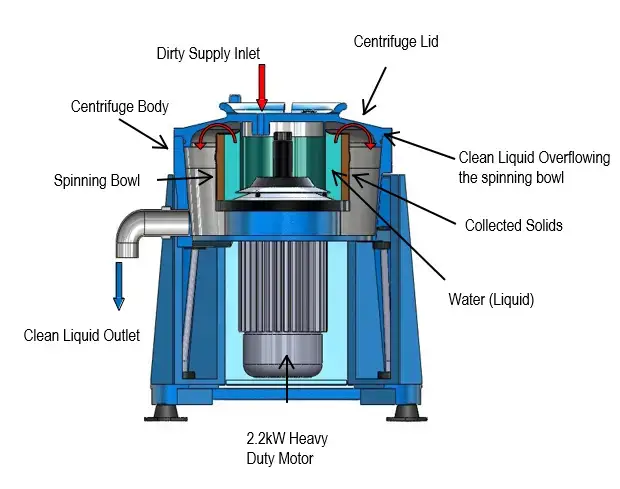

6. Industrial centrifuges

- Designed to separate mixtures using very high centrifugal forces accelerating the settling of solids from liquids or the separation of immiscible liquids depending on variations in density, industrial centrifuges are large-scale separation machines.

- They function by quickly rotating a rotor or bowl at rates that create forces thousands of times stronger than gravity, causing the denser particles to migrate outward toward the bowl wall while lighter components remain closer to the center

- Many industrial centrifuges have a continuous flow design whereby feed slurry is pumped into the rotating chamber and as centrifugal force acts on the mixture, a differential mechanism such a scroll or screw conveyor constantly ejects the compacted solids while the clarified liquid is removed through specified outlets.

- Applications requiring constant, continuous separation in industrial contexts would find these machines perfect as they are engineered for high throughput and can process great amounts of material with minimum human involvement.

- One significant advantage is their high separation efficiency; the powerful centrifugal force rapidly concentrates materials, hence decreasing product loss and enhancing the quality of the separated components, which is crucial in processes like wastewater treatment and chemical production

- Furthermore providing strong automation and sophisticated control systems that enable exact management of variables such rotor speed, feed rate, and differential speed, industrial centrifuges help to maximize the separation process and lower downtime.

- Nevertheless, for many activities the high initial cost and intricate mechanical design can result in extensive maintenance needs and more energy consumption than in smaller laboratory units, therefore making them a major investment.

- Furthermore natural to their functioning are noise, vibrations, and heat creation, which calls for cautious installation, frequent maintenance, and occasionally extra steps for vibration or sound reduction.

- Wastewater treatment makes extensive use of industrial centrifuges to dewater sludge and reducing disposal quantities, therefore improving the efficiency of next treatment and lowering transportation costs.

- Separating oil from drilling fluids, refining fuel mixes, and recovering valuable by-products from chemical process streams make them absolutely vital in the oil and gas sector.

- These centrifuges effectively remove particle debris and excessive water, thereby helping to clear liquids, separate cream from milk, and extract edible oils in the food and beverage industry.

- They also play significant roles in pharmaceutical and biotechnology industry for purifying proteins, nucleic acids, and cells, as well as in mining, recycling, and environmental remediation where quick and effective separation of materials is needed

7. Haematocrit centrifuge

- A haematocrit centrifuge is a specialized laboratory apparatus designed to separate whole blood into its cellular components so that the hematocrit—the volume percentage of red blood cells—can be precisely determined.

- It works by putting a tiny blood sample—usually taken in a capillary tube—into the rotor where fast spinning produces centrifugal force.

- Usually divided by a thin layer termed the buffy coat, this force drives the denser red blood cells toward the bottom of the tube while the lighter plasma stays at the top.

- After the centrifugation procedure, the length of the packed red blood cell layer is measured compared to the overall length of the blood column to get the hematocrit value.

- Rapid and consistent separation of blood components—which is essential for quick diagnosis and monitoring of disorders such anemia or polycythemia—is one main benefit of a hematocrit centrifuge.

- Given a low blood volume, it is particularly helpful in pediatric or neonatal environments when sample supply is constrained.

- With well defined processes for loading samples, adjusting speed and duration, and reading results, the gadget is usually easy to run and maintain, hence reducing operator error.

