For the creation of solutions and manipulation of liquids, numerous vessels and apparatuses are employed in the laboratory. They differ in their intended application and precision. Volumes must always be measured at a constant temperature because changes in temperature result in volume changes owing to thermal expansion. At 10 °C, water has a substantially smaller volume than at 80 °C.

Typically, volumetric vessels are calibrated at 20 °C (25 °C in the United States). Every volumetric vessel displays the calibration temperature. Changes in temperature during the dilution of an acid, for instance, can lead to substantial errors. During dilution, significant heat is emitted and the temperature rises. When the volume of acid is measured before it has cooled, the actual volume will be lower. Therefore, the criterion for constant temperature must be observed.

Devices for measuring volume of liquids

| Device | Usual range of volumes | Accuracy |

|---|---|---|

| Erlenmayer flask, beaker | 5–5000 mL | * |

| Volumetric flask | 5–2000 mL | high |

| Volumetric cylinder | 5–2000 mL | medium |

| Burette | 1–100 mL | high |

| Pasteur pipette | 1–5 mL | low |

| Glass pipette | 1–100 mL | high |

| Pipetor | 5–5000 μL | high |

| Automatic dispenser | 0.1–100 mL | medium |

| Microsyringe | 0.5–1000 μL | high |

| piston dispenser | 1–500 ml | medium |

* not suitable for measuring volumes, only approximate volume indicated

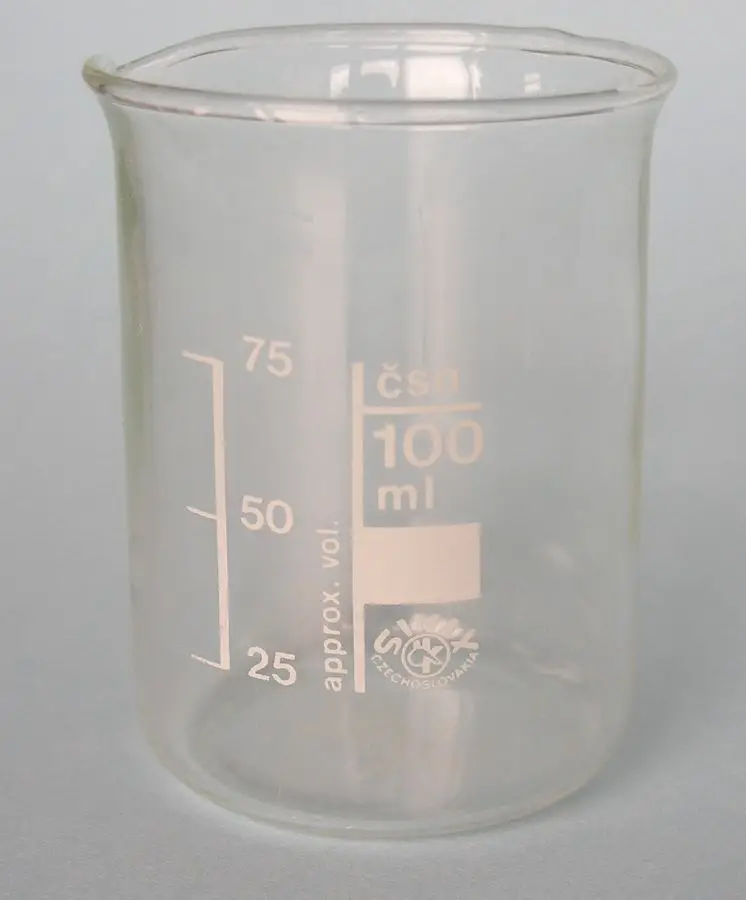

1. Beakers

- In labs, a beaker is a cylindrical container with a flat bottom used extensively to store, mix, and heat liquids.

- Usually built from robust polymers when high-temperature resistance is not needed, or from borosilicate glass, which provides outstanding resistance to thermal stress, they are

- Usually featuring a tiny spout meant to enable regulated pouring and reduce spillage during experiments, a beaker has

- Although many beakers have side measuring marks, these graduations are approximative and not meant for exact volumetric analysis.

