What is Laminar flow hood/cabinet?

A laminar flow hood, or laminar flow cabinet, is a type of work environment used in pharmaceutical, medical, and research laboratories that creates a well regulated, sterilised environment when working with delicate material or processes. The main job of a laminar flow hood is to maintain an area free of contaminates by using a series of filters to catch particles and not allow them to enter the cabinet.

A laminar flow hood uses a series of filters to purify incoming air, generating laminar (uni-directional flow) air within the cabinet. This means that air flows in a clean, straight line, free from any turbulence. These cabinets generally use a pre-filter, a HEPA (High-Efficiency Particulate Air) filter and sometimes an additional ULPA (Ultra-Low Penetration Air) filter. The filters trap and remove dust, bacteria, and other particles from the air to ensure a controlled environment within the cabinet.

Laminar flow hoods are highly effective in aseptic applications such as sterile fluid handling and distribution, cell lab works, plate pouring, etc. This sterile setting protects the materials being handled from contamination, which guarantees their integrity and reliability.

It should be emphasized that laminar flow cabinets differ from biosafety cabinets when it comes to user protection. A biosafety cabinet protects both the sample and the user from potential threats, including biological agents or volatile chemicals. Compared to biosafety cabinets, chemical fume hoods are a simpler design with fewer protection features like negative pressure or HEPA-filtered exhaust air for employee protection. On the other hand, laminar flow cabinet protects the sample or the material that is manipulated rather than the operator. The exhaust air in a laminar flow cabinet is sucked toward the user’s face, putting the user at risk of exposure to any toxic compounds in the work area.

In general, a laminar flow hood or cabinet is an essential piece of equipment for creating a sterile and controlled work area. By reducing contamination risk, it helps ensure the quality and reliability of sensitive processes and materials. In pharmaceutical research, medical laboratories, and other businesses with aseptic requirements, laminar flow hoods are critical to protecting the integrity of sensitive work.

Definition of Laminar flow

Laminar flow refers to the smooth, uninterrupted flow of fluid, such as air or liquid, in parallel layers without any significant mixing or turbulence.

