The GasPak Anaerobic System is a laboratory method used to grow bacteria that thrive in oxygen-free environments, known as anaerobes. Using throwaway sachets filled with compounds like sodium borohydride and sodium bicarbonate helps to create an anaerobic (oxygen-free) environment more quickly. These molecules combine to generate hydrogen and carbon dioxide when water is introduced. The hydrogen then interacts with any oxygen present in a sealed container, generating water (with the assistance of a palladium catalyst), while the carbon dioxide replaces the lost oxygen, therefore guaranteeing optimal circumstances for anaerobic bacteria to flourish. Often containing methylene blue, an indicator strip becomes colorless at complete elimination of oxygen, therefore verifying the ready condition for incubation.

Originally designed in the 1960s by Becton Dickinson (BD), the GasPak system was a reasonably priced substitute for more expensive, more complicated techniques like the McIntosh and Falde’s jar, which called for hand petrol pumping. Early forms removed oxygen using water-activated sachets and a palladium catalyst. Advances throughout time resulted in current systems like the BD GasPakTM EZ, which eliminated the need for water and additional catalysts, therefore simplifying and safer the process even for regular lab usage. Particularly in laboratories with smaller sample volumes, GasPak systems are increasingly embraced in clinical and research environments today for their dependability and simplicity of use.

By democratizing access to specialist culture techniques, this invention transformed anaerobic microbiology and allowed labs without sophisticated equipment to investigate oxygen-sensitive bacteria vital in areas such wound infection control and gut microbiome research.

Components of GasPak Anaerobic System

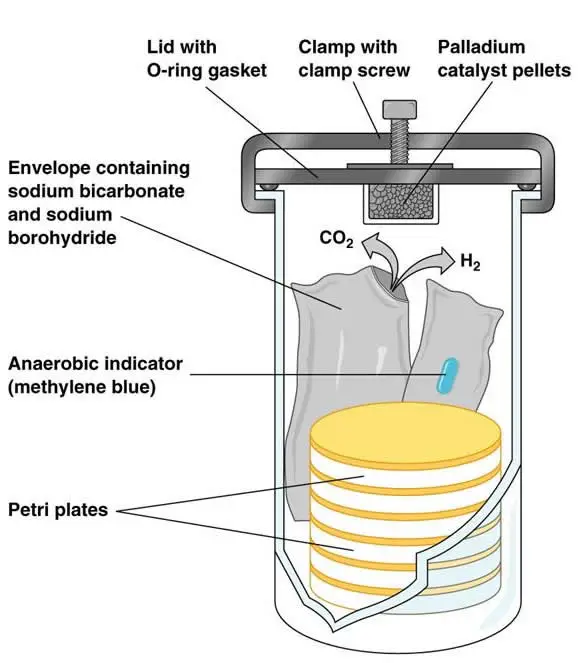

Designed to generate an oxygen-free environment fit for the growth of anaerobic microorganisms, the GasPak Anaerobic System Its main parts consist in:

- Anaerobic Jar or Container- Often constructed of polycarbonate, anaerobic jars or containers are robust, airtight vessels with a lid and gasket to stop airflow.

- Gas Generator Sachet- Made from sodium borohydride and sodium bicarbonate, a gas generator sachet is a throw-away bag. Usually brought on by water addition, these compounds react to generate hydrogen and carbon dioxide gasses when triggered.

- Often palladium, a catalyst is added to help the reaction between the produced hydrogen and leftover oxygen within the jar create water and thereby remove oxygen to preserve anaerobic conditions.

- Anaerobic Indicator Strip– An oxidation-reduction indicator, like methylene blue or resazurin, imprinted on a strip. This strip visually confirms anaerobic conditions by changing color in the presence of oxygen.

Principle of GasPak Anaerobic System

Together with the gas generator sachets and an indicator strip, inoculation tubes or plates are placed inside the polycarbonate container or anaerobic jar shut. When water is present and the chemicals in the bag—that is, sodium bicarbonate (NaHCO3) and sodium thermohydride (NaBH4)—chemical interaction generates carbon dioxide and hydrogen gas.

Water (which forms as condensation on the inside of the container) is produced when the hydrogen arising from the reaction interacts with the oxygen within the jar.

2H2 + O₂ + catalyst = 2H2O

The palladium mineral fastened to the underside of the container sets off this reaction. Anaerobic environment results from the replacement of the oxygen lost by carbon dioxide.

Note: The anaerobic gas-generating equipment of today does not call for water activation or catalysts. Before starting your project, review the handbook the manufacturer included for users.

How does a gaspak anaerobic system work?

Creating an oxygen-free atmosphere helps the commonly used GasPak Anaerobic System to grow anaerobic bacteria. Usually, the process consists in the following steps:

- Starting with the suitable culture media (like agar plates or broth), first asepticly inoculate the microorganism of interest.

- The inoculation medium should be placed inside the anaerobic jar or container.

- Put an anaerobic indicator strip in the jar inside. Often impregnated with methylene blue or resazurin, this strip will change color in the presence of oxygen, providing visible proof of anaerobic conditions.

- Introduce the Gas Generator Sachet. Open the gas generator sachet and slide it into the jar. These sachets in conventional GasPak systems include chemicals like sodium borohydride and sodium bicarbonate, which, when activated—usually by adding water—release hydrogen and carbon dioxide gasses. To produce an anaerobic environment, the hydrogen combines with remaining oxygen in the jar to make water and so removes oxygen. Modern variants, including the BD GasPak EZ system, streamline this process using waterless, catalyst-free sachets.

- To guarantee the jar is airtight and stop any outside air from getting in, securely seal the lid.

