What is Homogenizer?

- By lowering the size of scattered particles, a homogenizer—which is meant to mechanically mix or disperse heterogeneous mixtures into a homogeneous and stable emulsion—is able.

- It uses several technologies—such as high-pressure systems, rotor-stator mechanisms, ultrasonic cavitation, or bead milling—to apply strong shear forces breaking down big particles into smaller, uniformly dispersed ones.

- Homogenizers are used in both laboratory and industrial environments for a variety of purposes including cell lysis for biochemical analysis, tissue disruption in medical research, and food product processing like milk, where the fat globules are reduced to prevent separation.

- Homogenizers are important because they guarantee that all components are uniformly mixed, therefore improving product uniformity, texture, and following procedures as extraction, analysis, or chemical reactions.

- Originally homogenized using simple hand instruments like the mortar and pestle, technological developments produced advanced equipment with regulated, repeatable, and effective mixing capabilities.

- Modern homogenizers are necessary for high-quality sample preparation and industrial operations in many different fields as they have evolved to solve problems such cross-contamination, aerosol generation, and noise.

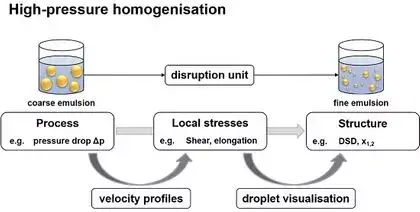

What is High Pressure Homogenizer?

- To generate strong shear forces, turbulence, and cavitation, a high pressure homogenizer—a specialist tool—forced a fluid or suspension through a small gap at very high pressures.

- By reducing the size of scattered droplets or particles, the procedure produces a homogeneous and stable emulsion or suspension.

- Food processing (for example, to produce homogenized milk), pharmaceuticals (to form emulsions and nanoparticle suspensions), and biotechnology (to disturb cells and release intracellular components) all make extensive use of it.

- Operating a high pressure pump raises the fluid’s pressure; as the product is forced through a specifically built valve, the extreme mechanical forces break down big particles into much smaller ones.

- Apart from increasing product uniformity and stability, the high pressure homogenization procedure raises active ingredient bioavailability and extraction efficiency.

- From simple hand tools like the mortar and pestle to complex high pressure systems providing exact control and repeatability, homogenization techniques developed historically from simple manual tools.

- To increase efficiency while maintaining the integrity of delicate materials, modern research keeps optimizing important factors such operating pressure, number of passes, temperature management, and valve design.

Working principle of high pressure homogenizer

High-pressure homogenization uses compressed liquid material driven through a gap at high speeds under high pressure and subjected to strong shear stresses. The fast decrease and rise in static pressure produces an explosive force and a strong impact force from the contact of the liquid substance on the metal ring. Comprehensive force allows the initial coarse emulsion or suspension to be transformed into a very fine, stable emulsion or suspension.

Usually 011 mm, the homogeneous material accelerates to 200 300 m/s in a split second when it passes through the adjustable gap h between the valve seat and the valve stem, so significantly lowering the pressure. Many micro-bubbles reduce the distance between the liquid and the gap outlet when the pressure falls to the operating temperature, so increasing the pressure by means of their saturated vapour pressure—that is, air separation.

The liquid starts “boiling,” fast “vaporizing,” and bubbles start to emerge when the pressure hits a specific threshold. When the bubbles in a liquid quickly rupture and re-condense, a phenomenon results whereby a great number of bubbles are produced and burst in a moment. It seems that the phenomena is an oversupply of little zha bombs. Great energy release produces very high frequency vibrations.

The instability of the fluid is created concurrently by the strong shear force generated by the intense turbulence, the softness of the liquid, the presence of semi-soft particles in the mixture, and the turbulent shearing all around. The force is broken up by the combined action of size and force into particles. High-speed contact between the pulverised particles and the impact ring allowed them to be further ground and scattered.

- It is most widely used method for preparing nanosuspensions of many poorly aqueous soluble drugs. It involves three steps.

- Firstly drug powders are dispersed in stabilizer solution to form pre-suspensions.

- Secondly the pre-suspension is homogenized in high pressure homogenizer at a low pressure for premilling.

- Finally homogenized at high pressure for 10 to 25 cycles until the nano-suspensions of desired size are formed.