- Accurate evaluation of a patient’s oxygen-carrying capacity depends on consistent and repeatable results, hence exact control over centrifugation settings guarantees this.

- However, drawbacks include the possibility of hemolysis if the blood sample is mishandled or if centrifugation settings are not adequately calibrated, which can lead to erroneous hematocrit results.

- Inaccuracies in the rotor or defective capillary tubes might potentially lead to erroneous readings resulting from confined plasma or erroneously low values should red blood cells be compromised throughout the procedure.

- In clinical laboratories, blood banks, and research institutions, hematocrit centrifuges are extensively used to assess red blood cell content, help to diagnose blood diseases, and track patient reactions to medication.

- In resource- constrained healthcare environments, their low sample volume needs, simplicity of usage, and cost-effectiveness make them very attractive.

- By offering a quick, precise, and effective way to ascertain the fraction of red blood cells in whole blood, the haematocrit centrifuge is overall rather important in medical diagnostics.

8. Low-speed centrifuges

- Usually running between 4,000 and 5,000 rpm, a low-speed centrifuge is a laboratory tool intended for regular separations at somewhat low rotating speeds.

- It operates by spinning samples in a rotor so that the mild centrifugal force produced leads heavier particles to settle to the bottom while lighter components remain above without subjecting sensitive samples to too strong shear stresses.

- Lower energy consumption, less heat generation, and minimum mechanical stress on samples are among the advantages; these characteristics make low-speed centrifuges perfect for processing delicate materials or quantities in regular diagnostic and research uses.

- Among the limitations include lengthier processing times for samples with modest density variations, a lack of improved temperature control in many models, and a reduced resolving power that could be insufficient for distinguishing extremely tiny particles or molecules.

- Clinical laboratories often employ low-speed centrifuges to separate blood cells from plasma; food and beverage companies use them to clear juices and dairy products; and wastewater treatment uses them to extract coarse particulates from liquid suspensions.

9. Continuous flow centrifuges

- Designed to process samples continuously, continuous flow centrifuges are specialized systems that let feed material be continuously introduced and simultaneous extraction of separated components possible.

- They work by feeding a liquid or slurry into a rapidly rotating chamber where centrifugal forces drive the denser particles or phases outward toward the walls while lighter fluids remain closer to the center; a mechanical device like a screw conveyor or scroll continuously discharges the concentrated phase as the clarified liquid exits through separate outlets.

- The constant design greatly increases throughput and efficiency by eliminating the requirement for batch loading and unloading, therefore enabling industrial-scale separations.

- Continuous flow centrifuges have several advantages: greater processing capacity; less downtime since they run constantly; and better uniformity in separation performance.

- In sectors such wastewater treatment, dairy and beverage processing, chemical manufacture, and petroleum refining—where significant quantities of material must be handled continuously—they are very helpful.

- High capital and operating expenses, more complexity in maintenance and operation, and the necessity of exact balance and control to reduce problems like vibration or product loss define limitations.

- Large-scale applications needing consistent, effective separation of solids from liquids or the isolation of immiscible liquid phases depend on continuous flow centrifuges, hence they are a fundamental part in many industrial processes.

10. Ultracentrifuges

- Ultracentrifuges are highly specialized scientific devices that operate at extremely high rotating speeds—typically between 60,000 and 150,000 rpm—to create large centrifugal forces

- Based on microscopic variations in density, size, and form, they are designed to separate extremely tiny particles and macromolecules like proteins, nucleic acids, viruses, and subcellular organelles.

- The ultracentrifuge drives denser particles to sediment quickly at the bottom while lighter components remain nearer the top by placing the sample in specially designed tubes within a rotor; this allows the ultracentrifuge to operate at high speed (often under vacuum to minimize friction and heating).

- Modern rotor designs, such as swinging or fixed-angle bucket rotors, guarantee that the samples remain balanced and experience consistent force, therefore improving the separation process’s accuracy.

- Important benefits are great resolving power, which helps to separate highly similar-density particles, and the capacity to use thorough analytical methods like sedimentation velocity and equilibrium analysis for molecular weight and interaction determination.

- In research settings where the purity and characterisation of biomolecules are vital, ultracentrifuges are very essential as they can rapidly and with great repeatability process samples.

- Still, they have important restrictions: Because of their complexity and harsh running conditions, ultracentrifuges are costly, waste a lot of energy, and need for highly qualified operators and careful maintenance.

