What is Solid State Fermentation (SSF)?

- Solid State Fermentation (SSF) refers as a process where microorganisms grow on solid materials in absence or very low moisture level.

- It mainly used for cultivation of fungi, actinomycetes and few bacteria species that prefer solid substrates.

- In SSF, the substrate (like wheat bran, rice husk, sugarcane bagasse etc.) act both as nutrient source and physical support.

- The moisture content usually maintained between 12–80%, but it depend by type of microorganism and substrate used.

- SSF is mostly applied for production of enzymes (like cellulase, amylase, protease), organic acids, pigments and bioactive compounds.

- Aeration and temperature control are crucial factors since heat and CO₂ generation occur during microbial metabolism.

- The process can define as eco-friendly and cost-effective technique compared to submerged fermentation (SmF).

- Fermentation take place in trays, columns or rotating drum bioreactors depending by scale and type of operation.

- The microorganisms used in SSF are mostly Aspergillus niger, Rhizopus oligosporus, Penicillium chrysogenum, etc.

- It provide higher product yield and stability because product concentration is higher and dilution is minimum.

- However, the process control is difficult due to uneven distribution of temperature, pH, and oxygen in solid mass.

- Such as, for enzyme industries SSF is more preferred because enzyme stability remain high and extraction is easier.

- It is also used by bioethanol production, composting, and bioconversion of agro-waste materials.

- Substrates are usually agricultural residues that are cheap and abundant, making process sturdy and hardy.

- The metabolism during SSF is mostly aerobic though in some cases partial anaerobic zones may develop, it affect yield.

- It has advantage of low wastewater generation which prevail the need of complex effluent treatment.

- For better productivity, parameters like particle size, moisture level, incubation time and inoculum density must be optimized.

- In comparison, SmF require large volume of water and high energy for agitation while SSF saves that energy significantly.

- The solid matrix provide surface area for growth, and they (microbes) adhere forming a dense mycelial network.

Definition of solid state fermentation

Solid State Fermentation (SSF) is a fermentation method that involves the growth of microorganisms on solid support, such as grain brans or oil seed cakes, without a free-flowing aqueous phase. It is used in various industries to produce valuable metabolites, including antibiotics, enzymes, and biofuels, among others.

Substrates are used for Solid State Fermentation (SSF)

- The substrate in SSF is described as the solid material on/with which microorganisms grow, providing nutrients and physical support.

- Agricultural-residues are commonly used as substrates (like cereal bran, rice husk, sugarcane bagasse) because they are cheap and abundant.

- Lignocellulosic materials are frequently selected because they contain fibres (cellulose, hemicellulose, lignin) that certain microbes (especially fungi) can degrade, they (substrates) work both as carbon source & support.

- Fruit and vegetable waste (peels, discards) have been used as substrate for SSF, they are processed and fermented to improve nutritive value (in animal feed context) or to produce bioactive compounds.

- Substrate properties (particle size, bulk density, porosity, moisture holding capacity) strongly influence SSF performance (heat transfer, oxygen diffusion, growth of microbe) so selection of substrate is not only about nutrient but also about physical / support properties.

- Some support materials (inert though) may be used with added nutrients so that substrate acts primarily as physical matrix rather than major nutrient source, for specialized SSF applications.

- Pre-treatment of substrates (like milling to reduce particle size, adjusting moisture, removing inhibitors) is often done so that microbial growth is enhanced.

- The substrate must permit low free-water phase (absence or near absence of free flowing liquid) because that is characteristic for SSF (growth on moist solid rather than submerged liquid).

- Cost-effectiveness is a major driver for substrate choice: using waste/by-products from agro-industry reduces cost of raw materials and helps sustainability.

- The same substrate often serves multiple roles: nutrient source, growth surface, and physical matrix.

- For enzyme production by SSF, substrates like wheat bran, rice bran, soya bean hulls have been reported (though I’m summarizing, the exact list is more extensive)

- Substrate selection must consider downstream product extraction: some substrates complicate product recovery if they bind or trap the product, so trade-offs exist.

Features of Solid Substrate Fermentation

- It is characterized by growth of microorganisms on solid materials where free-flowing water is absent or very low, which helps mimic their natural habitat.

- The substrate acts both as a nutrient source and a physical support, and the culture occurs at interface of solid/gas phases rather than liquid phase.

- Typically the moisture content is much lower (for example ~20-70% or lower) compared to submerged fermentation, which allows better oxygen penetration and avoids free water pooling.

