What is Laminar flow hood/cabinet?

- A laminar flow hood, also known as a laminar flow cabinet, is a specialised workstation used in industries such as pharmaceutical, medical, and research laboratories to produce a regulated and sterile atmosphere for working with delicate materials or processes. A laminar flow hood’s principal function is to keep an area free of contamination by utilising a series of filters to trap particles and prevent them from entering the cabinet.

- A laminar flow hood is designed with a series of filters that purify the incoming air while creating a laminar, or uni-directional, airflow within the cabinet. This indicates that the air flows in a clean, parallel pattern with no turbulence. A pre-filter, a HEPA (High-Efficiency Particulate Air) filter, and sometimes an additional ULPA (Ultra-Low Penetration Air) filter are generally utilised in these cabinets. These filters catch and eliminate airborne particles including dust, bacteria, and other contaminants, guaranteeing a clean and controlled environment inside the cabinet.

- Laminar flow hoods are very beneficial in aseptic applications such as the handling and distribution of sterile fluid, cell cultures, and plate pouring. The laminar flow cabinet’s sterile environment serves to prevent contamination of the materials being worked with, ensuring their integrity and reliability.

- It is vital to highlight that in terms of user protection, laminar flow cabinets differ from biosafety cabinets. A biosafety cabinet protects both the sample and the user from potential threats such as biological agents or volatile chemicals. To safeguard employees, biosafety cabinets have a more complicated design with additional features such as negative pressure or HEPA-filtered exhaust air. In contrast, the focus of a laminar flow cabinet is on safeguarding the sample or material being manipulated rather than the operator. The effluent air in a laminar flow cabinet is drawn into the user’s face, exposing the user to any potential toxins in the work area.

- Overall, a laminar flow hood or cabinet is an important tool for maintaining a sterile and controlled work environment. It contributes to the quality and dependability of delicate processes and materials by lowering the danger of contamination. Laminar flow hoods are essential in safeguarding the integrity of sensitive work in pharmaceutical research, medical laboratories, and other businesses that require aseptic techniques.

Definition of Laminar flow

Laminar flow refers to the smooth, uninterrupted flow of fluid, such as air or liquid, in parallel layers without any significant mixing or turbulence.

Principle of Laminar flow hood

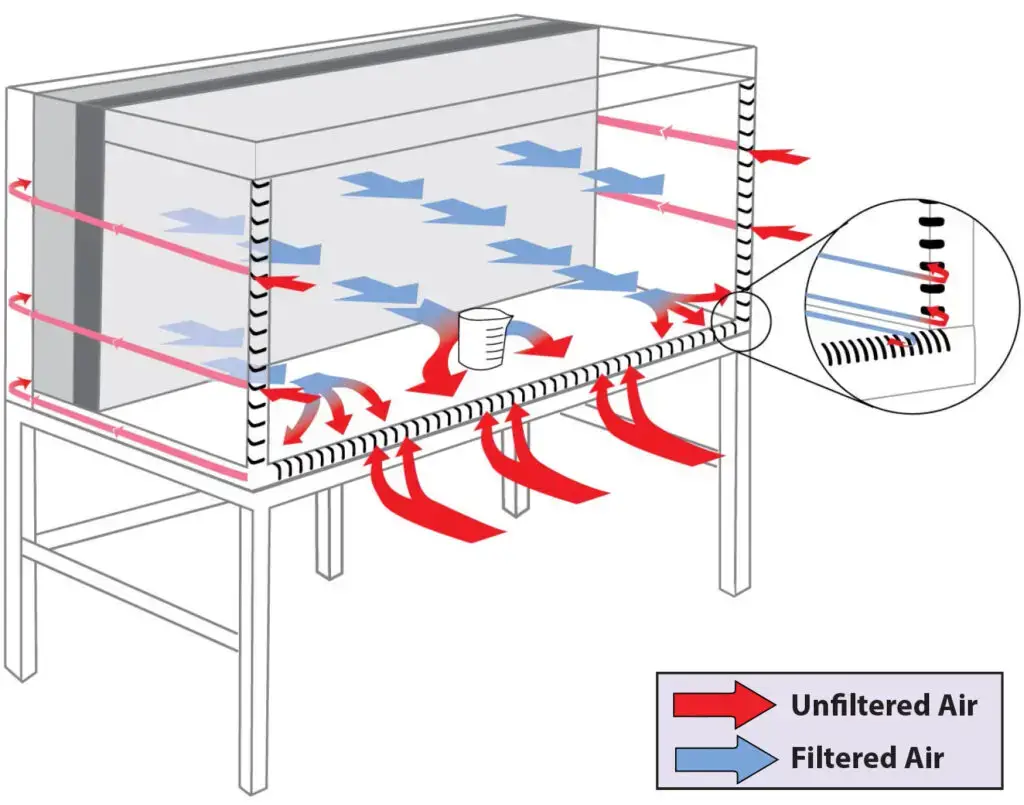

The working principle of a laminar flow hood is based on creating a controlled airflow within the cabinet to maintain a particulate-free environment. Here’s how it works:

- Inward Flow of Air: The laminar flow hood operates by drawing air from the surrounding environment into the cabinet. This incoming air is pulled through one or more HEPA (High-Efficiency Particulate Air) filters.