Principle of Laminar flow hood

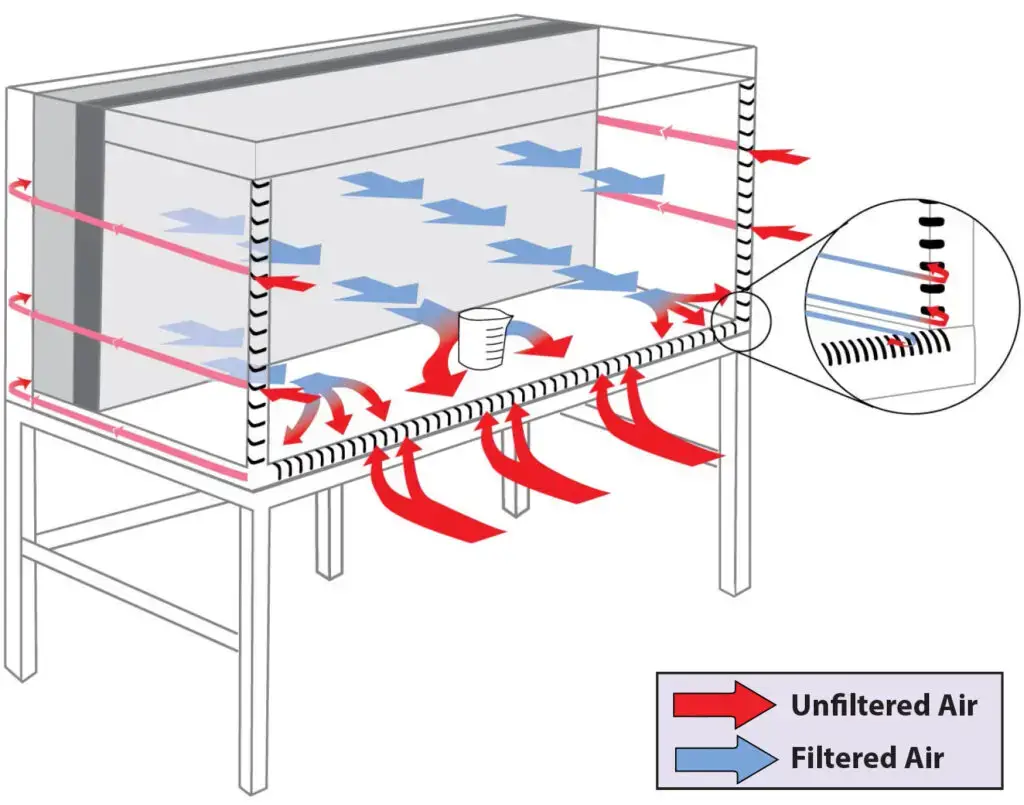

The laminar airflow hood is named after the laminar airflow that is produced within the unit. The unit relies on laminar airflow to pull air through one or more HEPA filters, creating air free of dust. The laminar flow is when the air is pulled through the filter system and exhausted over the work area. The air that comes into the unit first passes through the filter or pre-filter that generates the laminar flow in the unit. Next, the fan blows the air to the HEPA filters. The HEPA filters trap germs, dust and other particles, ensuring that air coming out of the unit is clean air. The rest of the exhaust moves the length of the workbench and comes out in the operator’s face, or is pulled through the intake in the back corner of the unit. A laminar flow hood is a completely sealed unit on all sides, with a constant positive air pressure from the inside that allows no (potentially contaminated) outside air to enter the room.

Components/ Parts of Laminar flow hood

- Cabinet- Stainless steel with welded seams or joints that do not trap debris or microbes; the cabinet houses the sterile chamber and protects it from external contamination.

- Work Surface- The surface of the cabinet chamber where work takes place. It is an expansive and easily cleaned surface so that equipment and samples are never compromised.

- Pre-Filter- Removes larger debris and particles from the air stream before they reach the HEPA filter, extending its life and the efficiency of the machine.

- HEPA Filter- The High-Efficiency Particulate Air (HEPA) filter captures 99.99% of all airborne particles down to 0.3 microns, ensuring that the air passing over the work surface is decontaminated.

- Fan/Blower – Draws air through the pre-filter and pushes air through the HEPA filter to create a laminar flow of sterile air over the work surface.

- UV Ligh- Decontaminates the inside of the cabinet when not in use to ensure no decontaminant is present on any surface.

- Fluorescent Light- Provides light inside the cabinet for viewing while working.

- Glass Screen- The cabinet door is a glass screen that swings open, or two cutouts allow hands to slide inside the cabinet.

Procedure for running the laminar flow cabinet

- Check the Cabinet- Check the laminar flow cabinet before you begin to make sure there is nothing inside that will be exposed to UV.

- Close the Cover Glass and Turn on UV- Close the cover glass of the hood and turn on the UV light. Let the UV light run for about fifteen minutes to decontaminate the bench area.

- Turn off UV and wait- After fifteen minutes, turn off the UV and wait another ten minutes before continuing.

- Turn on the Air- Finally, about five minutes before you begin, turn on the air to the laminar flow cabinet to ensure a filtered environment inside the cabinet.

- Detach the Cover Glass and Turn on the Fluorescent Light- Detach the cover glass from the cabinet to turn on the fluorescent light so you can see what you are doing.

- Optional: Sterilize the Countertop- You can also sterilize the countertop of the cabinet with 70% alcohol; However, this is not mandatory.

- Turn off the airflow and fluorescent lamp- At the end, turn off the airflow and fluorescent lamp. This saves energy and keeps the cabinet in good condition.

- Lower the glass shield of the laminar flow hood- At the end, lower the glass shield of the laminar flow hood.