- Put the sealed jar in an incubator set to the ideal temperature fit for the microorganism being grown.

- Check the anaerobic indicator stripe after a few hours of incubation. While a colorful strip indicates the presence of oxygen, therefore showing the absence of the anaerobic environment, a colorless strip demonstrates effective formation of anaerobic conditions.

Indicator of anaerobiosis

The efficacy of GasPak anaerobic system may be assessed using these methods:

- Anaerobic indicator strips:

- Impregnated with methylene Blue: remains colorless in anaerobic environments however, it turns blue upon contact with oxygen.

- Impregnated with resazurin. A Redox indicator Colorless (white) when in anaerobic conditions however it changes to pink when in when oxygen is present.

- Biological indicator: The plate is inoculated Pseudomonas is incubated alongside other plates inoculated with anaerobic culture. In the absence of any growth in Pseudomonas (which can be described as an obligatory aerobe) signifies that anaerobiosis is in the best possible state. is attained.

Applications of GasPak Anaerobic System

In microbiology, the Gaspak Anaerobic System is extensively used for various important purposes:

- Growing obligatory anaerobes, including species of Clostridium that cannot live in the presence of oxygen, requires an oxygen-free environment, hence cultivation of these anaerobes offers.

- In clinical laboratories, the technique is used to separate and identify anaerobic pathogens from patient samples, therefore supporting the identification of diseases brought on by anaerobic bacteria.

- Anaerobic Microbial Processes: Under regulated oxygen-free conditions, researchers utilize the GasPak system to investigate fermentation and anaerobic respiration among others.

- Food and environmental microbiology uses the system to identify and investigate anaerobic spoilage organisms and pathogens, therefore guaranteeing food safety and environmental monitoring.

Advantages of GasPak Anaerobic System

- Easy to Use- Simple setup of the device makes it easily accessible for regular laboratory tasks.

- Rapid Anaerobic Environment Creation– Quick establishment of an oxygen-free environment required for the growth of anaerobic organisms is achieved here.

- Cost-Effective– The GasPak system is a less expensive substitute for more complicated anaerobic workstations.

- Portability – Its small size makes travel and operation in many environments simple.

- Visual Confirmation – Anaerobic conditions have been reached immediately visually thanks to the attached anaerobic indicator strip.

- Versatility – Appropriate for research uses involving anaerobic microorganisms as well as clinical diagnostics.

Limitations of GasPak Anaerobic System

- Limited Duration- Anaerobic conditions are maintained only for a designated duration, hence they could not be enough for particularly slow-growing species.

- Capacity Restrictions – The tiny jar capacity restricts the simultaneous incubation capacity of the number of samples.

- Seal Dependency- The efficiency of the system depends on a flawless seal; any leak will allow oxygen in, therefore damaging the anaerobic environment.

- Sensitivity for Fastidious Organisms- Extremely oxygen-sensitive microbes may not survive even with very little residual oxygen for fastidious species.

- Limited Environmental Control- Restricted experimental flexibility results from limited environmental control—that is, from inability to change gas composition or temperature after the jar is shut.

Main Event Timeline

- 1960s: Becton Dickinson (BD) creates the first GasPak anaerobic system as a simpler and less expensive substitute for current techniques such the Jar of McIntosh and Falde. This first device removed oxygen using a palladium catalyst and water-activated sachets.

- Ongoing Development: Over time, improvements in the GasPak system provide systems that do away with the requirement for extra catalysts and water activation. One obvious example of this development is the BD GasPakTM EZ.

- Current Day: Because of their dependability, simplicity, and cost, GasPak systems—including contemporary variants—are extensively used in research and clinical laboratories. In labs with smaller sample quantities especially, they are quite helpful. Anaerobic organisms are grown, anaerobic diseases are tested for, and microbial processes and food rotting research is conducted using the systems among other uses.

Characters in Cast:

- Becton Dickinson (BD): Originally developing the GasPak anaerobic system in the 1960s, Becton Dickinson (BD) Modern, simpler, and waterless versions like the BD GasPakTM EZ are among the variants on this technology they keep developing and manufacturing. An important actor in enabling anaerobic culture to be more practical and accessible is BD.

- McIntosh and Falde: Scientists McIntosh and Falde created an earlier, more sophisticated anaerobic jar system requiring manual petrol pumping to produce an anaerobic atmosphere. Their technology was a more costly, difficult approach than the GasPak and before it.

- Anaerobic Bacteria:Anaerobic bacteria are the biological organisms the GasPak device is designed to target. These are microscopic creatures unable of surviving or flourishing in an oxygen environment. The system is meant to expand and research them. The paper notes Clostridium species as one example, together with their usage in studies on gut microbiomes and wound infections.

- Pseudomonas: Referenced as a biological indicator used in combination with the GasPak system to assess the efficacy of anaerobiosis, pseudomonas is an obligatory aerobe (needs oxygen to thrive) so will not develop if anaerobic conditions have been attained.

- https://integrativewellnessandmovement.com/iwmbasicscience/microiology/microbiology-gaspack/

- https://academic.oup.com/jambio/article-abstract/35/1/71/6728345

- https://microbeonline.com/gaspak-anaerobic-system/

- https://www.bd.com/en-us/products-and-solutions/solutions/capabilities/bd-gaspak–systems-and-accessories

- https://en.wikipedia.org/wiki/Gas-pak

- https://www.thomassci.com/Blog/_/creating-and-protecting-anaerobic-environments-with-anaerobic-systems-and-jars

- https://www.firsthope.co.in/cultivation-of-anaerobes

- https://www.fishersci.com/shop/products/bd-gaspak-ez-gas-generating-systems-supplies-pouch-systems-3/b260683