What is a Water Bath?

A Laboratory Water Bath can define as equipment used for maintaining constant temperature condition for samples during experiment or incubation process.

It is basically consist of container filled with water, which heated to desired temperature and samples are placed inside for uniform heating purpose.

The principle of operation based on transfer of heat from water to sample through conduction/convection, so temperature remain stable.

Commonly it used for applications like enzyme reactions, microbial culture incubation, melting point determination, warming reagents etc.

The device usually equipped with thermostat or digital controller which regulate and monitor temperature precisely.

In some modern type, agitation or circulation system also provided for even temperature distribution through whole bath.

Overview wise, laboratory water bath considered as one of basic thermal instrument found in microbiology, chemistry, molecular biology labs etc., because many experiment required controlled thermal environment.

Importance of water bath can seen as – without it, heating of sensitive biological or chemical sample will cause denaturation or evaporation due to direct flame.

It ensures gentle, gradual and uniform heating which is very important for maintaining biological activity of proteins, enzymes and culture cells.

Safety aspect also important, because it reduce risk of overheating and fire hazards during heating operation in lab.

From history viewpoint, early form of water bath was simple metal container placed over flame, temperature was controlled manually by observation method which was very inaccurate.

Later on, development of thermostatic regulators and electric heating elements in 19th–20th century made the water bath more precise and user-friendly.

Through time, digital and automatic models were introduced which can maintain 0.1°C accuracy, with timers, alarms, and cover lids etc.

Today they used widely across world, and even small research setup can’t prevail to work efficiently without presence of one.

In short, Laboratory Water Bath plays crucial role by providing controlled heating condition, so various chemical / biological processes can performed safely and accurately.

Definition of Laboratory Water Bath

A hot water bath or Laboratory hot water bath is one of the essential instruments of a laboratory, which contains a large container with heated water. It’s normally used for incubation of test samples underwater at constant temperature (hot or cold) over a long period of time without changing the concentration of constituents by evaporation.

Working Principle of a Laboratory Water Bath

Working principle of Laboratory Water Bath can define as a mechanism where water is heated by electric element and maintained at constant temperature for incubation / heating of samples.

The basic principle based on transfer of heat energy from heated water to sample by conduction and convection process.

When electricity passed through heating coil, it converted to thermal energy and that energy distributed through water medium.

Temperature of water monitored and controlled by thermostat or digital sensor, which maintain steady heat condition.

When temperature falls below set point, heating element automatically activated again to regain it.

Conversely, when water exceeds desired temperature, the power supply cut off to prevail overheating.

The sample containers like test tubes, flasks, or bottles are immersed partially or fully inside the heated water for even warming.

Due to high specific heat capacity of water, temperature fluctuations reduced, thus stable environment maintained for long duration.

The heat transfer efficiency also affected by circulation, in many models the water circulated by small motor or magnetic stirrer for uniform temperature.

Heat distribution happens both vertically and horizontally inside bath chamber, so sample at all positions receive nearly equal temperature.

In principle, water bath work as indirect heating device, because direct flame avoided to protect sensitive biological or chemical materials.

Some advanced models works with microprocessor controller which regulate heating cycle more precisely within ±0.1°C.

In short, working principle of laboratory water bath depend on controlled heat transfer from water medium to sample with help of thermostat regulated electric heating system.

