What is Laboratory Incubator?

A Laboratory Incubator is described as a device that is used to grow and maintain microbial / cell cultures under controlled temperature, humidity, and gas conditions.

The environment inside is usually kept stable, and temperature is controlled (often by thermostats/sensors), though fluctuations are caused by door openings.

For mammalian cells, a controlled CO₂ level (about 5%) is commonly maintained, and humidity is regulated to prevent media drying.

The inner chamber is often constructed from stainless steel, which is cleaned / disinfected frequently to avoid contamination.

Air circulation is provided in many models by fans, but in some types air-movement is minimized, to be gentle on samples.

Petri dishes, test tubes, flasks are commonly used to hold cultures, and they are placed on shelves which are adjusted for space.

The Temperature Control System is relied upon as the critical component and is monitored by digital displays and alarms, though analog controls are still used in older units.

Escherichia coli (E. coli) is often incubated at 37 °C for 24 hrs to promote colony growth, this is an example that is widely followed.

In some incubators, a shaking-platform is provided which mixes the culture to improve oxygenation and uniformity of growth.

Regular cleaning and sterilization are recommended, otherwise contamination is introduced from airborne particles or dust, it spoils experiments.

Power fluctuations are known to affect performance, therefore voltage stabilizers are sometimes implemented by labs.

Incubators are classified into types such as BOD, CO₂, shaking, and humidity-controlled incubators, and each are chosen for specific applications.

The samples are observed after an incubation period which may vary widely, from hours, to days, depending on organism and purpose.

When the door is opened frequently, heat loss is caused and growth rates are affected, so double doors or tight seals are often designed.

Used in microbiology, cell biology, molecular biology labs and pharma testing, they are essential for many experimental workflows.

Walking into the lab, humming was heard from incubators — a faint, constant sound that is noticed often.

The device is trusted for providing reproducible conditions, but they are still sensitive to user error and environmental changes.

Safety features (alarms, automatic cutoffs) are included in many models, though simple units may only have basic knobs; maintenance is required.

Incubator definition

A laboratory incubator is a heated, insulated device used to grow and maintain cell or microbiological cultures by controlling temperature, humidity, and CO2 levels.

Principle of Incubator

The Principle of Incubator is that a controlled environment is provided, so growth conditions (temperature, Humidity, gas composition) are held constant for biological samples.

Temperature Control System is relied upon as the primary mechanism and is regulated by sensors/thermostats, while heat is supplied by heaters and sometimes by hot water jackets.

A stable temperature is maintained (commonly 37°C or 25 °C depending on organism), and fluctuations are minimized by insulation, though door openings cause rapid change, which is noticed.

Humidity is controlled to prevent media drying and to maintain water balance, and it is often achieved by a water tray or a humidifier that is included in the chamber.

Gas composition (such as CO₂) is adjusted in CO₂ incubators to maintain pH of culture media, and gas is supplied from cylinders or built-in generators; pH is thus held indirectly.

Air circulation is provided in many units so uniform conditions are produced, but in some designs air-movement is reduced to avoid evaporation, and fans or baffles are used.

Sterility/ contamination control is attempted by materials selection (stainless steel inner chamber), by HEPA filters in some models, and by periodic cleaning/sterilization, yet contamination still occurs if protocols are not followed.

Sensors are calibrated and read-outs are monitored digitally, alarms are set to trigger if set-points are deviated, and manual checks are performed by users.

Heat transfer is accomplished by conduction and convection within the incubator, which ensures even temperature distribution though hot spots may be formed near walls.

Biological rationale: cell metabolism is influenced by environmental parameters, so control is provided to mimic in vivo conditions, examples include mammalian cells at 37°C and bacteria at lower or higher temps.

Such as, Escherichia coli (E. coli) is incubated at about 37°C for growth and its requirement is met by the incubator’s set-up.

Safety and reproducibility are emphasized, and reproducible results are obtained when conditions are kept constant, but user error can disrupt it easily.

The control loop is simple: sensor reads, controller compares to set-point, actuator (heater/cooler/humidifier) responds, and the environment is corrected, this feedback is continuous.

In some systems shaking or agitation is combined with temperature control (shaking incubators) so oxygenation and mixing are also provided for suspension cultures.

It is assumed that heat losses are prevented by insulation and door design, though sometimes, they are underestimated and experiments are affected.

Researchers set parameters actively, but most of the work is done automatically by the incubator once conditions are programmed, they then monitor outcomes.

