- A production or fermentation medium is a growth media intended for the culture of a production strain and subsequent manufacture of either microbial cells or a biochemical product.

- Designing an appropriate production medium is one of the challenges associated with industrialising fermentation. This is accomplished by trial and error.

- During batch fermentation, the fermentor is filled with the production medium, leaving headspace.

- According to the type of fermentation procedure, the producing strain is added in a particular way (e.g. surface culture or submerged culture method).

- Typically, liquid production media are employed to aid the fermentation process.

What is Fermentation media?

For a good output of product during a fermentation process, the selection of the optimal microorganisms and fermentation media is crucial. As it provides nutrients and energy for the growth of microorganisms, the quality of fermentation media is vital. This medium serves as a substrate for the production of a product in a fermentor.

- The components of fermentation media comprise of major and minor components.

- Sources of Carbon and Nitrogen are among the primary components.

- Inorganic salts, vitamins, growth stimulants, anti-foaming chemicals, buffers, dissolved oxygen, other dissolved gases, growth inhibitors, and enzymes are minor components.

The nutrients required for fermentation media also depend on the type of organisms to be fermented and the intended fermentation procedure. A poor selection of fermenting media may result in a low output yield. Product yield is always determined by the nutritional composition of the fermentation medium.

Role of Fermentation media

- During the fermentation process, the medium is rich in nutrients, microorganisms, and ideal conditions.

- When these microorganisms are incubated under optimal settings, they have a lavish metabolic rate. Due to the abundance of nutrients, the organisms involved in fermentation become hyperactive, resulting in the consumption of excess nutrients and partial destruction of the fermentation medium.

- The bacteria’ waste effluents could be the desired output product of the fermentation process.

- The amount of substrate provided to microorganisms should not reach inhibitory concentrations, as excess substrate inhibits key enzymes and may cause cell death. Additionally, cytoplasmic water is essential to the metabolic process.

- If sufficient sugar or salt is present in the fermentation medium, it will bind cytoplasmic water, which may lead to a lack of water for metabolism and the death of microorganisms, so decreasing fermentation yield.

- An excess of substrate can increase a cell’s osmotic pressure and inhibit enzyme activity. This extra substrate is excreted by microbes as partially digested fermentation medium.

- It is transformed into an insoluble inert chemical in the form of reserve food material, which is harmless to cells.

Types of Media

There are two uses of fermentation media

- Growth media: Low concentrations of nutrients are present in the growth medium. It is useful for the production of raw materials for further fermentation operations.

- Fermentation media: High concentrations of nutrients are present in fermentation media. It is utilised in the fermentation of final goods. For instance, yeast development requires 1% carbon. However, during alcohol fermentation, yeast requires 12 to 13% carbon in the medium.

Types of Fermentation media

There are two types of industrial fermentation media.

- Synthetic media

- Crude media

Synthetic media

- Because each and every component is chemically known and the exact composition of nutrients is predetermined, synthetic media is useful in the field of study.

- Therefore, fluctuation in nutrient amounts and concentration can be managed in synthetic medium. Here, by experimentation with synthetic medium, it is possible to examine the impact of nutrients on plant development and yield.

- We can modify synthetic media to suit our demands. It is highly beneficial for managing the growth and yield of lab-grown products. We can also use it to determine the metabolic pathway utilised during product synthesis.

- With the aid of radio-isotope tagging, we are able to determine the primary materials needed to generate the finished product. This enables us to determine the precise quantities of elements required for our method.

- We can optimise this process by utilising other sources of carbon or nitrogen and by developing an optimal fermentation medium.

- As the results are accurately reproducible for a given composition, the use of synthetic media permits us to experiment in the lab with various sources of fermentation medium.

- A well-designed synthetic medium has the advantage of lacking protein and peptide sources.

- Therefore, there is no foam development, and the likelihood of contamination is minimal. Pure components present in synthetic media facilitate product recovery.

- Although there is a lengthy list of synthetic media’s benefits, there are also some downsides. A significant drawback is the price of media.

- The most critical aspect of fermentation is that it be lucrative and cost-effective. Synthetic media are seldom employed on an industrial basis due to their high cost.

- This procedure is only suitable for laboratory testing on a modest scale.

