Photo bioreactor is an innovative type of reactor that has the advantages of biofilm reactors and photobioreactors that can be utilized to cultivate microalgae in wastewater treatment facilities (WWTPs). The major benefit of this type of system is its capacity to use sunlight as a source of energy for photosynthesis, which reduces the requirement for carbon from external sources.

Definition of Photobioreactor

- A photobioreactor is a term that’s used to refer to any process or device which makes use of solar light to transform organic material into biomass.

- It could also mean a sealed vessel equipped with artificial lighting to cultivate photoautotrophic organisms like algae, cyanobacteria bacteria, fungi and so on.

- Utilizing sunlight as the principal energy source.

- This technology is widely used in wastewater treatment systems to eliminate nutrients from the wastewater.

- Additionally it has been discovered that certain species of algae can produce important compounds like pigments, proteins, lipids carbohydrate, vitamins, polysaccharides, and more.

- The fundamental principle behind photobioreactors is to convert sunlight into chemical energy through the use the process of photosynthesis.

- The most commonly used kinds of photobioreactors are tube, flat as well as bubble column-type reactors.

- Flat plate reactors are comprised of two parallel plates , separated by about 0.5-1 meters. They are generally constructed from plastic or glass materials.

- Tubular reactors possess a circular shape and are usually constructed of pipe made of stainless steel.

- Bubble column reactors are similar to tall columns that have gas bubbles rise from into the fluid medium. These types of devices are often employed for wastewater treatment as they are able to mix well and enable effective elimination of solids suspended in the water.

Types of Photobioreactors

Therer are present two types of photo bioreactors such as;

1. Open systems

- The first method of controlled production of phototrophic species was to use a natural open pond (also known as artificial raceway) pond.

- The cultivation suspension that has all of the essential nutrients and carbon dioxide moved around in a continuous cycle that is illuminated directly by sunlight through its surface.

- Raceway ponds continue to be employed in industries because of their lower operational costs when compared with closed PBRs.

- They do however offer inadequate control over the reaction conditions because they rely on light sources from the environment, and carbon dioxide as well as the potential for contamination by other microorganisms.

- Open technologies also cause water loss through evaporation into atmosphere.

2. Closed systems

- Closed PBR construction reduces the risk of losses in water from the system, and the chance of contamination is diminished.

- Although closed systems are more efficient in performance than open systems because of the benefits mentioned above but they must be upgraded to make them appropriate for the production of commodities with low prices because cell density is still insufficient due to various limitation aspects.

- Modern photobioreactors have attempted to achieve a balance with a very thin film suspension of culture, optimal lighting, less use of energy for pumps, and capital expense and the purity of the microbial population. However, light attenuation as well as an increase in CO2 demands with the growth are two of the most likely changes to phototrophic cultures , which severely limit the efficiency of photobioreactors.

- The accumulation of oxygen from photosynthetic sources as microalgae grow in photobioreactors is believed to be a key element but it has been demonstrated by using dynamic models that levels of dissolved oxygen that exceed 400% air saturation aren’t inhibiting when the cell density is sufficiently high to block the light intensity in the later stages of microalgal culture. Numerous different methods have been evaluated, however only a handful of approaches could be used on large scale.

Types of Closed systems Photo bioreactors

There are present different types of Closed systems Photo bioreactors such as;

