What is Single Cell Protein(SCP)?

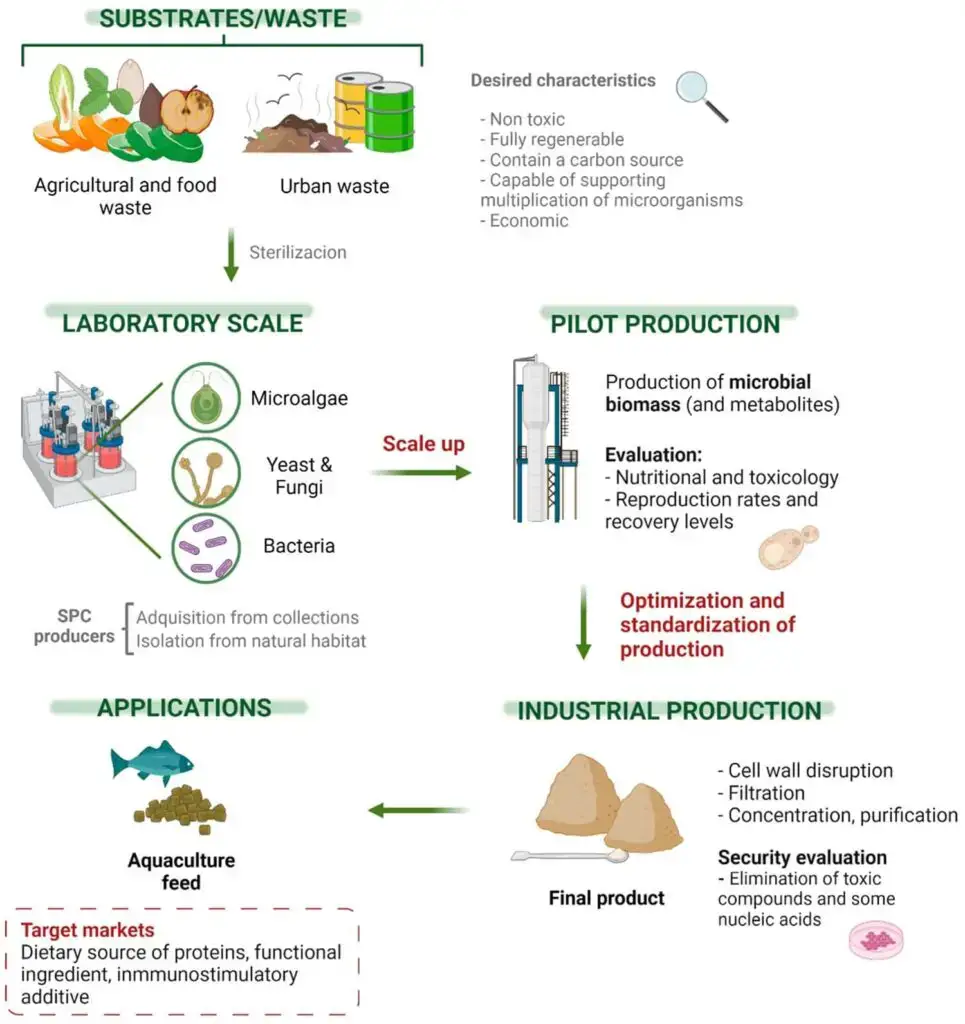

- Single Cell Protein (SCP), also known as microbial protein, refers to the edible proteins derived from unicellular microorganisms. These microorganisms can include algae, yeasts, fungi, and bacteria. SCP can be used as an ingredient or substitute for protein-rich foods, suitable for both human consumption and animal feeds.

- Traditional industrial agriculture is associated with various environmental issues such as high water usage, extensive land requirements, biodiversity destruction, and greenhouse gas emissions. In contrast, SCP production offers a more sustainable alternative. While current SCP production often relies on agricultural waste products, it can also be produced independently through autotrophic growth.

- Autotrophic SCP production takes advantage of the diverse microbial metabolism, providing different modes of growth and efficient nutrient recycling. Compared to conventional crops, autotrophic SCP production offers higher efficiency and significantly reduced land usage. In fact, a 2021 study demonstrated that photovoltaic-driven microbial protein production could require 10 times less land compared to soybean cultivation while providing an equivalent amount of protein.

- With the global population projected to reach 9 billion by 2050, there are concerns about the ability of traditional agriculture to meet the growing demand for food. Autotrophic SCP represents a fail-safe option for mass food production, capable of reliably producing food even under harsh climate conditions.

- Microorganisms like algae, fungi, yeast, and bacteria have a high protein content in their biomass. These microorganisms can be cultivated using inexpensive substrates such as agricultural waste and even human and animal waste. By utilizing the carbon and nitrogen present in these materials, microorganisms convert them into high-quality proteins that can supplement both human and animal feed.

- Single-cell proteins can be used as a protein supplement for various purposes, including fattening of livestock such as calves and pigs, breeding fish, and in poultry and cattle farming. SCP offers a viable solution to address protein deficiencies and meet the nutritional needs of the global population.

- The protein derived from single-cell protein sources contains essential nutrients such as vitamins (e.g., thiamine, riboflavin, pyridoxine, folic acid), essential amino acids (e.g., lysine, methionine), minerals, nucleic acids, and lipids. These microorganisms used for SCP production must possess certain desirable properties, including the absence of pathogenicity and toxicity, high protein content and quality, digestibility, favorable organoleptic qualities, rapid growth rate, adaptability to varying environmental conditions, and the ability to utilize carbon and nitrogen sources effectively.

- In summary, Single Cell Protein (SCP) offers a sustainable solution to address protein deficiencies and meet the growing demand for food. By utilizing microorganisms and their protein-rich biomass, SCP production provides an alternative to traditional agriculture, reducing land usage and environmental impacts. With its potential for autotrophic growth and versatile nutrient recycling, SCP represents a promising approach for mass food production, especially in challenging climate conditions.

