What is Magnetic Stirrer?

- A magnetic stirrer is a laboratory tool used to efficiently mix a solution by spinning a coated magnetic stir bar submerged in a liquid using a rotating magnetic field.

- Usually covered in PTFE, it comprises of a base housing either a spinning permanent magnet or a group of electromagnets to guarantee chemical inertness and avoid contamination.

- Crucially for repeatable chemical reactions, the spinning magnetic field drives the stir bar to spin quickly inside the vessel, producing a vortex that homogenizes the liquid and guarantees a consistent solute distribution.

- Many magnetic stirrers include an integrated heating element, which lets you simultaneously stir and adjust temperature; this dual use is crucial for processes needing exact thermal conditions.

- In chemical, biological, microbiological, and pharmaceutical laboratories, they are extensively utilized for dissolving materials, reagent preparation, and enhancement of effective reaction kinetics with little danger of outside contamination.

- Usually up to 4 liters, the device is best suited for low-viscosity liquids as greater viscosities or bigger quantities may call for different stirring techniques such overhead stirrers.

- The form, size, and coating of the stir bar are carefully selected to fit the dimensions of the vessel and the chemical characteristics of the solution; choices range from straight bars for flat-bottomed containers to oval or triangular forms for particular uses.

- Digital controls on modern magnetic stirrers let one precisely change the stirring speed (in RPM) and heating levels, hence maintaining constant and repeatable experimental conditions.

- Long-term studies and regular laboratory use find them perfect for their small design, simplicity of cleaning, and low mechanical wear—due of the absence of exposed moving components.

- By increasing efficiency, safety, and precision, technological developments in magnetic stirrer design—including better motor control and integration with digital interfaces—have broadened their use across many scientific disciplines.

Definition of Magnetic Stirrer

A magnetic stirrer is a laboratory device that uses a rotating magnetic field to spin a stir bar immersed in a liquid, allowing for efficient mixing and stirring of solutions.

Magnetic Stirrer Principle

- Operating on the concept of magnetism, a magnetic stirrer generates a rotating magnetic field using either an array of electromagnets positioned under the container containing the liquid or a motor-driven magnet.

- Usually covered in PTFE, this spinning field interacts with a tiny magnetic stir bar to guarantee chemical inertness, which is immersed in the liquid and causes it to spin and produce a vortex uniformly mixing the solution.

- The basic mechanism depends on the forces of magnetic attraction and repulsion, which guarantee that the stir bar tightly follows the motion of the external magnetic field without any physical contact, therefore lowering the danger of contamination and mechanical wear.

- Many magnetic stirrers additionally have a heating element that permits regulated heating and simultaneous stirring—qualities very essential for chemical processes needing exact temperature settings.

- These are most successful for low-viscosity fluids and small quantities as the efficacy of the stirring process depends on elements like the intensity of the magnetic field, the size and form of the stir bar, and the viscosity of the liquid.

- Essential for repeatable experimental results in many different scientific uses, users may fine-tune the mixing strength by changing the rotating speed of the magnetic field. This will produce a homogenous solution.

- A clever yet basic method for continuous mixing is the integration of electromagnetic ideas with fluid dynamics in a magnetic stirrer, therefore removing the requirement for mechanical stirring components subject to wear and tear.

Types of Magnetic Stirrers

Different kinds of magnetic stirrers have evolved to meet certain scientific needs. The several varieties of magnetic stirrers are explored in more detail below:

- Standard Magnetic Stirrers – Comprising a magnetic bar—also called as a stir bar or flea—placed in the liquid to be stirred, standard magnetic stirrers are the most basic kind of magnetic stirrers. The gadget creates a spinning magnetic field that drives the stir bar to swirl and combine the solution. Commonly employed in many laboratories, standard magnetic stirrers are perfect for simple mixing chores requiring low-viscosity liquids. Their quiet running and simplicity of usage really appeal.

