- A Homogenizer can define as a mechanical device used for making uniform mixture by breaking large particles/globules into very small one.

- In process, the material (liquid or semi-liquid) is forced by a narrow space/valve, where high pressure and turbulence occurs creating uniform dispersion.

- It is mostly used by industries like dairy, pharma, cosmetics etc. for achieving product stability and smooth texture.

- The main function of homogenizer is the reduction of particle size, so that the mixture will not separate easily after standing.

- Pressure is applied at very high level, sometimes more than 100 MPa, for obtaining fine emulsion or suspension.

- The operation is generally continuous or batch type depending by requirement of process and product type.

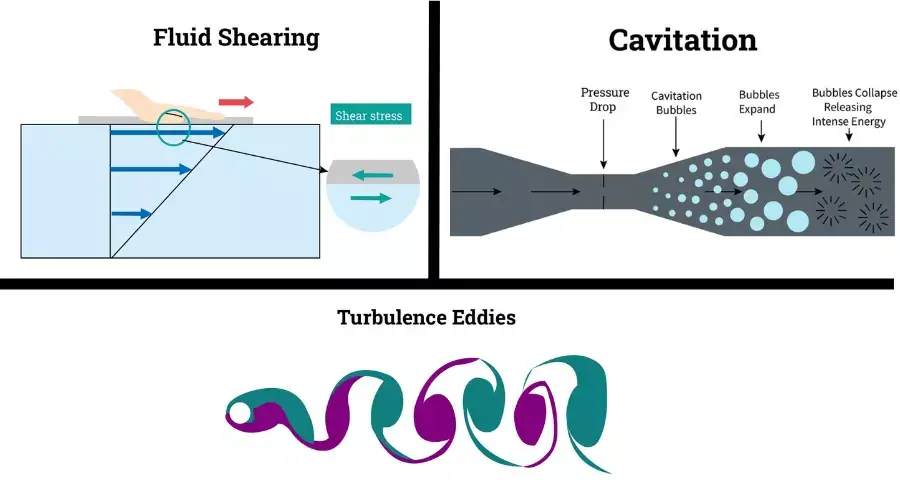

- During homogenization, physical forces like shearing, impact, and cavitation are involved, which cause the breakdown of droplets/cells.

- The mixture passes rapidly by the homogenizing valve; after that, sudden pressure drop causes turbulence and particle disintegration.

- By this action, the surface area of dispersed phase increases, which leads to better uniformity and stability of the system.

- Sometimes, homogenizer also used for cell disruption (like in Escherichia coli) for extracting intracellular components.

- A high-pressure type (HPH) is widely used, while rotor-stator types are applied for low viscous materials.

- The device is composed from pump, pressure valve, and homogenizing chamber (these are main parts).

- Energy conversion happens by mechanical to kinetic form, then back to pressure energy again – thus enabling dispersion.

- In food industries, milk homogenization is typical example, where fat globules are reduced in size for preventing cream layer formation.

- After process, the emulsion produced is stable, sturdy and hardy, which can be stored long time without separation.

- Some homogenizers also designed for laboratory use, small in size but work on same principle as industrial ones.

- As pressure increases, efficiency also increase but excess heat may prevail the product quality, so cooling system often attached.