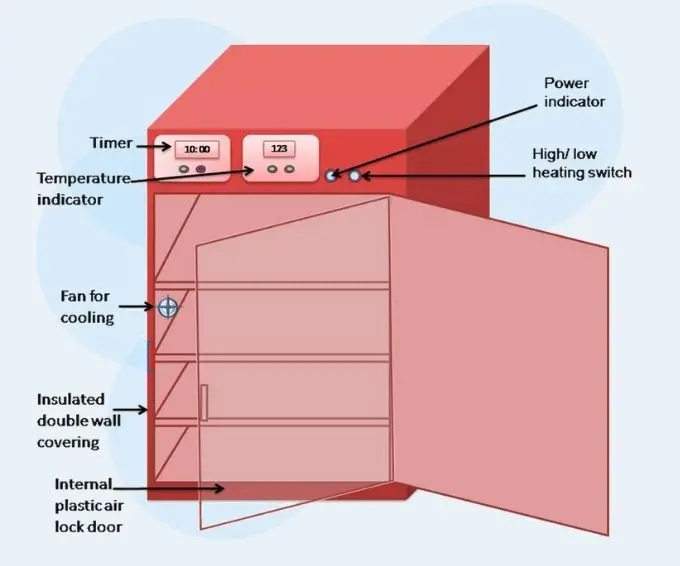

Parts/Components of Incubator

- Outer body – It is made usually of mild steel or stainless steel and it provides structural support, the finish is painted / powder-coated to resist corrosion.

- Inner chamber– Constructed of stainless steel, the working space is provided for samples and it is designed to resist moisture and contamination.

- Insulation layer – A layer (glass wool or polyurethane foam) is placed between outer and inner walls to reduce heat loss and maintain uniform temperature.

- Door / Viewing window – A double door arrangement is often fitted, the inner window is transparent so samples can be seen without opening the door.

- Shelves / Trays – Adjustable shelves are supplied for holding plates, flasks, tubes and they are removable for cleaning.

- Heating element – Electric heaters are installed around or beneath the chamber and heat is produced which is regulated by the controller (PID or simple thermostat).

- Thermostat / Temperature controller – The temperature is sensed by a probe, compared to set-point by the controller, and heating is adjusted automatically, alarms are set for deviation.

- Air circulation fan – Air movement is provided in many models to promote uniform conditions, though in some designs fans are omitted to reduce evaporation.

- Humidity control system – Humidity is maintained by water trays or automatic humidifiers so media drying is prevented, sometimes humidification is passive.

- CO₂ inlet system – Gas (CO₂) is supplied in CO₂ incubators, and pH is thereby stabilised for mammalian cultures (commonly 5% CO₂).

- HEPA filter / Sterilization features – HEPA filters, UV lamps or sterilizable surfaces are included in some models to lower contamination risk, but they are not fail-proof.

- Thermometer / Display panel – Digital or analog displays are provided to show temperature (and sometimes RH, CO₂), and alerts are triggered when set-points are missed.

- Safety devices – Over-temperature cut-off, fuses, and alarms are fitted to protect samples and equipment, manual overrides are sometimes present.

- Power supply / Voltage stabilizer – Power is supplied via mains and, when needed, voltage stabilizers are used to prevent performance disruption.

- Drain / Outlet port – A drain or outlet is provided at the base for removing condensate / cleaning fluids after maintenance.

- Lighting (optional) – Internal light is installed in some units for observation, though constant illumination is avoided for light-sensitive samples.

- Shaking platform (if present) – In shaking incubators a platform is mounted which is driven to provide agitation, oxygenation is improved for suspension cultures.

- Seals / Gaskets – Door seals are fitted to reduce heat loss and they are checked often, sometimes they are neglected and leaks are formed.

Types of Incubator in laboratory

There are present different types of laboratory incubator such as;

- BOD Incubator – It is mainly used for biological oxygen demand test (BOD test) which are performed at low temperature (around 20°C). The temperature control is maintained through compressor cooling and heating system. Often, these are used for studying fungi, bacteria and other microorganisms which grow in lower temperature environments.

- CO₂ Incubator – These incubators are designed for maintaining a controlled atmosphere of carbon dioxide (usually 5%) and humidity, used especially for mammalian cell culture. Inside chamber temperature usually remain 37°C. It is often operated automatically with sensors for gas and humidity level.