- Hot Plate Magnetic Stirrers – Hot Plate Magnetic Stirrers let solutions be simultaneously stirred and heated by combining the features of a heating element with a magnetic stirrer. In tests requiring temperature control—such as dissolving materials, running chemical reactions, or preserving cultures at precise temperatures—this mix is especially helpful. The integrated hot plate increases device adaptability by allowing exact temperature control. Chemical synthesis, biochemistry, and other disciplines where regulated heating and mixing are important depend on hot plate magnetic stirrers.

- Mini Magnetic Stirrers – Designed for labs with limited space or for uses requiring tiny amounts of liquid, micro magnetic stirrers are small and portable. Though tiny in mass, they provide exact control over stirring rates and can handle several lab chemicals. Their silent operation and minimal vibration fit sensitive investigations. Mini magnetic stirrers are widely utilized in research labs, teaching environments, and any situation where space is limited.

- Multi-Position Magnetic Stirrers – Multiple stirring locations on a single device enable numerous samples to be stirred concurrently on one Multi-Position Magnetic Stirrer. In high-throughput labs where several studies must be carried out concurrently, this function is quite helpful. Many times, each stirring motion may be regulated separately, allowing experimental design some freedom. In pharmaceutical research, chemical analysis, and other industries needing parallel processing, multi-position magnetic stirrers are invaluable because they improve efficiency and uniformity across many samples.

- Battery-Powered Magnetic Stirrers – Perfect for fieldwork or circumstances when access to electrical outlets is restricted, battery-powered magnetic stirrers provide mobility and convenience. Usually light-weight and easy-to-transport, they are appropriate for on-site research, environmental sampling, or educational displays outside of conventional laboratories. Many versions give enough stirring strength and duration to efficiently complete routine mixing chores even if they run on battery power.

- Heavy-Duty Magnetic Stirrers – Engineered to handle bigger volumes and higher viscosity solutions, heavy-duty magnetic stirrers have more powerful motors and greater magnetic fields. They are appropriate for industrial uses or large-scale lab research involving significant material mixing. These stirrers are made to be durable and strong, thereby guaranteeing constant mixing even under heavy demand. Applications include chemical manufacture, large-scale synthesis, and any situation needing the mixing of thick or heavy fluids.

- Air-Operated Turbine Magnetic Stirrers – When electrical sparking must be avoided, such as in the presence of flammable chemicals, air-operated turbine magnetic stirrers—which use compressed air to drive the churning mechanism—are perfect. Common usage in chemical factories, petrochemical facilities, and laboratories handling volatile compounds, they provide a safe substitute for electrically driven stirrers. Lack of electrical components lowers the risk of ignition, therefore improving safety in delicate applications.

- Magnetic Stirrers with Timer – These magnetic stirrers with timers let customers specify particular stirring times by means of an incorporated timer. The gadget automatically quiesces once the set time has passed. In tests requiring exact timing, including timed reactions, incubation times, or sequential step procedures, this function is very helpful. The timer feature guarantees consistency and releases the researcher from the obligation to keep constant observation of the procedure.

Features of Magnetic Stirrer

- A magnetic stirrer creates a revolving magnetic field that drives a covered stir bar within a container to guarantee consistent and effective liquid mixing.

- Usually covered with chemically inert materials like PTFE or glass, the stir bar keeps contamination and chemical interaction with the sample free.

- Variable speed control lets users exactly change the rotating speed to suit varying liquid viscosities and experimental requirements.

- Many versions have a hot plate that offers simultaneous heating and stirring—necessary for processes requiring temperature control.

- Modern devices can use microprocessor controls and digital screens to provide exact temperature and speed changes for repeatable results.

- Some systems have a timer that automatically switches off the stirrer after a certain duration, therefore lowering the danger of overheating or overmixing.

- For tabletop usage in labs with limited space, magnetic stirrers are appropriate because of their compact and space-saving design.

- Multiple-position models let many containers be simultaneously stirred to boost experimental efficiency and throughput.

- Minimal exposed moving components in the enclosed design help to lower maintenance requirements and lessen sample contamination risk.

- Safety elements include non-slip bases, automatic shut-off systems, and temperature sensors support dependable and safe running.

- Built from strong, chemical-resistant materials, these tools are sturdy and able to survive extreme temperatures and demanding lab environments.