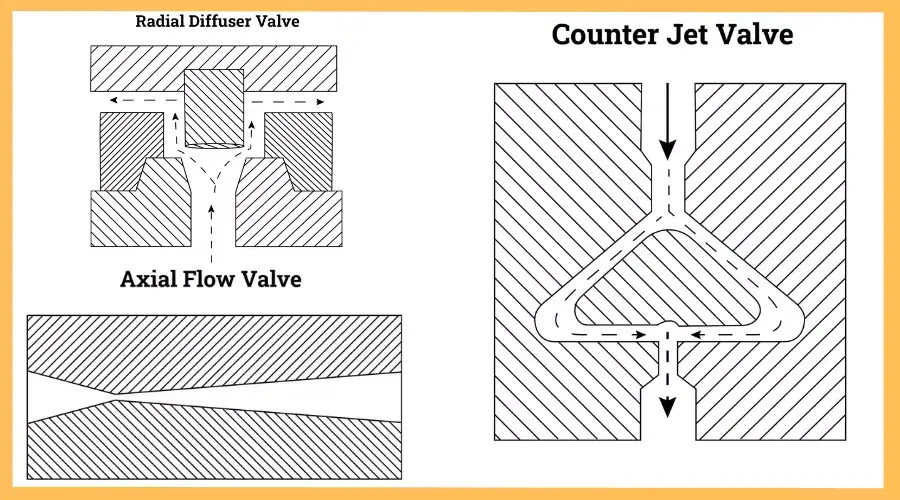

- It’s working mechanism depend not only on pressure but also geometry of valve and flow rate of fluid.

- The word “homogenize” itself means making the things same or uniform, which is exactly the purpose of this device.

- Therefore, a homogenizer is an essential equipment for many sectors where uniform texture, stability and appearance are required.

Homogenizer Definition

A homogenizer is a device used to mix, emulsify, and evenly distribute particles in liquids, creating a uniform and homogeneous mixture.

Principle of Homogenizer

- The principle of homogenization can define as a process where liquid mixture with large globules/particles are subjected to strong mechanical & fluid forces.

- These forces break down the big ones into smaller, more uniform sizes so stable emulsion / suspension / dispersion are formed.

- Mostly it’s a physical process, energy must supplied to overcome the resisting forces of droplet breakup.

- In high-energy devices like High-Pressure Homogenizer (HPH), breakup happens mainly due to shearing, turbulence, and cavitation working together.