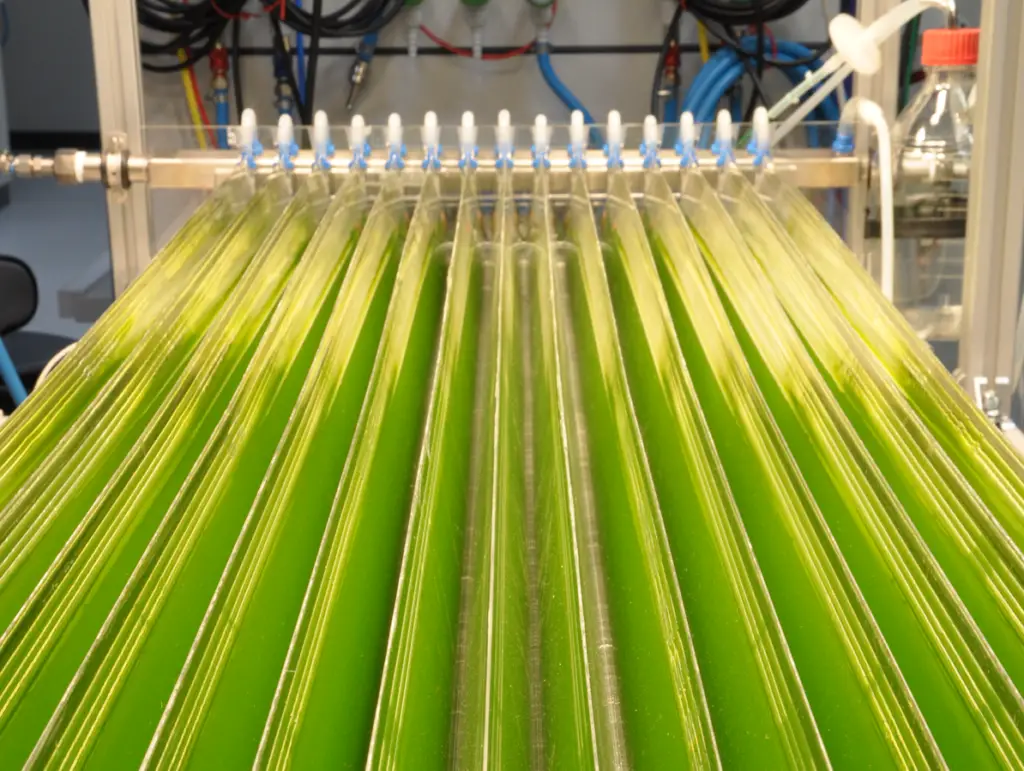

1. Tubular photobioreactors

- Made up of glass or plastic tubes, this photobioreactor is working well at a production scale.

- The tubes are laid either vertically or horizontally. They are connected to a central utility installation that includes sensors, pumps as well as CO2 and nutrients.

- Photobioreactors with tubular structures are used worldwide from the laboratory to the manufacturing scales, e.g. to make the carotenoid Astaxanthine from the green algae Haematococcus p. or to produce food supplements from the algae Chlorella vulgaris.

- Photobioreactors benefit of the purity levels and their high-efficiency outputs.

- The production of biomass is accomplished at a top quality level, and the high biomass content at the conclusion of the production permits an energy efficient downstream processing

Benefits

- The advantages of photobioreactors with tubular tubes at production scale can also be transferred to the laboratory scale. Combining the glass vessel with a fine tube coil can allow for appropriate biomass production rates on a the laboratory scale of research.

- Because of a sophisticated control system, the regulation of environmental conditions can reach an extremely high quality.

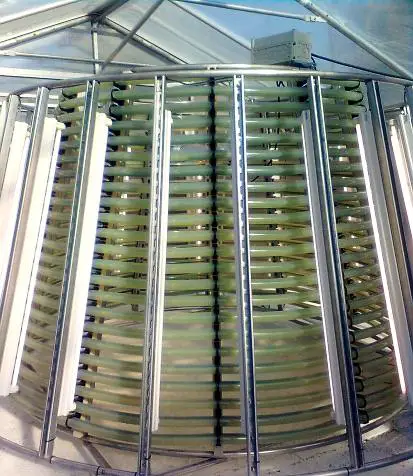

2. Christmas tree photobioreactor

- A different approach is demonstrated by a photobioreactor that is constructed in the shape of a tapered geometrical structure and is equipped with a helically connected to a transparent double hose system.

- This creates a design like the Christmas tree.

- Tubular systems are built in modules, and could theoretically be adapted outdoors to an agricultural scale.

- The location of the dedicated area isn’t essential, as is the case with the other systems that are closed, therefore, non-arable land can be used also.

- The material selection should stop biofouling as well as ensure high end biomass levels.

- Combining turbulence with the closed concept will allow an uncluttered operation as well as a high level of operational availability.

3. Plate photobioreactor

- Another method of development is observed in the building of glass or plastic plates.

- Plates with various technical designs are placed on top of the small layer of suspension that provides the best light source.

- Additionally, the less complicated design as compared to tubular reactors permits the use of cheaper plastics.

- From the variety of ideas e.g. design flow patterns that wind around and bottom gassed designs have been implemented and demonstrated good output results.

- Applications on a large scale are restricted by the scale plates.