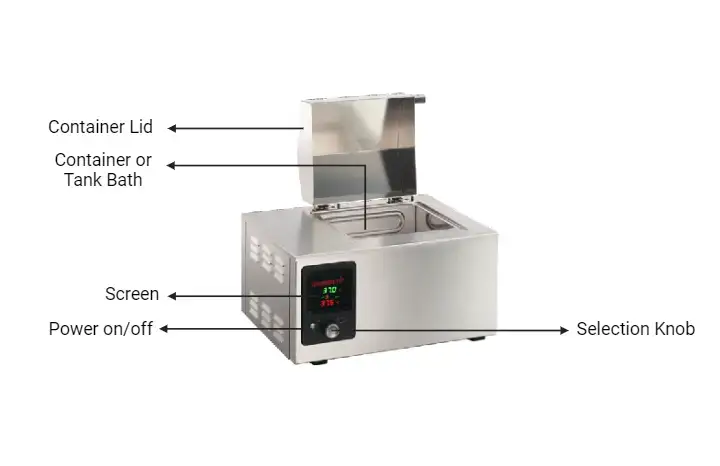

Parts of laboratory Water Bath

- Outer Body / Chamber – It usually made of stainless steel or sometimes mild steel coated with powder paint, which give durability and resistance against corrosion and chemical spillage.

- Inner Tank– The inner container that hold water, made from SS (stainless steel) to avoid rusting and to ensure easy cleaning after long use.

- Lid or Cover– A removable or hinged lid provided on top surface to minimize evaporation and heat loss from water bath during long operation period.

- Heating Element – Electric coil or rod located at bottom of tank, by which the water is heated through conversion of electric energy into thermal energy.

- Thermostat / Temperature Controller– It regulate the water temperature at desired level automatically, cutting power ON/OFF based on set point.

- Temperature Sensor (Thermocouple or Thermistor)– This part sense the current temperature of water and send signal to controller for maintaining constant condition.

- Indicator Lamps / Display Panel – Small lights or digital display used for showing power ON state and temperature reading etc., sometimes with alarm indication.

- Sample Rack / Platform – A perforated tray or rack fitted inside tank, used to hold sample containers like tubes or flasks safely above heating element.

- Drain Plug / Valve– A small outlet fitted at bottom side for draining out water after use or cleaning purpose.

- Power Switch & Cable– Electric connection component for switching ON/OFF and supplying power to heating system of water bath.

- Circulating Pump (in some models) – Used for continuous movement of water inside bath to maintain uniform temperature distribution throughout the chamber.

- Insulation Layer – Between outer body and inner tank, insulating material placed to reduce heat loss and increase energy efficiency.

- Safety Fuse or Cut-out – Protective device provided to avoid overheat or electric short circuit situation during operation.

All these parts work together as integrated system, so stable and uniform temperature environment created for experimental samples in laboratory.

Controls of a Laboratory Water Bath

The controls of a laboratory water bath play a crucial role in regulating and monitoring its operation. Here are some common controls found in laboratory water baths:

- Temperature Controller: Every water bath is equipped with a temperature controller, which can be in the form of a digital display or a dial. This controller allows users to set the desired temperature for the water bath. It ensures precise temperature control and maintains a constant temperature throughout the experiment or incubation process.

- Safety Controller: Many water baths include a safety controller as an additional precautionary measure. Typically located above the temperature controller or associated with the indicator light, the safety controller sets a maximum temperature limit that the water bath should not exceed. If the water bath somehow reaches or surpasses this maximum temperature, the safety light will be activated. The safety controller ensures that the water bath cannot go beyond the set temperature limit, even if the temperature setting is higher.

- Shaking Controller: Shaking water baths, designed for applications requiring sample agitation, may feature a shaking controller. This control allows users to adjust the speed of the shaker mechanism. It enables users to speed up or slow down the shaking motion as needed for their specific experiment. Additionally, the shaking controller may have the option to start or stop the shaking function altogether.

Types of laboratory Water Bath

There is present different types of water baths such as;

- Simple Water Bath – It considered as the most basic type, where water heated to required temperature and maintained by thermostat, samples immersed partly or fully inside.

- Circulating Water Bath – In this type, water continuously circulated by pump or stirrer to maintain uniform temperature distribution throughout the bath chamber.

- Non-Circulating Water Bath– Here, water remain stationary without circulation system, so temperature may slightly vary between different parts of bath.

- Shaking Water Bath – This type equipped with shaking platform or orbital motion mechanism, used when samples need constant movement during incubation process.

