What is Two pan or equal arm analytical balance?

- Two-pan analytical balance or Equal arm balance is described as classical, mechanical weighing device used for very precise mass comparison.

- The horizontal beam with two identical pans was supported on a central knife-edge, and the arms are equal in length so balance is attained when empty.

- The unknown mass is placed on one pan and standard weights are placed on the other, until equilibrium is achieved, this method is based on comparison not direct reading.

- High sensitivity is provided by the careful construction of the arms and the knife edges, and small differences in mass are detected (for example ranges like 0.1 mg, 0.01 mg in good models).

- The operation principle is explained as equality of torques about fulcrum, and the torque is balanced when m × g × l on one side equals on other side, simple physics but needs skill.

- The instrument is usually enclosed in a glass case (draft shield) to avoid air currents, dust and small disturbances, otherwise reading will be affected.

- Accuracy is mainly depending on arm equality, knife-edge sharpness, absence of friction, leveling and standard weights quality; careless handling will cause systematic errors.

- Calibration and adjustment are performed regularly, and the beam is checked for parallelism, spirit level is used, the user should take care.

- Arresting or damping device is often provided to stop the beam when not in use, and the knob is used to lift beam from knife edge to prevent wear.

- This balance is widely used in analytical chemistry labs for preparing standard solutions and gravimetric work, though they are slower than modern electronic balances.

- Nowadays many labs have replaced them by single-pan electronic balances, yet they are still used in teaching, demonstration, and where mechanical comparison is preferred.

- Small vibrations, static electricity, magnetism, uneven bench surface may introduce error, so anti-vibration and de-ionizing steps are suggested but sometimes omitted by users.

- Sensitivity adjustment is done by adding small riders or poise, and fine balancing requires patience, the user will prevail (intended malapropism for prevent) mistakes by careful technique.

- Measurements are influenced by temperature and buoyancy (air density), corrections are sometimes applied, and density of weights is considered for high precision work.

- Leveling screw and spirit level are provided on base, the level is checked and adjusted before weighing, otherwise results are biased.

- The balance is fragile and they should be handled gently, it requires regular cleaning and maintenance, and storage in dry place is recommended.

- Advantages are: high precision, mechanical reliability, no power needed, disadvantages are: slow operation, operator dependent, bulky, etc.

- The technique is taught to students to illustrate fundamental weighing principles, and the concept is considered as foundational in gravimetric analysis.

Principle of Two pan or equal arm analytical balance

- The principle of Two pan / Equal arm analytical balance can define as – the equality of moments or torques acting on both sides of a horizontal beam.

- It based on law of moments, which state that when beam is in equilibrium, the clockwise and anticlockwise torques about fulcrum are equal.

- The torque on each arm depends on the product of mass × gravitational force × arm length, and for balance both sides must produce equal torque.

- In simple way, when unknown weight on one pan is balanced by known standard weights on the other pan, the beam become horizontal that means both torques are same.

- The central knife-edge acts as pivot or fulcrum, and two other knife edges at arms support the pans, these edges must be sharp and equal to minimize friction.

- The beam is made of lightweight rigid material to reduce air buoyancy error, and arms are of equal length to ensure equal lever action.

- When both sides produce equal downward force, resultant torque is zero, and the pointer of beam rests at the central mark which indicate equilibrium position.

- Sensitivity of balance depends upon length of arms, mass of beam and position of center of gravity – smaller difference cause larger deflection of pointer.

- The balance works on comparison principle, not on direct measurement, so accuracy mainly rely on equality of arms and calibration of standard weights.

- For precise working, balance should kept level, free from air current, and the beam should not be touched during oscillation, else reading will get disturbed.

- The arrestment device is used for lifting beam from knife-edges when not in use, that help to prevail (prevent) wear and maintain accuracy for longer time.

- The equilibrium condition expressed mathematically as W₁ × L₁ = W₂ × L₂, where W₁ and W₂ are the weights placed on two pans, and L₁, L₂ are the lengths of arms.

- When L₁ and L₂ are equal, then W₁ = W₂ for equilibrium condition, that’s how unknown weight determined by comparing with known mass.