- They also produce a lot of heat, which calls for strong cooling systems; mishandled samples may cause damage or destruction of delicate biological components.

- In molecular biology, biochemistry, and pharmaceutical research, ultracentrifuges find extensive application for activities like ribosome isolation, virus purification, cellular organelle separation, and macromolecular complex characterization.

- Within the biotechnology and pharmaceutical sectors, its great accuracy in separating nanoscale particles finds uses in quality monitoring and product development.

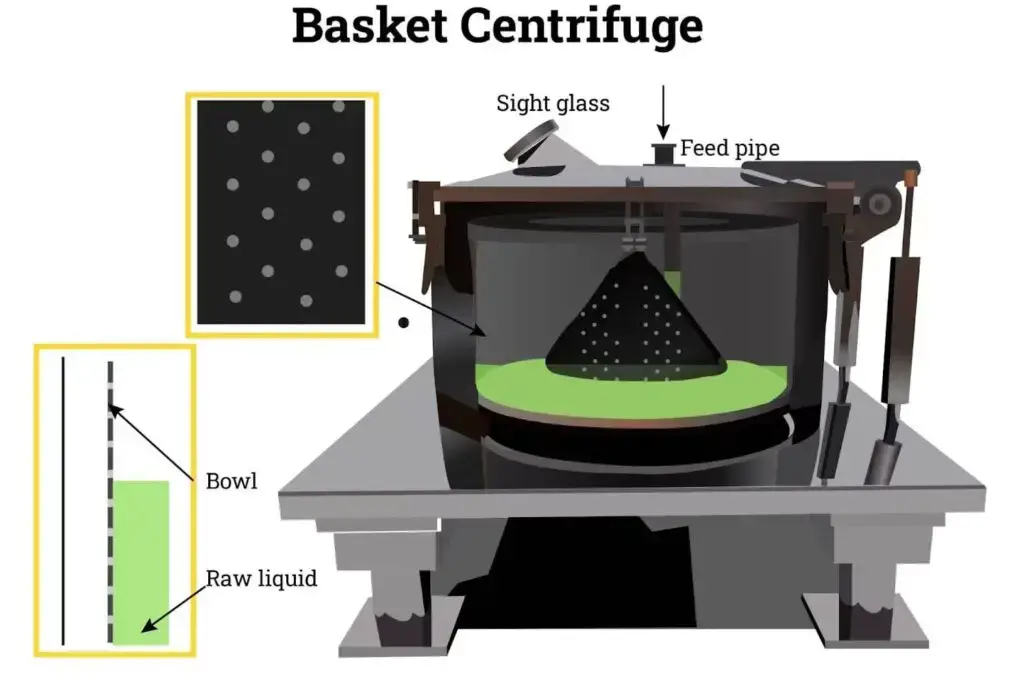

11. Basket Centrifuge

- Designed especially to separate liquids from solids by use of a revolving perforated basket, a basket centrifuge is a solid-wall centrifuge whereby the structure of the basket serves as a built-in filter.

- It works by pouring a slurry or liquid-solid combination into the spinning basket; the denser solid particles radially outward against the inner wall while the lighter liquid travels through the perforations and is collected separately as the basket spins at great speed.

- Usually consisting of a cylindrical or conical basket made of corrosion-resistant materials such stainless steel, the design of the basket centrifuge uses perforation sizes chosen depending on the target particle size to maximize separation efficiency.

- While the clarified liquid is drained out by gravity, the feed material is constantly or batch-fed into the basket and as the basket rotates the accumulated solids form a cake that is later discharged—either manually or through an automated mechanism such a scraper or hydraulic pusher.

- Because they provide a product with low moisture content, basket centrifuges have one major benefit in handling slurries with high solid concentrations; they are thus perfect for procedures where thick mixes must be dewatered or cleared.

- They offer great separation efficiency for a wide range of applications, including the separation of crystalline products, recovery of precipitates in pharmaceutical manufacture, and dewatering of sludge in wastewater treatment, all while keeping a small footprint

- Furthermore flexible in nature, basket centrifuges can be set up as continuous-flow systems for high-throughput industrial processes or batch systems for smaller volumes, so satisfying different operating needs.

- Still, there are constraints: Because of wear and tear from abrasive particles, basket centrifuges can be vulnerable to the development of a hard cake that is difficult to entirely remove. They also sometimes need a complicated cycle that can be labor-intensive and may incur greater maintenance expenses.