- Shaking Incubator– A shaker is attached inside the incubator that provide constant agitation / movement to liquid cultures. Used mainly for cell aeration and uniform mixing. Bacterial culture in broth media is generally grown in this type of incubator.

- Refrigerated Incubator – This incubator is capable of maintaining temperature below room temperature (often 5°C to 60 °C). It is applied when samples or cultures require cooler condition like enzyme storage or fish egg incubation.

- Dry Incubator– Heating is provided through dry air circulation instead of water jacket. The moisture level are not maintained, making it suitable for drying slides or samples rather than microbial culture.

- Hybrid / Combined Incubator – In such models, features of more than one type are combined (for example, shaking + CO₂ incubator). They are widely used in research setups where multiple environment control is required.

- Anaerobic Incubator – It is used for growing anaerobic microorganisms (which can’t tolerate O₂). The chamber is sealed and filled with specific gas mixture (N₂, CO₂, H₂). Sometimes, catalysts are used to remove traces of oxygen.

- Humidity Incubator– These are designed for maintaining specific humidity level (usually 90–95%) for samples that dehydrate easily. Common in tissue and plant culture labs.

Operating Procedure of an incubator

- Before use, the incubator chamber is usually cleaned properly with disinfectant or alcohol (70%) to remove any contamination, sometimes cotton swab is used for corners which are difficult to reach.

- The power switch is turned ON, and the main supply connection is checked whether it’s properly connected or not, sometimes fluctuations in power may affect temperature stability.

- Temperature is then adjusted according to the experimental requirement (like 25°C for fungi or 37 °C for bacteria), and the thermostat knob or digital controller is set accordingly.

- In many cases, the incubator is allowed to preheat for some time (approx. 15–30 min) until the internal temperature stabilizes near the desired point.

- After the temperature becomes steady, the inoculated culture plates / tubes / flasks are placed carefully inside the chamber shelves.

- It is ensured that sufficient space is kept between each sample for proper air circulation, because overcrowding may cause uneven heating in the chamber.

- The incubator door is closed tightly to prevent heat loss and contamination entry, the door shouldn’t be opened frequently during incubation.

- During operation, temperature (and sometimes humidity or CO₂ level in specific type) are observed at regular intervals to confirm stability of conditions.

- Incubation is carried out for the required time depending upon the organism or process, e.g., Escherichia coli usually 24 hrs at 37°C.

- After completion of incubation period, the cultures are removed, and the power of incubator is turned OFF.

- The inside chamber is cleaned again if any spillage or condensation was formed, to maintain hygienic condition for next use.

- Records of temperature and duration are written / logged in laboratory register for reference and quality purpose.

Application of Incubator

- Incubators are widely used for culturing of microorganisms such as bacteria, fungi, and yeast, where controlled temp (usually 35–37°C) is maintained for their proper growth and development.

- They are also applied in tissue culture works, mainly for maintaining the growth of animal and plant cells under sterile and controlled environmental conditions.

- In many biochemical experiments, reactions like enzyme kinetics or protein denaturation are carried out within incubators since precise thermal conditions are required.

- Microbial testing of pharmaceutical samples is done using incubators, where samples are kept for specified hours/days to check microbial load presence.

- Hatching of eggs / embryological studies are performed using special types of incubators which maintain humidity (60–70%) and warmth (37°C approx).

- Blood samples and serum incubation in clinical laboratories is another common application where biological materials are kept at specific temperature for reaction completion.

- Genetic engineering laboratories often use incubators for maintaining bacterial culture used for DNA cloning or plasmid amplification (like E. coli).

- In food and dairy industries, incubators are used for microbial testing / fermentation process (such as for yogurt making or spoilage test).

- Research and educational laboratories utilize incubators for demonstration and practical training on microbial growth patterns and colony morphology.

- Some incubators are applied for storage of temperature-sensitive materials, including reagents, culture media, and vaccines that require constant environmental conditions.

Advantages of Incubator

- The incubator provides a controlled environment where temperature, humidity, and sometimes CO₂ level are maintained for growth of organisms or cells.

- A stable temperature is ensured, so fluctuations are minimized which could otherwise affect results accuracy / reproducibility.

- Because of the enclosed chamber, contamination from outside air or dust is largely prevented though sometimes small leaks occur.

- Uniform heat distribution is achieved by internal fans or heating coils, that keeps every culture tube or plate in nearly same condition.