Crude Media

- Fermentation on an industrial scale typically utilises crude medium. Crude media contain a preliminary composition of fermentation-required media. It produces a high yield of product and contains unidentified ingredient sources.

- High levels of minerals, vitamins, proteins, growth factors, anti-foaming agents, and precursors are present in crude media.

- It is crucial to ensure that crude media does not contain any toxic substances that could hinder bacterial growth and product yield.

Ingredients of Crude Media

In the fermentation industry, carbohydrates represent the primary source of energy. For economic reasons, refined and pure carbohydrates such as glucose and sucrose are rarely used.

A. Substrates Used As Carbon Sources

- In the fermentation business, carbohydrates represent the primary source of energy.

- For economic reasons, refined and pure carbohydrates such as glucose and sucrose are rarely used.

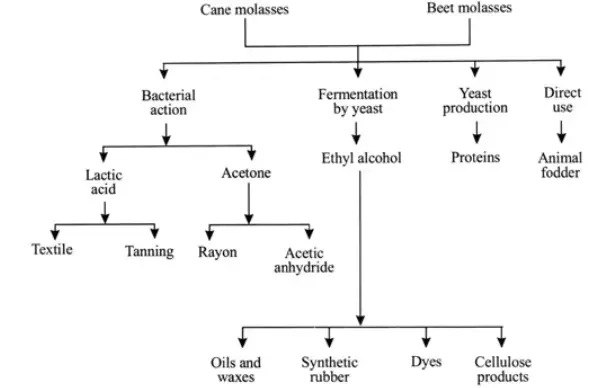

1. Molasses

- Molasses is a sugar industry waste and one of the cheapest sources of carbohydrates.

- Sugar cane molasses (about 48% sucrose) and sugar beet molasses (approximately 33% sucrose) are often utilised.

- In addition to being rich in sugar, molasses contains nitrogenous compounds, vitamins, and trace minerals.

- There is heterogeneity in the composition of molasses, which is largely dependent on climate and production method.

- Hydrol molasses, a byproduct of glucose synthesis from corn, is also utilised as a substrate for fermentation.

2. Malt extract

- Approximately 80% of malt extract, an aqueous extract of malted barley, consists of carbs (glucose, fructose, sucrose, and maltose).

- Nitrogen compounds represent roughly 4.5% (proteins, peptides, amino acids, purines, pyrimidine’s).

3. Starch, dextrin and cellulose

- Microorganisms may metabolise polysaccharides, including starch, dextrin, and cellulose.

- They are commonly employed for industrial alcohol production. The use of cellulose in alcohol production is intensively explored due to its vast availability and low cost.

4. Whey

- Whey is a dairy industry waste that is generated globally. The majority is ingested by humans and other animals.

- For the formation of alcohol, single-cell protein, vitamin B12, lactic acid, and gibberellic acid, whey is a reasonably good supply of carbon.

- The storage of whey is a barrier to its extensive application in the fermentation sector.

5. Methanol and ethanol

- Some microbes can use methanol and/or ethanol as a carbon source.

- The cheapest substrate for fermentation is methanol. However, only a few bacteria and yeasts can utilise it.

- Methanol is frequently used to produce single-cell proteins. Ethanol is quite costly.

- Nonetheless, it is being employed in the manufacturing of acetic acid.

B. Substrates Used As Nitrogen Sources

The fermentation bacteria may receive nitrogen from inorganic or organic sources.

1. Inorganic nitrogen sources

- Ammonium salts and free ammonia are inexpensive sources of inorganic nitrogen, particularly in industrialised nations.

- However, not all microbes can utilise them, therefore their application is limited.

2. Organic nitrogen sources

- Urea is an acceptable source of nitrogen. However, other more cost-effective organic nitrogen sources are preferred.

3. Corn steep liquor

- This is produced during the manufacturing of starch from corn.

- Microorganisms exploit the nitrogen-rich (about 4%) corn steep liquor with great efficiency.

- It contains many amino acids (alanine, valine, methionine, arginine, threonine, glutamate).

4. Yeast extracts

- They contain approximately 8 percent nitrogen and are abundant in amino acids, peptides, and vitamins. During yeast extraction, glycogen and trehalose combine to form glucose, which is a valuable carbon source.