Definition of Single Cell Protein(SCP)

Single Cell Protein (SCP) refers to edible proteins derived from unicellular microorganisms such as algae, yeasts, fungi, or bacteria. It can be used as a protein supplement in human or animal diets and is produced through the cultivation and processing of these microorganisms, which convert carbon and nitrogen sources into high-quality proteins. SCP offers a sustainable alternative to traditional agriculture and can help address protein deficiencies and food shortages.

History of Single Cell Protein (SCP)

The history of Single Cell Protein (SCP) dates back to the late 18th century when processes for preparing concentrated forms of yeast were established. In the early 20th century, Max Delbrück and his colleagues recognized the value of surplus brewer’s yeast as an animal feed supplement. During World War I and World War II, yeast-based SCP was extensively used in Germany to address food shortages.

In 1919, advancements in SCP production were made when inventors in Denmark and Germany developed the “Zulaufverfahren” (fed-batch) method, where a continuous supply of sugar solution was fed to aerated yeast suspension instead of adding yeast to a diluted sugar solution in batches. This invention marked a milestone in biotechnology.

In the post-war period, the Food and Agriculture Organization of the United Nations (FAO) highlighted the issues of hunger and malnutrition worldwide. The concept of the protein gap was introduced, indicating that a significant portion of the global population had insufficient protein intake. Concerns arose that agricultural production would struggle to meet the increasing food demands of humanity.

By the mid-1960s, large quantities of food yeast were being produced globally, with the Soviet Union alone producing around 900,000 tons of food and fodder yeast by 1970. In the 1960s, British Petroleum (BP) researchers developed a technology known as the “proteins-from-oil process.” This method involved using yeast fed by waxy n-paraffins, a byproduct of oil refineries, to produce SCP. Pilot plants were established in France and Britain, and the term SCP was coined in 1966 by Carroll L. Wilson of MIT.

The “food from oil” concept gained popularity in the 1970s, with paraffin-fed yeast facilities constructed in various countries. The primary use of SCP at the time was as feed for poultry and cattle. The Soviet Union, in particular, embraced SCP production and established large “protein-vitamin concentrate” plants next to oil refineries. However, due to concerns about the toxicity of alkanes in SCP and environmental pressures, the Soviet government eventually closed down or converted these plants to other microbiological processes.

In recent years, other types of SCP-based meat substitutes have emerged, such as Quorn, made from Fusarium venenatum mycoprotein, and Calysta, which utilizes bacteria. Various companies worldwide, including Unibio, Circe Biotechnologie, and String Bio, are also involved in SCP production.

SCP has been recognized as a potential source of alternative or resilient food, addressing issues such as food shortages and sustainability concerns. Its utilization in various forms holds promise for meeting global protein needs and providing viable food alternatives.

Sources of Single Cell Protein

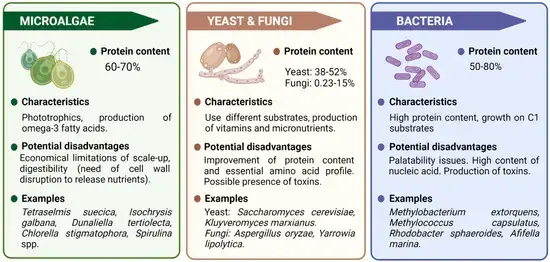

Single Cell Protein (SCP) can be obtained from various microorganisms, including fungi, yeast, algae, and bacteria. Here are some common sources of SCP and their average compositions:

- Fungi:

- Aspergillus fumigatus

- Aspergillus niger

- Rhizopus cyclopean Composition (% dry weight):

- Protein: 30-45%

- Fat: 2-8%

- Ash: 9-14%

- Nucleic Acid: 7-10%

- Algae:

- Spirulina (spa)

- Chlorella pyrenoidosa

- Chondrus crispus Composition (% dry weight):

- Protein: 40-60%

- Fat: 7-20%

- Ash: 8-10%

- Nucleic Acid: 3-8%

- Yeast:

- Saccharomyces cerevisiae

- Candida tropicalis

- Candida utilis Composition (% dry weight):

- Protein: 45-55%

- Fat: 2-6%

- Ash: 5-10%

- Nucleic Acid: 6-12%

- Bacteria:

- Pseudomonas fluorescens

- Lactobacillus

- Bacillus megaterium Composition (% dry weight):

- Protein: 50-65%

- Fat: 1-3%

- Ash: 3-7%

- Nucleic Acid: 8-12%

| Micro-organisms used | Substrate used |

| Algae | |

| Chlorella pyrenoidosa | CO2, light |

| Scenedesmus acutus | CO2, light |

| Spirulina maxima | CO2, combination gases, bicarbonate, sunlight |

| Bacteria | |

| Achromobacter delvaevate | Diesel oil in fermenter |

| Bacillus megaterium | Collagen meat packing in fermenter |

| Cellumonas spp | Bagassae |

| Methylomonas claza | Methanol |

| Pseudomonas spp | n-alkanes fuel oil |

| Actinomycetes | |

| Nocardia spp | n-alkanes |

| Thermoonospora fusca | Cellulose pulp |

| Fungi | |

| Yeast | |

| Candida lipolytica | n-alkanes |

| Candida utilis | Potato starch waste |

| Saccharomyces fragillis | Milk whey |

| Saccharomyces cerevisiae | Molasces and beer |

| Torulopsis spp | methanol |

| Molds | |

| Aspergillus niger | molasces |

| Trichoderma viridae | Starch and straw |

| Paccilomyces varioti | Sulfite waste liquor |

| Mushrooms | |

| Agaricus campestris | glucose |

| Morchella crassipes | Glucose, whey, sulfite liquor |

These microorganisms are selected for SCP production due to their ability to efficiently convert various substrates into protein-rich biomass. The compositions mentioned above indicate the approximate nutrient content in terms of protein, fat, ash, and nucleic acids present in the dried form of SCP derived from these sources.