- When running at high speeds required to provide enough centrifugal force, they also usually consume more energy; their efficacy may be compromised when processing materials with very small or similarly sized particles that contradict the intended perforation size.

- Industries including wastewater treatment for dewatering sludge, in the food and beverage sector for clarifying juices and separating sugar crystals, in pharmaceutical manufacturing for recovering precipitated active ingredients, and in oil extraction processes to separate and concentrate valuable oils find extensive application for basket centrifuges.

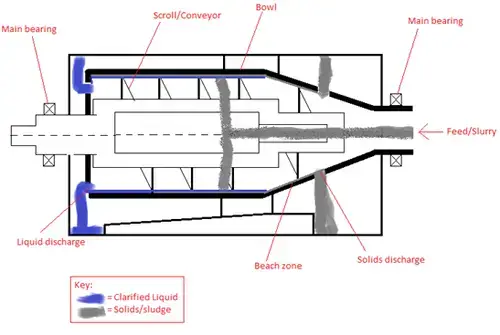

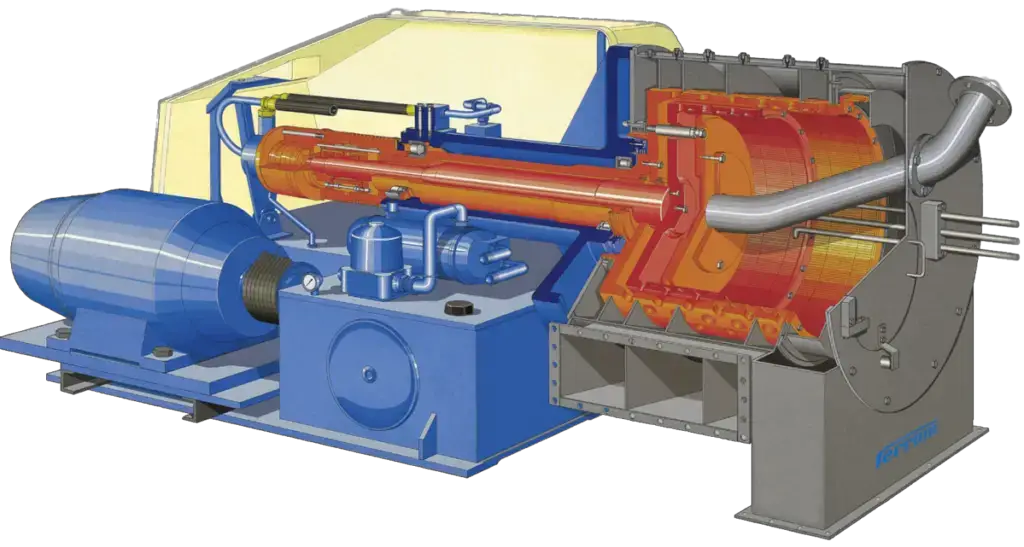

12. Decanter Centrifuge

- Usually referred to as a solid bowl centrifuge, a decanter centrifuge is a continuous separation tool based on density differences that employs high-speed spinning to separate solids from liquids.

- It operates by constantly slurry feeding into a spinning cylindrical or conical bowl where the heavier solids are pushed to gather around the inner walls by centrifugal force while the lighter liquid is pulled inward and discharged through an overflow exit.

- Inside the bowl, an internal screw or auger rotates constantly pushing the settled particles toward one end so that a compact, dewatered cake forms and may be released without stopping the process.

- Key advantages of decanter centrifuges include their ability to work continuously, which boosts throughput and overall process efficiency, as well as their excellent separation efficiency even with slurries having high solid concentrations

- While the automation of solids lowers manual labor and offers constant performance, their somewhat dry cake decreases waste volume and enhances downstream processing.

- Decanter centrifuges do, however, have many drawbacks like expensive initial capital and operating expenses, great energy consumption, and complicated mechanical systems needing frequent maintenance and specialized operation.

- Their performance can be susceptible to fluctuations in feed uniformity and particle size, and if not properly balanced or maintained, difficulties like vibration or ineffective separation may arise

- They find extensive application in many different sectors, including food and beverage for clarifying juices, separating milk fat, and recovering sugars from syrups, chemical and pharmaceutical processing for separating reaction products and precipitates, and wastewater treatment for dewatering sludge.