- Filtration System: The air passes through a filtration system, starting with a filter pad or pre-filter. This pre-filter allows for a streamlined flow of air into the cabinet while capturing larger particles.

- Air Direction: After passing through the pre-filter, the air is directed by a blower or fan towards the HEPA filters. These HEPA filters are highly efficient at trapping bacteria, fungi, and other particulate matter, ensuring that the air exiting the filters is virtually free of particles.

- Laminar Flow: The filtered air moves in a laminar flow pattern, typically from the top of the cabinet to the work surface. The laminar flow ensures that the air moves in parallel layers, with minimal turbulence or mixing.

- Work Surface and Operator Protection: As the filtered air flows over the work surface, it helps maintain a clean environment for handling sensitive materials or processes. Some of the air may pass through perforations located at the bottom rear end of the cabinet, while most of it exits the cabinet towards the face of the operator.

- Enclosed Design and Positive Pressure: Laminar flow hoods are enclosed on the sides to prevent the intrusion of contaminated external air. Additionally, a constant positive air pressure is maintained inside the cabinet, further minimizing the possibility of external air entering the workspace.

By utilizing the principles of laminar airflow and efficient filtration, a laminar flow hood creates a controlled, particulate-free environment that helps protect sensitive samples, materials, or processes from contamination.

Components/ Parts of Laminar flow hood

A laminar flow cabinets consists of the following elements:

1. Cabinet

- A laminar flow cabinet consists of a sturdy cabinet structure typically made of stainless steel. This material is chosen for its durability and resistance to corrosion. The design of the cabinet aims to minimize gaps or joints, ensuring that there are no spaces where spores or contaminants can accumulate, making it easier to clean and maintain a sterile environment.

- One of the primary functions of the cabinet is to provide insulation and containment for the inner environment created by the laminar flow system. It acts as a protective barrier, preventing the outside environment from interfering with the sterile workspace inside. The cabinet helps maintain a controlled environment by containing the laminar flow of filtered air and preventing the entry of airborne particles or microorganisms from the surroundings.

- At the front of the cabinet, a glass shield is typically installed. This shield serves as a transparent barrier that allows the user to observe the workspace while providing an additional layer of protection. In some laminar flow cabinets, the glass shield can be fully opened, providing complete access to the interior. In other designs, the glass shield may have two openings, often referred to as glove ports, which allow the user’s hands to enter the cabinet without compromising the sterile environment. These glove ports are sealed with gloves that the user can wear to perform tasks inside the cabinet while maintaining a barrier between their hands and the sterile workspace.

- The cabinet in a laminar flow hood plays a crucial role in providing structural integrity, containing the laminar flow system, and ensuring a clean and controlled working environment. It combines functionality, durability, and user protection to create a reliable and efficient workspace for various applications requiring aseptic conditions.

2. Working station

The working station inside a laminar flow cabinet serves as the designated area for carrying out various processes and manipulations in a controlled and sterile environment. Here’s some information about the working station:

- Flat Working Surface: The working station is a flat surface located within the cabinet where different tasks are performed. It provides a stable and clean area for placing equipment, materials, and samples during operations.

- Equipment Placement: On the working station, you can find various essential tools and equipment commonly used in aseptic techniques. This may include culture plates, Petri dishes, tubes, flasks, and other laboratory vessels. Additionally, items like burners and inoculation loops, used for sterilization and transferring samples, are also placed on the working station for convenient access during procedures.

- Stainless Steel Construction: The worktop of the working station is typically made of stainless steel. This material is chosen for its durability, resistance to corrosion, and ease of cleaning. Stainless steel prevents rusting, ensuring that the working surface remains hygienic and free from contaminants.

The flat working station provides a dedicated area within the laminar flow cabinet where operators can conduct their work in a controlled, sterile environment. The placement of equipment and materials on this surface allows for efficient and organized handling of samples, minimizing the risk of contamination and ensuring the integrity of the procedures being carried out. The use of stainless steel in the construction of the working station adds to its functionality and longevity, as it prevents deterioration and supports proper hygiene practices.

3. Filter pad/ Pre-filter

The filter pad, also known as a pre-filter, is an important component of a laminar flow cabinet that is situated on the top of the cabinet. Its purpose is to capture and trap larger particles, such as dust and some microbes, before the air enters the working environment within the cabinet. Here are some key points about the filter pad or pre-filter:

- Location: The filter pad is positioned at the entry point of the laminar flow cabinet. It is usually located on the top section, where the incoming air passes through before entering the cabinet.

- Particle Capture: The primary function of the filter pad is to capture and remove larger particles from the air. These particles can include dust, lint, fibers, and some microorganisms present in the ambient air.

- Protection: By capturing these larger particles, the filter pad helps protect the sensitive materials, samples, and processes being conducted within the laminar flow cabinet. It acts as a barrier, preventing contaminants from entering the controlled environment and compromising the integrity of the work.