- Some small variations occur due to buoyancy of air and temperature effect, but they are generally neglected for normal analytical work.

- It is a simple but very precise instrument, still used for teaching purpose to explain the mechanical principle of balance and concept of moment equilibrium.

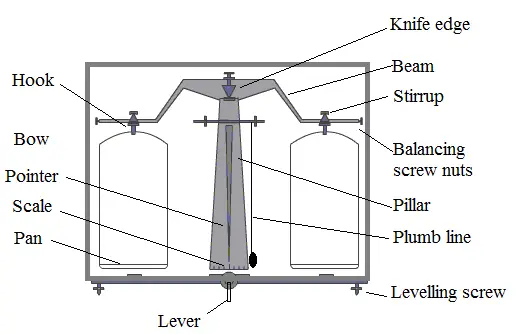

Parts of a Two pan or equal arm analytical balance

Beam – It is the main horizontal bar of the balance which carries two equal arms and supports the pans at its both ends. It made from rigid light metal to reduce air resistance and bending.

Pans – Two identical circular metal pans are suspended by stirrups from each arm of beam, one pan hold the substance and another hold the standard weights.

Knife-edges – There are three knife-edges, one at the center acts as fulcrum and two at the ends support the pans; these must be sharp and made of hard steel or agate for accuracy.

Central Pillar – It supports the beam by knife-edge, usually made of brass or alloy, fixed on base of the balance for stability.

Pointer – A thin metal pointer is attached vertically to the center of beam, it moves along a scale and show the deviation when beam tilt to any side.

Scale (Graduated Arc) – It placed behind the pointer for reading the movement of beam, equilibrium is indicated when pointer rests at zero mark.

Rider and Rider Hook – Small wire rider is used for measuring small fractions of weight by moving along graduated arm, and hook is provided to hold it.

Arrestment or Lifting Mechanism – This device used to raise beam from knife-edges when balance not in use, it help to prevail (prevent) damage or wearing.

Base – A strong and heavy base made of marble or metal to provide rigid support and prevent vibration during weighing.

Leveling Screws – Screws are fitted at the bottom for adjusting level of balance, spirit level is used to check proper alignment before operation.

Glass Enclosure – The whole balance kept inside transparent glass case which protect from air currents, dust and temperature variations.

Adjusting Screws – These are present at both ends of beam for fine adjustment and balancing of empty pans.

Support Frame – Frame hold all components in fixed position, ensuring equal arm distance and correct alignment for accurate measurement.

Spirit Level – Small glass tube partly filled with liquid and air bubble to indicate whether base surface is horizontal or tilted.

Weights Box – A separate box containing standard weights (1 mg to 100 g or more) used during weighing process etc.

How to Use Two pan or equal arm analytical balance?

- Before using the Two pan / Equal arm analytical balance, the instrument should placed on a firm table and leveled properly by adjusting the leveling screws till the bubble in spirit level stay at center.

- The balance must enclosed in its glass case, all doors kept closed during weighing to avoid air drift that can disturb pointer movement.

- Check that the pans are clean and dry, dust or moisture must removed by soft brush or clean tissue, else it affect accuracy of weighing.

- The beam is first arrested by using arresting knob, never should beam left free when adding or removing weights.

- Empty pans are balanced by adjusting the small screws or riders until pointer rests at the zero mark of scale when beam is released gently.

- The object or substance whose mass is to be measured placed on left pan, and the known standard weights from the weight box are placed on right pan.

- Always use forceps for handling weights, direct touching by hand avoided because moisture or oil from skin change actual mass.

- The beam is released carefully and pointer oscillation observed; if pointer move toward one side, weights are adjusted till beam become horizontal.

- Fine balancing done by adding small fractional weights or rider till the pointer comes exactly at zero mark after oscillations stop.

- After obtaining balance condition, total of all standard weights used is equal to mass of the object placed on other pan.

- Reading is recorded and beam again arrested immediately after weighing to prevail (prevent) damage of knife-edges.

- During whole operation, balance must not be touched or moved, vibration and air flow from fan or breath also avoided.