It’s important to note that the actual composition may vary depending on factors such as strain selection, growth conditions, and substrate used for cultivation. Additionally, advancements in genetic engineering and biotechnology allow for further optimization of microorganisms to enhance SCP production and tailor its composition to specific requirements.

The selection of the microorganism and its corresponding composition in SCP production depends on the desired application and nutritional profile sought. Understanding the different sources and their compositions aids in choosing the most suitable microorganism for specific SCP production purposes.

| Source | Microorganisms | Protein (%) | Fat (%) | Ash (%) | Nucleic Acid (%) |

| Fungi | Aspergillus fumigatus | 30-45 | 2-8 | 9-14 | 7-10 |

| Aspergillus niger | |||||

| Rhizopus cyclopean | |||||

| Algae | Spirulina (spa) | 40-60 | 7-20 | 8-10 | 3-8 |

| Chlorella pyrenoidosa | |||||

| Chondrus crispus | |||||

| Yeast | Saccharomyces cerevisiae | 45-55 | 2-6 | 5-10 | 6-12 |

| Candida tropicalis | |||||

| Candida utilis | |||||

| Bacteria | Pseudomonas fluorescens | 50-65 | 1-3 | 3-7 | 8-12 |

| Lactobacillus | |||||

| Bacillus megaterium |

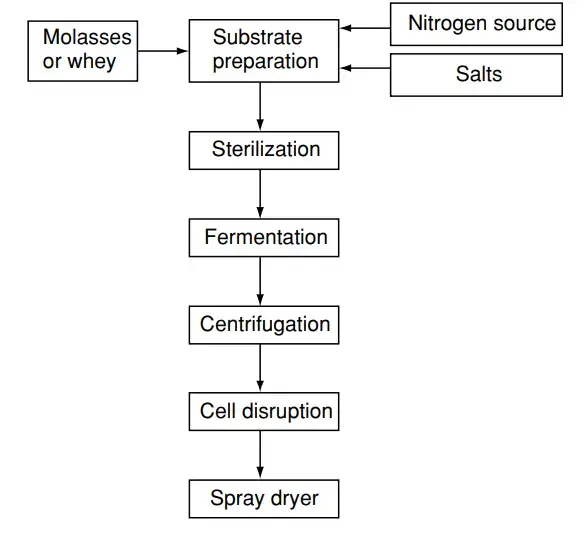

Method for Single Cell Protein production

The method for single cell protein (SCP) production involves several steps to ensure the growth, harvest, and processing of microorganisms rich in protein content. Here is an overview of the method:

- Selection of substrate and strain:

- Fast-growing microorganisms with high protein content and suitable growth characteristics are selected.

- Substrates that provide essential nutrients for the growth of the selected microorganisms are chosen.

- Fermentation:

- A fermenter, which is a specialized instrument for mass culturing plant or animal cells, is used.

- The selected microorganisms are inoculated into a suitable medium and placed in the fermenter.

- Conditions inside the fermenter, such as temperature, pH, and oxygen levels, are carefully controlled to optimize microbial growth and multiplication.

- Harvesting:

- After the fermentation process, the microbial cells need to be separated from the growth medium.

- Harvesting techniques vary depending on the specific microorganism and production setup.

- The challenge lies in effectively separating the cells from the medium without losing significant amounts of protein.

- Post-harvest treatment:

- The harvested microbial cells are subjected to a drying process to preserve them and reduce their volume for easier storage and transport.

- Drying methods can include air drying, spray drying, freeze drying, or other suitable techniques.

- SCP processing for food:

- Once the cells are dried, they undergo post-harvest treatment to remove impurities and enhance their nutritional quality, flavor, and texture.

- Processing methods may include grinding, sieving, and refining to obtain a more refined protein product.

- Additional steps may involve fortification with essential nutrients or flavor additives to improve the overall quality of the SCP.

It’s important to note that the specific details of each step may vary depending on the microorganism, substrate, and intended application of the single cell protein. Continuous research and development are carried out to optimize these processes and improve the efficiency and quality of SCP production.

Single cell protein from Algae

Single-cell protein (SCP) derived from algae offers several advantages and disadvantages in its application.

Advantages of using algae for SCP:

- Utilization of CO2 and sunlight: Algae, particularly members of the genera Chlorella, Scenedesmus, and Spirulina, can be grown in ponds or tanks and utilize carbon dioxide (CO2) and sunlight as substrates. These resources are abundant and cost-free, making algae an attractive option for SCP production.

- High protein content: SCP derived from algae typically contains around 60% crude protein. Algae proteins have a favorable amino acid composition, except for a deficiency in sulfur-containing amino acids. This high protein content makes algae-based SCP suitable as a protein-rich supplement in animal feed.

Disadvantages of using algae for SCP:

- Rich chlorophyll content: Algae naturally contain a high concentration of chlorophyll, which gives them their green color. However, this chlorophyll content can be unsuitable for direct human consumption due to its taste and potential health effects. Additional processing steps may be required to remove or reduce the chlorophyll content in SCP derived from algae.

- Low cell density: Algae cultures often have low cell densities, typically ranging from 1 to 2 grams of dry weight per liter. This means that a large volume of culture is required to obtain a significant amount of SCP, which can pose challenges in terms of scalability and efficient production.

- Risk of contamination: Algae cultures are prone to contamination by other microorganisms, such as bacteria or other algae species. Contamination can impact the quality and safety of the SCP produced, leading to potential loss of the batch or additional purification steps to remove contaminants.

- Costly recovery methods: The extraction and recovery of unicellular algae can be a costly process. Efficient separation methods are required to harvest the algae biomass and extract the protein content. These recovery methods may involve energy-intensive processes or specialized equipment, contributing to the overall production costs.

While algae-based SCP offers several advantages, such as utilizing abundant resources and providing high protein content, the challenges related to chlorophyll content, low cell density, contamination risks, and costly recovery methods need to be addressed for successful and economically viable production of SCP from algae.