4. Horizontal photobioreactor

- The photobioreactor is an elongated plate with peaks and valleys that are arranged with regular distance.

- This geometry results in the dispersion of light reflected off the larger area, which is equivalent to an effect of dilution.

- This can also help solve one of the most fundamental problems in phototrophic farming, since many microalgae species are sensitive to intense light levels. The majority of microalgae suffer from the phenomenon of light saturation at low levels of light intensity, which are significantly lower than the maximum intensity of daylight of around 2000 W/m2. In the same way, a greater amount of light can be utilized to increase the efficiency of photoconversion.

- Mixing is achieved via a rotary pump which creates a cylindrical rotation of the broth used for culture.

- Contrary to vertical reactors, horizontal ones consist of only thin layers media that have a lower hydrodynamic pressure. This can have a positive effect on the energy required and also reduces costs for materials in the process.

5. Foil photobioreactor

- The pressure from market prices has led to the development of photobioreactors based on foils. Cheap PVC as well as PE foils are positioned into vessels or bags that cover algae suspensions as well as expose them sunlight.

- The prices of photobioreactors has been increased by using foil systems.

- It is important to keep in the mind that these systems have an insufficient lifespan since the foils must be replaced on a regular basis. time.

- To calculate the full balance the amount of investment required for support systems must be calculated, too.

6. Porous substrate bioreactor

- The porous bioreactor of substrate (PSBR) which is which is being developed at the University of Cologne, also called the twin-layer system employs a brand new method to isolate the algae from a nutrient-rich solution using an impermeable reactor surface which the microalgae can be encased in biofilms.

- This method reduces by up to 100 percent the volume of water required to operate compared to current method, which cultivates the algae that is suspended in.

- This is why the PSBR procedure drastically decreases the energy requirement while also increasing the number of the algae which can be grown.

Photobioreactor design

A photobioreactor is a device used to cultivate microorganisms using light as an energy source. The design of a photobioreactor depends on the specific microorganism being cultivated, as well as the desired end product of the cultivation process. Some common features of photobioreactor design include:

- Light source: Photobioreactors often use artificial light sources such as LED bulbs or fluorescent lamps to provide the necessary light for photosynthesis. The intensity and spectrum of the light can be customized to optimize growth of the microorganisms.

- Culture medium: The culture medium is the liquid or gel in which the microorganisms are grown. It should provide the necessary nutrients and support the growth and metabolism of the microorganisms.

- Mixing and aeration: Photobioreactors often include mechanisms for mixing the culture medium and providing oxygen to the microorganisms. This can be achieved through mechanical stirring or by bubbling air through the culture medium.

- Temperature control: The temperature of the photobioreactor must be carefully controlled to support the growth of the microorganisms. This may involve the use of heating or cooling elements, as well as insulation to maintain a stable temperature.

- pH control: The pH of the culture medium must be maintained within a certain range to support the growth of the microorganisms. This may involve the use of pH buffers or the addition of acid or base to adjust the pH.

- Sterilization: Photobioreactors must be designed to prevent contamination of the culture medium by other microorganisms. This may involve the use of sterile filters or other sterilization techniques.

There are many different types of photobioreactors, each with its own specific design features. Some common types include flat panel photobioreactors, tubular photobioreactors, and airlift photobioreactors.

What is algae photobioreactor?

A photobioreactor (PBR) is a specialized device used to cultivate algae under controlled conditions. Algae are a diverse group of aquatic microorganisms that are capable of photosynthesis, and they have a number of important applications, including the production of biofuels, food, and other products.

A photobioreactor is a closed system that provides the necessary light, temperature, and other conditions for algae to grow and multiply. It typically consists of a transparent container (such as a glass or plastic vessel) that is equipped with a light source and a system for controlling the temperature and other conditions. The algae are suspended in a liquid medium (such as water), and the light source is used to stimulate photosynthesis and promote the growth of the algae.

Photobioreactors can be used to cultivate a wide range of algae species, including microalgae and macroalgae, and they are used in a variety of applications, including the production of biofuels, food, and other products. They are also used for research and development purposes, as they allow scientists to study the growth and metabolism of algae under controlled conditions.

Overall, photobioreactors are an important tool for the cultivation of algae, and they have a wide range of applications in industries such as energy, food, and biotechnology.

How does a photobioreactor work?