- When weighing of several samples required, each item should be placed only after removing previous one and ensuring zero adjustment again.

- After use, all weights are returned to proper places in box and balance kept arrested with glass doors closed.

- Regular cleaning and calibration must done by expert to maintain high precision and avoid cumulative errors etc.

Precautions Two pan or equal arm analytical balance

- The Two pan / Equal arm analytical balance should always placed on firm, vibration free table and properly leveled before starting weighing operation.

- Balance must kept inside glass enclosure during use, air current or dust particle can cause wrong reading by disturbing the beam movement.

- Both pans should checked that they are clean, dry and free from any chemicals or powders, contamination may change the real weight.

- The beam always arrested before placing or removing substance / weights, releasing when pans loaded can damage knife-edges permanently.

- All standard weights must handled by using forceps or tweezers, never by fingers because sweat or grease deposit make small but real error.

- Weighing should always done after closing glass doors to prevent movement of air or vibration inside the chamber.

- The balance must be adjusted to zero position before every use, pointer should rest exactly at middle mark when empty pans balanced.

- Heavy objects not weighed directly on the pan, they should placed in container or paper to avoid scratching or corrosion of pan surface.

- The weights are added and removed gently, and beam released slowly to avoid jerk that might prevail (prevent) permanent damage.

- Substances producing vapors, moisture or heat must not weighed directly, they will affect weight due to air convection and corrosion.

- The balance should never be shifted or rotated suddenly, delicate knife-edges and bearings are easily injured.

- Standard weights kept always in their respective places in box after use, and not left on pan unnecessarily.

- Any magnetized or charged material should not be weighed as they disturb equilibrium by magnetic field or static charge.

- The pointer oscillation should be small and steady, large vibration indicate unlevelled base or friction issue, which must corrected before reading.

- Always arrest the beam after every measurement and close the glass case properly when not in use.

- Regular cleaning and calibration are compulsory, dust on knife-edge, or unequal arms create systematic error.

- Do not speak or blow air near balance during weighing; even small air pressure can deflect pointer and affect precision.

- Avoid direct sunlight or heat near the balance, thermal expansion changes metal dimension and lead to false result etc.

Some common errors to avoid when using a two-pan or equal-arm analytical balance

- One common error is using the Two pan / Equal arm analytical balance without checking level; when base is tilted, equilibrium reading becomes false even though beam seems balanced.

- The beam sometimes released while adding or removing weights, this cause bending or wearing of knife-edge which affect accuracy permanently.

- Many users forget to clean pans before and after use, dust or residues left over time create small mass error that accumulate during repeated use.

- Touching the standard weights by bare fingers is wrong practice, sweat and oil add invisible film increasing their actual weight gradually.

- Keeping balance doors open during weighing allow air movement inside, this disturbs pointer and cause continuous oscillation so reading cannot be fixed correctly.

- Placing hot, moist or volatile samples directly on pan create buoyancy and convection current; also it damage pan surface or corrode metal parts.

- Using rough or heavy object directly on pan may scratch it or deform the supporting stirrup, hence light container or paper should always used.

- Ignoring zero adjustment before starting each weighing leads to systematic error, pointer must rest at central mark before any measurement.

- Balance sometimes handled roughly, shaking or shifting position while loaded will prevail (prevent) proper equilibrium and harm alignment.

- Allowing balance to stay unarrested after weighing is a major mistake, knife-edges wear off quickly when beam left swinging freely.

- Using uncalibrated or dirty weights from other set make whole result unreliable, only certified clean weights should used each time.

- Reading pointer while it still oscillating gives false measurement, it must allowed to stop or oscillate equally on both sides before reading taken.

- Balance kept near window, fan, sunlight or heat source experience temperature gradient that change metal expansion and disturb equal arm condition.

- Some users forget to replace weights properly after weighing, mixing different values in box lead to wrong combination in next experiment.

- Not maintaining glass enclosure clean and closed causes dust deposition on knife-edges, pointer friction increase, and balance become insensitive.

- Vibration from nearby equipment or even footsteps produce irregular pointer motion, balance should not placed near centrifuge, motor, etc.