Single cell protein from Filamentous fungi

Filamentous fungi offer certain advantages and disadvantages in the production of Single Cell Protein (SCP).

Advantages of using filamentous fungi for SCP:

- Utilization of polysaccharide hydrolysates: Filamentous fungi have been widely employed to produce SCP from various polysaccharide hydrolysates, including starch hydrolysates and sulfite liquor derived from wood pulp industries. This allows for the utilization of by-products or waste streams from other processes, promoting sustainability and resource efficiency.

- Easy recovery by filtration: Filamentous fungi typically form mycelial structures, which can be easily separated from the culture medium by filtration. This facilitates the recovery of the SCP biomass, simplifying the downstream processing steps.

- Moderate protein content: SCP derived from filamentous fungi generally contains around 50-55% crude protein. While this protein content is slightly lower than that of some other sources, it can still provide a valuable protein supplement. However, it is important to note that the sulfur-containing amino acids may be present in lower quantities.

Disadvantages of using filamentous fungi for SCP:

- Slow growth rate: Filamentous fungi generally exhibit slower growth rates compared to bacteria and yeast. This slower growth can affect the overall productivity and scalability of SCP production. It may require longer cultivation times and larger fermentation volumes to achieve significant biomass production.

- Contamination risks: Filamentous fungi cultures are susceptible to contamination by other microorganisms, particularly yeasts. Contamination can result in changes to the composition and quality of the SCP produced, leading to potential batch loss or the need for additional purification steps.

- High nucleic acid content: Filamentous fungi often have higher nucleic acid contents compared to other microorganisms used for SCP production. High nucleic acid levels can impact the taste and digestibility of the SCP and may require additional processing steps to reduce nucleic acid content.

- Evaluation for mycotoxin production: Some filamentous fungi species have the potential to produce mycotoxins, which are toxic compounds that can pose health risks. Therefore, when using filamentous fungi for SCP production, careful evaluation and monitoring should be carried out to ensure the absence or minimal presence of mycotoxins in the final product.

Considering the advantages such as utilization of polysaccharide hydrolysates and easy recovery, as well as the disadvantages of slower growth rate, contamination risks, high nucleic acid content, and the need for mycotoxin evaluation, the use of filamentous fungi as a source of SCP requires careful consideration and optimization for successful and safe production.

Single cell protein from Yeast

Yeast is a popular source of Single Cell Protein (SCP) and offers various advantages and disadvantages in its application.

Advantages of using yeast as SCP:

- Widely used genera: Yeast species such as Saccharomyces, Candida, and Torulopsis are commonly employed for SCP production. These genera have been extensively studied and optimized for industrial-scale fermentation processes.

- High protein content: SCP derived from yeast typically contains around 55-60% crude protein. Yeast proteins exhibit a good balance of amino acids, providing a valuable protein source. However, there may be a deficiency in sulfur-containing amino acids.

- Rich in Vitamin B: Yeast is naturally rich in various B vitamins, including thiamine, riboflavin, niacin, and biotin. These vitamins are essential for human and animal nutrition and contribute to the nutritional value of yeast-based SCP.

- Versatile applications: Yeast SCP is suitable for both human food and animal feed supplementation. It can be used as a protein-rich ingredient in various food products and as a feed additive to enhance the nutritional profile of animal diets.

- Low risk of bacterial contamination: Yeast cultures are less prone to bacterial contamination compared to other microorganisms used in SCP production. This reduces the risk of unwanted microbial growth and helps maintain the purity of the SCP product.

- Easy recovery by continuous centrifugation: Yeast cells can be efficiently separated from the culture medium using continuous centrifugation. This simplifies the recovery process and facilitates the collection of the SCP biomass.

Disadvantages of using yeast as SCP:

- Slower growth rate than bacteria: Yeast generally exhibits a slower growth rate compared to bacteria. This slower growth can impact the overall productivity and scalability of SCP production, requiring longer fermentation times and larger fermentation volumes to achieve significant biomass yield.

- High nucleic acid content: Yeast cells can have a relatively high nucleic acid content compared to other microorganisms. The presence of high nucleic acid levels can affect the taste and digestibility of the SCP and may require additional processing steps to reduce nucleic acid content.

- Deficiency in sulfur-containing amino acids: Yeast-based SCP may have a deficiency in sulfur-containing amino acids, such as methionine and cysteine. This nutritional limitation should be taken into account when formulating diets or food products with yeast-derived SCP.

Despite these disadvantages, yeast remains a valuable source of SCP due to its high protein content, vitamin richness, versatility in applications, low risk of bacterial contamination, and ease of recovery. Optimization of fermentation processes and genetic engineering approaches can further enhance the efficiency and nutritional quality of yeast-based SCP.

Single cell Protein from Bacteria

Bacteria offer certain advantages and disadvantages when used for Single Cell Protein (SCP) production.

Advantages of using bacteria as SCP:

- Wide range of bacterial species: There is a large number of bacterial species that have been utilized for SCP production. This diversity allows for the selection of bacteria that are well-suited to specific substrates or environmental conditions.

- Utilization of various substrates: Bacteria can utilize a wide variety of substrates for growth and protein synthesis. This versatility enables the use of different waste materials or inexpensive carbon sources, making SCP production cost-effective and sustainable.

- Commercial-scale production: Some bacterial species, such as Methylophilus and Methylotrophus, have been successfully employed for SCP production at a commercial scale. This demonstrates the feasibility of large-scale bacterial SCP production.

- High crude protein content: Bacteria-based SCP typically has a high crude protein content, often exceeding 80%. The amino acid composition of bacterial SCP is generally favorable, although there may be a small deficiency in sulfur-containing amino acids.

Disadvantages of using bacteria as SCP:

- High nucleic acid content: Bacterial cells often contain higher levels of nucleic acids compared to other microorganisms used for SCP production. The presence of nucleic acids can negatively impact the taste and digestibility of the SCP product, necessitating additional processing steps to reduce nucleic acid content.