- Refrigerated Water Bath – It used for maintaining temperature below room temperature, by combining heating and cooling system to get precise control from around –10°C to +100°C range.

- Digital Water Bath – In this version, temperature controlled by microprocessor-based digital controller and displayed on LCD screen for accuracy and easy monitoring.

- Serological Water Bath – Commonly used in microbiology and immunology labs, for warming of serum or reagents at 37°C; it designed specially for biological applications.

- High Temperature Water Bath – It designed for operation above 100°C using oil or glycol instead of water, because water evaporate at high temp.

- Each of these water bath types designed according to application requirements, temperature range and precision level needed in laboratory works.

Operating Procedure of a Laboratory Water Bath

Filling of Water – The inner tank should filled with clean distilled water up to the marked level; overfilling or low level must avoided because it affect temperature control and may damage heater.

Checking of Components – Before switching ON, the power cord, fuse, and thermostat knob are checked properly to ensure no loose connections or leakage present.

Switching ON Power – The main power switch turned ON, then heating system activated; indicator light show that heating element start working.

Setting of Desired Temperature – The temperature adjusted by thermostat or digital controller according to requirement of experiment (like 37°C for incubation, 60°C for reagent warming etc.).

Monitoring Temperature – The temperature rise observed on display or thermometer; it take some time till water reach the set value and stabilized uniformly.

Placing of Samples – After temperature become steady, samples placed carefully in racks or holders, making sure water level properly cover them without spillage.

Closing the Lid / Cover – The lid placed to reduce evaporation and maintain uniform temperature inside the chamber during the operation.

Observation During Operation – During heating, the temperature and water level regularly checked; if water evaporate, then small amount of warm distilled water added to maintain level.

Completion of Process – After required incubation or heating period, the samples removed carefully with forceps or hand gloves to avoid burn injury.

Switching OFF and Cleaning – The main switch turned OFF and water allowed to cool down, then drained through outlet valve or plug for cleaning purpose.

Drying and Storage – The inner chamber dried by clean cloth or air dried to prevent corrosion and microbial growth before next use.

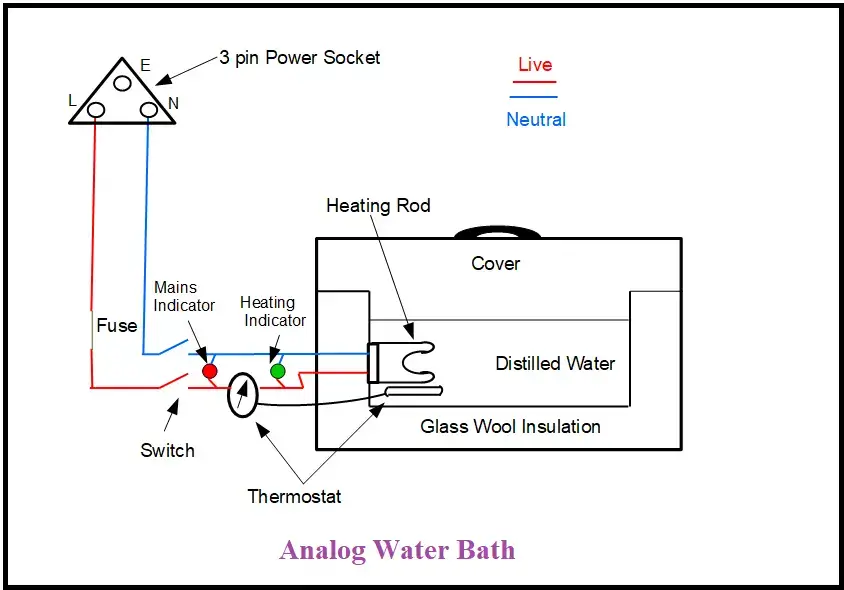

What is Analog water bath?

Analog water bath is a kind of water bath instrument in lab where temperature is controlled by analog / mechanical parts rather than digital electronics.