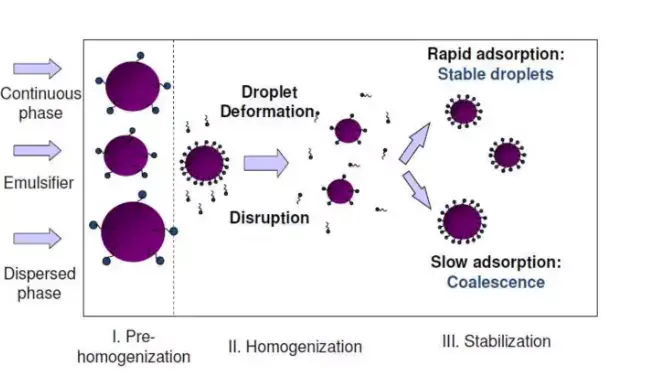

Homogenization Mechanism

- The homogenizer’s basic idea is to submit a heterogeneous mixture to strong mechanical forces that break down big particles or droplets into a homogeneous dispersion without changing the fundamental characteristics of the material.

- Velocity gradients in the fluid induce shearing; when the mixture is forced through small gaps, friction between layers generates differential motion that deforms and fragments more massive particles.

- When a fast pressure decrease creates localized vapor bubbles in the fluid, cavitation results; the following implosion of these bubbles generates shock waves that further disintegrate particles and droplets.

- As the fluid rushes through narrow channels, turbulent eddies created by their chaotic interaction squander kinetic energy and encourage more particle breakdown through violent, irregular flow patterns.

- These mechanisms are coupled in high-pressure homogenizers by forcing the sample through a homogenizing valve under high pressures, where the synergistic effects of shear, cavitation, and turbulence produce effective cell disruption or emulsion generation with controlled particle size distribution.

- Operating factors include applied pressure, valve shape, and the number of passes control the homogeneity and stability of the homogenized product, therefore guiding the efficiency of the homogenizing process.

Working of High Pressure Homogenizer

- Check that the homogenizer is placed correctly, that all safety interlocks are engaged, and that the control panel and gauges on the instrument—pressure, temperature—are operating as they should.

- Make sure the water—or other coolant—is flowing to prevent overheating the high-pressure pump and valve assembly and thus start the cooling and lubricating systems.

- To calibrate the pressure controls and expel any remaining pollutants, pre-run a stabilization cycle by moving a suitable liquid—often water—through the system.

- To avoid clogging of the narrow homogenizing valve, prepare the sample by making sure it is in a premixed, homogeneous condition and, if required, is filtered.

- To start controlled sample delivery, insert the sample into the homogenizer via the feed line via suitable 3-way or sample inlet valve adjustment.

- Turn on the high-pressure pump to drive the sample into the homogenization chamber, so accelerating the fluid across the constricted valve.

- To get the intended level of shear force, change the main pressure settings; make sure the pressure gauges show the operational pressure needed for efficient homogenization.

- If utilizing a two-stage homogenizer, adjust the secondary (backpressure) valve to the right proportion of the total pressure to fine-tune the particle size reduction and promote product homogeneity.

- Monitor the flow of the sample as it endures high shear, cavitation, and turbulent mixing within the homogenizing valve, ensuring that the process parameters stay consistent throughout the run.

- Let the sample past the homogenizer the appropriate number of times; many passes may be required to get best dispersion or cell disturbance.

- Adjust the bypass valve to direct the product flow into the specified collection system once homogenization is finished so that the homogenized material is effectively and safely released.

- Change the pressure regulating mechanism to progressively release the working pressure, therefore preventing sudden depressurization that can compromise the system or the product.

- Flushing the homogenizer with a suitable cleaning solution or water will start a cleaning process and help to eliminate leftover product and stop batch cross-contamination.

- Following manufacturer advised shutdown procedures, power down the motor and turn off the cooling and lubrication systems only after the system has been totally flushed and confirmed clear of active product.

- For quality control and to enable any required troubleshooting or improvement of future operations, record all operational parameters and run observations.