- Sterility maintenance: Bacterial SCP production requires strict maintenance of sterility throughout the process. The pH of bacterial cultures is typically kept between 5-7, which creates an environment that is susceptible to contamination by unwanted microorganisms. Proper sterilization techniques and aseptic conditions are crucial to prevent contamination.

- Risk of pathogenic contamination: There is a potential risk of contamination by pathogenic bacteria during SCP production. Stringent measures must be implemented to ensure the absence of harmful bacteria in the final SCP product to guarantee its safety for consumption.

- Challenges in product recovery: Recovering bacterial SCP from the culture medium can be challenging compared to other microorganisms. Bacterial cells may require specialized techniques or equipment for efficient separation and biomass recovery.

- Evaluation for endotoxin production: When gram-negative bacteria are used for SCP production, careful evaluation for endotoxin production is necessary. Endotoxins are components of bacterial cell walls that can trigger immune responses and pose health risks. Thorough testing and quality control measures should be implemented to ensure the absence or minimal presence of endotoxins in the final SCP product.

While bacteria offer advantages such as substrate versatility, high protein content, and commercial scalability, the challenges associated with nucleic acid content, sterility maintenance, contamination risks, product recovery, and endotoxin evaluation require careful attention and optimization in bacterial SCP production processes.

Substrates for SCP production

Substrates for Single Cell Protein (SCP) production can vary widely, ranging from inorganic carbon sources like CO2 to industrial effluents and various organic materials. These substrates can be categorized into two groups: fossil carbon sources (non-renewable) and renewable carbon sources.

1. Fossil carbon sources

- Gaseous hydrocarbon: C1 to C4 gaseous hydrocarbons, such as methane, have been extensively studied for SCP production. Methane, in particular, is highly desirable as it is available in high purity from natural gas. It can be easily removed from the fermentation process and supports high productivity in continuous processes. However, efficient cooling is necessary to manage heat generation.

- Liquid hydrocarbon: Saturated straight-chain hydrocarbons, known as n-alkanes, which are present in crude oil, can be used as SCP substrates. Generally, n-alkanes with 9-18 carbon atoms are utilized. Various bacteria, actinomycetes, yeast, and molds have the ability to use liquid hydrocarbons as substrates.

- Methanol: Methanol, a product of the efficient chemical conversion of methane, is fully water-soluble and can be used by many bacteria for SCP production. It poses little danger of explosion and is used in industrial production with organisms like Methylophilus and Methylotrophus to produce protein-rich biomass called “pruteen.”

- Ethanol: Ethanol can be derived from ethylene or organic substrates through alcoholic fermentation. It serves as a substrate for SCP production and can be utilized by bacteria, yeast, and mycelium fungi. Ethanol produced from renewable sources can be particularly suitable for SCP production intended for human use.

2. Renewable carbon sources

- CO2: Algae have the ability to utilize CO2 as a substrate for SCP production, deriving the required energy from sunlight. This makes CO2 a renewable carbon source for algae-based SCP production.

- Molasses: Molasses, a byproduct of wheat processing, is used for alcoholic fermentation. Baker’s yeast (Saccharomyces cerevisiae) and Torula yeast (Candida utilis) are traditionally produced on this substrate.

- Whey: Whey, the liquid portion remaining after the curd is separated during cheese production, can serve as a substrate for SCP production. Yeasts like Candida krusei, in combination with Lactobacillus bulgaricus and Candida intermedia, are commonly used for commercial-scale SCP production from whey.

- Cellulose hydrolysate: Cellulose, obtained from fungi like Trichoderma viride, can be hydrolyzed to produce glucose, which serves as a substrate for SCP production. Cellulose hydrolysate is a cost-effective substrate and is often utilized for mushroom production.

- Starch hydrolysate: Starch hydrolysate, although relatively expensive, can be used for SCP production with organisms like Fusarium graminearum. The resulting SCP, known as mycoprotein, has a fibrous meat-like texture and is marketed for human consumption.

- Industrial effluent: Effluents from various industries, including breweries, distilleries, confectionery, potato processing, and canning, can serve as substrates for SCP production. For example, sulfite liquor from wood pulp industries contains significant amounts of carbohydrates and other organic compounds suitable for SCP production.

The selection of an appropriate substrate depends on factors such as availability, cost, nutritional requirements of the chosen microorganism, and desired application of the resulting SCP.

Nutritional Aspects Of SCP

The nutritional aspects of Single Cell Protein (SCP) can vary depending on the microorganisms and substrates used in its production. Several factors are important in assessing the nutritional value of SCP, including amino acid profiles, protein, carbohydrate, and lipid contents, as well as the presence of minerals and vitamins. Palatability, allergies, and gastrointestinal effects should also be considered.

In terms of long-term feeding trials, it is important to monitor toxicological and carcinogenic effects associated with SCP consumption. Various parameters are used to evaluate the nutritional aspects of SCP, such as protein efficiency ratio (PER), biological value (BV), net protein utilization (NPU), and protein digestibility value (PDV).

For nutritional analysis, different microorganisms yield SCP with varying compositions:

- Algae: Algae are rich in proteins (40-60%), fats (5-20%), vitamins A, B, C, D, E, minerals (7%), and nucleic acids (4-6%).

- Fungi: Fungi contain the B-complex group of vitamins, and their amino acid content is reasonably high.

- Dry yeast: Dry yeast typically contains about 50% proteins and 20% non-proteins. Yeasts are a good source of lysine, thiamine, biotin, riboflavin, niacin, and folic acid but may be deficient in methionine.

- Aspergillus niger: SCP produced by Aspergillus niger is well balanced and meets the standards prescribed by the World Health Organization (WHO).

- Bacteria: Bacterial SCP usually contains around 80% crude protein of the dry weight.