It is mostly used to maintain sample (tubes, flasks) at somewhat constant temp (below boiling) over long time.

Heating is done by immersion heater, and thermostat (mechanical dial) is used to regulate, current flows until the set point is reached.

In analog water bath the display is minimal or none, temperature reading often by external thermometer or simple dial.

Accuracy is lower in analog type (often ± some °) compared with digital baths.

Because of simplicity, analog water bath is cheaper and easier to repair.

It is favored when high precision is not needed, but steady warming is enough.

Limitations: drift in temp, lack of fine control, no programmability.

The working range is usually from ambient + few °C up to ~ 99.9 °C (since water cannot exceed 100°C normally).

A thermostat shuts heater off when temperature reaches set point, and allows heater again when temperature drops.

Uniformity is somewhat poorer (variation across bath) since circulation may not be present.

Safety: over‐temperature protection is needed, water level must be maintained, avoid dry heating.

In many labs, analog bath is replaced by digital bath when better control is demanded.

Principle of Analog water bath

Current is supplied to analog water bath and passed to thermostat (mechanical dial sensor). When water temp is lower than the preset value, current is allowed by thermostat to flow through immersion heater (heating element submerged in water).

Heating is applied, water temperature rises by conduction and convection. When water reaches the set temperature, thermostat cuts off current to heater. Thus heater is turned off and no more heating happens until water temp falls.

As water cools (due to ambient loss), thermostat will again allow current flow, so heater is energized. This on/off cycle maintains approximate constant temperature. In some analog models a simple thermometer (liquid filled) is used to monitor actual temp.

Uniformity is managed by natural convection currents in water (warmer water rises, cooler sinks). Safety or over‐temp cut‐off may be included (mechanical switch) to prevent runaway heating. The mechanism is simple, robust, low cost, though less precise than digital/PID systems.

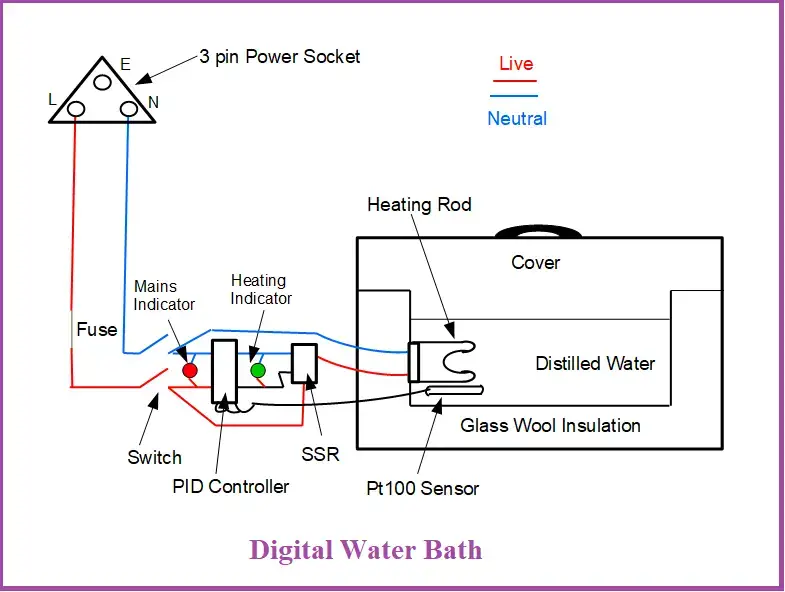

What is Digital Water Bath?

Digital water bath is a kind of water bath where temperature is controlled by digital electronics (microcontroller / PID etc) rather than simple mechanical dial.

A temperature sensor (often RTD or thermistor) is placed in water, its signal (resistance, voltage) is fed to controller.

The controller compares sensor reading with the set / desired temperature, computes error, then issues control signal.

A solid state relay (SSR) or electronic switch is used to drive heating element (immersion heater) on / off or in pulses.