13. Other Types of Centrifuge

a. Inverting Filter Centrifuge

The objective of the design of an inverted filter centrifuge is to remove all cake material without leaving any heel. An inverting filter centrifuge, like a horizontal peeler centrifuge, features a revolving drum. Instead of using peeler blades to remove the cake, the cake is pushed out of the bottom of the drum. The pushing action extends so far that the filter fabric is inverted, hence eliminating the need for any type of mechanical cleaning.

Inverting filter centrifuges ensures the highest level of product purity achievable. They are utilised with difficult-to-filter items and in situations when operator interaction with the product must be avoided.

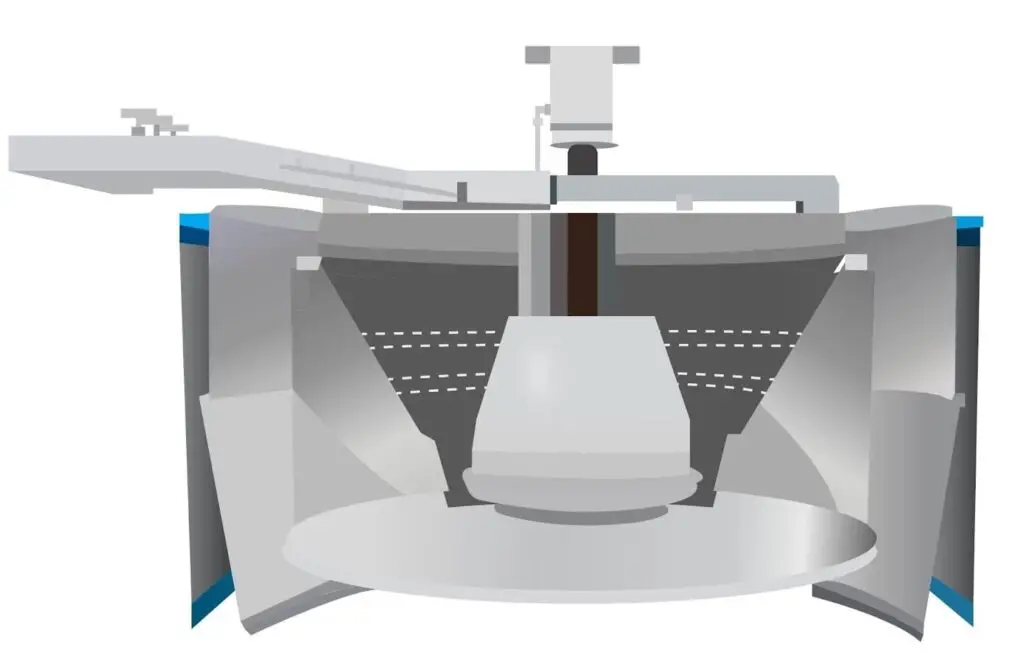

b. Vertical Solid Bowl Centrifuge

Solid bowl vertical centrifuges are clarity centrifuges that separate mixed materials using centrifugal force. The slurry is placed within the rotating bowl. As the bowl’s speed increases, the g forces remove dense and solid items from the liquid and deposit them on the bowl’s inner wall.

Since there are no apertures in a solid bowl vertical centrifuge, it must be routinely opened and cleaned away. This is carried out throughout the scrape cycle. Solid bowl vertical centrifuges are not continuous flow centrifuges since they must be regularly stopped and scraped out.