- Through autolysis (at 50-55°C) or plasmolysis, yeast extracts are derived from baker’s yeast.

- Yeast extracts are an excellent source of numerous industrially significant microorganisms.

5. Soy meal

- Following the extraction of soy bean oil from soy bean seeds, the remaining residue is soy meal.

- It is high in protein (about 50%) and carbs (around 30%). Soy meal is commonly used in the manufacture of antibiotics.

6. Peptones

- Peptones are the collective term for protein hydrolysates, and they are excellent food sources for numerous bacteria.

- Meat, soy meal, peanut seeds, cotton seeds, and sunflower seeds are sources of peptones.

- Additionally, casein, gelatin, and keratin can be hydrolyzed to produce peptones.

- In general, peptones obtained from animal sources include more nitrogen, whereas plant-derived peptones contain more carbohydrates.

- Peptones are significantly more expensive; hence, their industrial application is limited.

C. Sources of Growth Factors

- Some microbes lack the ability to synthesise one or more growth agents, such as vitamins.

- Pure forms of these growth hormones are quite costly, hence crude sources are preferable.

- Yeast extract is an abundant source of virtually all growth factors. In general, the mineral concentration of crude substrates obtained from plant or animal sources is relatively high.

- Mineral (phosphate, sulphate) supplementation may be necessary on occasion.

D. Buffers

- Buffers are used to prevent pH from fluctuating drastically. Occasionally, media components may serve as buffers. At neutral pH, protein, peptides, and amino acids serve as effective buffers.

- As needed, inorganic buffers such as K2HPO4, KH2PO4, and CaCO3 can sometimes be added.

- During the fermentation process, pH typically shifts to an acidic or alkaline state. CaCO3 is the cheapest and most readily accessible buffer.

Characteristics of An Ideal Fermentation Media (Production Medium)

There is no single producing medium that is superior or suitable for all uses. This is not surprising given the range of conditions in which media can be utilised, the variances in chemical composition, and the vast number of products that can be generated. If there had existed a perfect production medium, it would have possessed an impressive diversity of qualities. A single production medium with these characteristics may never be discovered. Nonetheless, the below-described specifications can be used to design new manufacturing media, and they should be taken into account when evaluating the media made available for practical usage.

1. Chemical composition

- The medium for production must have an appropriate chemical composition. The medium should typically contain a carbon source, an nitrogen source, growth factors, and mineral salts.

2. Precursors

- In particular fermentations (e.g., the fermentation of penicillin), the medium should provide the necessary precursor for improved yields of a desired product.

3. Buffering capacity

- Due to the accumulation of acidic and/or basic molecules, depending on the nature of the fermentation process, it is crucial to keep the pH within the optimal range for the success of the process.

- To regulate the pH of the medium, buffers (such as CaCO) should be introduced to the media.

- In the pH range close to neutrality, media containing significant concentrations of proteins, peptides, and amino acids have a high buffering capacity.

- In this pH range, phosphates give additional buffering capacity (e.g. mono- and dihydrogen potassium or sodium phosphates).

4. Avoidance of foaming

- Foaming is a severe concern in the fermentation sector, since it can contribute to the contamination of the fermentation medium and cause other issues.

- For controlling foam, defoamers (such as lard oil combined with octadecanol for penicillin fermentations) should be employed.

- These defamers may be introduced at the stage of media preparation (before to sterilisation), after sterilisation, or as needed during the fermentation process.

5. Toxicity

- Being an ideal production medium, it should be free from any toxic effect on culture or product formation.

6. Consistency

- In aerobic fermentations, sterile air must be introduced into the medium. Under these conditions, agitated liquid media permit the diffusion of air throughout the medium.

- This explains why the majority of fermentation methods utilise liquid media. Additionally, fermentation media should not be viscous, as the viscosity of the medium hinders the penetration of air into the interior of the medium.

- In other words, the liquid does not readily absorb air.

7. Contamination

- Some conditions of the manufacturing medium are useful for detecting contamination. For instance, low pH levels in the synthesis of citric acid using Aspergillus niger keep contamination in check.

- Furthermore, low pH media can be sterilised at low temperatures.

8. Recovery

- Recovery of the targeted product is a crucial procedure that affects the product’s final cost.