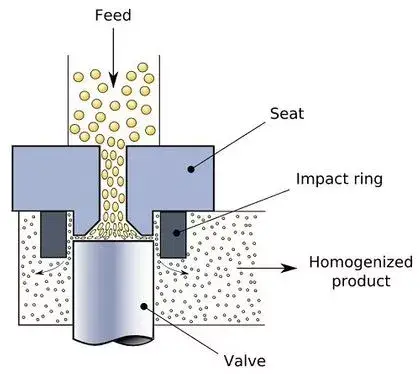

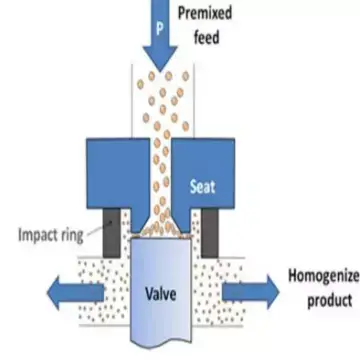

Homogenization valve Assembly

- Homogenizers can have a single valve assembly (single-stage) or two valves connected in series (two-stage).

- For the majority of items, a single-stage valve is adequate. A two-stage assembly that applies less than 10% of the total pressure to the second stage regulates back pressure and reduces clumping.

- This enhances the droplet size reduction and the particle size distribution narrowing. When great homogenization efficiency is desired, two-stage homogenization is typically employed.

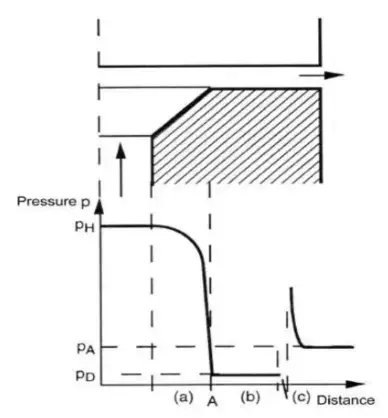

Physical Process inside the homogenization valves

- On entering the homogenization valve, the flow speed greatly increases → pressure drops (Bernoulli) to reach the vapor pressure PD at point A.

- Since PD is lower than the external pressure PA → cavitation and two phase fluid flow.

- Pressure signal transduction in multi-phase flows is slower than in single phase flow → equilibration with external pressure occurs late (close to exit).

- Sudden pressure jump leads to collapse of cavitational bubbles and the flow reverts to a one-phase flow

- Droplet disruption is therefore due to

- Laminar and turbulent flow at entrance of valve (a)

- Growth of cavitational bubbles in zone (b)

- Collapse of bubbles in zone (c)

Homogenization in Aqueous media (Dissocubes)

- Forcing the of the suspension under pressure through a narrow aperture valve.

- Dissocubes was developed by Muller et al in 1999.

- This instrument can be operated at pressure varying from 100-1500 bars (2800-21300 psi).

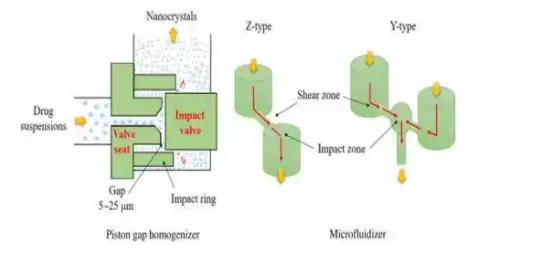

- It is the most widely used method for the preparation of nanosuspensions of many poorly water soluble drugs. Dissocubes are engineered using Piston-gap-type high pressure homogenizers.

- A commonly used homogenizer is the APV Micron LAB 40. However, other piston-gap homogenizers from Avestin and Stansted can also be used Gap.

- A high-pressure homogenizer consists of a high pressure plunger pump with a subsequent relief valve (homogenizing valve).

- The task of the plunger pump is to provide the energy level required for the relief. The relief valve consists of a fixed valve seat and an adjustable valve. These parts form an adjustable radial precision gap. The gap conditions, the resistance and thus the homogenizing pressure vary as a function of the force acting on the valve

Principle of Dissocubes

- Particle size reduction in piston gap homogenizers is based on the cavitation principle. Particles are also diminished as a result of significant shear forces and collisions between particles.

- The dispersion enclosed in a cylinder with a 3 cm diameter abruptly travels through a 25 m-wide slit.

- According to Bernoulli’s Law, the liquid flow volume per cross section in a closed system is constant. The drop in diameter from 3 centimetres to 25 micrometres causes an increase in dynamic pressure and a decrease in static pressure below the boiling point of water at ambient temperature.

- As a result, water begins to boil at ambient temperature and generates gas bubbles, which implode when the suspension leaves the gap (known as cavitation) and normal air pressure is achieved.