In general, SCP products contain approximately 50-70% crude proteins. These protein-rich sources can be utilized as valuable nutritional supplements. It is important to consider the specific nutritional composition of SCP, including its amino acid profile, vitamins, minerals, and other components, to assess its potential as a protein source in human and animal diets.

Factors Affecting Scp Production

Factors affecting Single Cell Protein (SCP) production are diverse and can significantly impact the success and viability of the process. Some key factors include the selection of microorganisms and considerations related to safety and acceptability.

Selection of Microorganisms: When choosing a microbial strain for SCP production, several characteristics must be considered:

- Growth rate, productivity, and yields on specific low-cost substrates: The chosen strain should exhibit efficient growth and high productivity when utilizing the selected substrates.

- Temperature and pH tolerance: The microorganism should be able to thrive under the desired temperature and pH conditions required for the fermentation process.

- Oxygen requirements, heat generation, and foaming characteristics: These factors impact the aeration and agitation requirements during fermentation, as well as the heat dissipation and foaming control strategies.

- Growth morphology and genetic stability: The microorganism’s growth morphology should be suitable for easy recovery of SCP, and its genetic stability is important to maintain consistent performance during fermentation.

- Downstream processing requirements: The ease of SCP recovery and the necessity for additional downstream processing steps should be taken into account.

- Structure and composition of the final product: Considerations include the desired protein content, amino acid profile, RNA levels, flavor, aroma, color, and texture.

Safety and Acceptability: Several factors related to safety and acceptability influence SCP production:

- Intended use: Most SCP products are used as animal feed, and therefore, safety requirements for animal consumption must be met. Regulatory approval for producing proteins for human consumption is a lengthier and more expensive process.

- Nucleic acid content: Many microorganisms naturally have high levels of nucleic acids, which can be problematic. Digestion of nucleic acids by humans and animals leads to the generation of purine compounds, which can have adverse health effects.

- Sensitivity and allergic reactions: Potential allergic reactions to microbial proteins or indigestion issues should be examined. Slow digestion of microbial cells within the gut can also be a concern.

- Absorption of toxic or carcinogenic substances: Certain growth substrates may contain or produce toxic or carcinogenic compounds, such as polycyclic aromatic compounds. The absorption of these substances from SCP products must be evaluated.

Considering these factors and conducting thorough evaluations of the chosen microorganisms and substrates are essential for ensuring safe, acceptable, and successful SCP production.

Single Cell Protein Production Processes

Single Cell Protein (SCP) production processes involve various cultivation methods and fermentation techniques. Here are some key points regarding SCP production processes:

Cultivation Methods:

- Process development begins with microbial screening to obtain suitable production strains, which can be isolated from various sources such as soil, water, air, or biological materials.

- The selected strains are optimized through selection, mutation, or other genetic methods to enhance their productivity.

- Technical cultivation conditions are established to promote the growth of the microorganisms and maximize cell mass production.

- Metabolic pathways and cell structures of the microorganisms are determined to understand their behavior during the fermentation process.

- Process engineering and apparatus technology are employed to adapt the technical aspects of the production process for large-scale use.

- Economic factors, such as energy consumption and cost efficiency, are considered during process development.

- Safety requirements and environmental protection measures are taken into account in both the process and product aspects of SCP production.

- Legal aspects, including operating licenses, product authorizations, and protection of intellectual property rights for new processes and strains, are also addressed.

Submerged Fermentation:

- In submerged fermentation, the cultivation substrate is in a liquid state, providing the necessary nutrients for microbial growth.

- A fermentor is used to contain the substrate, and the process is often operated continuously.

- The biomass produced during fermentation is continuously harvested using techniques such as filtration or centrifugation.

- Aeration is an important operation in submerged fermentation to provide oxygen to the microorganisms and remove heat generated during the process.

- Various methods are employed to recover the microbial biomass, with centrifugation typically used for single-cell organisms like yeast and bacteria, while filtration is suitable for filamentous fungi.

- After harvesting, the biomass is processed by filtering, centrifuging, and drying to remove excess water and obtain the final SCP product.

Semisolid Fermentation:

- Semisolid fermentation involves the use of a substrate that is not fully clarified and is often in a solid or semisolid state, such as cassava waste.

- It is a cost-effective alternative to submerged fermentation, as it requires less capital investment and has lower operating costs.

- The cultivation process involves stirring and mixing the substrate, providing oxygen to the microorganisms, and managing heat transfer.

- A specialized bioreactor called a U-loop fermentor is designed to study mass and energy transportation phenomena in semisolid fermentation.

- The production of SCP in semisolid fermentation follows similar steps as in submerged fermentation, including medium preparation, preventing contamination, cultivating microorganisms, and separating and processing the synthesized biomass.

Solid State Fermentation (SSF):

- Solid state fermentation is a well-studied process for the production of various value-added products, including SCP.

- It involves depositing a solid culture substrate, such as rice or wheat bran, on flatbeds or trays and inoculating it with microorganisms.

- The substrate is then incubated at a controlled temperature for several days, allowing the microorganisms to grow and produce SCP.

- SSF is suitable for the production of SCP, feeds, enzymes, organic acids, pigments, and other valuable compounds.

- The main steps in SSF include medium preparation, fermentation, separation of the SCP biomass, and downstream processing.

Overall, SCP production processes involve careful selection of microorganisms, optimization of cultivation conditions, appropriate substrate choice, effective biomass recovery, and subsequent processing to obtain the final SCP product.

Parameters For Optimum Scp Production

Several parameters play a crucial role in optimizing Single Cell Protein (SCP) production. These parameters include:

- Microorganisms used: The selection of the appropriate microorganism(s) is essential for optimal SCP production. Factors such as growth rate, productivity, substrate utilization efficiency, and tolerance to cultivation conditions should be considered when choosing the microorganism for SCP production.

- Culture conditions: The cultivation conditions, including temperature, pH, oxygen availability, and agitation, need to be optimized to create an environment conducive to the growth and productivity of the chosen microorganism. Different microorganisms may have specific requirements, and these conditions must be adjusted accordingly.