- Oxygen diffusion and heat removal are important features since microorganisms are mostly aerobic and heat builds up in the packed solid matrix; thus aeration and temperature control are essential.

- A high surface area to volume of substrate is often required so that microbes contact the solid particles effectively, this allows good colonisation of the substrate by the microbe.

- It is considered more cost‐effective (lower energy, less water, less effluent) because less water means less heating/cooling and less effluent treatment.

- The process is often heterogeneous (solid, liquid film, gas phases together) rather than uniform liquid phase; this heterogeneity influences microbial behaviour and process control.

- The solid substrate matrix must allow good aeration and be able to hold moisture (in absorbed state) yet permit gas phase between particles; otherwise oxygen supply or heat removal get impaired.

- Dense microbial mats or mycelial growths are common, especially when filamentous fungi are used, which helps colonisation but may also hinder mass transfer if not well managed.

- Process scale-up is challenging because heat and mass transfer limitations become more severe at larger size; substrate packing density, particle size, porosity matter a lot.

- Product concentration tends to be higher because less dilution from liquid, and downstream separation may be simpler for some products.

- Because of low free water, contamination risk is sometimes lower but monitoring and control (moisture, O₂, CO₂) become more difficult compared to submerged systems.

Organisms Used in Solid State Fermentation (SSF)

- In SSF, mostly filamentous fungi are used because they adapt well to moist solid substrates without free water.

- For example, Aspergillus niger (A. niger) often used for citric acid production by SSF.

- It has been reported that Rhizopus oligosporus (R. oligosporus) is used for enzyme production in SSF (phytase etc.).

- Yeasts and bacteria also can be used, though less commonly, for certain SSF applications.

- For bacteria, strains like Bacillus species for enzyme production have been applied in SSF.

- The selection of organism is influenced by its ability to grow with low moisture, good oxygen penetration, and strong colonising of solid substrate.

- Some fungi species can degrade lignocellulosic substrate and they give high yields in SSF because they mimic their natural habitat.

- It is known that when species are used they (the microbes) must handle heat evolution and CO₂ build-up in solid matrix, so organism robustness matters.

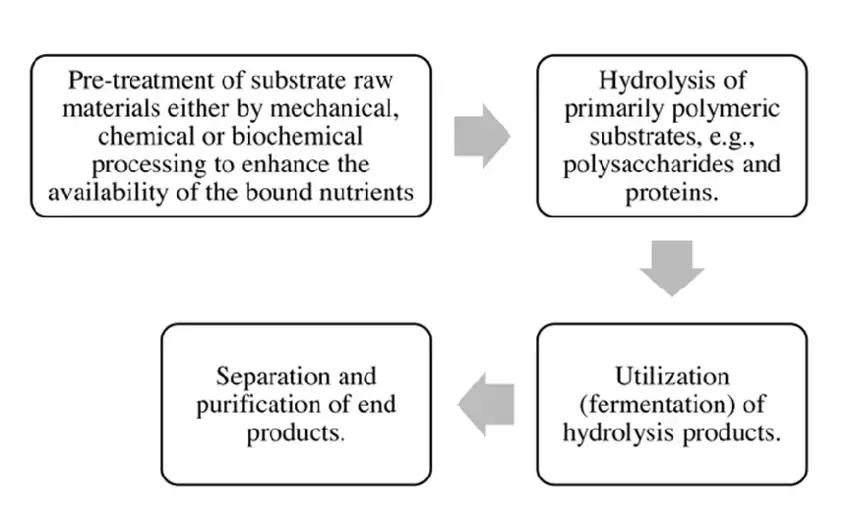

Solid State Fermentation (SSF) Steps

SSF is usually a multistep process comprising those steps as follows:

Solid State Fermentation (SSF) typically involves multiple steps to achieve the desired product:

- Substrate preparation is done first, where solid material (for example agro-industrial residue) is pre-treated (mechanical, chemical or biochemical) to improve nutrient availability and surface area.

- Inoculum preparation follows where selected microorganism culture is grown (or spores are formed) and then introduced into substrate.

- Inoculation of substrate with the microorganism is done, the substrate is seeded and mixed (if needed) so microbe colonisation will occur.

- Incubation or fermentation happens under controlled conditions (temperature, humidity, aeration) where the microbes grow on the solid matrix and produce desired product.

- Monitoring of process parameters like moisture content, oxygen / CO₂ levels, heat build-up, pH are done though control may be difficult because of heterogeneity of solid medium.