- The achievable size of drug nanocrystals is primarily determined by temperature, number of homogenization cycles, homogenizer power density, and homogenization pressure.

Homogenization in Non-Aqueous media (Nanopure)

- The drug suspensions in the non- aqueous media were homogenized at 0oC or even below the freezing point and hence are called Deepfreeze homogenization

- Advantages:

- Evaporation is faster and under milder conditions.

- This is useful for temperature sensitive drugs.

Types of High Pressure Homogenizer

Types of High Pressure Homogenizer By energy source

1. Electric

An electric motor powers electric homogenizers. This homogenizer category can be further broken into two types: direct-drive and intensifier.

- Direct-drive type: The motor drives the crankshaft to reciprocate the plunger, directly applying pressure on the material. Multiple plungers on the crankshaft collaborate to generate consistent pressure and a high flow rate; vast volumes of materials are necessary to generate constant pressure. The motor requires a multi-stage gear reduction mechanism to drive the crankshaft, which makes the equipment bulky. The homogenizer with a crankshaft is appropriate for low-pressure, large-scale manufacturing applications.

- Intensifier type: In intensifier-type high pressure homogenizers, the motor presses the material through the interaction chamber by driving the intensifier. The intensifier system may generate a higher pressure, hence enhancing the efficiency of the homogenization procedure. Compared to the homogenizer with a crankshaft, the homogenizer with an intensifier has a lower flow rate, requires less material, and has a greater pressure. It can be utilised for laboratory applications involving small sample volumes and industrial applications involving high pressure. When fitted with a diamond interaction chamber, the electric high pressure homogenizer with an intensifier is categorised as a premium homogenizer. This type is commonly used in laboratories for biology, pharmaceuticals, and nanotechnology. The conventional intensifier is hydraulic, but a new type of electric cylinder with a linear actuator is more effective.

2. Hand Driven

Manually powered homogenizers provide pressure on the material. A hand homogenizer has a low flow rate, but it is portable and simple to instal and disassemble. It is useful for small-scale investigations because to the minimal amount of materials required. This type of gadget is capable of meeting the research and development requirements of biopharmaceutical laboratories. Manual high-pressure homogenizers are also known as Handgenizers.

3. Air Driven

The air-powered homogenizer transfers compressed gas pressure to hydraulic pressure. Therefore, it requires a nitrogen cylinder or an air compressor for assistance. This homogenizer has a high gas consumption, significant noise levels, and a relatively low maximum homogenization pressure. Due to the absence of a separate intensifier pump structure, its volume is modest, and it is suited for sites with compressed nitrogen.

Types of High Pressure Homogenizer By principle and structure of the interaction chamber

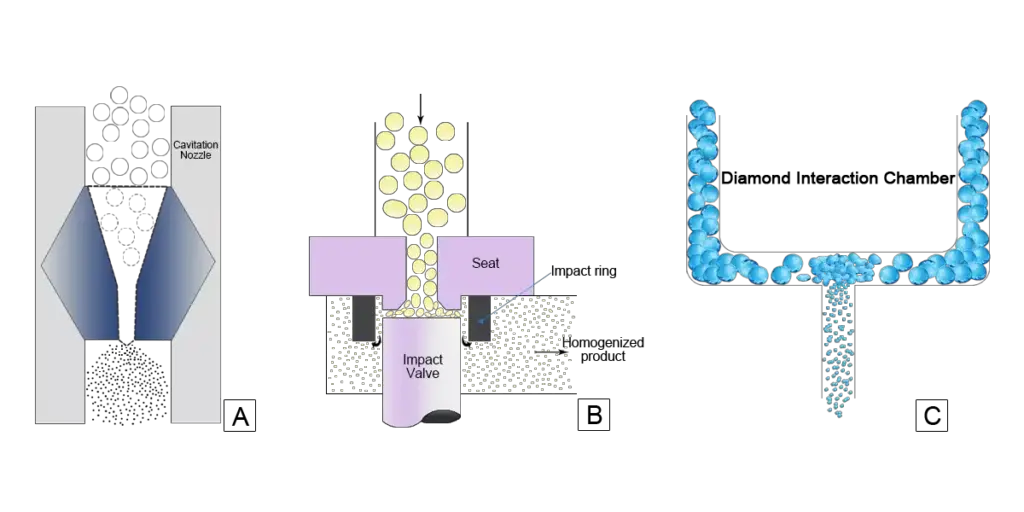

1. First Generation: Impact Type

- Cavitation nozzles: The primary function of this nozzle is cavitation, which separates the emulsion and increases particle size. The materials flow into the cavitation nozzle with a very small aperture at several times the speed of sound under the pressure of the homogenizer. In the meantime, there is strong friction and impact between the particles and the metal valve components. This friction decreases the equipment’s service life, and the impacts cause metal particles to enter the final goods.