- Therefore, the medium’s components should be such that separation and extraction of the product are simple and inexpensive.

9. Availability of raw materials

- The necessary raw materials for the design of the production medium should be easily accessible and reasonably priced.

- This explains why non-synthetic media (or crude media) are widely used in large-scale manufacturing processes.

- Synthetic media, on the other hand, are insufficient for research because they are expensive and offer low yields.

- However, these media are repeatable, allowing researchers to examine the effect of various medium components on culture and product development. Again, media can have simple or complicated compositions.

Raw Materials

Numerous types of raw materials are utilised in various industrial fermentation processes. Typically, crude nutritive sources are favoured due to their affordability. In fermentation industries, agricultural products are the primary source of raw materials. Agricultural wastes are of importance to us for the following reasons:

- Large quantities of agricultural wastes are generated. In the United States alone, almost two billion tonnes of animal faeces are produced annually.

- As the majority of these wastes have a high biological oxygen demand (B.O.D. ), they pose a potential pollution risk. It is exceedingly costly to dispose of these materials in accordance with federal environmental regulations.

- These wastes include a substantial amount of proteins and carbs that are potentially useful. It would be beneficial to recover the proteins and carbohydrate materials present in wastes in light of the increasing global demand for protein now and the anticipated increase in demand for protein over the next thirty years.

- It is possible to recover the caloric value of wastes as biogas and/or ethanol.

- Since the majority of agricultural wastes are renewable, there is an abundance of fermentable substrate.

- Typically, there are few costs associated with recovering trash.

- Agricultural wastes are almost never a part of the human food chain, and any recycling method will not compete with human food sources.

According to Taiganides, wastes are actually’resources out of place or out of time,’ and it is crucial that maximum efforts be made to transform our ‘effluents into wealth’

A. Saccharine Materials

This classification may include sugar cane, sugar beets, molasses, and fruit juices. The discussion of molasses and fruit juices will be brief.

1. Molasses

- Molasses is a byproduct of the production of cane and beet sugar. It is recovered at any of the numerous phases of sugar refining. Variable chemical composition characterises sugar cane blackstrap molasses.

- It depends not only on the quality and diversity of the cane, but also, and to a far greater extent, on the manufacturing method.

- Approximately 95% of the sugar in cane molasses is fermentable. Biotin, pantothenic acid, thiamine, phosphorus, and sulphur are particularly abundant.

- The organic nitrogen level is lower than that of beet molasses due to the absence of betaine. However, yeasts cannot digest this chemical. Molasses from beets is manufactured using the same methods as molasses from sugarcane.

- Also found are vitamins such as biotin, pyridoxine, thiamine, pantothenic acid, and inositol. However, beet molasses may contain low levels of biotin.

- In yeast-based fermentations, a tiny amount of cane blackstrap molasses or another biotin-containing substance should be added to the production medium.

- This is due to the fact that yeasts require biotin for development. Molasses derived from sugarcane and beets are frequently utilised in fermentation industries, as indicated below.

- Currently, the biggest use of cane blackstrap molasses in India is in the alcohol sector, which uses it to produce spirit (ethyl alcohol), country liquors, and other alcoholic beverages such as rum, brandy, gin, and whisky.

2. Fruit juices

- Fruit juices contain soluble sugars. For instance, grape juice includes both glucose and fructose.

- Therefore, fruit juices can be utilised in fermentation businesses as a carbon source. Grapes are utilised in the winemaking process.

- After grapes have been harvested, they are crushed to produce unpasteurized juice (or must). Must is an extremely acidic liquid.

- It has 17% ww sugar, 1% acid (mostly D-tartaric and a small amount of malic), and 0.3% ash (predominantly containing potassium and phosphorus).

- It is preferable for grapes to have a low nitrogen concentration, as an overabundance of nitrogen might cause undesired fermentation.

3. Cheese whey

- Cheese whey is the straw-colored liquid produced as a byproduct of cheese production. This is a significant byproduct of the cheese business. It cannot be discarded without proper disposal.

- Consequently, it is preferable to utilise it for helpful things. Significant effort has been devoted to discovering its applications.

- However, it is frequently more profitable to sell as pig feed. Currently, the United States cheese business produces about 30 billion pounds of liquid whey each year.