- Product recovery / extraction is done after fermentation is complete, the product is separated & purified from substrate (or substrate itself may be final product in some cases).

- Downstream processing (if needed) is conducted where the harvested material is processed further (filtration / centrifugation / drying) to obtain the final form.

- Cleanup and substrate disposal or reuse is done, sometimes the residual solid may be used for feed, composting etc though this is often overlooked in simple summaries.

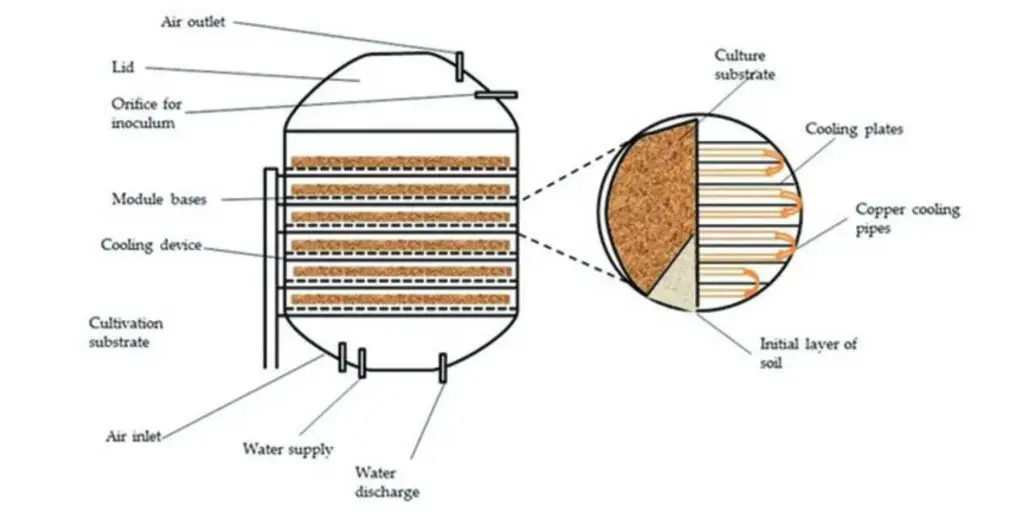

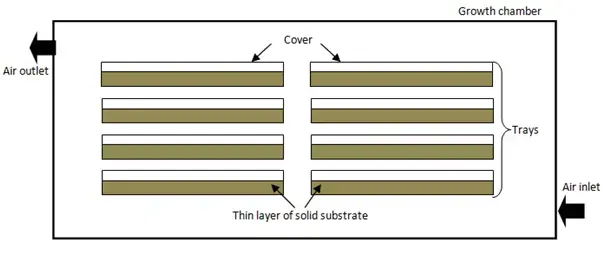

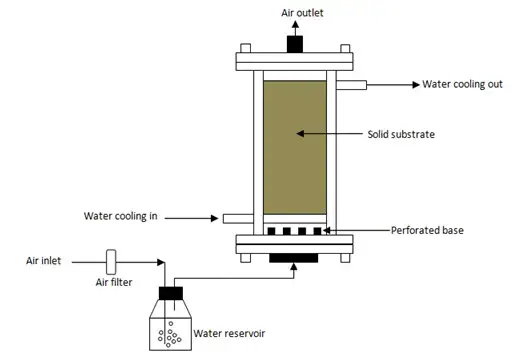

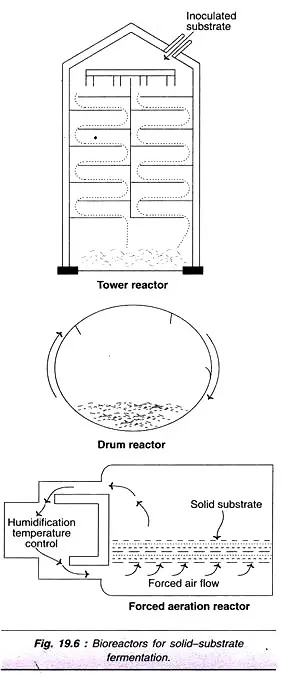

Types of Solid state bioreactors

1. Tray bioreactors – The substrate is laid out in thin layers on trays (or sometimes stacks of trays) and the microorganisms are allowed to grow with minimal mixing, which makes the design simple and cost-effective, though heat build-up is a problem.