- Impact valve: Using tungsten alloy materials, the impact valve and impact ring structure moderately reduce local wear and extend the homogenization chamber’s service life. The impact valve’s function is a combination of impact and cavitation. Nonetheless, its fundamental idea is the collision of the suspended substance with the structure of a high-hardness metal (such as tungsten alloy). Consequently, the impact valve cannot resolve the issue of metallic particle residue. In the first decade of the 20th century, the majority of high-pressure homogenizers included an impact valve.

2. Second Generation: Interaction Type (Y-type interaction chamber)

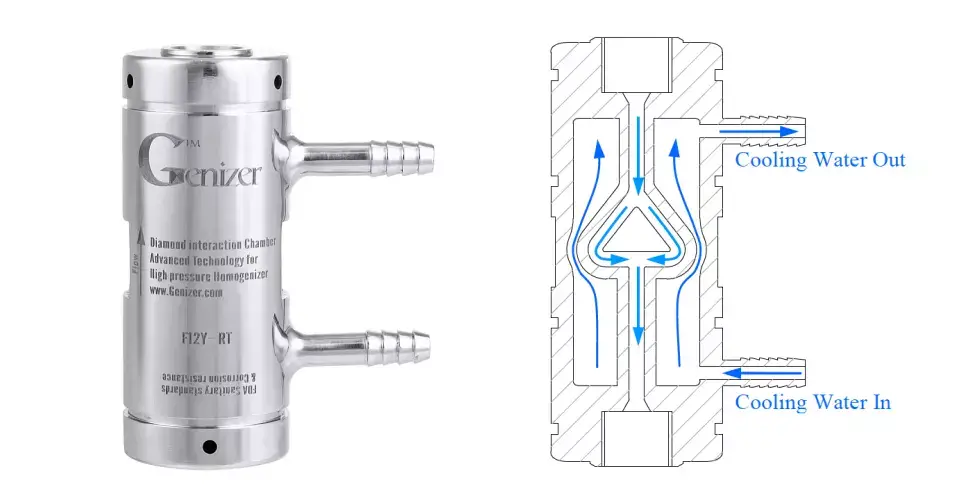

Several firms in the United States have utilised the Y-type interaction chamber, considered one of the most effective homogenization chambers to date. In these systems, the flow stream is divided into two channels, which are then redirected at right angles over the same plane and driven into a single flow stream. A high pressure encourages a high velocity at the intersection of the two flows, resulting in severe shear, turbulence, and cavitation over the single outgoing flow stream.

With the distinctive Y-type structure, the high-velocity moving materials in the high-pressure solution clash with each other, a process that significantly increases the chamber’s service life compared to conventional designs. Utilizing diamond material inhibits metal particle residual generation.

Because it minimises cavitation and produces excellent, stable particle size and PDI (poly dispersity index) control ability, the Y-type interaction chamber is commonly employed in the manufacturing of pharmaceutical emulsions. The major manufacturers of the diamond interaction chamber are Genizer and Microfluidics Corp. Currently, the Y-type diamond interaction chamber is mostly utilised in high-end nanotechnology and accounts for more than 90% of the US pharmaceutical sector. The temperature-controlled interaction chamber of Genizer prevents temperature spikes and enables up to 60,000 psi of working pressure.

Low emulsification efficiency and metallic particle residue are two issues generated by impact-designed homogenization chambers. During the manufacturing of pharmaceutical injections, inert metallic particles are generated when particles clash with internal metal components. These metallic particles might combine to generate larger particles. In pharmaceutical applications, this is a problem since large particles reduce capillary blood flow, which in turn causes mechanical damage to human tissues, resulting in acute or chronic inflammation. The interaction chamber eliminates particle residue and demulsification issues. However, because of the chamber’s internal structure, when the concentration and viscosity of the product are high, the chamber is more likely to produce flow blockage than impact homogenizers.