- Beakers are flexible instruments for securely handling liquid reagents, mixing solutions, and running chemical reactions in both research and teaching environments.

- Differentiating beakers from flasks, which often have smaller necks and are used for more exact measurements, is the simple shape with straight edges.

- To guarantee best performance in the lab, one should take into account the experimental needs including the necessity of heat resistance or chemical compatibility while choosing a beaker.

- Their strong structure and simplicity of cleaning make beakers indispensable for frequent use in research, therefore promoting effective and safe laboratory methods.

- Knowing the limits of beakers, including their inaccurate graduations, emphasizes the need of employing specific volumetric equipment when exact measurements are absolutely important.

- Beakers are a basic piece of laboratory equipment that enables a variety of scientific operations and learning activities thanks in large part to their straightforward yet effective design.

Features

- For daily lab work as well as for research, beakers—cylindrical containers with a flat bottom—offer steadiness.

- Among them are a little pouring spout that reduces the danger of spillage in hectic lab settings and allows regulated liquid flow.

- Though robust polymers are also available for low-temperature uses, most beakers are constructed of borosilicate glass, which provides great heat resistance and chemical inertness.

- Though they are not intended for exact volumetric analysis, graduated marks on the side offer approximate volume measures helpful for mixing and transfer of liquids.

- Easy visual monitoring of chemical reactions made possible by their transparent design is crucial for both advanced research and teaching experiments.

- From a few milliliters to several liters, beakers come in a range of sizes to suit different experimental requirements and sample quantities.

- Beakers’ strong and straightforward construction makes cleaning and reusing them simple, which helps to explain why they are a flexible, daily equipment used in laboratories of many scientific fields.

How to use laboratory Beakers?

- Before use, make sure the beaker is completely clean and free of any residues or fractures as even minute pollutants might affect the results of the experiments.

- Estimate liquid quantities using the approximative graduated marks; remember, a graduated cylinder is better appropriate for exact measurements.

- Particularly in delicate reactions, limit splashing and prevent inadvertent spills by gradually adding and pouring liquids using the spout of the beaker.

- Always set the beaker on a wire gauze or heat-resistant surface while heating liquids; if the glass isn’t certified for high temperatures, never expose it straight to an open flame.

- Add ingredients gradually for chemical mixing using a clean stirring rod to guarantee that every component is thoroughly combined without generating unintended reactions.

- Cover the beaker with a watch glass to lower any evaporation or contamination concerns during an experiment and still provide enough spout ventilation.

- When handling chemicals or boiling liquids in a beaker, always observe laboratory safety rules by donning suitable protective gear including gloves and goggles.

- After usage, gently rinse and check the beaker to eliminate all chemical residues; then, completely dry it to guarantee it is ready for next tests without cross-contamination.

Applications of laboratory Beakers

- Beakers are used to mix chemical reagents in solutions and reactions.

- Their heat-resistant borosilicate glass allows direct placing on hot plates or Bunsen burners, making them useful for heating liquids.

- Their transparent shape allows real-time monitoring of reaction progress, such as color changes or precipitate development, in research and teaching labs.

- Beakers can be used for preliminary measurements before switching to more accurate volumetric equipment because their approximate graduated markings allow rapid liquid volume estimation.

- They are often used to decant liquids by gently pouring out solids or undesirable stages.

- In titration experiments, beakers hold the titrant or analyte for repeated mixing and observation.

- Beakers store solutions and waste liquids temporarily, ensuring safe handling and transfer during experiments.

- In educational laboratories, they demonstrate basic chemistry and experimental methodologies because to their adaptability.