- In 1974, it was anticipated that just little more than half of the generated whey was utilised.

- About 820 million pounds of dried whey were produced that year. It has an equally well-balanced chemical makeup. According to Mattick and Cook, the composition of whey is impacted by the type of cheese being produced. In certain fermentation industries, whey can be a crucial raw material (e.g lactic acid production, SCP production, etc.).

- It comprises carbohydrate (lactose), nitrogenous compounds such as vitamins (such as riboflavin), and inorganic salts.

B. Starchy Materials

There are two main sources of commercial starches:

- Cereals, (e.g. wheat, rice, maize, etc.)

- Roots and tubers, (e.g. potatoes, tapioca, etc.)

The moisture content of grains is modest, while that of tubers and roots is extremely high.

Starch must be pretreated before it can be converted into fermentable sugars. This is achieved via enzymatic (plant or microbial origin) or chemical agents. There are numerous strategies for turning complicated carbs into relatively basic substances. Generally, enzyme preparations, dilute acids, or a combination of both are used to saccharify starchy materials. The choosing of a conversion method depends on:

- The use intended, and

- The availability and relative pricing of hydrolytic agents. For instance, a continuous method (the Symba process) developed in Sweden for biomass production used yeast (Endomycopsis fibuligeris) to convert starch to fermentable sugars. On these sugars, Candida utilis was subsequently cultivated.

C. Cellulosic Materials

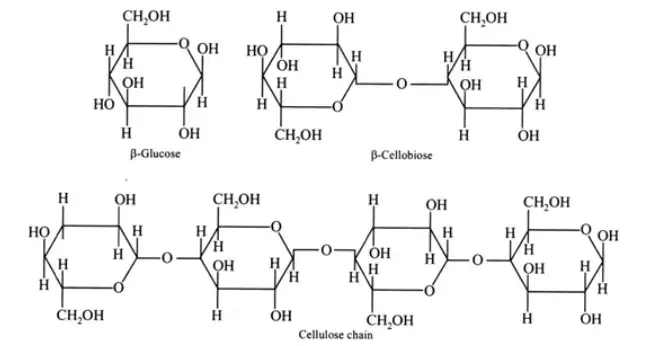

- Cellulosic materials are complex carbohydrate compounds. The cellulose molecule is composed of repeated beta-glucose units.

- The production of beta-cellobiose requires two beta-glucose molecules connected by a 1, 4-linkage. Finally, 1000 to 10,000 units of cellobiose are required to create cellulose, a basic linear polymer.

- As seen below, the units of cellobiose are connected end to end by 1, 4-beta-glycosidic bonds.

- Therefore, cellulosic materials necessitate some form of preparation (i.e. hydrolysis). Under cellulosic materials, sulfite waste liquor, wood molasses, and rice straw have been briefly discussed.

Sulphite waste liquor

- In the production of paper-pulp, wood is treated to hydrolysis with the aid of calcium bisulfite under high heat and pressure.

- The term for this operation is digestive process. At the conclusion of this procedure, the remaining liquid is referred to as sulphite waste liquor.

- It is inappropriate to discard this liquid without treatment. In terms of its chemical composition, sulphite waste liquor contains 10 to 12 percent solids, of which approximately 20 percent are sugars.

- In other words, the sulfite waste liquor is a diluted sugar solution with a sugar concentration of around 2%. Primarily, there are two types of monosaccharides:

- Heroses: D-glucose, D-galactose and D-mannose.

- Pentoses: D-xylose and L-arabinose.

- The proportional amount of these monosaccharides in sulphite waste liquor is changeable due to the fact that the chemical composition of the waste liquor varies based on the type of wood used.

- Angiosperms create sulfite waste liquors comprising 3% sugars, of which approximately 70% are pentoses (mostly xylose), while gymnosperms produce liquors containing approximately 2% sugars, of which approximately 75% are hexoses (principally mannose).

- Based on the chemical composition of the liquor, it appears that it could be utilised as a diluted fermentation medium in some fermentation businesses.

- It is utilised, for example, in the industrial manufacture of ethyl alcohol (using Saccharomyces cerevisiae) and in the growth of Torula utilis cells for animal feed. Torula utilis utilises both hexoses and pentoses, whereas S. cerevisiae requires solely hexoses.