The heating element is turned on when water temp is lower than set point, and turned off (or reduced) when temperature is close or above set.

The PID (Proportional-Integral-Derivative) algorithm is often used so that overshoot and oscillation are minimized. Thus smooth regulation is achieved: the heater is not simply on/off aggressively but modulated, more stable temperature results.

Digital display shows actual temperature and set temperature, so user can observe error / deviation. Over-temperature protection and alarms are integrated in many digital models.

Uniformity is improved (with optional circulation) because controller reacts fast. Accuracy is higher (often ±0.1 °C or so) compared with analog type.

The feedback control loop (sensor → controller → heater) is central.

Principle of Digital Water Bath

- Digital water bath is a water bath instrument where temperature control is handled by digital electronics and automatic feedback rather than by simple mechanical dial.

- A sensor (often RTD or thermistor) is immersed in water, its measured value (resistance/voltage) is transmitted to controller.

- The controller compares measured temperature with set / desired temperature, error is computed.

- A solid state relay (SSR) or electronic switching element is driven by controller to turn heating element ON / OFF (or modulate) based on error.

- When water temp is below set point, controller sends signal to SSR to permit current to heater.

- When temp approaches or exceeds set value, controller turns off or reduces heater drive to avoid overshoot.

- PID algorithm (Proportional-Integral-Derivative) is often used in controller to minimize fluctuations, stabilize temp, reduce overshoot.

- The heating element output is thus regulated smoothly, not just crude on/off, giving better stability.

- A digital display shows actual temperature and set temperature, user sees deviation and can adjust.

- Safety circuits (over-temperature cutoffs, alarms) are built in many digital baths.

- The feedback loop (sensor → controller → SSR → heater) is the core principle.

- Uniform heating is aided by water convection and sometimes circulation pumps.

Analog Water Bath Vs Digital Water Bath

- Analog water bath is controlled by mechanical / electromechanical means (dial, thermostat) while digital water bath is controlled by electronic / microcontroller system.

- Temperature in analog bath is monitored via simple dial or external thermometer, while in digital bath a sensor (RTD / thermistor) is read by controller and a digital display is shown.

- In analog, heater is turned ON or OFF by mechanical thermostat, in digital control, switching is done via SSR or electronic switch, often modulated.

- Stability / accuracy is lower in analog (larger swings) and higher in digital (smaller error).

- In digital bath, PID (proportional‐integral‐derivative) control is often used to reduce overshoot and maintain steady temperature.

- Analog is simpler, cheaper, easier to repair; digital is more complex, costly, needs calibration but gives better performance.

- In analog, uniformity is poorer especially for large bath, while digital may incorporate circulation or stirring to improve uniformity.

- Safety features (over-temperature cutoff, alarm) are basic or optional in analog, built-in and more sophisticated in digital.

- For routine tasks where precision is not critical analog suffices, for sensitive experiments digital is preferred.

| Features | Analog Water Bath | Digital Water Bath |

|---|---|---|

| Temperature Control System | Analog temperature control system using a dial or knob. | Digital temperature control system with a digital display and buttons. |

| Precision | Less precise, manual adjustments may result in slight temperature variations. | More precise, allows for setting specific temperature values. |

| User-friendliness | Requires manual adjustments using a dial or knob, lacks a display board. | User-friendly with a digital display and buttons for easy temperature control and monitoring. |

| Cost | More affordable, suitable for budget-conscious laboratories. | Generally more expensive due to the advanced features and digital control system. |

Advantages of laboratory Water Bath

- A laboratory water bath gives gentle heating of samples, so that sudden heat shock is avoided and delicate substances are safe.

- It allows uniform temperature around vessels (by water conduction / convection) so sample is heated more evenly.

- Constant / stable temperature is maintained for long periods, helping reproducibility of experiments.

- It provides safe heating especially when direct flame is risky (for flammable reagents) — heat via water not flame.

- Simplicity of operation is advantage — ease to use by students/technicians, minimal training needed.