- Pre-treatment of substrates: Substrate pre-treatment methods, such as grinding, sterilization, hydrolysis, or extraction, may be necessary to enhance the availability of nutrients and facilitate microbial growth and substrate utilization. Pre-treatment methods are employed to make the substrates more accessible and suitable for the microorganisms.

- Nutrient supplementation: Depending on the nutritional requirements of the microorganisms, the substrates used for SCP production may need to be supplemented with additional nutrients, such as vitamins, minerals, or nitrogen sources. These supplements ensure that the microorganisms have an optimal nutrient balance for growth and protein synthesis.

- Types of fermentation processes: Different types of fermentation processes, such as submerged fermentation, solid-state fermentation, or semisolid fermentation, can be employed for SCP production. The choice of the fermentation process depends on the specific microorganism and substrate being used and the desired product characteristics.

- Strain improvement: Strain improvement techniques, such as mutation breeding or selection, can be employed to enhance the desired traits of the microorganism used for SCP production. This can include improving growth rate, productivity, nutrient utilization efficiency, or tolerance to various cultivation conditions.

- Genetic engineering techniques: Genetic engineering can be used to modify the genetic makeup of the microorganism, allowing for the development of strains with improved characteristics for SCP production. This includes manipulating metabolic pathways, enhancing nutrient utilization, or increasing protein synthesis capabilities.

By optimizing these parameters, SCP production can be enhanced, leading to increased yields, improved protein quality, and more efficient utilization of substrates. The continuous improvement and optimization of these parameters are crucial for the development of cost-effective and sustainable SCP production processes.

Advantages of Single Cell Protein

Single cell protein (SCP) offers several advantages due to the use of microorganisms in its production. Here are some key advantages:

- Rapid growth: Microorganisms have a faster growth rate compared to protein-rich grains, which can take months or even years to reach maturity. Microorganisms can multiply rapidly, allowing for quicker production of SCP.

- High protein quality and quantity: SCP derived from microorganisms typically exhibits high protein content, often ranging from 60% to 80%. This protein is of good quality, containing essential amino acids required for human and animal nutrition.

- Utilization of inexpensive raw materials: Microorganisms used for SCP production can utilize a wide range of inexpensive raw materials as substrates. These substrates may include agricultural by-products, waste materials, or industrial by-products, thereby reducing the dependency on traditional protein sources.

- Simple production process: The production process for SCP is relatively easy and straightforward. Once the appropriate microorganisms and substrates are selected, the fermentation and harvesting processes can be efficiently carried out with proper control of environmental factors.

- Genetic manipulation: Microorganisms used for SCP production can be easily subjected to genetic manipulation. This allows for the optimization of their growth characteristics, protein content, and other desirable traits, further enhancing the efficiency and quality of SCP production.

- Year-round production: Microorganisms can be cultured and produced throughout the year, irrespective of seasonal variations. This ensures a consistent and continuous supply of SCP, unlike certain crops that have specific growing seasons.

- Wide substrate utilization: Microorganisms used for SCP production have the ability to utilize a wide range of substrates. This flexibility allows for the utilization of various agricultural, industrial, or waste materials, thereby reducing waste and promoting resource efficiency.

- Eco-friendly, cost-effective, and energy-efficient: SCP production is considered environmentally friendly due to its potential to utilize waste materials as substrates and reduce reliance on traditional protein sources. It can also be a cost-effective and energy-efficient process, especially when compared to resource-intensive conventional protein production methods.

Overall, the advantages of SCP production using microorganisms make it a promising alternative protein source that can contribute to sustainable and efficient food Overall, the advantages of SCP production using microorganisms make it a promising alternative protein source that can contribute to sustainable and efficient food production systems. Ongoing research and development in this field aim to further optimize these advantages and expand the applications of SCP in various industries.

Disadvantages of Single Cell Protein

While Single Cell Protein (SCP) offers several advantages, there are also certain disadvantages associated with its production and consumption. Here are some key disadvantages:

- Complex production process: SCP production involves a complex process that requires strict control over various environmental factors such as temperature, pH, and oxygen levels. Achieving optimal conditions for the growth and multiplication of microorganisms can be challenging and may require advanced equipment and expertise.

- Harvesting and purification challenges: Maintaining the quality of SCP after production poses difficulties. Harvesting and separating the microbial cells from the growth medium can be a complex task, and the purification process to remove impurities may be challenging. These steps require careful handling to ensure the final product meets quality standards.

- Incomplete amino acid profile: SCP is not a complete source of all essential amino acids required by the human body. It may lack certain amino acids or have imbalanced ratios. Therefore, SCP is often used as a supplement or complement to other protein sources to ensure a well-rounded amino acid profile in the diet.

- Consumer perception and acceptance: Despite its potential benefits, consumer perception and acceptance of SCP remain a challenge. Some individuals may have reservations or skepticism about consuming a protein derived from microorganisms. Overcoming these perceptual barriers and educating consumers about the safety and nutritional value of SCP can be a significant hurdle in its widespread adoption.

- Allergenic potential: Some individuals may have allergies or sensitivities to specific microorganisms used in SCP production. This can limit its suitability for individuals with certain dietary restrictions or allergies, requiring careful consideration and labeling of SCP products.

- Cultural and culinary acceptance: SCP may face cultural and culinary barriers in certain regions or cuisines where the consumption of microbial-based products is not traditionally practiced or accepted. Adapting SCP into local diets and culinary practices may require additional efforts to ensure its integration and acceptance.

- Regulatory considerations: The production and commercialization of SCP may be subject to regulatory requirements and standards. Compliance with these regulations, such as food safety and labeling regulations, can add complexity and cost to the production and marketing of SCP products.

It is important to address these disadvantages through ongoing research, technological advancements, and consumer education to maximize the potential benefits of SCP while addressing the concerns and challenges associated with its production and acceptance.