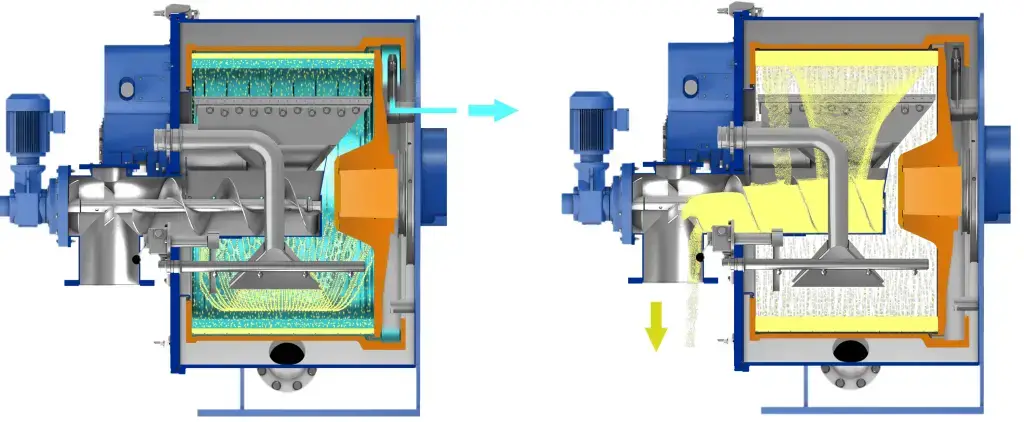

c. Pusher Centrifuge

Pusher centrifuges, also known as horizontal basket centrifuges, have a hydraulic piston with metal screening sheets or slotted sieves. They can filter liquids to create filter cakes utilising an oscillating pushing motion from the hydraulic piston to move the cakes out of the bowl or have them washed away. Pusher centrifuges are continuous-operation centrifuges developed for high-volume solids with purity and residual moisture requirements.

The pusher centrifuge’s basket generates the centrifugal force necessary to separate particles from slurry. Each forward stroke of a hydraulically driven piston that rotates with the basket expels solids from the basket. Liquids drain through the basket’s metal screen or slotted sieve, while solids are deposited on the screen.

d. Horizontal Peeler Centrifuge

Peeler centrifuges are batch centrifuges with cloth filters and perforated bowls. Liquids are centrifuged at high speeds to create cakes of solids on the filter cloth. The cakes are dried by a spinning method. After the cakes have dried, peeler knives are used to scrape them off. After the heel has been scraped, remaining heel must be removed. Changes are made to the position of the scraper, and high-pressure nitrogen is utilised to eliminate the residual.

A horizontal peeler centrifuge is a filtration machine with continuous flow that may be toggled between automatic and manual control.

e. Oil Centrifuge

The oil centrifuge is also known as a centrifugal oil filter since it is utilised in places where oils must be filtered. The machine’s dirty lubricating oil circulates through the centrifuge oil filter. The oil is then forced under pressure through a filter and into a bowl. The bowl is then spun at extremely high rates of 5,000 to 8,000 rpm, depending on the oil inlet pump pressure. The resulting gravitational force attracts any particles to the bowl walls, while the clean, purified oil returns to the machine for use. During normal engine operation, soot and other impurities are eliminated frequently.

Importantly, the oil filter is not a barrier-type filtration mechanism, therefore it does not rely on filtration media to remove hydraulic or lubricant oil-contaminated particles.

References

- Moran, S. (2017). Centrifuges. Process Plant Layout, 389–397. doi:10.1016/b978-0-12-803355-5.00027-5

- Bridges, S., & Robinson, L. (2020). Centrifuges. A Practical Handbook for Drilling Fluids Processing, 475–488. doi:10.1016/b978-0-12-821341-4.00021-x

- Berk, Z. (2009). Centrifugation. Food Process Engineering and Technology, 217–232. doi:10.1016/b978-0-12-373660-4.00009-0

- https://www.ehs.uci.edu/sop/hazardous-operations/centrifuge-sop.pdf

- https://www.mls.be/en/p/lab-apparatus/centrifuges/centrifuges-hettich/hematocrit-centrifuges/

- https://www.sigmaaldrich.com/IN/en/technical-documents/technical-article/protein-biology/protein-pulldown/centrifugation-separations

- https://www.iqsdirectory.com/articles/centrifuge.html

- https://www.tec2med.com/centrifuge-rotor-rcf-rpm/

- https://www.toppr.com/guides/chemistry/is-matter-around-us-pure/centrifugation/

- https://www.biocompare.com/Lab-Equipment/Laboratory-Centrifuges/

- https://druckerdiagnostics.com/knowledge/how-a-centrifuge-works/

- https://study.com/academy/lesson/what-is-centrifugation-definition-process-uses.html

- https://www.genfollower.com/centrifuges-types-uses-in-laboratories/

- https://www.labmanager.com/product-focus/the-basics-of-centrifuge-operation-and-maintenance-1433

- https://www.coleparmer.in/c/centrifuges

- https://microbenotes.com/centrifuge-principle-parts-types-uses-examples

- https://www.labtron.com/centrifuge

- https://www.vedantu.com/chemistry/uses-of-centrifuge