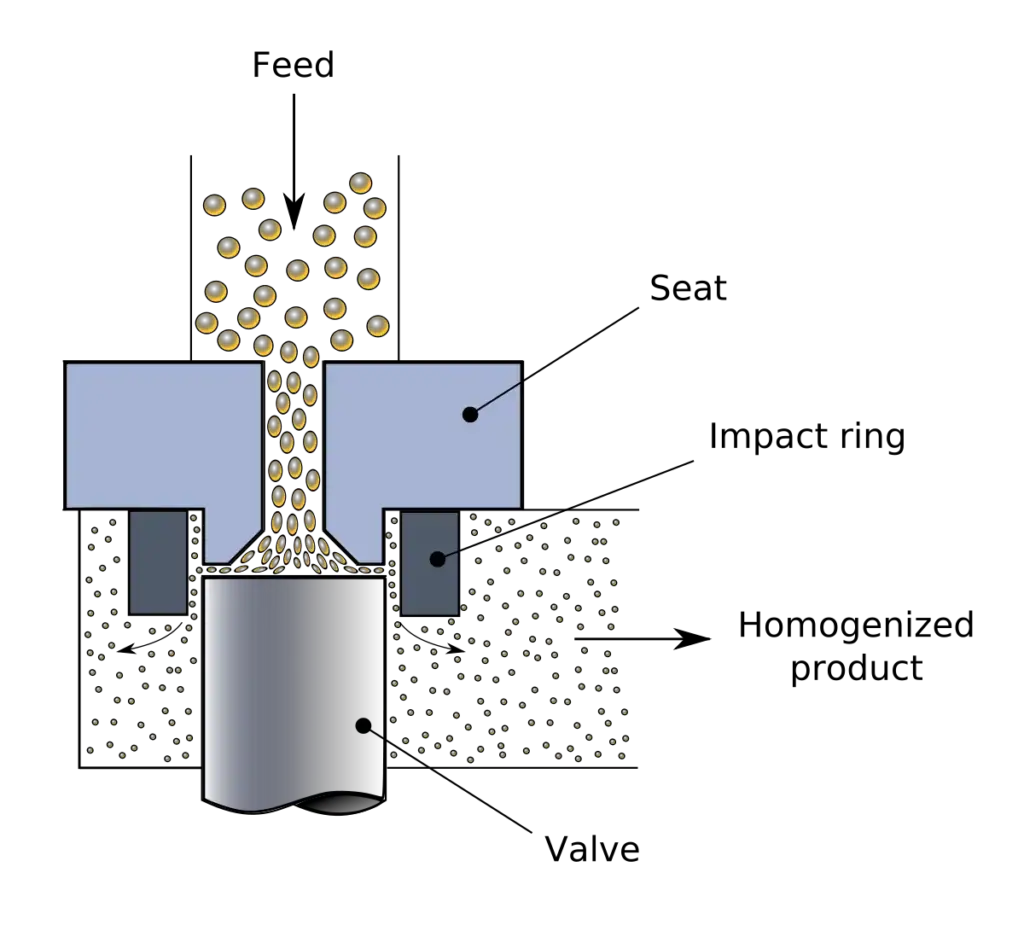

- During this, the premix (mixture before treatment) is forced under very high static pressure by a small adjustable gap that form between valve and valve seat.

- When liquid pass by this narrow space, flow accelerates so rapidly—strong shear and turbulence (eddy currents) created that fragments the big particles efficiently.

- After that, a sudden drop of pressure occur as the fluid exits the gap, and cavitation forms small vapor bubbles which collapse violently creating shockwaves.

- Those shockwaves disrupt particles more, making them tiny and uniformly distributed.

- The final product shows smaller particle size, that improves texture / appearance / shelf stability etc.

- For emulsion to form properly, enough energy should be given for particle breakup and an emulsifier required to reduce interfacial tension so droplets don’t rejoin immediately.

- Thus, stability of the emulsion largely depend by both – energy input and surfactant action working together.

- The principle of homogenizer can define as based on the application of mechanical forces for reducing particle size in a fluid medium.

- In the working, liquid mixture is forced by a narrow space or valve at very high pressure (50–150 MPa), causing intense turbulence and shear.

- As the fluid passes rapidly by this gap, a sudden pressure drop occurs, which leads to cavitation and impacting of particles.

- These physical forces (shear/impact/cavitation) act simultaneously, breaking large droplets or cells into fine and uniform particles.

- Thus, homogenization process depends on conversion of mechanical energy to kinetic and pressure energy within the system.

- The material experiences very high velocity gradients, due to which dispersed phase is splitted and distributed evenly.

- A valve seat and impact ring usually help in controlling intensity of pressure, they make the homogenizing action more effective.

- When the mixture exits from the valve, the sudden expansion occurs causing disintegration of fat globules or cell walls etc.

- Energy dissipation happen in microseconds, but the effect on uniformity is strong and stable.

- The degree of homogenization mainly depend by applied pressure, viscosity of fluid, and temperature of operation.

- A high-pressure homogenizer (HPH) work on same principle but use multi-stage valves for better efficiency.

- As more pressure applied, more smaller the particle becomes, however too much pressure may prevail the overheating problem.

- In general, the whole principle rely on the balance of pressure, velocity and turbulence to obtain stable emulsion or suspension.

- It can say that homogenizer works by destroying the particle boundaries so that uniform mixture is achieved in final product.

- Therefore, the principle of homogenizer is purely mechanical one, based on energy transformation and intense fluid dynamics.

Parts of Homogenizer

1. Homogenizing Valve – It is the main part where actual homogenization occur, the liquid is forced by a very small gap creating high velocity & pressure drop.

2. Piston Pump – Pressure is generated by piston/plunger which push the fluid by valve seat, mostly operated by electric motor or hydraulic system.

3. Pressure Gauge – Used for measuring the applied pressure (in MPa/bar); it helps operator to monitor process level accurately but sometimes readings fluctuates due to flow pulsation.

4. Cooling System – Water jacket or cooling coils are provided to absorb heat produced during high pressure operation, it prevails overheating and product damage.

5. Homogenizing Chamber – It is the zone between valve and seat where turbulence, shearing, and cavitation takes place, resulting in particle size reduction.