- Maintenance: The filter pad requires periodic maintenance and cleaning to ensure its effectiveness. Over time, the accumulated particles may reduce the airflow and efficiency of the filter. Regular cleaning or replacement of the filter pad is necessary to maintain optimal performance and prevent any potential blockages.

While the pre-filter is effective at capturing larger particles, it should be noted that it is not as efficient as the HEPA (High-Efficiency Particulate Air) filters typically used in laminar flow cabinets. HEPA filters are responsible for removing finer particles, including bacteria, fungi, and other contaminants, ensuring a high level of air purity within the cabinet.

In summary, the filter pad or pre-filter serves as the initial layer of filtration in a laminar flow cabinet, capturing larger particles and some microbes from the incoming air. It plays a crucial role in maintaining a clean and controlled working environment, safeguarding sensitive materials, and preventing contamination.

4. Fan/ Blower

The fan or blower is an integral component of a laminar flow cabinet, playing a crucial role in the movement and circulation of air within the system. Here are some key points about the fan in a laminar flow cabinet:

- Location: The fan is typically positioned below the filter pad, near the bottom section of the cabinet. Its location allows it to draw in air from the environment and propel it through the filtration system.

- Air Movement: The primary function of the fan is to create airflow within the cabinet. It sucks in the ambient air through the filter pad, pulling it into the cabinet and moving it towards the HEPA (High-Efficiency Particulate Air) filter.

- HEPA Filter Efficiency: As the air is propelled by the fan towards the HEPA filter, the remaining microbes and fine particles that were not captured by the pre-filter or filter pad become trapped in the HEPA filter’s dense filtration media. HEPA filters are highly efficient at removing particles as small as 0.3 microns, ensuring a high level of air purity within the cabinet.

- Air Circulation: The fan’s continuous operation creates a circulation of air within the laminar flow cabinet, helping to maintain a uniform laminar flow pattern. This laminar flow ensures that the filtered air moves in parallel layers, with minimal turbulence or mixing, providing a clean and controlled working environment.

- Fan Speed Control: In some laminar flow cabinets, the fan’s speed can be adjustable or have different settings. This allows the operator to regulate the airflow according to the specific requirements of the work being performed.

The fan or blower is an essential component that facilitates the movement of air within a laminar flow cabinet. By drawing in air from the environment and propelling it towards the HEPA filter, the fan helps to ensure that the remaining microbes and fine particles are effectively trapped and removed, resulting in a controlled and sterile working environment.

5. UV lamp

In certain laminar flow hoods, you may find a UV (Ultraviolet) germicidal lamp as an additional feature. The UV lamp serves the purpose of sterilizing the interior of the cabinet and its contents before any operations take place. Here are some key points about the UV lamp in a laminar flow hood:

- Sterilization Function: The UV germicidal lamp emits ultraviolet light, which has germicidal properties. When turned on, the UV lamp emits UV-C radiation, which is highly effective in killing or inactivating microorganisms, including bacteria, viruses, and fungi. The UV light penetrates the genetic material of these microorganisms, disrupting their cellular function and rendering them non-viable.

- Pre-Operation Activation: To ensure optimal sterilization, the UV lamp is typically turned on about 15 minutes before any operations or tasks are performed inside the laminar flow hood. This allows sufficient time for the UV light to disinfect the cabinet’s interior and any equipment or materials placed within it.

- User Safety Precautions: It’s important to note that UV-C radiation can be harmful to human skin and eyes. To prevent exposure to the user, the UV lamp should never be turned on while a person is present in the vicinity. The recommended practice is to activate the UV lamp and then leave the immediate area until the designated sterilization time has elapsed. After the UV sterilization process, the lamp should be turned off before the user resumes work inside the laminar flow hood.

- Additional Sterilization Method: The UV lamp is often used as an additional measure of sterilization alongside the laminar flow system and HEPA filters. While the laminar flow and filtration already provide a controlled environment and particle removal, the UV lamp acts as an extra layer of protection by targeting any remaining microorganisms that might have bypassed the filters or settled on surfaces.

It’s worth noting that not all laminar flow hoods are equipped with UV lamps, and their inclusion depends on specific requirements and applications. However, when present, the UV lamp serves as an effective tool for enhancing the sterility of the laminar flow cabinet’s interior and contents, contributing to a more thorough disinfection process before work begins.

6. Fluorescent lamp

A fluorescent lamp is commonly used in a laminar flow cabinet to provide appropriate lighting during operations. Here’s some information about fluorescent lamps in this context:

- Lighting Purpose: The fluorescent lamp is installed inside the cabinet to illuminate the working area. It ensures proper visibility, allowing the operator to perform tasks accurately and efficiently within the controlled environment.

- Bright and Even Lighting: Fluorescent lamps are known for their bright and uniform illumination. They provide a consistent light output across the workspace, minimizing shadows and ensuring optimal visibility of the materials, equipment, and samples being handled.

- Energy Efficiency: Fluorescent lamps are relatively energy-efficient compared to other types of lighting. They produce more light per unit of electrical energy consumed, resulting in less energy wastage and lower electricity costs over time.