- Versatile in usage, magnetic stirrers find employment in chemistry, biology, and pharmaceutical labs for jobs ranging from reagent mixing and solution production to dissolving solids and titrations.

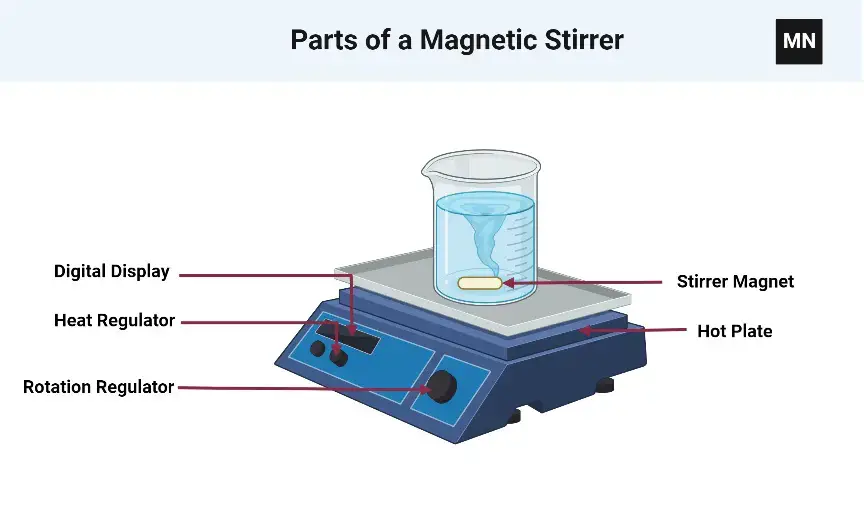

Parts of a Magnetic Stirrer

A magnetic stirrer is a laboratory tool used in effective mixing of liquids using a rotating magnetic field. Its structure consists of numerous important parts, each of which adds to its usefulness:

- Base Housing – The internal mechanisms—including the motor and electromagnets—are contained in this basic framework. It gives the whole machine stability and support.

- Top Plate/Hot Plate – Perched on the base, the top plate provides the surface for containers. Usually it is made from materials like ceramic or stainless steel. Because of its chemical resistance and fit for jobs needing clear vision, including titrations, ceramic plates are preferred. Strong magnetic coupling and effective stirring action abound from stainless steel plates.

- Rotating Magnet or Electromagnet Assembly – Found under the top plate, this component creates a revolving magnetic field using a rotating magnet or electromagnet assembly. While some systems call for fixed electromagnets to provide the required magnetic field, others use motor-driven spinning magnets. Driving the stir bar in the solution depends on this spinning field.

- Stir Bar (Spin Bar) – A tiny, magnetic bar covered in an inert substance like polytetrafluoroethylene (PTFE) is called a stir bar, or spin bar. Placed within a container on top plate, the external magnetic field rotates the stir bar, therefore homogenizing the fluid. varying vessel kinds and solution viscosities call for varying forms and sizes of stir bars.

- Control Panel – Equipped with user interfaces like knobs or digital displays, the control panel lets you change stirring speed and, in models with heating capability, temperature settings. This guarantees exact control over the mixing process to satisfy certain experimental criteria.

- Heating Element (in Hot Plate Stirrers) – Integrated into models with heating capabilities, the heating element in hot plate stirrers lets solutions be simultaneously heated and stirred. In research where temperature control is vital, like chemical processes needing heat to occur, this is very helpful.

- Stir Bar Retriever -Made to properly remove the stir bar from the solution during mixing, Stir Bar Retriever is Usually consisting of a magnet wrapped in an inert substance such as PTFE, it is linked to a rod and allows simple recovery free from direct contact with the solution.

Magnetic Stirrer operating procedure

- Before usage, make sure the magnetic stirrer is absolutely clean and free of dust or any other contaminants; furthermore, make sure the stir bar is whole, correctly coated, and suitable for the amount and kind of solution being mixed.

- On the stirrer plate, set the pre-prepared liquid in the reaction vessel or beaker on a level, sturdy surface.