- Failure to arrest beam during non-use and improper cleaning after each session are most repeated causes of long-term damage.

- Overloading balance beyond capacity bend arms slightly, even invisible bending results permanent error that cannot easily corrected.

- Using magnetized or electrically charged sample also wrong, they attract metallic parts and give false torque value.

- Ignoring periodic calibration or maintenance inspection results in cumulative instrumental error which spoil precision completely.

Factors that can affect the accuracy of a two-pan analytical balance

Temperature – Sudden change in room temperature cause expansion or contraction of beam and arms, due to which equality of arms get disturbed.

Air Currents – Movement of air inside glass case or from fan, window etc., produce oscillation of beam and pointer, disturbing true balance point.

Humidity – High humidity cause corrosion or moisture absorption by weights or sample, hence measured mass become higher than real value.

Vibration – External vibration from table, footsteps or nearby machines affect stability of balance and make pointer move irregularly.

Dust and Dirt – Small dust particle accumulated on knife-edges or pans increase friction, it reduce sensitivity and accuracy.

Level of Balance – Improper leveling by screws cause unequal torque on both sides even when weights are same, so reading appears wrong.

Condition of Knife-edges – Blunt or worn knife-edges increase friction at pivot point, result in sluggish movement and false equilibrium position.

Improper Handling – Jerky movement of beam, or touching weights with hand add oils / moisture and change actual mass.

Static Electricity – Electrically charged sample or container attract dust or repels pan surface, that lead to unstable readings.

Buoyancy Effect – Difference in air density with temperature or pressure change cause small but real variation in apparent weight.

Unequal Arms – Small mechanical defects during manufacturing or bending due to overloading alter equality of arms, giving systematic error.

Magnetic Fields – Weighing of magnetic materials near iron components of balance disturb balance position due to attraction / repulsion forces.

Uncalibrated Weights – Using old or unverified standard weights directly cause error as their actual mass may deviate from nominal value.

Operator’s Technique – Reading pointer before oscillation stops or parallax error in observation lead to incorrect result.

Air Buoyancy Correction – Neglecting buoyancy correction in very precise work especially for large objects lead to small measurable error.

Improper Maintenance – Lack of regular cleaning, lubrication, or calibration cause slow, unequal response of beam and systematic deviation.

Exposure to Sunlight – Direct sunlight fall on balance heat one side more, that create unequal expansion and torque imbalance.

Overloading – Placing excess mass beyond designed capacity bend the beam slightly and permanently damage sensitivity.

Contaminated Pans – Residual chemicals or moisture left on pans alter weight of sample placed, producing small bias in measurement.

Neglect of Zero Adjustment – Failing to set pointer exactly at zero before weighing always introduce constant offset error in each reading.

How do you calibrate a two-pan or equal-arm analytical balance?

- The two-pan analytical balance is usually calibrated to ensure both arms of the beam are equal and that both pans give identical readings when equal weights are placed.

- Before calibration, the balance must be placed on a flat and stable surface, free from vibration and air currents etc.

- The pointer of the beam should first be checked when both pans are empty, it should rest exactly at the center mark, if not, the zero adjustment screw is turned until it does.

- After that, equal standard weights are placed on both pans, for checking whether the beam remain horizontal or not. If beam tilt toward one side then arms are not equal length or unequal friction at knife-edges.

- For balancing, the rider or adjusting screws at the beam ends are used to correct the inequality until the pointer again comes to zero when equal weights are on both sides.

- Sometimes, small lead shots or metal chips are added to the lighter pan side to equalize both arms, this method is called trimming.

- The calibration must be done carefully by using certified standard weights which already standardized by metrological authority, otherwise wrong calibration occur.

- After equal-arm adjustment, the ratio arm check is done by interchanging the weights between the pans, the reading should remain same if balance is properly calibrated.

- If a difference observed after interchanging, then small correction again made until both positions give same indication.

- The beam arrest knob must always be used during weight placing or removing to avoid damage of knife-edges, many students forget that and it affect calibration accuracy later.

- Calibration usually repeated 2–3 times for confirm stability, because temperature and air humidity can also affect metal beam expansion slightly.