A photobioreactor is a device used to cultivate microorganisms using light as an energy source. The microorganisms, usually algae or cyanobacteria, are grown in a culture medium, typically a liquid or gel. The photobioreactor provides the necessary light and nutrients for the microorganisms to grow and produce the desired end product, which could be a biomass, a chemical, or a fuel.

The photobioreactor typically includes a light source, such as LED bulbs or fluorescent lamps, to provide the necessary light for photosynthesis. The intensity and spectrum of the light can be customized to optimize growth of the microorganisms. The culture medium provides the necessary nutrients and supports the growth and metabolism of the microorganisms.

The photobioreactor may also include mechanisms for mixing the culture medium and providing oxygen to the microorganisms. This can be achieved through mechanical stirring or by bubbling air through the culture medium. The temperature of the photobioreactor must be carefully controlled to support the growth of the microorganisms, and the pH of the culture medium must be maintained within a certain range. The photobioreactor must also be designed to prevent contamination of the culture medium by other microorganisms.

The specific design of a photobioreactor depends on the specific microorganism being cultivated and the desired end product of the cultivation process. There are many different types of photobioreactors, each with its own specific design features.

Why is photobioreactor important?

Photobioreactors are important for a number of reasons:

- Sustainable production of biofuels: Photobioreactors can be used to cultivate microorganisms that can produce biofuels, such as algae or cyanobacteria. Biofuels produced in this way have the potential to be more sustainable and environmentally friendly than fossil fuels.

- Production of chemicals and pharmaceuticals: Photobioreactors can be used to cultivate microorganisms that can produce a wide range of chemicals and pharmaceuticals. This can be a more sustainable and cost-effective way to produce these materials compared to traditional chemical synthesis methods.

- Waste treatment: Photobioreactors can be used to treat industrial and agricultural waste by cultivating microorganisms that can break down the waste into less harmful substances.

- CO2 capture: Some microorganisms grown in photobioreactors can absorb and fix atmospheric CO2, potentially reducing greenhouse gas emissions.

- Food and feed production: Photobioreactors can be used to cultivate microorganisms that can be used as food or feed for animals. This can help to reduce the environmental impact of food and feed production.

Overall, photobioreactors have the potential to contribute to a more sustainable and environmentally friendly future by providing alternatives to traditional methods of producing biofuels, chemicals, pharmaceuticals, food, and feed.

Advantages and Applications of Photo bioreactors

The benefits of using photobioreactors in wastewater treatment are:

- There is no need for any other carbon resources.

- The high efficiency of removal of nutrient.

- Excellent mixing conditions.

- Simple operation and maintenance.

- Low cost.

- Small footprint.

- It is possible to operate all year long.

- Easy to integrate in existing WWTPs.

- It is possible to design reactors that can accommodate various dimensions of reactors.

- It is suitable to perform large-scale applications.

- It is suitable to create high density and low density ones.

- It is possible to use microalgae for development in the open air.

Disadvantages of Photo bioreactors

- Capital costs are very high.

- The production and productivity costs in certain enclosed photobioreactor systems aren’t much different from open-pond bioreactors.

- The technical challenge in sterilization.

Application of Photo bioreactors

- This can be used for making various products such as biofuels as well as animal feed and nutritional supplements, pharmaceuticals and cosmetics, etc.

- Useful for continuous flow processes.

- It can be used to perform batch operations.

- This can be used for aerobic and anaerobic reactions.

- Useful to create single cell cultures.

- It can be used to conduct study of mixed cultures.

- Useful for small volumes of cultures and arger quantities of media.

- Useful for higher concentrations of media, and for less media concentrations.

- This can be used for non-sterile and sterile environments.

- This can be used to fulfill multiple functions simultaneously.

- Useful for long periods of time with no need for cleaning.

- This can be used for both anaerobic and aerobic reactions.

- Useful for shrimp farming, fish farming, farm oyster farm, coral reef farming, seaweed agriculture.

- This can be used for agricultural land-based or marine-based farms, and marine based.

- Useful for hydroponic systems.

- Aeroponics can be utilized for this.

- It can be used to grow soil-based plants.

- It can be used to grow cultivating greenhouses.

- Useful to grow indoors and for outdoor cultivation.

- This can be used to create closed loop systems as well as open loop systems.

- It can be used to create semi-recirculating loops as well as recirculating loops.

- It can be used to design any kind of reactor design.