- It is cost-effective / economical, maintenance is simpler and parts are less expensive.

- It reduces risk of sample overheating or localized hot spots (since water distributes heat)

- Versatility is offered — wide range of applications (enzymes, cell culture, thawing, reagent warming etc)

- It is compatible with circulating / stirring options to further improve uniformity and reduce gradient.

- It allows precise / fine control in better models (especially digital water baths) which improves experiment accuracy

- In many labs, it is durable and hardy (robust) under repeated use.

Limitation of laboratory Water Bath

- Microbial growth / contamination is allowed by warm water that sits some time (like untreated hot tub) so bath water may support undesirable microbes.

- Frequent water replacement is required if tap water is used, otherwise salts buildup / corrosion occurs.

- Evaporation of water occurs gradually, so water level must be topped up, else heating element may be exposed.

- Temperature limit is constrained by boiling point of water (~100°C), so it’s not suitable for reactions >100°C.

- Uneven temperature / gradients may occur especially in large bath if circulation is absent.

- Dependence on power is strong — if power fails, heating stops immediately and sample may be lost / cooled.

- Slow heating or response is possible especially for large volume baths or big temperature jumps.

- Contamination risk / cross contamination is higher since many samples touch shared water medium.

- Maintenance heavy — cleaning, disinfection, removal of scale / residues is often needed.

- Limited for heat‐sensitive or moisture-sensitive samples because water contact or humidity may damage them.

Application of laboratory Water Bath

- Application in microbiology / cell biology labs is incubation of bacterial cultures, yeast, or other microbes at fixed temperature (e.g. 37°C).

- Enzyme reactions / biochemical assays are performed in water bath so that temp sensitive reactions are controlled.

- Reagents / solutions warming / pre-heating is done by water bath (to bring to working temp).

- Melting of substrates / low-melting point materials is done by water bath (instead of direct flame).

- Thawing of frozen samples or reagents is aided by water bath gently warming them.

- In chemical labs, controlled heating of reactions that must not exceed ~100°C is done using water bath.

- For heating flammable chemicals water bath is preferred since no open flame is needed.

- In serology / diagnostic labs, water baths are used for tissue culture, enzyme tests, growth observation, fermentation / coliform determination etc.

- Uniform temperature applications (like circulating / shaking baths) are used when sample uniformity is important.

- In vaccine / industrial / corrosion tests / simulation labs water baths are used for testing / stability / controlled heating of samples / materials

Precautions

- Hands dry must be kept when plugging / switching on power, to avoid electric hazard.

- Correct water level must be maintained so heater is fully immersed, else dry heating / damage occurs.

- Only distilled / deionized water should be used (not tap water) to prevent scale / mineral deposits on heater.

- Lid / cover should be closed during use to reduce evaporation / contamination / heat loss.

- Sample containers must be sealed / capped to prevent water ingression / cross-contamination.

- Unit must be properly grounded, and damaged plugs / cords should not be used.

- The bath must not be run dry — never operate without water.

- Use heat-resistant gloves / tongs when retrieving hot vessels to avoid burns.

- Periodic cleaning / disinfection must be done (e.g. 10% bleach or 70% ethanol) to avoid microbial growth / contamination.

- Mineral scaling must be removed (descaling) to maintain efficiency and avoid damage.

- High temperature settings must be controlled, overheat protection must be active, avoid exceeding safe limits.

- Bath must be turned off / unplugged when not in use, to prevent heating, power waste, hazards.

- The surroundings / bench must be dry and free from spills, avoid placing bath near water spray / flammable materials.