- Check that the instrument is attached to a correctly e grounded mains power source to avoid electrical risks.

- Turn on the magnetic stirrer and look for a display or indicator light verifying correct operating readiness and power supply.

- Should the device include a heating element, change the temperature control knob to the necessary value and let the solution attain the target temperature before starting stirring.

- Carefully slide the magnetic stir bar into the jar such that it is totally submerged in the liquid to facilitate effective coupling with the magnetic field.

- Starting at a low speed to minimize splashing or too much turbulence, progressively adjust the speed control knob to begin the stirring action.

- Keeping a close eye on the stir bar’s rotation will let you gradually raise the stirring speed until the solution is homogeneous and guarantees stability and centering.

- Track the stirring operation constantly to ensure consistent mixing and to find any anomalies such possible splashing or unequal rotation.

- Should more changes be required throughout the process, carefully fine-tune the speed or temperature controls without interfering with the continuous mixing.

- Turn the knob in the other direction to progressively lower the stirring speed once the mixing procedure is finished until the stir bar comes to a halt completely.

- To guarantee safe shutdown and stop any unintentional action, turn off the instrument and cut it off from the mains power supply.

- Remove the reaction vessel from the stirrer plate gently, then, if needed, detach the magnetic stir bar with an external retrieval tool.

- To eliminate any chemical residue, immediately wipe the stir bar and stirrer plate with a lint-free cloth moistened with distilled water or a 70% isopropanol solution.

- After cleaning, check the instrument to be sure there are no damage or leftover pollutants before storing it.

- For maintenance and quality control, note in the instrument log book the usage information including the date, operator name, operating settings, and any observations or problems.

- Always use the correct personal protective gear—gloves, a lab coat, and safety goggles—and keep the surrounding space clutter-free to reduce hazards during operation.

- For both regular operation and troubleshooting, follow all departmental standard operating guidelines and manufacturer instructions to preserve long-term instrument performance.

- Make sure that all components are operating as expected by following the set schedule to confirm that frequent maintenance inspections guarantee this.

- Always follow laboratory safety procedures; make sure no flammable or dangerous material is present close to the magnetic stirrer while it is running.

Magnetic Stirrer Calibration

- Before starting the calibration procedure, carefully clean the surface and stir bar to guarantee the magnetic stirrer is entirely free of dust and residue.

- Check that all safety procedures are followed to avoid any electrical dangers during calibration and that the instrument is hooked to a correctly e grounded power supply.

- Turn on the magnetic stirrer and let it achieve its standby condition while making sure the control panel shows the right state and that no error indications show presence.

- To guarantee appropriate contact with the heating surface, set a clean vessel with a determined liquid volume on the stir plate for temperature calibration.

- Adjust the temperature control to a fixed point and place a calibrated NIST-traceable thermometer into the liquid such that the sensor does not come into touch with the vessel walls for reliable readings.

- Usually lasting five to ten minutes, give enough time for the system to attain thermal equilibrium so that the thermometer reading and the control display can steady themselves.

- Record the temperature shown on the control panel of the device together with the reading from the calibrated thermometer and compare these readings to ascertain whether they are within reasonable tolerance limits.

- To guarantee accuracy and consistency throughout the whole temperature spectrum, repeat the temperature calibration at many set points over the operational range.

- Using the speed control knob, set the magnetic stirrer to a designated speed for stirring speed calibration; then, use a tachometer to find the magnetic stir bar’s real RPM.

- Examine any differences between the recorded RPM and the figure shown on the control panel to point up any mechanical problems or calibration drift.

- Should variances beyond the allowed tolerance, change the calibration parameters or service the instrument to bring the observed values into line with the intended speeds.

- Carefully enter all calibration data—set points, measured values, ambient variables, operator details, date of calibration—into a separate calibration record page.

- Should the instrument fail the stated calibration standards, mark it as “out of calibration” and schedule remedial action or recalibration before additional use.

- Perform a post-calibration cleaning to eliminate any leftovers from the calibration process and return the instrument to standby once calibration is finished satisfactorially.