Types of laminar flow cabinet

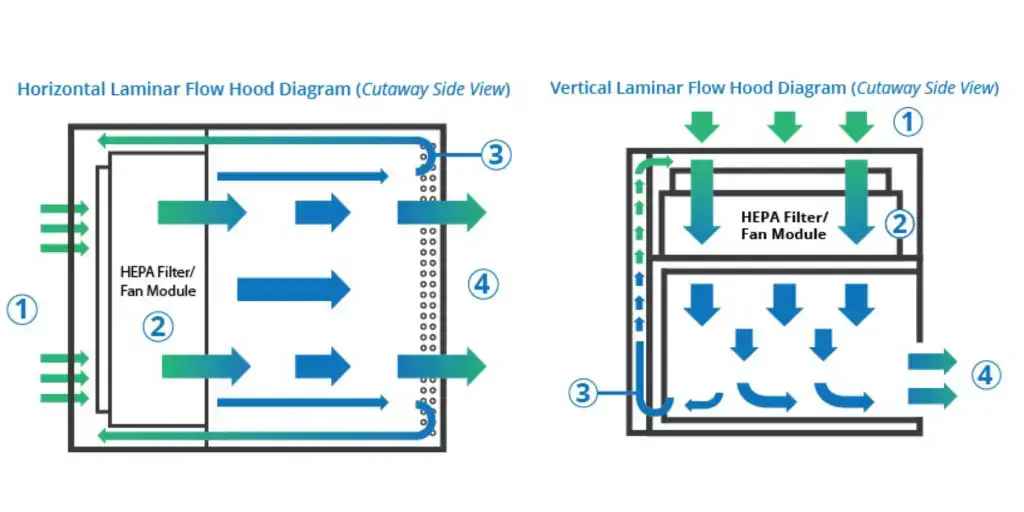

Based on the direction in which the air moves the laminar flow cabinets are classified into two kinds:

1. Vertical laminar flow cabinet

A vertical laminar flow cabinet is a type of laminar flow hood where the direction of airflow is vertically oriented. Here are some key features and advantages of a vertical laminar flow cabinet:

- Airflow Direction: In a vertical laminar flow cabinet, the air moves from the top of the cabinet downward towards the bottom. This vertical airflow pattern ensures that the clean, filtered air is directed towards the work surface and materials placed on it.

- Space Efficiency: Compared to horizontal airflow hoods, vertical laminar flow cabinets require less depth and floor space. This makes them more compact and easier to accommodate in laboratory or workspace settings. The reduced footprint also decreases the chances of airflow obstruction or movement of contaminated air downstream, ensuring a more consistent and reliable airflow.

- Improved Safety: One advantage of a vertical laminar flow cabinet is that it does not blow the filtered air directly towards the person carrying out experiments or tasks. This design feature enhances operator safety by minimizing the risk of exposure to potentially contaminated air. The vertical airflow helps to contain any potential contaminants generated during the operation within the cabinet, reducing the likelihood of their dispersal.

- Sterile Working Environment: The vertical laminar flow cabinet creates a highly controlled and sterile working environment. The downward airflow pattern effectively flushes away any particles, including dust, microorganisms, or contaminants, that may be present in the air, preventing them from settling on the work surface or materials.

- Easy Access: Vertical laminar flow cabinets typically feature a front access opening or sash that can be easily lifted or lowered. This allows convenient access to the work area and materials while maintaining the integrity of the sterile environment.

Overall, a vertical laminar flow cabinet offers advantages such as space efficiency, improved safety by avoiding direct airflow towards the operator, and a highly controlled sterile environment. These features make it a preferred choice for laboratories and workspaces where a clean and reliable airflow is required for sensitive procedures and experiments.

Vertical Laminar Flow Hood Advantages

- Space Efficiency: Vertical laminar flow hoods have a smaller depth, requiring less floor space compared to other types of laminar flow hoods. This makes them more manageable and suitable for laboratories or workspaces with limited space availability.