Quiz

What is the primary purpose of a laboratory water bath?

a) To cool samples

b) To sterilize equipment

c) To heat and maintain samples at a specific temperature

d) To measure pH levels

Which type of water bath is most suitable for incubating large volumes of samples and maintaining a uniform temperature over an extended period?

a) Shaking water bath

b) Non-circulating water bath

c) Circulating water bath

d) Immersion water bath

What type of water bath is typically used when gentle mixing of samples is required along with precise temperature control?

a) Shaking water bath

b) Oil bath

c) Sand bath

d) Circulating water bath

Which material is commonly used to construct polycarbonate water baths due to its durability and resistance to chemicals?

a) Glass

b) Stainless steel

c) Aluminum

d) Polycarbonate

In a water-jacketed heating block, what surrounds the heating element to evenly distribute heat to the samples?

a) Air

b) Water

c) Oil

d) Sand

What type of bath is typically used for incubating samples at temperatures below 25°C?

a) Shaking water bath

b) Non-circulating water bath

c) Low-temperature water bath

d) High-temperature water bath

Which water bath type is known for its lightweight, break-resistant properties, and resistance to acids and bases?

a) Circulating water bath

b) Shaking water bath

c) Polycarbonate water bath

d) Water-jacketed heating block

What does PID feedback stand for in the context of high-precision temperature control in some water baths?

a) Proportional-Integral-Derivative feedback

b) Primary-Intermediate-Derivative feedback

c) Precise-Incremental-Differential feedback

d) Power-Intensity-Differential feedback

In a sand bath, what material is commonly used as the heating rod?

a) Copper

b) Aluminum

c) Stainless steel

d) Iron

What safety feature is often included in shaking water baths to prevent samples from splashing during operation?

a) Slow start

b) Automatic locking

c) High-speed motor

d) Continuous shaking

FAQ

What is a laboratory water bath?

A laboratory water bath is a device used to incubate samples at a controlled temperature in a water-filled chamber.

How does a laboratory water bath work?

A laboratory water bath works by heating the water in the bath and maintaining it at a specific temperature using a temperature control system.

What are the main types of laboratory water baths?

The main types of laboratory water baths are analog water baths and digital water baths.

What are the advantages of a digital water bath over an analog water bath?

Digital water baths offer more precise temperature control, user-friendly digital displays, and the ability to set specific temperature values.

How accurate are laboratory water baths in maintaining temperature?

Laboratory water baths can typically maintain temperature accuracy within a range of +/- 1°C.

Can I use tap water in a laboratory water bath?

It is recommended to use distilled water in a laboratory water bath to prevent mineral buildup and contamination of samples.

Can I use a laboratory water bath for flammable or volatile substances?

No, laboratory water baths are not suitable for use with flammable or volatile substances as they can present a safety hazard.

How often should I clean a laboratory water bath?

It is good practice to clean the water bath after each use to prevent cross-contamination and ensure optimal performance.

Can I adjust the temperature during operation?

Yes, both analog and digital water baths allow you to adjust the temperature during operation to meet the requirements of your experiment.

Are there any safety precautions I should take when using a laboratory water bath?

Yes, some precautions include ensuring electrical safety, avoiding contact with moving parts, maintaining proper water levels, and using appropriate cleaning agents to prevent contamination.

- https://www.tec2med.com/water-bath-working-handling-maintenance/

- https://www.labkafe.com/blog/how-to-use-water-bath-in-laboratory-working-principal-types-maintenance#:~:text=WorkingprincipleofwaterbathThesensortransferwatertemperature,maintainwaterinconstanttemperature.

- https://www.stericox.com/water-bath/

- https://www.labrotovap.com/working-principle-of-water-bath/

- http://www.lanphan.com/lab-instruments/working-principle-of-water-bath-605.html

- https://www.slideshare.net/TayyabTariq8/water-bath-instrument

- https://www.slideshare.net/goldenalzaidy/pdf-water-bath-laboratory-applications

- https://en.wikipedia.org/wiki/Laboratory_water_bath

- Text Highlighting: Select any text in the post content to highlight it

- Text Annotation: Select text and add comments with annotations

- Comment Management: Edit or delete your own comments

- Highlight Management: Remove your own highlights

How to use: Simply select any text in the post content above, and you'll see annotation options. Login here or create an account to get started.