6. Inlet and Outlet Valves – Inlet valve allow feed mixture to enter chamber, while outlet valve control discharge after homogenization; sometimes both are spring loaded for tight sealing.

7. Pressure Adjustment Screw – By rotating this screw, pressure on the valve can be changed as per need of homogenization level.

8. Drive Mechanism – It consists of motor, belt, and crankshaft assembly which convert rotary motion into reciprocating motion of plunger.

9. Feed Hopper / Reservoir – The premix or sample to be homogenized is placed here before entering the pump, sometimes equipped with stirrer for uniform feeding.

10. Cylinder Block – It holds pistons and forms pressure-tight enclosure; made usually of stainless steel to resist corrosion.

11. Sealing Gaskets – They are fitted at joints to prevent leakage of fluid during high pressure, sometimes wear out quickly due to friction.

12. By-pass Line – Used for returning excess material back to hopper when the valve is closed or during cleaning operation.

13. Base Frame – Whole assembly is mounted on sturdy base which provides balance and reduce vibration during operation.

14. Control Panel – It contains switches, indicators, and pressure controls, used for operating and monitoring the machine safely.

15. Safety Valve – When pressure exceed the set limit, this valve automatically releases excess pressure, preventing equipment damage or explosion.

Operating Procedure of Homogenizer

- Before starting, the pressure control knob is checked to ensure it’s in idle position and not tightened.

- The cooling water is turned on for lubricating and cooling the pistons during operation.

- The premix or sample to be homogenized is prepared properly and placed in feed hopper/reservoir.

- Air present in suction line must be removed, otherwise pressure fluctuation can occur later.

- As the pump motor is started slowly, material begins to enter the compression chamber by suction.

- The pressure valve is gradually tightened until the required working pressure is reached, not done suddenly to avoid shock.

- The liquid is then forced by the homogenizing valve at high pressure (sometimes up to 150 MPa) creating intense turbulence and shearing action.

- After that, the product passes by narrow gap between valve and seat, where cavitation and impact causes particle breakdown.

- The homogenized mixture is collected by outlet valve, which may connected to storage tank or sample vessel.

- During running, temperature rise should be observed; cooling water flow must not stop otherwise product may burn or denature.

- The operating pressure and flow rate are maintained constant for uniform result, sudden fluctuation should be avoided.

- After completion of process, the pressure is released slowly by loosening adjustment screw.

- The motor is stopped and inlet valve closed, preventing backflow of fluid.

- Water or cleaning solution is circulated by system for washing internal parts from residue or deposits.

- The homogenizing valve and seals are checked after operation to ensure no damage occur due to high pressure.

- Equipment surface is dried and left in idle position ready for next batch.

- For safety, the operator must not open valve when machine is under pressure, it can cause serious hazard.

- Thus, operation of homogenizer mainly involves controlled pressure increase, continuous monitoring and proper shutdown sequence.

Types of Homogenizer

- High–Pressure Homogenizers (HPH) –

- Mixture is pushed by very high pressure (15,000 psi or more) through tiny valve.

- Intense shear, turbulence / cavitation forces are produced, it helps to break droplets and particles fast.

- Mostly used in milk, cream, emulsions and liposome formation in big industries.

- After sudden pressure drop, the vapor bubbles form and then collapse, causing mixing occur strongly.

- Ultrasonic Homogenizers (Sonicators) –

- The probe vibrates by ultrasonic frequency; pressure waves created in liquid.

- Cavitation happens; bubbles formed collapse quickly, so high local energy generated.

- Used for cell lysis in DNA/RNA extraction, nanoparticle dispersion, fine emulsions etc.

- Preferred in lab-scale, cause it’s easy and give very high energy in small area.

- Mechanical / High–Shear Homogenizers –

- A. Rotor–Stator Type –

- Rotor spins at high speed inside stator (fixed ring).

- Material drawn into gap where shear force and turbulence reduce particle size.