- Long Lifespan: Fluorescent lamps have a relatively long lifespan, which reduces the need for frequent replacements. This contributes to cost savings and reduces the maintenance required for the lighting system within the laminar flow cabinet.

- Wide Availability: Fluorescent lamps are widely available and come in various sizes and color temperatures to suit different lighting requirements. They can be easily replaced or upgraded if needed.

The presence of a fluorescent lamp in a laminar flow cabinet ensures that the operator has proper lighting for performing tasks accurately and safely. It enhances visibility within the workspace, enabling precise manipulation of samples, equipment, and materials while maintaining the necessary sterile conditions.

7. HEPA filter

The HEPA (High-Efficiency Particulate Air) filter is a critical component of a laminar flow cabinet that significantly contributes to creating a sterile environment for operations. Here’s some information about the HEPA filter:

- Sterility Enhancement: The HEPA filter is positioned within the laminar flow cabinet to enhance the sterility of the environment. It is designed to effectively capture and trap microscopic particles, including fungi, bacteria, and other dust particles that may be present in the air.

- Filtration Mechanism: The pre-filtered air, which has already passed through the filter pad or pre-filter, enters the HEPA filter. The HEPA filter consists of a dense mat of fibers arranged in a pleated configuration. This arrangement allows the filter to capture particles as small as 0.3 microns with an efficiency of 99.97%. It traps and retains these particles within the filter media, preventing them from circulating back into the cabinet.

- Contamination Reduction: By removing airborne particles, the HEPA filter ensures a highly purified and sterile condition inside the laminar flow cabinet. It plays a crucial role in reducing the chances of contamination during sensitive procedures by providing a barrier against microorganisms and particulate matter.

- Certification Standards: HEPA filters used in laminar flow cabinets must meet specific standards to ensure their effectiveness. These standards include efficiency ratings such as EN 1822 or ISO 29463, which define the minimum filtration efficiency required for HEPA filters to be classified as such.

- Maintenance and Replacement: HEPA filters require regular maintenance and periodic replacement to maintain their effectiveness. Over time, the accumulated particles in the filter can restrict airflow, reducing filtration efficiency. Regular inspections, cleaning, and timely replacement of the HEPA filter are necessary to ensure optimal performance and a consistently sterile environment.

The presence of a HEPA filter in a laminar flow cabinet is crucial for maintaining a sterile condition inside the cabinet. By effectively trapping microorganisms, fungi, bacteria, and other dust particles, the HEPA filter significantly reduces the risk of contamination during operations, ensuring a controlled and sterile environment for sensitive tasks.

Procedure for running the laminar flow cabinet

- Check the Cabinet: Before starting the laminar flow cabinet, ensure that there are no items inside the cabinet that are susceptible to UV rays.

- Close the Glass Shield and Switch on UV Light: Close the glass shield of the hood and turn on the UV light. Allow the UV light to run for approximately 15 minutes to sterilize the working bench surface.

- Turn off UV Light and Allow Time: After 15 minutes, switch off the UV light and allow a time period of around 10 minutes before proceeding.

- Switch on Airflow: Around 5 minutes before starting the operation, switch on the airflow in the laminar flow cabinet. This ensures a continuous supply of filtered air within the cabinet.

- Open the Glass Shield and Turn on Fluorescent Light: Open the glass shield of the cabinet and switch on the fluorescent light to provide proper illumination during the operation.

- Optional: Sterilize the Working Bench: For additional protection, you can sterilize the working bench of the cabinet using disinfectants like 70% alcohol.

- Perform the Operation: Carry out the desired tasks or experiments within the laminar flow cabinet while maintaining proper aseptic techniques.

- Close Airflow and Fluorescent Lamp: Once the work is completed, switch off the airflow and the fluorescent lamp to conserve energy and maintain the integrity of the cabinet.

- Close the Glass Shield: Finally, close the glass shield of the laminar flow cabinet to secure the cabinet and prevent any potential contamination.

Types of laminar flow cabinet

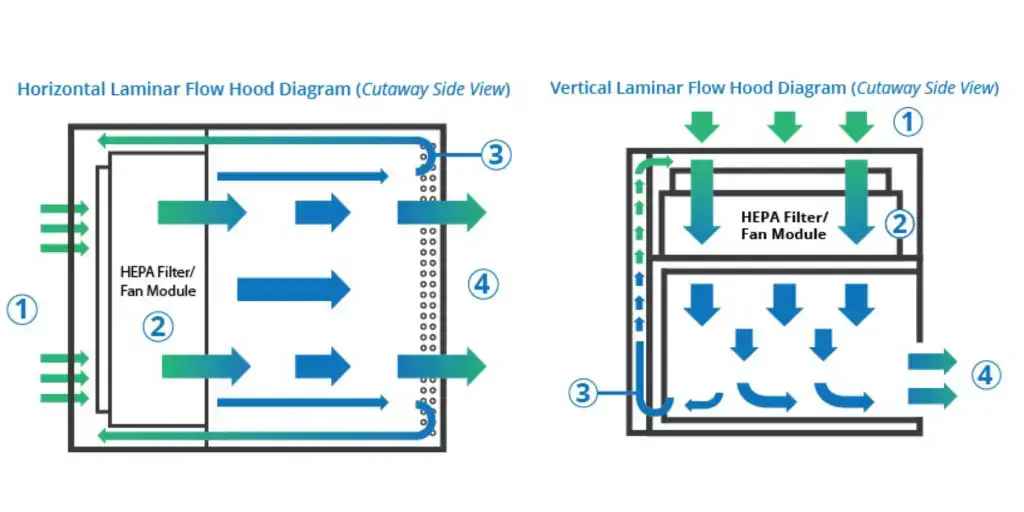

Based on the direction in which the air moves the laminar flow cabinets are classified into two kinds:

1. Vertical laminar flow cabinet

A vertical laminar flow cabinet is a type of laminar flow hood where the direction of airflow is vertically oriented. Here are some key features and advantages of a vertical laminar flow cabinet:

- Airflow Direction: In a vertical laminar flow cabinet, the air moves from the top of the cabinet downward towards the bottom. This vertical airflow pattern ensures that the clean, filtered air is directed towards the work surface and materials placed on it.

- Space Efficiency: Compared to horizontal airflow hoods, vertical laminar flow cabinets require less depth and floor space. This makes them more compact and easier to accommodate in laboratory or workspace settings. The reduced footprint also decreases the chances of airflow obstruction or movement of contaminated air downstream, ensuring a more consistent and reliable airflow.

- Improved Safety: One advantage of a vertical laminar flow cabinet is that it does not blow the filtered air directly towards the person carrying out experiments or tasks. This design feature enhances operator safety by minimizing the risk of exposure to potentially contaminated air. The vertical airflow helps to contain any potential contaminants generated during the operation within the cabinet, reducing the likelihood of their dispersal.

- Sterile Working Environment: The vertical laminar flow cabinet creates a highly controlled and sterile working environment. The downward airflow pattern effectively flushes away any particles, including dust, microorganisms, or contaminants, that may be present in the air, preventing them from settling on the work surface or materials.

- Easy Access: Vertical laminar flow cabinets typically feature a front access opening or sash that can be easily lifted or lowered. This allows convenient access to the work area and materials while maintaining the integrity of the sterile environment.

Overall, a vertical laminar flow cabinet offers advantages such as space efficiency, improved safety by avoiding direct airflow towards the operator, and a highly controlled sterile environment. These features make it a preferred choice for laboratories and workspaces where a clean and reliable airflow is required for sensitive procedures and experiments.

Vertical Laminar Flow Hood Advantages

- Space Efficiency: Vertical laminar flow hoods have a smaller depth, requiring less floor space compared to other types of laminar flow hoods. This makes them more manageable and suitable for laboratories or workspaces with limited space availability.

- Operator Safety: In vertical laminar flow hoods, the filtered air is not blowing directly at the operator. This design feature enhances operator safety by minimizing the risk of exposure to potentially contaminated air. Additionally, the presence of a sash provides a physical barrier in front of the operator’s face, further protecting them from any potential hazards.

- Easy Filter Access: The filters in a vertical laminar flow hood are located on top of the hood. This positioning makes them easily accessible for routine maintenance, such as filter replacement or servicing. This facilitates regular upkeep and ensures the continuous effectiveness of the filtration system.

- Reduced Turbulence: The vertical airflow pattern in these hoods results in less turbulent airflow. Large objects or processing equipment positioned on the work surface do not experience a significant striking force from the air, reducing turbulence and maintaining a more stable environment.

- Reduced Cross-Contamination: The vertical airflow in these hoods minimizes the cross-contamination of items placed on the work surface. The downward airflow helps to flush away any particles or contaminants, preventing them from settling on the surface and potentially transferring to other materials or samples.

- Increased Working Height: Vertical laminar flow hoods provide more working height compared to other types of hoods. This extra space accommodates tall or large equipment, allowing for convenient and comfortable use within the hood.

Vertical Laminar Flow Hood Disadvantages

- Overhead Clearance Requirement: Vertical laminar flow hoods may have overhead clearance requirements, especially when it comes to changing filters or servicing the unit. This might necessitate the use of a step-ladder or additional precautions to ensure safe access.

- Restricted Work Surface: To maintain proper airflow, items or hands cannot be placed on top of each other in a vertical laminar flow hood. This can limit the available work area and require careful organization and placement of materials and equipment.

- Increased Turbulence on the Work Surface: Due to the downward airflow, there may be an increased turbulent effect when the air strikes the work surface. This turbulence can disrupt delicate procedures or sensitive samples, requiring extra care during manipulations.

2. Horizontal laminar flow cabinet

A horizontal laminar flow cabinet is a type of laminar flow hood where the direction of airflow is horizontal. Here are some key features and considerations related to a horizontal laminar flow cabinet:

- Airflow Direction: In a horizontal laminar flow cabinet, the surrounding air is drawn in from behind the working bench and propelled by a blower towards the HEPA filters. The filtered air is then exhausted in a horizontal direction towards the workplace environment.