- This information is necessary when utilising sulfite waste liquor, the composition of which changes depending on the type of wood used in the production of paper-pulp.

- The paper-pulp industry’s sulphite waste liquor cannot be used directly in the fermentation sector.

- Since these substances are hazardous to microorganisms, it is vital to eliminate any free sulphur dioxide or sulphurous acid from the waste liquor. They can be eliminated using steam stripping or lime precipitation.

Wood molasses

- By acid hydrolyzing wood cellulose, sugars comparable to those found in sulfite waste liquor can be generated.

- This could result in 65 to 85 percent fermentable sugars. Several acid hydrolysis techniques were developed mostly during the Second World War.

- Typically, sulfuric acid with a 0.5% concentration is employed between 150 and 185 degrees Celsius. From sawdust, a syrup can be produced using a continuous process.

- This syrup may comprise between 4% and 5% reducing sugars (a mixture of glucose and pentoses), with an overall yield between 45% and 55%. It can be concentrated to yield a substance similar to wood molasses.

- Wood molasses derived from conifers includes approximately 85 percent hexoses and 15 percent pentoses, while wood molasses derived from broad leaf trees contains approximately 65 percent hexoses and 35 percent pentoses.

- Candida utilis consumes pentoses efficiently, it should be emphasised. Recent research has demonstrated that heated and powdered cellulose is sensitive to enzymatic hydrolysis. As an example, a Trichoderma viride culture filtrate may be used as the enzyme preparation for this purpose.

- In a continuous system (using ultrafiltration membranes), it is feasible to hydrolyze all of the cellulose that passes the membrane into glucose. In addition to fermentable sugars derived from cellulose and their application in fermentation industries, unprocessed cellulosic wastes can be used to make microbial protein.

- This is possible by cultivating cellulolytic microorganisms on these untreated cellulosic wastes. Both filamentous fungi (Trichoderma viride) and bacteria (Cellulomonas spp.) are being examined in this area.

- Rice straw and other similar agricultural resources can be used as a cellulose source. In Asia, rice straw is an important agricultural byproduct. Its yearly production in Asia is 561 million tonnes, which accounts for 90% of the global total.

- In its natural state, it is a poor-quality animal feed due to its bulkiness, poor palatability, low protein content, and low digestibility. Significant effort has been devoted to the creation of animal feed from straw.

- Numerous methods of fermentation have been devised to produce microorganisms or microbial compounds that enhance the nutritional content of animal feed.

- Numerous species are capable of utilising cellulose as a source of nutrition (e.g. yeasts and mushrooms). Rice straw has been utilised as a substrate for fermentation in the manufacture of silage and single cell protein (SCP), mushroom cultivation, etc.

- Currently, research on the use of rice straw as animal feed has only reached the laboratory or pilot plant stage.

D. Hydrocarbons and Vegetable Oils

Typically, hydrocarbon substrates for fermentation are mixes of several hydrocarbon components. These fermentation ingredients are reasonably inexpensive. However, hydrocarbon fractions and molecules that have been purified are more expensive. Single-cell protein (SCP) products are produced using hydrocarbon substrates (such as gas oil and n-paraffins). Under aerobic conditions, considerable quantities of yeast biomass (e.g., Candida lipolytica, C. kofuensis, C. tropicalis, Candida spp. ATCC 20, 343, etc.) can be produced in this manner. »- n-Paraffin-based processes have been used on a substantial pilot plant scale by numerous businesses. Molecular sieve adsorption techniques are utilised to produce paraffin used as carbon and carbon sources in yeast SCP processes. The obtained n-paraffins are between 97.5% and 99% pure.

Vegetable Oils

Oils obtained by deoiling vegetable seeds are called vegetable oils. On the basis of their degree of unsaturation, they can be classified into three broad groups:

- Oleic (or *non-drying’ type): These oils are oleic (or non-drying), and include olive and groundnut oils.

- Linoleic (or “semi-drying”): These oils contain more of the double unsaturated fatty acid (linoleic acid) present in corn, sunflower, and cottonseed oils.

- Linolenic (or ‘drying’ type): Linolenic (or “drying”) oils include linseed and soya bean oils having a fatty acid with three double bonds (linolenic acid).