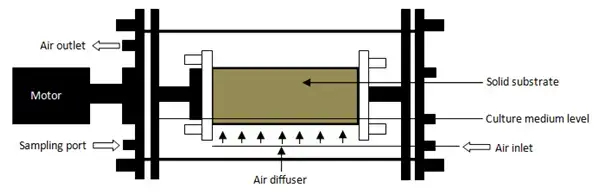

2. Packed‐bed bioreactors – The solid substrate is packed into a bed (column or vessel) and aeration (bottom to top) or some forced air is provided, and heat/oxygen transfer are improved relative to static trays.

3. Rotary drum bioreactors (or rotating‐drum systems) – The vessel is a drum (horizontal or slightly inclined) which is rotated or tumbled to mix the substrate and enhance heat/mass transfer, and the design is used for larger scale SSF.

4. Stirring drum / stirred bed systems– The substrate bed is stirred (or the drum has internal mixing) so the substrate is more evenly distributed, this helps avoid dead-zones and uneven growth though shear may harm the microbe.

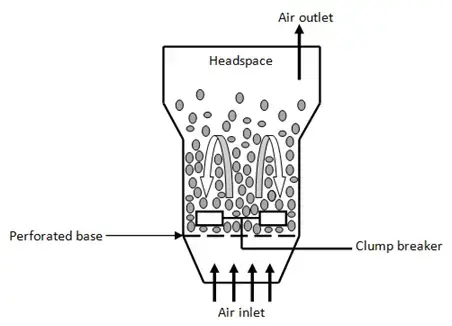

5. as‐solid fluidised bed bioreactors – The solid particles are partially fluidised (suspended) by a gas flow (air) to improve mixing, oxygen supply and heat removal, this is more complex but gives better mass/heat transfer.

6. Disk‐type or tray‐stacked systems (static)– A variant of tray systems where multiple trays or disks are stacked, air flows between them but no or very little mechanical mixing is used, simple yet limited by heat diffusion.

Applications of Solid State Fermentation (SSF)

- In the food industry the process is used for production of enzymes, organic acids, natural flavours and aroma compounds by SSF on solid substrates.

- Agro-industrial wastes are valorised by SSF to give value-added products such as bioactive compounds, pigments, antioxidants which otherwise would be wasted.

- SSF has been applied for production of biofuels (like bioethanol, biodiesel, biohydrogen) from solid residues by microorganisms growing on low-moisture substrate.

- In the pharmaceutical and chemical industries SSF is used to make antibiotics, secondary metabolites, and bio-surfactants by solid substrate cultivation of microbes.

- For animal feed and nutrition the method is used to enhance protein content and digestibility of feed-stocks by microbial action on solid residues (substrate modification) which improves nutritional value.

- SSF is used in environmental applications like bioremediation, or waste treatment, by using microorganisms on solid wastes or polluted soils to degrade toxins or convert wastes.

- In agriculture the technology is used (or has potential) for production of biopesticides, biostimulants, microbial biomass on solid substrate for application in soil and plant health.

- In textile/paper/detergent industries the enzymes produced by SSF (like cellulases, xylanases, proteases) are applied for processing fibres, bleaching, detergent formulation etc.

Advantages of Solid State Fermentation (SSF)

- A major advantage is that low water activity is required, so waste-water generation is much less compared to submerged fermentation.

- Energy usage is reduced because less mechanical agitation and less large volumes of liquid are needed, making the process more cost-effective and less energy intensive.

- Cheap / abundant substrates (especially agro-industrial residues) can be used, turning waste into value and reducing raw material costs.

- Higher product concentration and higher volumetric productivity are often achieved because dilution by liquid is minimal and microbes act in more concentrated environment.

- The process often resembles natural habitat of filamentous fungi (many used microbes grow naturally on solids), which improves growth/production for those organisms.

- Down-stream processing is simpler because product is more concentrated and less liquid means less volume to handle, purification sometimes easier.

- Capital investment / operational cost is lower because simpler vessels, less need for intense sterilization, less water treatment, simpler design.

- Environmental footprint is smaller: less water, less effluent, use of waste substrates, less chemical input, so more sustainable and hardy from viewpoint of waste-management etc.

Limitations of Solid State Fermentation (SSF)

- Precise monitoring of parameters like moisture content, oxygen (O₂) / carbon-dioxide (CO₂) levels and pH is very difficult because the solid substrate is heterogeneous and gradients are formed.

- Scale-up of the SSF process is problematic because heat build-up, mass/oxygen transfer limitations and moisture gradients become more severe when volume increases.