- Constant Velocity: One advantage of a horizontal laminar flow cabinet is that the airflow is parallel to the work surface. This provides a consistent and uniform cleansing effect throughout the workspace. The constant velocity of the airflow helps to minimize the potential for turbulence or pockets of stagnant air, ensuring a more controlled and sterile environment.

- Operator Exposure: One consideration with horizontal laminar flow cabinets is that the effluent air, after passing over the work surface, is directed towards the operator. This direct airflow towards the operator can reduce the security level of this type of laminar flow cabinet, as there is a higher potential for the operator to come into contact with any contaminants or particles that may be present in the air.

- Workspace Accessibility: Horizontal laminar flow cabinets typically feature a front access opening or sash that can be raised or lowered, providing easy access to the work area. This allows the operator to comfortably carry out tasks while maintaining the cleanliness and sterility of the workspace.

- Suitability and Applications: Horizontal laminar flow cabinets are commonly used in applications where a clean and sterile working environment is required, such as in laboratory research, pharmaceutical compounding, electronics assembly, or other precision manufacturing processes. They provide a controlled airflow pattern that helps to minimize the risk of contamination and maintain the integrity of sensitive work.

When choosing a laminar flow cabinet, the choice between horizontal and vertical airflow should be based on the specific requirements of the application, considering factors such as operator safety, workspace accessibility, and the desired airflow pattern. The horizontal laminar flow cabinet offers a parallel airflow that ensures consistent cleansing of the environment but requires attention to operator exposure.

Horizontal Laminar Flow Hood Advantages

- Parallel Airflow: In horizontal laminar flow hoods, the airflow is parallel to the work surface. This eliminates the turbulent effects caused by vertical airflow striking the work surface perpendicularly. The parallel airflow provides a consistent and uniform environment for working with sensitive samples or delicate procedures.

- Enhanced Positioning of Sterile Equipment: The horizontal airflow allows for easier positioning and staggering of sterile equipment and materials on the work surface. By placing them closer to the filter face (upstream), they are protected from potential contaminants present downstream. This configuration helps maintain a higher level of sterility for critical operations.

- Reduced Contamination from Hands and Gloves: In horizontal laminar flow hoods, hands and gloves are generally positioned downstream of the sample or work area. This reduces the risk of contamination, as any potential contaminants generated by the hands or gloves are carried away from the sterile workspace by the laminar airflow.

Horizontal Laminar Flow Hood Disadvantages

- Rear Access for Filter Change or Service: Changing filters or performing maintenance on a horizontal laminar flow hood often requires repositioning the hood for rear access. This can be more time-consuming and may disrupt ongoing work in the hood during the servicing process.

- Potential Contamination from Large Samples: Large samples or objects placed on the work surface can obstruct the laminar airflow and create areas of turbulence. This turbulence can lead to contamination of downstream samples or materials, requiring careful consideration of sample placement to maintain the integrity of the sterile environment.

- Risk of Blowing Fumes or Powders into Operator’s Face: If used without a sash or proper containment measures, a horizontal laminar flow hood can blow fumes or powders directly into the operator’s face. This can pose a risk to the operator’s safety and potentially compromise the sterility of the working environment. It is important to use appropriate containment measures, such as a sash or suitable enclosures, to prevent such incidents.

Vertical vs Horizontal Laminar Airflow Hoods

| Aspect | Vertical Laminar Flow Hood | Horizontal Laminar Flow Hood |

|---|---|---|

| Airflow Direction | Top to bottom | Back to front |

| Space Efficiency | Requires less depth, suitable for limited floor space | Requires more depth, may require more floor space |

| Operator Safety | Air does not blow directly at the operator, sash provides barrier | Airflow parallel to the operator, may blow fumes or powders |

| Filter Access | Filter located on top, easily accessible | Filter change or service may require repositioning for rear access |

| Turbulent Effects | Less turbulent, reduced effect on large objects | Parallel airflow, reduced turbulence on work surface |

| Cross-Contamination | Reduced cross-contamination of items on work surface | Large samples can obstruct airflow, may contaminate downstream area |

| Working Height | Limited working height | More working height, suitable for tall or large equipment |

| Overhead Clearance Requirement | Minimal overhead clearance required | Potential overhead clearance requirement for filter change/service |

| Sample Placement Restrictions | No restrictions on placing items on top of each other | Items cannot obstruct airflow, careful placement required |

Uses of Laminar flow hood

- Plant Tissue Culture: Laminar flow cabinets are commonly used in laboratories for plant tissue culture processes. The sterile environment created inside the cabinet helps prevent contamination and maintain the integrity of plant cultures.

- Media Plate Preparation: Laminar flow cabinets are ideal for preparing media plates used in microbiological laboratories. The cabinets provide a contamination-free environment, ensuring the plates remain sterile and suitable for culturing microorganisms.

- Organism Culture: Laminar flow hoods are used for culturing organisms in laboratory settings. The controlled environment inside the cabinet prevents the introduction of contaminants and maintains the purity of the cultures.