- In some laboratory the calibration is verified daily before starting weighing operations, while complete mechanical calibration done after long usage or repair.

- Any dust, oil or residue from previous samples should removed from pans using soft brush (not hand), otherwise mass error happen.

- The pans must be checked for equality by placing a known standard on one side and adjusting counterpoise on other until balance come to rest at zero position.

- When the two-pan balance calibrated properly, both arms have equal torque, and readings become accurate for unknown mass determination by substitution method.

- Improper calibration may cause systematic error in all future measurements, so this procedure is very crucial in analytical chemistry work.

- Regular calibration record must be maintained with date/time, balance ID, and standard weights used for traceability purpose (many labs keep it in logbook).

- So, calibration of equal-arm balance basically involve checking zero error, arm equality, pan equivalence, and ratio test by substitution of weights / loads etc., ensuring it provide true mass measurement every time.

Uses of Two pan or equal arm analytical balance

- The two-pan analytical balance is primarily used for direct comparison of masses, where sample mass and standard mass are placed on opposite pans and equality is sought.

- Standard solutions preparation is often done by using this balance, accurate amounts of solute are weighed (g) and transferred for molarity / normality calculations.

- Gravimetric determinations are frequently performed, the weight of precipitate or crucible is measured and recorded for mass percent, assay and calculations.

- The instrument is used in pharmaceutical labs for small quantity weighing, active ingredients are measured precisely for formulation and assay, quality checks are done.

- In teaching labs the principle of moments and equilibrium is demonstrated, students are shown torque, fulcrum and beam action, they learn by hands-on.

- Calibration of other weights and balances is sometimes carried out by this balance, standard masses are compared and verification of 1 g, 10 g, 100 g etc. is performed.

- The balance is employed for density determination of solids, mass in air and mass in liquid are compared to find specific gravity (such as, water immersion method).

- Quality control checks are performed by it, sample uniformity, tablet weight variation, and packing weight verification are done in many industries.

- Where electricity is absent or unreliable, the equal-arm balance is preferred, because it is mechanical and sturdy, it will work without power.

- Inter-comparison by metrology labs is done with two-pan balances, traceability of mass standards is established and they are certified by comparison.

- Small corrections or trimming are performed on the beam to achieve equality, this balance is used when micro-adjustments and microgram sensitivity are required.

- In research experiments of physics and chemistry, direct comparative measurements are preferred, unknowns are weighed against standards for accuracy.

- The instrument is utilized for reagent weighing before titrations, exact reagent mass is required for stoichiometric calculations and precise end-point determination.

- Educational demonstration of error sources is given by using this balance, effects of air currents, temperature, and friction at knife-edges are shown.

- The equal-arm balance is used for sample substitution method, where unknown mass is obtained by replacing standard weights — the method is simple and reliable.

- Routine verification and daily check are often performed by lab personnel, logbook entries are maintained for traceability and audit purposes.

Advantages of Two pan or equal arm analytical balance

- The two-pan analytical balance provide very high accuracy in weighing because both arms of beam are equal and it work on simple mechanical principle of equilibrium.

- It not depend on electronic circuit or power, so it’s reliable and can used anywhere, even in field or laboratory without electricity.

- The balance design is sturdy and hardy, it can last for long period with minimal maintenance or repair need.

- Since both pans are compared directly, the error due to unequal torque or mechanical drift are automatically compensated by beam equilibrium.

- Equal arm system eliminate systematic error caused by unequal sensitivity of beam sides, because mass comparison is done simultaneously.

- It allow direct substitution method of weighing, giving precise measurement for unknown mass by comparing with standard weight.

- The knife-edges and agate bearing arrangement minimize friction, providing smooth oscillation and high sensitivity to very small mass differences.

- Calibration of balance is easier because zero adjustment and arm equality can checked manually without external instrument.

- Mechanical two-pan balance not affected by electromagnetic interference or vibration like digital ones, hence more stable under certain conditions.

- It is simple to understand and operate, so very suitable for students’ practical learning about mass measurement principles.

- It gives consistent results for multiple trials since beam equilibrium principle is independent of gravity variations within same place.