- Used by emulsifying, viscous mixing or partial cell breaking in lab or pilot plants.

- B. Bead Mill Type –

- Tube filled with small beads (glass, ceramic or metal) which shake rapidly.

- Impact & grinding of beads break hard sample materials.

- Used for tough tissues like plant/animal parts or microbial cells (yeast, bacteria) etc.

- A. Rotor–Stator Type –

- Other Types –

- Colloid Mill Homogenizer – like rotor-stator; high-speed rotor make strong shear, used to make stable colloid suspensions.

- Basic Tools (mortar–pestle / Dounce homogenizer) – manual way, grinding or crushing by hand for soft or gentle tissues, usually for small-scale.

Applications of Homogenizer

- A homogenizer is mostly used by a dairy industry where the milk is treated to reduce the size of the fat globules and the texture, the flavor, and the stability of the milk, cream, yogurt, etc. are improved.

- In a pharmaceutical area, it is applied for the production of emulsions/suspensions and liposomes where a uniform particle size is necessary for better drug absorption and bioavailability. The emulsions are sometimes stabilized by an addition of a surfactant for a longer shelf life.

- The food processing industries use a homogenizer to make the consistency of such products as sauces, dressings, mayonnaise, ice-cream, and fruit juices better. The pleasing texture and the prevention of phase separation are the results of this.

- In biotechnology and microbiology, cell disruption along with the release of the intracellular components (like proteins, enzymes, DNA) is carried out by either a high-pressure or an ultrasonic homogenizer. The process breaks the cell wall thoroughly without using a chemical reagent.

- The device used in the production of cosmetics and personal care articles like creams, lotions, perfumes, and gels is one with a fine dispersion. It enhances the product’s appearance, stability, and viscosity balance, which, if left standing, would separate.

- Chemical industries also use homogenizers in the manufacturing of paints, polymer emulsions, detergents, etc. The particle uniformity is what makes the final product more reactive and stable. At times temperature control (30–80°C) is used for viscosity control.

- In biomedical research, homogenization is one of the methods for tissue sample preparation prior to analysis by centrifugation, electrophoresis, chromatography, etc., and that with minimal mechanical damage as well.

- Nanotechnology sector has it for forming nanoemulsions/nanodispersions for drug delivery and coating purposes. Under intense pressure, the droplet size is decreased to <100 nm, which results in increased solubility and bio-reactivity.

- On top of that, homogenizers are put to use for wastewater treatment in order to break down oily particles and suspended solids for easier biodegradation, however, the efficiency depends on the feed composition and the pressure applied.

- With regard to agro and pesticide formulations, it is utilized to produce the uniform suspension/emulsion of the active ingredient that in turn leads to improved spray performance and storage stability.

Advantages of Homogenizer

- The dispersed phase particle size is changed uniformly as a result of the use of homogenizer to one that has a smoother and more stable product texture.

- Emulsion stability is also improved through homogenization, as the large fat droplets are broken into the smaller ones which, can’t separate again easily.

- The products taste and are made visually pleasing as well, e.g., milk, cream, juice are made to appear more creamy and consistent.

- One can explain better digestibility of homogenized milk based on fat globules being more finely divided and evenly distributed.

- The shelf-life of liquid food products are lengthened because of less creaming/sedimentation as well as microbial stability, that has been improved.

- In the pharmaceutical sector, homogenization process can lead to higher bioavailability and faster absorption of drugs in the form of suspensions or emulsions.

- By this method, uniform dispersion of ingredients is the main factor which leads to better color, flavor, and consistency of the final product.

- By the application of high shear force, natural emulsification is promoted thereby reducing the requirement for stabilizers or emulsifiers in some cases.

- Comparatively, cleaning and maintenance are hassle-free, because most modern units are equipped with CIP (clean-in-place) system for sanitation purpose.

- Continuously, the operation can be done which is a time and energy saver if compared to traditional mixing methods.

- Moreover, it facilitates standardization of industrial output as the quality of the product is maintained by the regulation of pressure and flow rate parameters.