- Particle-Sensitive Electronic Device Operations: Laminar flow cabinets provide a clean and controlled environment for working with particle-sensitive electronic devices. The cabinets help protect the devices from dust particles and other contaminants that could impact their performance or functionality.

- Pharmaceutical Industry: In the pharmaceutical industry, laminar flow hoods are utilized for drug preparation techniques. The cabinets ensure a particulate-free environment during the preparation of drugs, reducing the risk of contamination and maintaining the quality and safety of the products.

- Specialized and General Laboratory Techniques: Laminar flow cabinets can be customized for specialized works in various laboratory sectors, including microbiology and industrial applications. Additionally, they can be used for general lab techniques that require a sterile environment and protection against contamination.

Overall, laminar flow hoods play a crucial role in maintaining a sterile and controlled working environment in laboratories across various industries. They are essential for processes that require protection against contamination and the maintenance of sample integrity.

Precautions

- Sterilization with UV Light: Before and after each operation, it is important to sterilize the laminar flow cabinet using UV light. This helps eliminate any potential contaminants and maintain a clean working environment.

- Separation of UV Light and Airflow: Avoid using the UV light and airflow simultaneously. These two functions should be operated separately to ensure safety and prevent any interference between the UV sterilization and the laminar airflow.

- No Operations during UV Light Use: Do not carry out any operations inside the laminar flow cabinet while the UV light is switched on. UV light can be harmful to the skin and eyes, so it is important to allow sufficient time for sterilization and ensure the UV light is turned off before conducting any procedures.

- Personal Protective Equipment: When working with a laminar flow cabinet, it is advisable to wear appropriate personal protective equipment, such as lab coats and long gloves. This helps prevent contamination and protects the operator from any potential hazards.

- Sterilization of Components: Before starting work and after completing the tasks, ensure that the working bench, glass shield, and other components inside the laminar flow cabinet are properly sterilized. This helps maintain a clean and sterile environment for the next operation and prevents cross-contamination.

By following these precautions, laboratory personnel can ensure a safe and sterile working environment within the laminar flow cabinet, minimizing the risk of contamination and maintaining the integrity of samples and experiments.

How to Clean a Laminar Flow Hood

Air filtration and cleanliness are vital to maintaining the level of sterility in a cleanroom or lab as well as for the laminar airflow hood. A proper cleaning and maintenance process can yield accurate results. If the cleaning procedure is not implemented, contamination can cause your results to be unusable. Cleaning the hoods of laminar flow should be carried out regularly by every lab employee.

Follow these simple steps will ensure that your device is clean.

Cleaning Equipment

- 70% ethanol (Most effective in killing microbes) – Avoid using soap and water

- Laboratory-grade wipes

- Biohazard trashbags

- Lint-free cleanroom cloths

- Laboratory gowns or coats should be worn

- Gloves, face, and eye protection

Vertical Laminar Flow Hood Cleaning Steps

- Begin by cleaning the back of the hood of your laminar flow

- Clean the walls of the side by sweeping them between left and right, moving from top to the bottom

- Finally, wash the work area. Start at the side of the unit, and move to the front

Horizontal Laminar Flow Hood Cleaning Steps

- Begin by cleaning the ceiling of the laminar flow hood

- Clean the walls on the sides using a sweeping motion starting from the left from top to the bottom

- Finally, wash the surface of your work. Start from the side of the unit, and move to the front

Cleaning Tips

- Do not spray disinfectant directly on the HEPA filter, or get it in contact with the filter.

- Check the hood for spills or stains. If there is any you can spray the wipe with disinfectant and then clean it up.

- To clean, grab an old towel and fold it into half or quarters. There are slight variations in the process of cleaning based on the type of hood you have, whether horizontal or vertical hood.

- A new fabric should be used on every wall

- Always wash from top to bottom from all the way down to the bottom

- Overlap every swipe

- Filters should be replaced each 3 to 5 years

Do’s and Don’ts When Using Laminar Flow Cabinets

It is important to be aware of how to make use of any equipment correctly. This is not just to ensure efficient performance, but, most importantly, to attain the maximum level of security.

Watch the following video about the things you have to be aware of and what not to do when working with Laminar Flow Cabinets. Enjoy!

Do

- Always minimize clutter: Laminar flow cabinets aren’t storage cabinets. Clutter can impede the flow of laminar air around the work space. In addition, clutter makes it extremely difficult to clean the surface.

- Always clean your hands and arms prior to going into the premises: The personnel is the primary source of contamination. Touching is one of the most frequent ways of introducing bacteria into the sterile products. Hand washing properly is vitally essential as your fingers contain numerous bacterial components. Hand washing must not just be carried out prior to working at the workplace but as well after.

- Arrange objects in such a way that full benefits of the laminar flow of air can be achieved: Properly arranging all items in the laminar flow workbench provides a work area that is directly bathed with clean air from the ULPA filter.

- Do not spray or squirt solutions on the HEPA/ULPA filter: There should be no way for the solution to touch the HEPA/ULPA filter in order to prevent pollution with air that flows downstream.

- Remove wraps and outer pouches near the edge of the work space: Wraps and pouches that are outside are not sterile, which means they could introduce contaminants onto the work area. They can also be considered obstructions, and therefore they could interfere with the flow of air through the laminar air.