- The cost is relatively lower compared with modern analytical balances, but still it offer excellent precision in mass determination.

- Because of equal arm design, any change in air buoyancy or temperature affects both pans equally, reducing influence of environmental error.

- The visual pointer movement gives instant feedback to operator about small mass differences, allowing precise manual control.

- It can used for calibration of weights, density determinations, gravimetric analysis and educational demonstrations etc.

- Maintenance of two-pan balance is simple—cleaning, leveling and occasional lubrication of bearings are sufficient for accurate working.

- The instrument is independent of electrical failure or data corruption, making it very dependable in long-term laboratory usage.

- So, the main advantages of equal arm analytical balance lie in its accuracy, durability, simplicity and independence from power source, making it still valuable tool for precise mass measurement.

Disadvantages of Two pan or equal arm analytical balance

- The two-pan analytical balance are slow for routine weighing, because substitution of weights is required each time, and the process is time-consuming.

- Very small quantities (milligram or sub-mg) are often not measured reliably, since knife-edges and beam friction limit sensitivity and tiny differences are masked.

- Operator skill is heavily relied, parallax and human judgement errors are introduced when pointer is read, so consistency suffers.

- Sensitivity is reduced by dust, oil or rust on pivots, and frequent cleaning / maintenance is demanded, otherwise accuracy will drift.

- Leveling and alignment must be checked every use, if not, unequal arm error are produced and results become biased.

- The instrument occupy larger bench area because of long beam and two pans, so it is not suitable for cramped or micro-lab benches.

- No tare or direct digital readout is offered, therefore multiple samples or sequential weighing are inconvenient, data logging is manual.

- Mechanical wear of pivots/ bearings happen over time, knife-edges are blunted, and recalibration / repair are required more often than with electronic balances.

- Temperature/humidity changes slightly alter beam length and metal properties, minute mass errors are caused and they may prevail the measurement if unattended.

- Vibration and air currents disturb equilibrium easily, so draught shields and stable table are demanded, field use is limited unless precautions are taken.

- Training is required for proper use, inexperienced users may mishandle arrest knob or overload pans, permanent damage can arise.

- For ultra-sensitive gravimetric analysis, modern analytical balances are preferred, because two-pan types lack speed and microgram sensitivity.

- Connectivity with computers or printers is absent, so digital records, automatic averaging, or statistical output cannot be obtained directly.

- Repeated placing/removing of standard weights increases chance of contamination of pans (samples, residues), cross-contamination risk is higher.

- When heavy samples are mistakenly placed, bending of beam or pivot deformation occur, accuracy is then severely compromised.

- Calibration and verification are manual and somewhat tedious, traceability is possible but time-consuming, audits require more effort.

FAQ

What is a two-pan or equal arm analytical balance?

A two-pan or equal-arm analytical balance is a type of weighing instrument used in laboratories and other settings that require precise measurements. It consists of a central beam supported by a fulcrum, with two pans suspended from each end of the beam. The pans are used to hold the object being weighed and the counterweights, respectively.

How does a two-pan or equal-arm analytical balance work?

The balance operates on the principle of comparing the weights of two objects. The object to be weighed is placed on one pan, while counterweights are added to the other pan until equilibrium is achieved, resulting in a balanced beam. The weights on the counterpan are adjusted to match the weight of the object, indicating the object’s weight.

What are the advantages of a two-pan or equal-arm analytical balance?

The advantages of a two-pan or equal-arm analytical balance include:

High accuracy: These balances can provide precise measurements up to four decimal places.

Stability: The weight of the object being weighed is evenly distributed across two pans, ensuring stability even for small or delicate objects.

Ease of use: They have a relatively straightforward design and are user-friendly, often accompanied by clear instructions.

Durability: These balances are constructed with high-quality materials, ensuring durability and long-term use.

Affordability: Compared to other high-accuracy balances, two-pan analytical balances are relatively affordable, making them suitable for facilities with budget constraints.

Sensitivity: They can detect even small changes in weight, making them suitable for measuring tiny amounts of materials.