Due to the oxidation of the unsaturated components, these oils may experience drying if exposed to air.

Commercial vegetable oils (e.g., corn oil) may be used in conjunction with surface-active agents as anti-foaming agents or alone as a source of carbon nutrition.

E. Nitrogenous Materials

1. Corn-Steep Liquor (CSL)

- During the production of starch, gluten, and other maize-based products, corn is steeped in used steep water.

- This byproduct is concentrated to around 50 percent solids, and the resulting liquid is known as corn-steep liquor.

- There are substantial differences in chemical makeup between batches from the same producer and batches from other manufacturers. Consequently, it can reduce the repeatability of industrial fermentations.

- Consequently, it is necessary to estimate certain components (e.g., a specific amino acid, vitamin, or precursor) of the corn-steep liquor to be utilized, as they are required in minute but essential amounts.

- This is essentially an all-inclusive growing medium. Initially, corn-steep liquor was discovered to be useful for the synthesis of penicillin.

- However, it is currently acknowledged as a valuable component in numerous fungal antibiotic fermentation media. In addition, it is utilised in the production of culinary products.

2. Soya bean meal

- Soybean meal is the remaining residue after deoiling the soya bean seeds. Soybean meal contains roughly 8% nitrogen by weight.

- This is in contrast to corn-steep liquor, as soya bean meal is a much more complex nitrogenous source than corn-steep liquor and is therefore not readily accessible to microorganisms.

- This is a component used in fermentation media (e.g. in the production medium for streptomycin).

3. Pharmamedia

- Pharmamedia consists solely of a pure, yellow, finely ground powder made from the embryo of cotton seed.

- It is 56% protein by weight, 24% carbohydrates, 5% fat, and 5% ash. Ash itself is composed of calcium, iron, chloride, phosphorus, and sulphate.

- It is utilised as a component of production medium (e.g. in tetracycline production).

4. Distillers solubles

- In the production of alcohol from grain or maize, alcohol is distilled from fermented grain or maize, leaving a residue containing between 6 and 8 percent by weight of total solids.

- Screening eliminates the suspended particles from the residue, leaving effluent. The effluent is then concentrated until the solid content reaches 35% w/w, resulting in “evaporator syrup.”

- The syrup is subsequently drum-dried to produce distillers’ solubles. This can be utilised as a component of a production medium because it contains nitrogen (in the form of protein) as well as numerous dietary supplements (e.g. vitamin B complex).

- Other natural organic nitrogenous substances include ground-nut meal, fish meal, Bacto peptone, and Difco yeast extract.

Screening For Production Media

- The production medium is a crucial aspect in the success of a fermentation process because, among other reasons, the costs associated with the production medium can represent a significant amount of the entire cost of an industrial fermentation (e.g. recovery of fermentation products or microbial cells).

- It is intended that the production medium possess the majority of the characteristics outlined under the heading “ideal production medium.” In other words, the characteristics of an ideal production medium must be considered when building a new useable production medium.

- The method of trial and error may be used to determine a suitable medium. Various tests, including the effects of altering the quantities of different components, are conducted on newly designed production media.

- Such research permits the investigator to select one or two useful media and, at times, to dismiss a large number of ineffective media.

- These selected media are explored from multiple perspectives. During the fermentation process, for instance, quantitative measurements of the residual medium components are performed.

- The purpose of these calculations is to maximise the concentrations of essential carbon and nitrogen nutrients. In addition, one may be aware of the phenomena of diauxy if it occurs during fermentation.

- In addition, the effect of the potential precursor on the creation of the fermentation product is investigated, assuming the chemical structure of the final product is known. Keep in mind that the majority of these experiments are conducted without the addition of an anti-foaming agent.

- If necessary, defamer may be applied as the inert silicone kind. A particular examination of the crude defamers is conducted in order to identify any possible interference or stimulation of product creation by a defoamer.

- After the laboratory investigation is complete, all parameters (such as aeration and agitation) are reevaluated in miniature fermentors. Ultimately, the healing process and its cost are determined.

- If production medjum cost estimation reveals an unfavourable economic picture, it is vital to investigate alternative media.

- Therefore, the screening programme for manufacturing media is laborious and costly. Therefore, it remains confidential.