- Operator Safety: In vertical laminar flow hoods, the filtered air is not blowing directly at the operator. This design feature enhances operator safety by minimizing the risk of exposure to potentially contaminated air. Additionally, the presence of a sash provides a physical barrier in front of the operator’s face, further protecting them from any potential hazards.

- Easy Filter Access: The filters in a vertical laminar flow hood are located on top of the hood. This positioning makes them easily accessible for routine maintenance, such as filter replacement or servicing. This facilitates regular upkeep and ensures the continuous effectiveness of the filtration system.

- Reduced Turbulence: The vertical airflow pattern in these hoods results in less turbulent airflow. Large objects or processing equipment positioned on the work surface do not experience a significant striking force from the air, reducing turbulence and maintaining a more stable environment.

- Reduced Cross-Contamination: The vertical airflow in these hoods minimizes the cross-contamination of items placed on the work surface. The downward airflow helps to flush away any particles or contaminants, preventing them from settling on the surface and potentially transferring to other materials or samples.

- Increased Working Height: Vertical laminar flow hoods provide more working height compared to other types of hoods. This extra space accommodates tall or large equipment, allowing for convenient and comfortable use within the hood.

Vertical Laminar Flow Hood Disadvantages

- Overhead Clearance Requirement: Vertical laminar flow hoods may have overhead clearance requirements, especially when it comes to changing filters or servicing the unit. This might necessitate the use of a step-ladder or additional precautions to ensure safe access.

- Restricted Work Surface: To maintain proper airflow, items or hands cannot be placed on top of each other in a vertical laminar flow hood. This can limit the available work area and require careful organization and placement of materials and equipment.

- Increased Turbulence on the Work Surface: Due to the downward airflow, there may be an increased turbulent effect when the air strikes the work surface. This turbulence can disrupt delicate procedures or sensitive samples, requiring extra care during manipulations.

2. Horizontal laminar flow cabinet

A horizontal laminar flow cabinet is a type of laminar flow hood where the direction of airflow is horizontal. Here are some key features and considerations related to a horizontal laminar flow cabinet:

- Airflow Direction: In a horizontal laminar flow cabinet, the surrounding air is drawn in from behind the working bench and propelled by a blower towards the HEPA filters. The filtered air is then exhausted in a horizontal direction towards the workplace environment.

- Constant Velocity: One advantage of a horizontal laminar flow cabinet is that the airflow is parallel to the work surface. This provides a consistent and uniform cleansing effect throughout the workspace. The constant velocity of the airflow helps to minimize the potential for turbulence or pockets of stagnant air, ensuring a more controlled and sterile environment.

- Operator Exposure: One consideration with horizontal laminar flow cabinets is that the effluent air, after passing over the work surface, is directed towards the operator. This direct airflow towards the operator can reduce the security level of this type of laminar flow cabinet, as there is a higher potential for the operator to come into contact with any contaminants or particles that may be present in the air.

- Workspace Accessibility: Horizontal laminar flow cabinets typically feature a front access opening or sash that can be raised or lowered, providing easy access to the work area. This allows the operator to comfortably carry out tasks while maintaining the cleanliness and sterility of the workspace.

- Suitability and Applications: Horizontal laminar flow cabinets are commonly used in applications where a clean and sterile working environment is required, such as in laboratory research, pharmaceutical compounding, electronics assembly, or other precision manufacturing processes. They provide a controlled airflow pattern that helps to minimize the risk of contamination and maintain the integrity of sensitive work.

When choosing a laminar flow cabinet, the choice between horizontal and vertical airflow should be based on the specific requirements of the application, considering factors such as operator safety, workspace accessibility, and the desired airflow pattern. The horizontal laminar flow cabinet offers a parallel airflow that ensures consistent cleansing of the environment but requires attention to operator exposure.

Horizontal Laminar Flow Hood Advantages

- Parallel Airflow: In horizontal laminar flow hoods, the airflow is parallel to the work surface. This eliminates the turbulent effects caused by vertical airflow striking the work surface perpendicularly. The parallel airflow provides a consistent and uniform environment for working with sensitive samples or delicate procedures.