What are the disadvantages of a two-pan or equal-arm analytical balance?

The disadvantages of a two-pan or equal-arm analytical balance include:

Slow weighing speed: Balancing the pans manually can be time-consuming, especially for complex or large weighing tasks.

Limited weight capacity: These balances typically have a limited capacity, making them unsuitable for weighing large or heavy objects.

Susceptibility to environmental factors: Factors like temperature, humidity, and air currents can affect the accuracy of readings.

Sensitive to vibrations: Vibrations can disturb the balance, resulting in inaccurate measurements.

Calibration requirements: Regular calibration is necessary to maintain accuracy, which can be time-consuming and costly.

Lack of portability: They are typically fixed in a specific location and not easily transported.

Specialized training: Proper operation requires specialized training, which can be a barrier for inexperienced users.

What is the accuracy of a two-pan or equal-arm analytical balance?

Two-pan or equal-arm analytical balances can typically provide accuracy up to four decimal places, depending on the specific model and quality of the balance. This level of accuracy allows for precise measurements in laboratory and analytical applications.

How do you calibrate a two-pan or equal-arm analytical balance?

To calibrate a two-pan or equal-arm analytical balance, a set of calibrated weights is used. The balance is first balanced with no weights on either pan. Then, the calibrated weights are placed on one pan, while the appropriate counterweights are added to the other pan to achieve equilibrium. The process is repeated with different weight combinations to ensure accurate and consistent measurements.

How do you use a two-pan or equal-arm analytical balance?

To use a two-pan or equal-arm analytical balance, follow these steps:

Ensure the balance is clean and free from any debris or substances that could affect the weighing.

Place the object to be weighed on one pan.

Begin adding counterweights to the other pan until the beam is balanced and the pointer is at zero on the scale.

Read and record the weight indicated by the counterweights.

Remove the object from the pan.

Clean and reset the balance before the next weighing.

What are the safety precautions to take when using a two-pan or equal-arm analytical balance?

When using a two-pan or equal-arm analytical balance, consider the following safety precautions:

Handle weights with care to avoid injury. They can be heavy, and dropping them can cause harm.

Be cautious when adjusting the balance or adding/removing weights to prevent damage or breakage.

Avoid excessive force when operating the balance to prevent misalignment or mishandling.

Ensure the balance is placed on a stable surface to minimize vibrations that can affect measurements.

Follow any specific safety guidelines provided by the manufacturer or your organization.

What are the common errors to avoid when using a two-pan or equal-arm analytical balance?

To ensure accurate measurements and reliable results, it is important to avoid the following common errors when using a two-pan or equal-arm analytical balance:

Overloading the balance by placing an object that exceeds its weight capacity.

Not properly cleaning the balance between weighings, which can lead to contamination and inaccurate results.

Ignoring the effects of environmental factors such as temperature, humidity, and air currents on the balance’s performance.

Failing to calibrate the balance regularly, resulting in inaccurate measurements.

Mishandling or dropping the weights, which can affect their accuracy and potentially cause injury.

Not properly training users on the correct operation and maintenance of the balance, leading to errors in weighing procedures.

What are the uses of a two-pan or equal-arm analytical balance?

Two-pan or equal-arm analytical balances are used in various applications that require precise measurements, such as:

Scientific research: They are commonly used in laboratories for weighing chemicals, reagents, or samples.

Pharmaceutical manufacturing: They play a crucial role in accurately measuring ingredients for drug formulation.

Quality control and assurance: These balances are utilized in industries to ensure the consistency and accuracy of products.

Analytical chemistry: They are used to measure precise amounts of substances for chemical analyses and experiments.

Educational settings: Two-pan analytical balances are often used in teaching environments, allowing students to learn weighing techniques and principles.

Jewelry and precious metals: These balances are employed to determine the weight and purity of jewelry or precious metal samples.

- Text Highlighting: Select any text in the post content to highlight it

- Text Annotation: Select text and add comments with annotations

- Comment Management: Edit or delete your own comments

- Highlight Management: Remove your own highlights

How to use: Simply select any text in the post content above, and you'll see annotation options. Login here or create an account to get started.