Applications of Single Cell Protein

Single Cell Protein (SCP) finds diverse applications across various industries and sectors. Here are some key applications of SCP:

- Animal feed and nutrition: SCP is widely used as a feed ingredient in the livestock industry. It is employed in the stuffing and fattening of poultry, laying hens, calves, and pigs. By incorporating SCP into animal diets, it helps to enhance their nutritional value, promote growth, and improve overall animal health.

- Food additives and enhancers: SCP is utilized as a food additive in different forms. It serves as a carrier for vitamins and aromas, an emulsifying agent, and a nutritional enhancer for baked goods, ready-made meals, soups, and other food products. Additionally, SCP is used as starter cultures in the production of baker’s yeast, brewer’s yeast, and wine yeast.

- Industrial processes: SCP is employed in various industrial processes. It acts as a foam-stabilizing agent, aiding in the production of foams used in diverse applications. SCP also finds applications in the paper and leather processing industries, where it contributes to the improvement of product characteristics and performance.

- Nutritional supplementation: SCP is considered an excellent source of protein and essential nutrients. It is utilized to provide protein-supplemented food for undernourished children, addressing their nutritional needs and promoting healthy growth. SCP is rich in vitamins, amino acids, minerals, and other beneficial components, making it a valuable nutritional supplement.

- Therapeutic and medicinal applications: SCP has been explored for its therapeutic properties and potential health benefits. It is used in the development of natural medicines aimed at controlling obesity, lowering blood sugar levels in diabetic patients, reducing body weight, cholesterol, and stress. SCP is also known to prevent the accumulation of cholesterol in the body, contributing to improved cardiovascular health.

- Cosmetics and personal care products: SCP has found its way into the cosmetics industry. It is utilized in various cosmetic products aimed at maintaining healthy hair and promoting overall skin health. SCP is incorporated into the production of herbal beauty products, such as biolipsticks, herbal face creams, and other skincare formulations.

The applications of SCP continue to expand as research and development in the field progress. Its versatility and nutritional benefits make it a valuable resource for a wide range of industries, offering sustainable and innovative solutions in animal nutrition, food production, healthcare, and cosmetics.

FAQ

What is Single Cell Protein (SCP)?

Single Cell Protein refers to protein-rich biomass produced by growing microorganisms, such as bacteria, fungi, yeast, or algae, as a food source for humans or animals.

How is Single Cell Protein produced?

SCP is produced through a fermentation process where selected microorganisms are grown in a controlled environment using suitable substrates. The microorganisms multiply and accumulate protein, which can then be harvested and processed.

What are the advantages of Single Cell Protein?

Some advantages of SCP include rapid growth of microorganisms, high protein content, utilization of inexpensive raw materials, easy production process, genetic manipulability, year-round production, and eco-friendly nature.

What are the main applications of Single Cell Protein?

SCP finds applications in animal feed, food additives, industrial processes (foam-stabilizing agent, paper, and leather processing), nutritional supplements, therapeutic and natural medicines, and cosmetics.

Can Single Cell Protein be used as a sole protein source?

SCP is not a complete source of all essential amino acids, so it is typically used as a supplement to other protein sources to enhance their nutritional value.

Is Single Cell Protein safe for consumption?

Yes, SCP is generally considered safe for consumption. The microorganisms used for SCP production undergo rigorous testing and quality control to ensure their safety.

Are there any challenges in the production of Single Cell Protein?

Challenges in SCP production include maintaining strict environmental control, ensuring quality during harvesting and purification, and addressing consumer perception and acceptance of a product derived from microorganisms.

What are the common sources of Single Cell Protein?

Common sources of SCP include fungi (e.g., Aspergillus), algae (e.g., Spirulina, Chlorella), yeast (e.g., Saccharomyces cerevisiae), and bacteria (e.g., Pseudomonas, Lactobacillus).

Is Single Cell Protein environmentally friendly?

Yes, SCP production is considered eco-friendly as it requires fewer resources, land, and water compared to traditional protein sources like livestock farming.

Can Single Cell Protein help address food security and sustainability?

Yes, SCP production offers a promising solution for addressing global food security and sustainability challenges. It can provide a protein-rich food source that is less resource-intensive and can be produced in large quantities.

References

- Najafpour, G. D. (2007). Single-Cell Protein. Biochemical Engineering and Biotechnology, 332–341. doi:10.1016/b978-044452845-2/50014-8

- García-Garibay, M., Gómez-Ruiz, L., Cruz-Guerrero, A. E., & Bárzana, E. (2003). SINGLE-CELL PROTEIN | Algae. Encyclopedia of Food Sciences and Nutrition, 5269–5276. doi:10.1016/b0-12-227055-x/01087-7

- García-Garibay, M., Gómez-Ruiz, L., & Bárzana, E. (1999). SINGLE-CELL PROTEIN | Yeasts and Bacteria. Encyclopedia of Food Microbiology, 2027–2034. doi:10.1006/rwfm.1999.1450

- García-Garibay, M., Gómez-Ruiz, L., Cruz-Guerrero, A. E., & Bárzana, E. (2003). SINGLE-CELL PROTEIN | Yeasts and Bacteria. Encyclopedia of Food Sciences and Nutrition, 5277–5284. doi:10.1016/b0-12-227055-x/01088-9

- García-Garibay, M., Gómez-Ruiz, L., Cruz-Guerrero, A. E., & Bárzana, E. (2014). SINGLE CELL PROTEIN | Yeasts and Bacteria. Encyclopedia of Food Microbiology, 431–438. doi:10.1016/b978-0-12-384730-0.00310-4

- García-Garibay, M., Gómez-Ruiz, L., Cruz-Guerrero, A. E., & Bárzana, E. (2014). SINGLE CELL PROTEIN | The Algae. Encyclopedia of Food Microbiology, 425–430. doi:10.1016/b978-0-12-384730-0.00309-8