- Enhanced Positioning of Sterile Equipment: The horizontal airflow allows for easier positioning and staggering of sterile equipment and materials on the work surface. By placing them closer to the filter face (upstream), they are protected from potential contaminants present downstream. This configuration helps maintain a higher level of sterility for critical operations.

- Reduced Contamination from Hands and Gloves: In horizontal laminar flow hoods, hands and gloves are generally positioned downstream of the sample or work area. This reduces the risk of contamination, as any potential contaminants generated by the hands or gloves are carried away from the sterile workspace by the laminar airflow.

Horizontal Laminar Flow Hood Disadvantages

- Rear Access for Filter Change or Service: Changing filters or performing maintenance on a horizontal laminar flow hood often requires repositioning the hood for rear access. This can be more time-consuming and may disrupt ongoing work in the hood during the servicing process.

- Potential Contamination from Large Samples: Large samples or objects placed on the work surface can obstruct the laminar airflow and create areas of turbulence. This turbulence can lead to contamination of downstream samples or materials, requiring careful consideration of sample placement to maintain the integrity of the sterile environment.

- Risk of Blowing Fumes or Powders into Operator’s Face: If used without a sash or proper containment measures, a horizontal laminar flow hood can blow fumes or powders directly into the operator’s face. This can pose a risk to the operator’s safety and potentially compromise the sterility of the working environment. It is important to use appropriate containment measures, such as a sash or suitable enclosures, to prevent such incidents.

Vertical vs Horizontal Laminar Airflow Hoods

| Aspect | Vertical Laminar Flow Hood | Horizontal Laminar Flow Hood |

|---|---|---|

| Airflow Direction | Top to bottom | Back to front |

| Space Efficiency | Requires less depth, suitable for limited floor space | Requires more depth, may require more floor space |

| Operator Safety | Air does not blow directly at the operator, sash provides barrier | Airflow parallel to the operator, may blow fumes or powders |

| Filter Access | Filter located on top, easily accessible | Filter change or service may require repositioning for rear access |

| Turbulent Effects | Less turbulent, reduced effect on large objects | Parallel airflow, reduced turbulence on work surface |

| Cross-Contamination | Reduced cross-contamination of items on work surface | Large samples can obstruct airflow, may contaminate downstream area |

| Working Height | Limited working height | More working height, suitable for tall or large equipment |

| Overhead Clearance Requirement | Minimal overhead clearance required | Potential overhead clearance requirement for filter change/service |

| Sample Placement Restrictions | No restrictions on placing items on top of each other | Items cannot obstruct airflow, careful placement required |

Uses of Laminar flow hood

- This is used in laboratories for cell culture to prevent contamination.

- This is used in the pharmaceutical industry for sterile drug preparation.

- This helps maintain food safety in food processing and packaging.

- This is used in electronics to keep components dust-free during assembly.

- This is essential for aseptic tissue culture techniques.

- This provides a sterile environment for virus inoculation in research.

- This ensures contamination-free media preparation and sterilization.

- This is used in hospitals to protect patients in ICUs and operating rooms.

Disadvantages of Laminar flow hood

- Limited workspace – Small area restricts handling large items.

- High energy consumption – Requires continuous electricity use.

- Frequent maintenance – Needs regular cleaning and filter changes.

- Noisy operation – Fans and filters can create distractions.

- Overhead clearance needed – Requires space for servicing and filter changes.

- Airflow disruption – Fast movements or improper placement can affect sterility.

- Limited airflow control – Cannot be used for high airflow applications.

Advantages of Laminar flow hood

- Prevents contamination – Filters out airborne particles to maintain cleanliness.

- Consistent airflow – Minimizes turbulence, reducing cross-contamination.

- Protects products – Keeps sensitive materials safe during processes.

- Versatile – Used in microbiology, electronics, pharmaceuticals, and more.

- Improves accuracy – Ensures reliable experimental results by maintaining sterility.