- Make sure the whole calibration process follows accepted standard operating guidelines and legal criteria, therefore preserving traceability and quality control all through the process.

- securely file the calibration records and any related documents for next audits and to assist continuous laboratory quality control.

Maintenance of a magnetic stirrer

- Before starting any maintenance, disconnect the magnetic stirrer from its power supply and let it cool totally.

- Using a lint-free cloth moistened with distilled water or 70% isopropanol, carefully wipe the exterior surface and control panel for dust, chemical residue, or wear and damage sensitive components.

- After every usage, carefully wash the stir bar using distilled water to preserve its magnetic integrity and stop cross-contamination by looking for damage or residual deposits.

- To guarantee electrical safety and correct functioning, examine all power cords, plugs, and connecting cables for fraying or physical damage.

- During a functional test, make sure the speed and temperature control knobs run smoothly free from friction and that the display indications show correct values.

- If you can, clean the inside of the stir plate housing to eliminate any dust or chemical splashes that can compromise performance or cause overheating.

- Check the magnetic coupling mechanism often to make sure the stir bar rotates consistently and stays centered throughout operation; if anomalies are found, either replace or modify the components.

- Plan regular calibration and performance testing to verify that, within prescribed tolerances, the stirrer keeps constant stirring speeds and temperature settings.

- To guarantee traceability and facilitate future troubleshooting, record every maintenance operation in a logbook noting the date, activities taken, observations, and any parts replaced.

- To extend the life of the instrument and preserve best performance, follow manufacturer guidelines and standard operating procedures for comprehensive cleaning and frequent periodic service.

Precautions

- To eliminate inadvertent tipping or vibrations during operation, make sure the magnetic stirrer is constantly set on a level, firm surface.

- Before use, make sure the instrument is spotless and free of any chemical traces or dust to guarantee correct functioning and lower the danger of contamination.

- Before turning on the device, always make sure the stir bar is completely submerged in the liquid; poor immersion may cause erratic stirring or bar breakage.

- Never run the magnetic stirrer without a vessel in situ to prevent splashing or possible device damage from overheating.

- Never use more than the manufacturer’s advised stirring speeds to avoid solution splashing and unnecessary mechanical strain.

- To reduce electrical risks during operation, make sure the gadget is hooked to a correctly e grounded power supply.

- Before doing any maintenance, cleaning, or inspections, always unplug the device from the power source and let it cool.

- When running or cleaning the stirrer, use suitable personal protective gear including gloves and safety eyewear to guard against chemical contact and heat.

- Steer clear of abrasive or harsh cleaning products that can compromise the surface of the stir plate or influence the magnetic coupling mechanism.

- Inspect all cables, plugs, and connections often for wear or damage to guarantee the instrument’s safe and dependable running condition.

- Especially while the heating element is in operation, never let the stirrer run unattended to avoid possible fire dangers or inadvertent burns.

- Carefully follow manufacturer instructions and your laboratory’s standard operating procedures to guarantee the magnetic stirrer’s safe and efficient operation.

Applications of Magnetic Stirrer

- Chemical labs use magnetic stirrers to mix reaction solutions quickly and uniformly

- Microbiology labs employ them to prepare culture media and suspend cells consistently

- Biochemical experiments rely on them to maintain stable enzyme reactions and protein solutions

- Pharmaceutical production uses them for uniform mixing of drug formulations and excipients

- Analytical labs utilize them for preparing samples and ensuring homogeneity before testing

- Environmental studies use magnetic stirrers to process water and soil samples effectively

- Educational institutions use them to demonstrate principles of mixing and magnetism in practical experiments

Advantages of Magnetic Stirrer

- Enables uniform mixing and constant temperature control

- Prevents boiling over in sealed containers

- Increases mixing efficiency and evaporation rate

- Supports long-duration processes like protein dialysis

- Reduces contamination risk with a small, easily cleaned stir bar

- Delivers precise, quiet, and energy-efficient operation

- Can mix various volumes, typically up to one liter

- Features a compact design with minimal wear due to no external moving parts

Limitations of magnetic stirrer

- Limited to small volumes due to stir bar size

- Ineffective for mixing highly viscous liquids

- Poor at dispersing nanoparticles and solid particles

- Lower stirring power for high-shear applications

- Stir bar magnetic strength may decrease with use

FAQ

What is a magnetic stirrer?