Types of High Pressure Homogenizer By principle of pressurization

To achieve high pressure levels, the ultra-high pressure homogenizer requires a considerable thrust to propel the piston in the cylinder. The rotating motor must reduce speed, increase torque, and convert linear motion to linear reciprocating motion with high thrust in order to obtain linear reciprocating motion. The pressurisation principle acts differently in homogenizers of the direct-drive and intensifier types.

1. Direct-drive type

The motor drives the crankshaft to reciprocate the plunger and directly apply pressure to the material. Multiple sets of plungers generate consistent pressure, and the homogenizer’s flow rate is high. However, both the minimal material requirements and the amount of residue produced are significant.

The motor-driven crankshaft of these homogenizers requires a multi-stage gear reduction mechanism, limiting their efficiency and necessitating huge unit dimensions. This type of homogenizer is appropriate for use in the food and chemical industries, as well as other low-pressure applications.

2. Intensifier type

The intensifier-type homogenizer is the outcome of recent technological advancements in ultra-high pressure. The motor operating the oil pump to pressurise the material through the hydraulic system is one of its mechanisms. The hydraulic system provides greater pressure than direct-drive homogenizers, but the volume and minimum material demand are reduced. The intensifier-type homogenizer is applicable to both high-pressure laboratory and industrial homogenizers.

The hydraulic intensifier may accomplish low-frequency and high-thrust piston movement, which extends the machine’s service life and saves its maintenance expenses. Using parallel four-cylinder technology, ultra-high pressure of up to 45,000 psi can be maintained without the use of an accumulator.

In the past, the majority of high pressure homogenizers were direct-drive models, despite the apparent disadvantages of this design. It has a short service life and requires frequent maintenance on its wearing parts, especially when the pressure exceeds 100 MPa. Hydraulic homogenizers are expensive to manufacture, but they have a long service life and require little wear-parts maintenance.

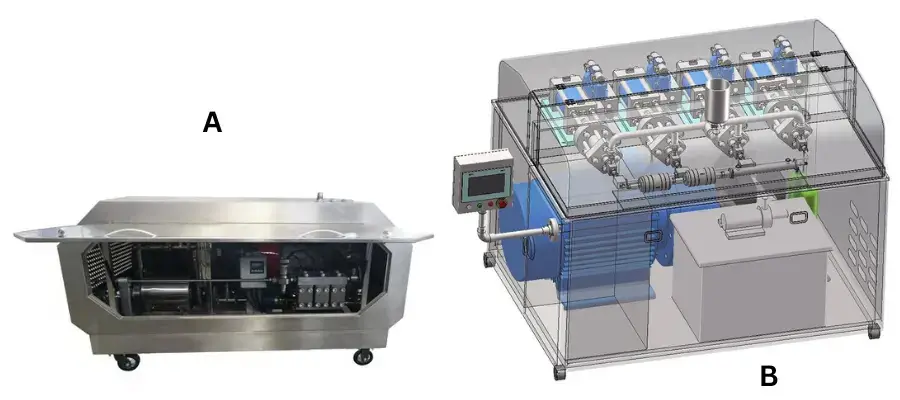

Parts of High Pressure Homogenizer

A high pressure homogenizer typically has several key parts, including:

- A high pressure pump: This generates the high pressure needed to homogenize the sample.

- A homogenization valve: This regulates the flow of the sample and controls the pressure at which it is homogenized.

- A homogenization chamber: This is where the sample is subjected to high pressure, causing it to be homogenized.

- A cooling system: This is used to cool the sample and prevent overheating during the homogenization process.

- A pressure gauge: This measures the pressure inside the homogenizer.

- A control panel: This allows the operator to adjust the settings of the homogenizer, such as pressure and flow rate.

- A pressure relief valve: This releases excess pressure to prevent damage to the homogenizer.

- An inlet and outlet: These are used to feed the sample into the homogenizer and to remove the homogenized sample from the homogenizer.

Applications of High a Pressure Homogenizer

- In biopharmaceutical applications, high-pressure homogenizers are extensively utilized to destroy cells, remove intracellular proteins, and release viral particles for vaccination manufacture, therefore guaranteeing effective cell lysis and consistent product quality.

- These homogenizers shrink fat globules in milk, increase the stability of emulsions in sauces and drinks, and help to improve the texture and shelf life of nutritious items in the food and dairy sectors.

- High-pressure homogenization helps formulations for cosmetics and personal care by stabilizing pigment dispersion, creating homogenous emulsions in creams and lotions, and generating nanoemulsions improving product uniformity and performance.