- User-friendly – Ergonomic and easy to use.

- Ensures safety – Protects both the user and the product.

- Meets standards – Helps comply with industry cleanliness and contamination control.

Precautions

- Wear PPE – Use lab coat, gloves, and safety goggles.

- Turn off UV light – Avoid exposure during operation.

- Do not block airflow – Keep materials arranged properly.

- Work inside the hood – Stay at least 6 inches inside.

- Perform regular maintenance – Check and clean filters regularly.

- Avoid rapid movements – Prevent airflow disruption.

- Limit talking – Reduce contamination risk.

- Keep the hood clean – Disinfect before and after use.

How to Clean a Laminar Flow Hood

Cleaning a laminar flow hood isn’t rocket science, but it’s one of those tasks where attention to detail really matters. If you’ve ever worked in a lab, you know these hoods are the unsung heroes of sterile work—so keeping them clean is non-negotiable. Let me walk you through the process like I’d explain it to a coworker grabbing coffee between experiments.

What You’ll Need:

- 70% isopropyl alcohol (the gold standard for disinfecting)

- Sterile wipes (lint-free, unless you enjoy chasing stray fibers)

- Distilled water (tap water leaves mineral spots—no thanks)

- Disposable gloves (protect your hands and the workspace)

- A spray bottle (for mixing alcohol and water)

- A small brush or vacuum (for crumbs… or whatever ends up in there)

Step 1: Prep Work

First things first—turn off the hood and unplug it. You don’t want airflow blowing your cleaning solution everywhere (or worse, accidentally aerosolizing contaminants). Let it sit for 10-15 minutes to settle any particles. While you wait, throw on gloves and wipe down your tools with alcohol. Even your spray bottle needs to stay clean—no cross-contamination allowed.

Step 2: Wipe Down Surfaces

Mix 70% alcohol with a splash of distilled water in the spray bottle. Avoid soaking surfaces; a light mist does the trick. Start at the back wall and work forward, using smooth, overlapping strokes with sterile wipes. Think of it like painting a wall—no random swiping. Pay extra attention to corners and crevices where gunk loves to hide.

For stubborn residue, let the alcohol sit for a minute. If it’s still not budging, check if your lab approves a stronger disinfectant (but never mix chemicals—safety first!).

Step 3: Clean the Filter Grilles

The filter area is delicate, so skip the harsh scrubbing. Use a soft brush or a vacuum with a HEPA filter to gently remove dust from the grilles. If there’s visible grime, lightly dampen a sterile wipe with alcohol and wipe in one direction. Aggressive scrubbing here is like using a chainsaw for origami—just don’t.

Step 4: Tackle the Exterior

Spray the outside surfaces (sides, control panels, etc.) with alcohol and wipe them down. Don’t forget the base or wheels—dirt loves to hitchhike there. If the hood has a glass screen, use a streak-free glass cleaner after disinfecting.

Step 5: Final Checks

Let everything air-dry completely before restarting the hood. Double-check that no wipes or tools are left inside (we’ve all been there). Run the hood for 10-15 minutes to flush out any lingering particles.

Pro Tips:

- Frequency: Clean before and after every use. Deep-clean monthly.

- Avoid Bleach: It corrodes stainless steel—stick with alcohol.

- Log It: Track cleaning dates. Future-you will high-five past-you during audits.

Why Bother?

A dirty laminar flow hood is like a surgeon using a rusty scalpel—it defeats the purpose. Regular cleaning keeps experiments uncontaminated and ensures the hood lasts longer. Plus, lab managers notice when someone skips steps.