- Keep large objects away from the back of the hood: Large objects contaminate all the other items downstream and also disrupt the laminar airflow pattern which suspends the contaminants and removes them from the area.

- Keep coughing, quick movements, and talking to a minimum in the main work area: The activity of employees can create particles. They can disrupt the circulation of air. This could also be a source of contamination. If you must talk make sure you keep it out of the workstation.

- Always clean your surfaces prior to getting into the cabinets: Only sterile items are allowed to be put in the area that is clean. Be sure that all of your items are cleaned properly to prevent any contamination on the work area.

Don’t

- Put any waste and other items in the hood: Non-sterile and waste items cause turbulent airflows and can introduce contaminants into the clean work surface and the sample that is sterile.

- Wear jewelry on your wrists and hands: Jewelry is not sterile, which means they can introduce particles or bacteria into the work environment. They also decrease the cleanliness of hands when worn around the work area.

- Remove any items that are critical from the air source: Make sure there is a clear pathway between your filter and the place within the hood in which the procedures are being carried out. Air that is emitted from nonsterile items can be contaminated by the particles that come by these objects.

- Keep your eyes on to the filter while opening ampoules, or when adjusting the syringes: Syringes andampoules contain salt solutions, which could get deposited on the HEPA/ULPA filter. This could damage the filter.

- Introduce unnecessary objects into the work area: It is not recommended to introduce unnecessary items into the work space should be avoided as often as it is possible. The flow of traffic into a clean space should be kept to a minimum.

- Set large objects at the cabinet’s back as they can disrupt the flow of air, and can contaminate everything downstream.

- Do not use materials that have not been disinfected: Products that weren’t disinfected may cause contamination on the clean work area, thus contravening the primary function of an laminar flow cabinet that is to safeguard your equipment from contamination.

FAQ

What is a laminar flow hood/cabinet?

A laminar flow hood/cabinet is an enclosed workstation used to create a contamination-free environment by directing filtered air in a unidirectional flow.

How does a laminar flow hood/cabinet work?

The hood/cabinet draws in ambient air, which is filtered through HEPA filters to remove particles and microorganisms. The filtered air is then released in a laminar flow over the work surface, providing a sterile environment for various laboratory processes.

What is the difference between a laminar flow hood and a biosafety cabinet?

While both laminar flow hoods and biosafety cabinets provide a controlled environment, the main difference is in the direction of airflow. In a laminar flow hood, the air flows towards the work surface, while in a biosafety cabinet, the air is recirculated to protect both the sample and the user.

What are the advantages of a laminar flow hood/cabinet?

Some advantages of laminar flow hoods/cabinets include creating a sterile work environment, preventing contamination of samples, providing a barrier against external contaminants, and facilitating aseptic techniques in laboratory processes.

What are the different types of laminar flow hoods/cabinets?

There are two main types: vertical laminar flow hoods/cabinets, where air flows from top to bottom, and horizontal laminar flow hoods/cabinets, where air flows from the back to the front.

What are the typical applications of laminar flow hoods/cabinets?

Laminar flow hoods/cabinets are commonly used in microbiology laboratories, pharmaceutical industries, plant tissue culture, electronics assembly, and other processes that require a sterile and controlled environment.

How often should the filters in a laminar flow hood/cabinet be replaced?

The frequency of filter replacement depends on various factors, such as the level of usage, the type of contaminants being handled, and the manufacturer’s recommendations. It is important to follow the maintenance guidelines provided by the manufacturer.

Can a laminar flow hood/cabinet eliminate all types of contaminants?

Laminar flow hoods/cabinets are highly effective in removing airborne particles and microorganisms. However, they may not be able to eliminate certain chemical vapors or gases. Additional precautions may be necessary when working with hazardous substances.

How should the laminar flow hood/cabinet be cleaned and maintained?

Regular cleaning of the work surface and other components with appropriate disinfectants is important to maintain a sterile environment. The cabinet should also undergo periodic maintenance and filter replacement as recommended by the manufacturer.

Are there any safety considerations when using a laminar flow hood/cabinet?

It is crucial to adhere to safety protocols and wear appropriate personal protective equipment (PPE) when working with a laminar flow hood/cabinet. This includes wearing gloves, lab coats, and safety goggles to protect against potential hazards and maintain aseptic conditions.

References

- http://escolifesciences.pk/news/1368/

- https://www.terrauniversal.com/blog/horizontal-vs-vertical-laminar-flow-hoods/

- https://microbenotes.com/laminar-flow-hood/

- https://www.lamsys.com/products/vertical_laminar_flow/

- https://www.laminarflows.co.uk/

- https://magnaflux.eu/en/Resources/FAQs/FAQs-UV-Lamps

- https://en.wikipedia.org/wiki/Laminar_flow_cabinet

- https://www.trane.com/residential/en/products/indoor-air-quality/cleaneffects/

- https://www.sciencedirect.com/topics/immunology-and-microbiology/laminar-flow-cabinet

- https://www.safety.rochester.edu/ih/uvlight.html