- Homogenizers are a versatile machine, capable of various operations in industries such as dairy, pharma, cosmetic, chemical, beverage, etc., thus, it is a cost-effective investment.

- The heat generated throughout the homogenizing operation can be used for mild pasteurization, which might prevent microbial spoilage to some extent.

- In many food preparations (like sauces, creams, ice-cream) after the process, the viscosity is improved along with the mouthfeel.

- The overall efficiency of mixing and dispersion is significantly improved, even for highly viscous or semi-solid materials.

Limitations of Homogenizer

- The homogenization process needs very high pressure, so a large amount of power is consumed which increases the operating cost.

- The equipment cost of a high-pressure homogenizer (HPH) is high; therefore, it is not easily affordable for small industries.

- Excess heat generated during the process may affect the product’s quality, especially heat-sensitive components like vitamins, enzymes, etc.

- If the product is over-homogenized, its structure may be damaged or the fat droplets may coalesce instead of being stabilized.

- Maintenance and cleaning are difficult tasks as fine spaces/valves need to be kept from clogging.

- The piston, valves, and seals of the machine suffer from mechanical wear and tear quite often, and thus, they need regular replacement and calibration.

- A homogenizer can’t effectively process very viscous or solid-containing materials, as there may be a blockage inside the homogenizing valve.

- It is not appropriate for materials that have abrasive particles since these particles cause erosion of the parts inside the machine.

- At times, contamination risk may be present due to improper cleaning or seal leakage, especially in the continuous operation mode.

- Large-scale units require a skilled operator for pressure adjustment and troubleshooting, otherwise, the performance of the unit may be affected.

- When not insulated properly, the noise and vibration during the operation of the machine are high and may create an uncomfortable working environment.

- Because of the high pressure, safety measures must always be observed; otherwise, a bursting accident may take place (which is rare but possible).

- Homogenization cannot biologically make a liquid safer unless it is combined with heat/pasteurization; thus, microbial spoilage is still possible.

- In certain formulations, the addition of an emulsifier or a stabilizer is still required to maintain stability in the long term, so the process alone is not sufficient.

- The efficiency of homogenization varies with the pre-treatment and feed temperature, thus, the performance is not always constant.

Precautions

- It is very important that the pressure setting be checked carefully at the very beginning of the work. Overpressure can cause damage of valve and seal.

- Cooling water through the cylinder must always be on before the piston is moved otherwise the parts will get overheated or will even seize.

- The feed material should be filtered properly, because any solid particles or fibers can easily clog a homogenizing valve or orifice.

- The lubrication oil level in the crankcase should always be kept; otherwise the friction and wear will increase abnormally.

- The unit must not be operated in a dry condition, as extreme damage may be caused to the plunger and the check valves.

- It is very important that the pressure be changed gradually during operation, sudden change of pressure may cause vibration and shock load to the mechanical parts.

- Sprint and safety covers should be tightly fitted; an accidental touch of the moving part may be dangerous.

- During cleaning, only the recommended detergent/alkaline solution should be used, as corrosive chemicals may damage metal surfaces.

- The inlet temperature of the liquid should be within the permitted limit (normally <70°C). If it is higher the seal will be damaged and it will be hard to change the liquid.

- It is very dangerous to open a pressure release valve or pipe fittings when there is system load! Never do that!

- A good earthing connection is necessary for the electric motor and control panel in order to avoid the risk of electric shock.

- Operators are required to wear PPE such as gloves, goggles, apron etc., as splashing of the high-pressure liquid can harm the skin or eyes.

- The machine should be definitely depressurized and the power switched off before any maintenance work is carried out.

- All the connections, bolts and joints should be checked regularly for leakage or looseness.

- The calibrating of pressure gauge and safety valve should be done on a regular basis to ensure accurate and safe working conditions.

- Only trained personnel should use the homogenizer, as it is suggested. Mishandling may cause a serious accident or poor performance.