- High-pressure homogenizers are used in nanomaterial synthesis and pharmaceutical formulations to lower particle size for the creation of nanocellulose, nanocarbon, and liposome-based drug delivery systems, hence producing enhanced bioavailability and controlled release profiles.

- These homogenizers are used in chemical and industrial processes to produce stable dispersion and emulsions in formulations like coatings, adhesives, and specialty chemicals, therefore assuring consistent particle distribution and improved product stability.

- Research uses include sample preparation for cell fractionation, nucleic acid and protein extraction, and analytical technique development where high-pressure homogenization offers homogenous and repeatable samples for precise analysis.

Advantages of High a Pressure Homogenizer

- By applying strong shear, cavitation, and turbulence, high-pressure homogenizers produce outstanding particle size reduction, thereby producing homuesuesums and dispersions.

- Their design simplifies procedures in both laboratory and industrial environments by allowing automatic operation with minimum operator interaction.

- Because it provides excellent homogenization with reduced energy consumption and maintenance needs, the method is less expensive than substitutes such ultrasonic cleaning.

- These systems guarantee constant product quality for several industries like medicines, food processing, and cosmetics by processing a wide variety of viscosities and sophisticated formulations.

- Integrated temperature control systems reduce heat generation during manufacturing, therefore shielding heat-sensitive components and maintaining product integrity.

- The capacity to execute repeated runs through the homogenizer enables for fine-tuning of particle size distribution, which promotes the stability and repeatability of the finished product.

Limitations of High a Pressure Homogenizer

- High capital and maintenance expenses limit use mostly to industrial or large-scale applications, so tiny laboratories and research environments find them less easily available.

- When processing samples with high particle or solid content, the small valves and channels are prone to clogging; thus, regular cleaning and thorough pre-treatment are rather important.

- Shear, impact, and cavitation are among strong mechanical forces that can cause sensitive biomolecules to degrade or denature, therefore jeopardizing the integrity of proteins and other fragile components.

- Particularly with temperature-sensitive materials, significant heat generation during operation calls for strong cooling systems to prevent thermal damage.

- Accurate control of operational factors like pressure, temperature, and flow rate is vital and calls for qualified experts; variations may provide inconsistent processing results.

- High pressure homogenizers’ physical weight and size can restrict portability and demand dedicated space, so presenting difficulties for smaller or mobile laboratory configurations.

- Processing very viscous or non-homogeneous fluids may be ineffective because of greater resistance during pumping, which might speed equipment wear and lower general performance.

- Frequent cleaning and sterilization to minimize cross-contamination lead to greater downtime and higher operating expenses, particularly in applications such as food processing and pharmaceutical manufacturing

- Chen, Qishen & Xue, Feng & Ding, Enyong. (2019). Preparation of POSS-triol/wollastonite composite particles by Liquid phase mechanochemical method and its application in UV curable coatings. Science and Engineering of Composite Materials. 26. 183-196. 10.1515/secm-2019-0001.

- Chen, Qishen & Xue, Feng & Ding, Enyong. (2019). Preparation of POSS-triol/wollastonite composite particles by Liquid phase mechanochemical method and its application in UV curable coatings. Science and Engineering of Composite Materials. 26. 183-196. 10.1515/secm-2019-0001.

- Bonthagarala, Brahmaiah & Balamarkonda, CH & Rao, V & Adamkhan, Patan & Sreekanth, Dr. Nama. (2013). A REVIEW ON SIGNIFICANCE OF NANOCRYSTALS IN DRUG DELIVERY. International Journal of Pharmacy. 3. 56-61.

- https://dairyprocessinghandbook.tetrapak.com/chapter/homogenizers

- https://www.slideshare.net/AnilPethe/high-pressure-homogenization-107148064

- https://www.sciencedirect.com/topics/engineering/high-pressure-homogenisation#:~:text=The%20principle%20behind%20high%2Dpressure,11.3).

- https://www.slideshare.net/AnilPethe/high-pressure-homogenization-107148064

- https://www.solidswiki.com/index.php/High_Pressure_Homogenizers

- https://homogenizers.net/pages/ac-high-pressure-homogenization

- https://www.pmg.engineering/high-pressure-homogenization/

- https://www.scientzbio.com/info/working-principle-of-high-pressure-homogenizer-44061763.html