- Only those microorganisms which tolerate low free-water / low moisture conditions can be used effectively, so microbial choice is limited.

- Heat dissipation is a major issue and excess heat can kill or inhibit the culture, and they (microbes) might suffer in the deeper parts of the substrate due to poor air circulation.

- The substrate-matrix often is solid and insoluble and complex, therefore nutrient accessibility and uniform microbial growth may be impaired, which reduces reproducibility / standardisation.

- Down-stream processing may be more complex when product is bound to or trapped in solid particles, or when extraction from the solid phase is required.

- The capital / engineering demands for designing solid-state bioreactors with proper aeration, temperature control, compact substrate layering are higher than often assumed, especially for industrial scale.

- Contamination control may still be tricky; though low water activity reduces some risks, irregular zones in the solid may allow unwanted microbes to flourish, so process control is harder.

FAQ

What is Solid State Fermentation (SSF)?

Solid State Fermentation (SSF) is a biotechnological process in which microorganisms grow and metabolize on solid substrates with minimal or no free water. It is a fermentation process that occurs in the absence or near-absence of liquid medium.

How does SSF differ from Liquid State Fermentation (LSF)?

In SSF, microorganisms grow on solid substrates with low moisture content, while in LSF, microorganisms grow in a liquid medium. SSF typically utilizes solid materials such as grains, bran, or sawdust as substrates, while LSF uses liquid media like broth or solution.

What are the advantages of SSF over LSF?

SSF has several advantages over LSF, including the production of less waste and liquid effluent, lower energy expenditure, lower capital investment, reduced microbial contamination, and simplified downstream processing. SSF also allows for the utilization of agro-industrial residues, making it an environmentally friendly and cost-effective process.

What are the main applications of SSF?

SSF finds applications in various industries for the production of microbial products such as feed, fuel, food, industrial chemicals, and pharmaceutical products. It is commonly used for the production of enzymes, organic acids, flavoring compounds, fermented foods (e.g., cheese, soy sauce), and bioprocesses like bioleaching and bioremediation.

Which microorganisms are used in SSF?

SSF can utilize different microorganisms depending on the specific application. Fungi, including molds and yeasts, are commonly used in SSF due to their ability to grow on solid substrates with low moisture. Bacteria can also be used in SSF, although they generally require higher moisture levels for efficient fermentation.

What are the steps involved in SSF?

SSF typically involves pre-treatment of substrate raw materials, hydrolysis of polymeric substrates, utilization (fermentation) of hydrolysis products, and separation/purification of end products. These steps may vary depending on the specific process and product being produced.

What are the challenges in SSF?

SSF poses challenges in terms of monitoring and control of parameters like oxygen levels, moisture content, and pH gradients due to the heterogeneity of the culture. The slow growth of microorganisms in SSF can also limit product formation. Additionally, regulating heat production and maintaining optimal growth conditions can be difficult in SSF.

What are the types of solid state bioreactors used in SSF?

Solid state bioreactors used in SSF can be classified into different groups based on their aeration and mixing characteristics. These include tray bioreactors, packed-bed bioreactors, rotating drum bioreactors, and fluidized-bed bioreactors.

Can SSF utilize waste materials as substrates?

Yes, one of the advantages of SSF is its ability to utilize various agro-industrial and food waste materials as substrates. This provides an alternative avenue for the utilization and value-addition of otherwise underutilized or non-utilized residues.

Is SSF economically feasible?

SSF has proven to be economically feasible due to its lower energy and capital investment requirements, utilization of inexpensive substrates, and simplified downstream processing. The cost-effectiveness of SSF depends on the specific application and the market value of the end products.

- Jai S Ghosh (2016) Solid State Fermentation and Food Processing: A Short Review. J Nutr Food Sci 6: 453. doi: 10.4172/2155-9600.1000453

- Ashok Pandey (2003). Solid-state fermentation. , 13(2-3), 81–84. doi:10.1016/s1369-703x(02)00121-3

- Manan MA, Webb C. Design aspects of solid state fermentation as applied to microbial bioprocessing. J Appl Biotechnol Bioeng. 2017;4(1):511-532. DOI: 10.15406/jabb.2017.04.00094

- https://www.biologydiscussion.com/notes/short-notes-on-solid-substrate-fermentation/10044

- https://www.researchgate.net/figure/Steps-involved-in-solid-state-fermentation-process_fig1_337824396

- https://edepot.wur.nl/200086