FAQ

What is homogenizer?

A homogenizer is a machine or device that is used to homogenize or emulsify liquids and suspensions. It works by applying mechanical force to a liquid sample to break down large particles or droplets into smaller, more uniform particles. Homogenization is a process that is commonly used in the food, cosmetic, and pharmaceutical industries to create stable emulsions, suspensions, and dispersions, and to improve the consistency and quality of products.

There are several types of homogenizers, including mechanical homogenizers, such as high-pressure homogenizers and high-shear homogenizers, and ultrasonic homogenizers. Mechanical homogenizers use a mechanical force, such as high pressure or high shear, to break down particles, while ultrasonic homogenizers use high-frequency sound waves to create small, uniform particles.

Homogenizers can be used in a variety of applications, including the production of cream and cheese, the preparation of emulsions and suspensions for pharmaceuticals and cosmetics, and the processing of food and beverage products such as milk, juice, and sauces.

What is homogenization example?

Homogenization is the process of breaking down large particles or droplets into smaller, more uniform particles in a liquid or suspension. An example of homogenization is the production of milk. Before homogenization, milk is made up of small droplets of fat suspended in water. However, the fat droplets tend to rise to the top and form a layer of cream. Homogenization is used to break down the fat droplets into smaller, more uniform particles that remain suspended in the milk, resulting in a more consistent product.

Another example is the production of salad dressings. Salad dressings typically contain oil and water, which naturally separate over time. Homogenization process is used to emulsify the oil and water, creating a stable, homogeneous mixture that will not separate.

In the pharmaceutical industry, Homogenization is used to create stable emulsions and suspensions of active ingredients. For example, an antibiotic solution may be made by suspending small particles of the antibiotic in water, then using a homogenizer to break down the particles into smaller, more uniform droplets. This ensures that the active ingredient is distributed evenly throughout the solution, making it more effective.

In the cosmetic industry, Homogenization is used to create smooth and consistent creams, lotions, and other personal care products by breaking down solid particles and incorporating them into a liquid base.

Why is homogenization important?

Homogenization is important because it improves the consistency, stability and quality of a wide range of products. It helps to create stable emulsions, suspensions, and dispersions, ensuring that ingredients are evenly distributed throughout the product. This ensures that the product is more consistent and effective, and can also help to extend its shelf life. In addition, homogenization can improve the texture and appearance of a product, making it more appealing to consumers. Homogenization is also used to improve the bioavailability and efficacy of drugs and other active ingredients, making them more effective and efficient.

Which pump is used in homogenizer?

Homogenizers typically use a high-pressure pump to generate the high pressure needed to homogenize liquids and suspensions. Two types of pumps that are commonly used in homogenizers are positive displacement pumps and centrifugal pumps.

Positive displacement pumps, such as reciprocating pumps or diaphragm pumps, are used in high-pressure homogenizers. These pumps work by trapping a fixed volume of liquid and then compressing it to generate high pressure. They are commonly used in low-volume, high-pressure homogenization applications.

Centrifugal pumps are used in high-shear homogenizers. These pumps use the principle of centrifugal force to generate high shear forces. They are commonly used in high-volume, low-pressure homogenization applications.

Both types of pumps can work with a variety of liquids and suspensions, and can be adjusted to produce different levels of pressure and shear force depending on the application. The choice of pump will depend on the nature of the sample, the desired homogenization results and the production scale.

Is homogenization positive or negative?

The effects of homogenization can be both positive and negative, depending on the context and application.

Positive effects of homogenization include:

Improved consistency and stability of products.

Improved texture and appearance of products.

Increased shelf life of products.

Improved bioavailability and efficacy of active ingredients.

Improved production efficiency and productivity.

However, there are also negative effects of homogenization that should be considered.

Homogenization can cause denaturation or damage of labile components.

Homogenization process may cause thermal damage to the sample.

Homogenization can lead to loss of nutritional value in food products.

Homogenization can lead to negative changes in the taste, smell, and color of food products.