A magnetic stirrer is a laboratory device that uses a rotating magnetic field to cause a stir bar immersed in a liquid to spin and stir the solution.

How does a magnetic stirrer work?

A magnetic stirrer works by placing a magnetic stir bar in the liquid sample and using a rotating magnetic field to rotate the stir bar, thereby stirring the solution.

What are the advantages of using a magnetic stirrer?

Some advantages of using a magnetic stirrer include the ability to mix reagents at a constant temperature, increased reaction rates and evaporation rates, ease of cleaning and disinfection, and compact size.

What are the limitations of magnetic stirrers?

Magnetic stirrers have limitations such as their inefficiency in dispersing nanoparticles, difficulty with viscous liquids or thick suspensions, and limited capacity for larger experiments.

Can a magnetic stirrer be used with corrosive chemicals?

Yes, magnetic stirrers can be used with corrosive chemicals. However, it is important to use non-metallic containers, such as glass or other non-metallic beakers, to avoid interference with the magnetic field.

Can a magnetic stirrer be used for heating purposes?

Yes, many magnetic stirrers come with a heating element, allowing simultaneous heating and stirring of the sample.

How do you adjust the speed of a magnetic stirrer?

The speed of a magnetic stirrer can be adjusted using a speed control knob or button, allowing you to increase or decrease the rotation speed of the stir bar.

Can a magnetic stirrer be used for long-duration experiments?

Yes, magnetic stirrers can be used for long-duration experiments, including overnight stirring, as they are designed to run continuously for extended periods.

Are magnetic stirrers noisy?

No, magnetic stirrers are generally quiet during operation, providing a noise-free working environment in the laboratory.

Can a magnetic stirrer be used in fields other than chemistry?

Yes, magnetic stirrers have applications in various fields, including chemistry, biology, microbiology, pharmaceuticals, and research, where mixing or stirring of liquids is required for experiments, analysis, or sample preparation.

References

- https://agris.fao.org/agris-search/search.do?recordID=US202100121906

- https://www.medicalexpo.com/prod/velp-scientifica/product-98393-768228.html

- https://www.biobase.com/product/hotplate-magnetic-stirrer

- https://www.medicalexpo.com/prod/thermo-scientific/product-78678-507120.html

- https://www.thomassci.com/Equipment/Magnetic-Stirrers/_/Mini-Magnetic-Stirrer-1?q=Mini%20Magnetic%20Stirrer

- https://matob.web.id/random/science/what-is-magnetic-stirrer-and-its-function/

- https://www.alphapedia.net/magnetic-stirrer/

- https://www.exposedmagazine.co.uk/features/what-is-a-magnetic-stirrer-types-and-function/

- https://www.pce-instruments.com/f/english/media/magnetic-stirrer-introduction.pdf

- http://impactfactor.org/PDF/IJPCR/9/IJPCR,Vol9,Issue9,Article2.pdf

- https://www.scienceequip.com.au/blogs/news/magnetic-stirrers-uses-types

- https://www.dwkltd.com/en/azlon-magnetic-stirrer-bar-retriever-ptfe-1

- https://www.kewlab.com/blog/post/magnetic-stirrer-working-principle-and-uses

- https://orgchemboulder.com/Technique/Equipment/Benchequip/Stirbar.shtml

- https://microbeonline.com/magnetic-stirrer-parts-principle-and-types/

- http://www.lanphan.com/lab-instruments/How-Does-a-Magnetic-Stirrer-Work-414.html

- https://camblab.info/a-guide-to-different-types-of-stirrers/

- https://www.kjmagnetics.com/blog.asp?p=stir-bars

- https://neuationcentrifuges.wordpress.com/tag/magnetic-stirrer-components/

- https://microbenotes.com/magnetic-stirrer-principle-parts-types-uses-examples/