- It is easy to operate and handle, no complex setup is usually required except for digital or CO₂ types.

- Cultures can be observed and monitored periodically without disturbing the growth environment much (especially if glass door is present).

- The incubator allows consistent and repeatable results, since same environmental condition can be maintained in each experiment.

- For long-term incubation, samples are protected from drying or over-heating by regulated humidity and temperature balance.

- Because experiments are done inside closed cabinet, safety of operator from microbial exposure is also increased (though not fully sterile chamber).

- Energy efficiency is quite good for modern incubators, as temperature is automatically adjusted through thermostatic control systems.

Limitations of Incubator

- Temperature fluctuations are often observed especially when door is opened frequently, causing uneven growth in cultures or sudden stress in cells.

- The incubator is highly dependent on electricity, so any power failure may interrupt incubation cycle and damage samples.

- Contamination risk remains a big problem if cleaning or sterilization is not done properly inside chamber walls or shelves.

- In many simple models, humidity and CO₂ levels can’t be controlled precisely, which limit their use for sensitive cell cultures.

- Due to continuous operation, heat accumulation inside lab room sometimes make working conditions uncomfortable for person.

- Space limitation occurs because only few culture plates or flasks can be placed depending on size, larger batches require multiple units.

- Long incubation period may lead to sample dehydration or overgrowth of unwanted colonies (especially for bacteria like Bacillus subtilis).

- Maintenance is required regularly, since dust, moisture, and microbial residues may build up on internal parts causing faulty temperature reading.

- Incubators are often expensive for advanced types (like CO₂ incubator) and their repair cost can also be quite high sometimes.

- When temperature sensors or thermostats malfunction, serious overheating or underheating may happen leading to complete experiment loss.

Precautions

- The incubator must be cleaned / sterilized before use, surfaces are to be wiped down and old culture residues should be removed, otherwise contamination may be introduced.

- Temperature setting is to be checked and the thermometer calibrated (if available) before samples are placed, because wrong temp leads to bad results.

- Frequent door opening should be avoided, as sudden heat loss is caused and uneven conditions are produced inside the chamber.

- Samples must be arranged with space between them so airflow is not blocked, overcrowding are often found to cause patchy growth.

- Before placing, glassware and media are to be sterilized, and they should be kept covered to reduce dust/airborne contamination.

- Spills of liquid medium are to be prevented since heater elements can be damaged, and moisture build-up may result in sensor faults, it is risky.

- The incubator should be located in a dry, dust free area, away from direct sunlight and vibration; otherwise temperature fluctuation will occur.

- Electric cords and switches must be inspected regularly, Check the cords yourself because short-circuit / spark may cause power failure or fire.

- Regular maintenance and disinfection are to be performed (alcohol, mild disinfectant), shelves must be removed and cleaned, dust and residues are otherwise accumulated.

- Flammable solvents must not be stored inside incubator, high temp may cause fumes or explosion, safety is compromised.

- In CO₂ / humidity models, water reservoirs are to be cleaned often because stagnant water promotes fungal growth such as Aspergillus niger, they are sneaky.

- Gloves and lab-coat must be used when handling cultures, since direct exposure can lead to contamination or infection, and hands are to be washed afterwards.

FAQ

Do all incubators need CO2?

Not all incubators include a system for controlling the concentration of carbon dioxide (CO2) in the air inside the incubator. Some incubators rely on other methods to regulate the humidity and temperature inside the incubator.

However, many incubators, particularly those used for incubating eggs from certain species, do include a CO2 control system. This is because the concentration of CO2 in the air can affect the humidity and temperature inside the incubator, and by controlling the CO2 concentration, incubator operators can better regulate these variables. Maintaining a stable and controlled environment inside the incubator is important for the proper development of the eggs being incubated, as it can improve the chances of successful hatching.

Ultimately, whether or not an incubator needs a CO2 control system depends on the specific requirements of the eggs being incubated and the goals of the incubator operator. Some eggs may require a specific humidity or temperature range to develop properly, and a CO2 control system may be necessary to achieve these conditions.

Why are incubators kept at 37 degrees?

Incubators are often kept at a temperature of around 37 degrees Celsius (98.6 degrees Fahrenheit) because this is the temperature that is optimal for the development of many types of eggs, including chicken eggs. This temperature is close to the body temperature of the parent bird, and it is believed to be the temperature that provides the best environment for the embryo to grow and develop.