Homogenization can increase the production cost and maintenance cost.

It is important to carefully evaluate the potential positive and negative effects of homogenization in a given application and make an informed decision about whether or not to use it.

How does a 2 stage homogenizer work?

A 2-stage homogenizer is a type of high-pressure homogenizer that uses two stages of homogenization to achieve a more efficient and effective process. It typically consists of a high-pressure pump and two homogenizing valves, one located after the pump and one after the first valve. The first valve is used to apply high pressure to the liquid, breaking down larger particles or droplets. The second valve further reduces the particle size and improves the uniformity of the particles.

The 2-stage homogenizer works by drawing the liquid sample into the high-pressure pump, which increases the pressure to a level that is high enough to break down the particles. The liquid is then forced through the first valve, which applies intense shear forces to the particles and breaks them down into smaller, more uniform particles. The liquid then passes through the second valve, which further reduces the particle size and improves the uniformity of the particles.

This process of two-stage homogenization allows for more efficient and effective homogenization, producing a more stable and consistent product with smaller particle size than one stage homogenization. However, it also increases the costs and maintenance of the homogenizer.

Why do we homogenize milk products?

Homogenization is used in milk products to create a more consistent and stable product by breaking down the fat globules in milk so they remain suspended throughout the liquid. Without homogenization, the fat globules will rise to the top and form a layer of cream. Homogenization makes the milk more consistent in texture, appearance and taste, increases its shelf life and also improves the nutritional value of the milk by making the fat-soluble vitamins more available for absorption. Homogenization also prevents creaming and sedimentation of milk, which is important for the production of milk-based products like ice cream, cheese and chocolate milk.

- Mondal, Pijush Kanti & Mandal, Bijan. (2019). A comparative study on the performance and emissions from a CI engine fuelled with water emulsified diesel prepared by mechanical homogenization and ultrasonic dispersion method. Energy Reports. 5. 639-648. 10.1016/j.egyr.2019.05.006.

- Onaneye-Babajide, Omotola & Petrik, Leslie & Bamikole, Amigun & Farouk, Ameer. (2010). Low-Cost Feedstock Conversion to Biodiesel via Ultrasound Technology. Energies. 3. 10.3390/en3101691.

- Cho, S.-C., Choi, W.-Y., Oh, S.-H., Lee, C.-G., Seo, Y.-C., Kim, J.-S., … Lee, H.-Y. (2012). Enhancement of Lipid Extraction from Marine Microalga,ScenedesmusAssociated with High-Pressure Homogenization Process. Journal of Biomedicine and Biotechnology, 2012, 1–6. doi:10.1155/2012/359432

- http://ecoursesonline.iasri.res.in/mod/page/view.php?id=6146

- https://ouat.nic.in/sites/default/files/7-homogenisation_of_milk_dairy_and_food_engineering.pdf

- https://www.centri-force.co.uk/products/homogenizers/

- https://homogenizers.net/pages/ac-rotor-stator-homogenization

- https://www.pharmapproach.com/colloid-mill-2/

- https://www.iqsdirectory.com/articles/mixer/homogenizer.html

- https://www.biocompare.com/Protein-Biochemistry/12986-Laboratory-Homogenizers/

- https://www.beei.com/blog/purpose-of-homogenization

- https://proscientific.com/the-field-of-homogenizing

- https://www.sciencedirect.com/topics/engineering/homogenizer

- https://microbeonline.com/homogenizer-parts-types-and-function/

- https://microbenotes.com/homogenizer-principle-procedure-parts-types-uses-examples/

- https://us.vwr.com/store/category/homogenizers/590438

- https://dairyprocessinghandbook.tetrapak.com/chapter/homogenizer

- https://www.labcompare.com/General-Laboratory-Equipment/5173-Homogenizing-Systems/

- https://www.labotronics.com/homogenizers

- https://www.ultragroup.in/homogenizers.html

- https://www.labindiainstruments.com/rotor-stator-homogenizers.html