There you go—no jargon, no fluff. Just a straightforward routine to keep your hood (and your experiments) in top shape. Now go forth and sterilize! 🔬✨

Do’s and Don’ts When Using Laminar Flow Cabinets

Do’s

- Wipe the work surface with a disinfectant such as 70% isopropyl alcohol before and after use

- Use only items that have been properly sterilized

- Wash hands before and after using the cabinet

- Wear proper protective gear like gloves, a lab coat, and a hair net

- Arrange items in line with the laminar airflow

- Use the UV-C light only for pre-use sterilization and turn it off during work

- Check that the airflow is within the recommended range

- Follow the manufacturer’s guidelines for regular maintenance and HEPA filter replacement

Don’ts

- Do not place non-sterile items or waste inside the cabinet

- Do not overload the work area with unnecessary items

- Do not block the airflow with large objects or equipment

- Do not spray cleaning solutions directly onto the HEPA filter or cabinet walls

- Do not work in the cabinet if the airflow is disrupted or if the equipment malfunctions

- Do not use the cabinet with the UV-C lamp on during work

- Do not use the cabinet for handling hazardous or infectious materials

FAQ

What is a laminar flow hood/cabinet?

A laminar flow hood/cabinet is an enclosed workstation used to create a contamination-free environment by directing filtered air in a unidirectional flow.

How does a laminar flow hood/cabinet work?

The hood/cabinet draws in ambient air, which is filtered through HEPA filters to remove particles and microorganisms. The filtered air is then released in a laminar flow over the work surface, providing a sterile environment for various laboratory processes.

What is the difference between a laminar flow hood and a biosafety cabinet?

While both laminar flow hoods and biosafety cabinets provide a controlled environment, the main difference is in the direction of airflow. In a laminar flow hood, the air flows towards the work surface, while in a biosafety cabinet, the air is recirculated to protect both the sample and the user.

What are the advantages of a laminar flow hood/cabinet?

Some advantages of laminar flow hoods/cabinets include creating a sterile work environment, preventing contamination of samples, providing a barrier against external contaminants, and facilitating aseptic techniques in laboratory processes.

What are the different types of laminar flow hoods/cabinets?

There are two main types: vertical laminar flow hoods/cabinets, where air flows from top to bottom, and horizontal laminar flow hoods/cabinets, where air flows from the back to the front.

What are the typical applications of laminar flow hoods/cabinets?

Laminar flow hoods/cabinets are commonly used in microbiology laboratories, pharmaceutical industries, plant tissue culture, electronics assembly, and other processes that require a sterile and controlled environment.

How often should the filters in a laminar flow hood/cabinet be replaced?

The frequency of filter replacement depends on various factors, such as the level of usage, the type of contaminants being handled, and the manufacturer’s recommendations. It is important to follow the maintenance guidelines provided by the manufacturer.

Can a laminar flow hood/cabinet eliminate all types of contaminants?

Laminar flow hoods/cabinets are highly effective in removing airborne particles and microorganisms. However, they may not be able to eliminate certain chemical vapors or gases. Additional precautions may be necessary when working with hazardous substances.

How should the laminar flow hood/cabinet be cleaned and maintained?

Regular cleaning of the work surface and other components with appropriate disinfectants is important to maintain a sterile environment. The cabinet should also undergo periodic maintenance and filter replacement as recommended by the manufacturer.

Are there any safety considerations when using a laminar flow hood/cabinet?

It is crucial to adhere to safety protocols and wear appropriate personal protective equipment (PPE) when working with a laminar flow hood/cabinet. This includes wearing gloves, lab coats, and safety goggles to protect against potential hazards and maintain aseptic conditions.

- http://escolifesciences.pk/news/1368/

- https://www.terrauniversal.com/blog/horizontal-vs-vertical-laminar-flow-hoods/

- https://microbenotes.com/laminar-flow-hood/

- https://www.lamsys.com/products/vertical_laminar_flow/

- https://www.laminarflows.co.uk/

- https://magnaflux.eu/en/Resources/FAQs/FAQs-UV-Lamps

- https://en.wikipedia.org/wiki/Laminar_flow_cabinet

- https://www.trane.com/residential/en/products/indoor-air-quality/cleaneffects/

- https://www.sciencedirect.com/topics/immunology-and-microbiology/laminar-flow-cabinet

- https://www.safety.rochester.edu/ih/uvlight.html