Maintaining a stable and consistent temperature inside the incubator is important for the proper development of the eggs being incubated. If the temperature fluctuates too much or is too high or too low, it can disrupt the development of the embryo and may result in abnormal or unsuccessful hatching.

It’s worth noting that the optimal temperature for incubating eggs may vary depending on the species of the eggs being incubated. For example, some species of reptiles and birds may require slightly higher or lower temperatures than chicken eggs. Incubator operators should carefully research the specific temperature requirements of the eggs they are incubating to ensure that the incubator is set to the appropriate temperature.

How long can an incubator stay without electricity?

The length of time that an incubator can stay without electricity will depend on a variety of factors, including the type of incubator, the stage of development of the eggs being incubated, and the ambient temperature.

In general, incubators that are designed for incubating chicken eggs can usually stay without electricity for a few hours without harming the eggs, as long as the ambient temperature is not too hot or cold. However, if the incubator is without electricity for an extended period of time, the eggs may start to lose moisture and the embryos may begin to dry out, which can lead to abnormal or unsuccessful hatching.

If the eggs being incubated are at a more advanced stage of development, they may be more sensitive to changes in temperature and humidity and may be more likely to be affected by a power outage. In this case, it may be necessary to try to restore power to the incubator as soon as possible in order to maintain the optimal environment for the eggs.

It’s important to note that if the incubator is without electricity for an extended period of time, it may be necessary to discard the eggs and start again with fresh eggs. This is because the eggs may have been exposed to conditions that are not suitable for their development, which can result in abnormal or unsuccessful hatching.

Is oxygen necessary for incubator?

Oxygen is necessary for the proper development of eggs being incubated in an incubator. The embryo inside the egg uses oxygen as a source of energy for growth and development. Without an adequate supply of oxygen, the embryo may not develop properly and may be more likely to experience abnormal or unsuccessful hatching.

Incubators are designed to provide a controlled environment for the eggs being incubated, and this includes regulating the amount of oxygen in the air inside the incubator. Most incubators include a ventilation system that helps to circulate fresh air and maintain a proper oxygen level inside the incubator.

It’s worth noting that the specific oxygen requirements for incubating eggs may vary depending on the species of the eggs being incubated. Some eggs may require higher or lower levels of oxygen than others in order to develop properly. Incubator operators should carefully research the specific oxygen requirements of the eggs they are incubating to ensure that the incubator is providing an optimal environment for the eggs.

Does incubator need water?

Incubators typically do not require a direct water supply, as the eggs being incubated are not directly in contact with water. However, the air inside the incubator may need to be humidified in order to maintain a suitable environment for the eggs being incubated.

One way that incubators maintain humidity is by controlling the concentration of carbon dioxide (CO2) in the air. CO2 can be absorbed and released by water, and by controlling the concentration of CO2, incubator operators can regulate the humidity inside the incubator.

Another way that incubators maintain humidity is by using a water pan or tray. This is a container that holds water and is placed inside the incubator. As the water evaporates, it helps to increase the humidity inside the incubator. The water pan or tray should be kept full in order to maintain a sufficient level of humidity inside the incubator.

Overall, while incubators do not typically require a direct water supply, they may require a source of water in order to maintain the proper humidity inside the incubator, which is important for the proper development of the eggs being incubated.

Why do you put water in an incubator?

The water in an incubator is used to help maintain the humidity inside the incubator at a suitable level for the eggs being incubated. The eggs need a certain level of humidity in order to develop properly, as the eggs absorb and release moisture during the incubation process.

One way that incubators maintain humidity is by using a water pan or tray. This is a container that holds water and is placed inside the incubator. As the water evaporates, it helps to increase the humidity inside the incubator. The water pan or tray should be kept full in order to maintain a sufficient level of humidity inside the incubator.

It’s worth noting that the specific humidity requirements for incubating eggs may vary depending on the species of the eggs being incubated. Some eggs may require higher or lower levels of humidity than others in order to develop properly. Incubator operators should carefully research the specific humidity requirements of the eggs they are incubating to ensure that the incubator is providing an optimal environment for the eggs.

- Text Highlighting: Select any text in the post content to highlight it

- Text Annotation: Select text and add comments with annotations

- Comment Management: Edit or delete your own comments

- Highlight Management: Remove your own highlights

How to use: Simply select any text in the post content above, and you'll see annotation options. Login here or create an account to get started.