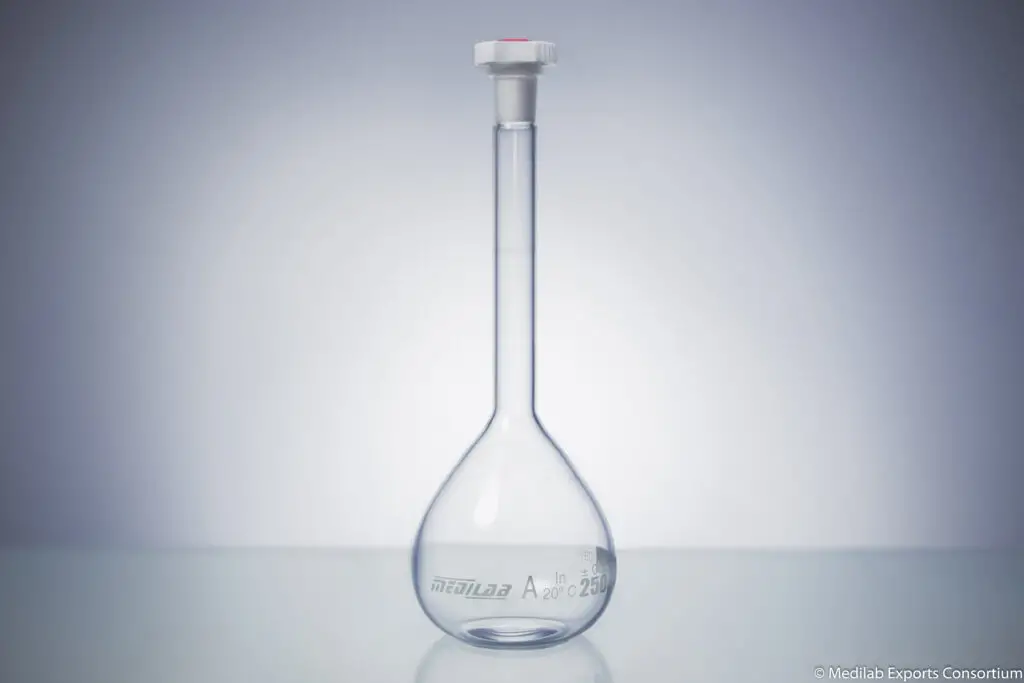

2. Volumetric Flasks and Cylinders

- Precision glassware with a pear-shaped body and a long, thin neck distinguished by a single calibration line guarantees an exact volume of liquid is held at a given temperature in volumetric flasks.

- They are mostly used to make standard solutions for quantitative chemical investigations where precision is crucial and even small volume variations could influence experimental results.

- Conversely, volumetric cylinders—often known as graded cylinders—are tall, thin containers having several marks along their length that let one measure different liquid amounts with good accuracy.

- Although they lack the same degree of accuracy as volumetric flasks, graduated cylinders are adaptable and extensively used for everyday liquid measurements in the lab.

- Usually built from borosilicate glass or tough polymers, which offer chemical resistance and endurance against heat stress, both kinds of equipment are made from

- While graduated cylinders are perfect for general volume measurements in many laboratory uses, volumetric flasks shine in conditions when exact solution preparation is needed.

Volumetric Flasks

- Designed to hold exactly a volume of liquid, a volumetric flask is a precise piece of glassware distinguished by its pear-shaped body and long, thin neck.

- It has a single calibration mark on the neck, which guarantees that the flask has a precisely known volume when filled to this line—this is absolutely important for making standard solutions.

- Usually composed of borosilicate glass, it is perfect for quantitative analytical techniques as it provides great resistance to heat stress and chemical attack.

- The design guarantees that the solution stays homogenous across the container by helping solutes to be fully mixed with solvents.

- Often used with volumetric flasks, a stopper or cap helps to prevent contamination and evaporation, therefore preserving the concentration of the solution.

- In labs, they are indispensable for chores including titration, equipment calibration, and any application where exact solution volume is critical.

- To prevent residue accumulation and guarantee accurate, repeatable results in next tests, volumetric flasks must be properly cleaned and handled.

Volumetric Cylinders

- Often known as graded cylinders, volumetric cylinders are tall, thin containers made especially for reasonably accurate liquid volume measurement.

- Their many marks throughout their length let users rapidly estimate quantities for regular laboratory chores.

- Usually constructed from transparent, robust polymers or borosilicate glass, these cylinders offer outstanding chemical resistance and clarity for meniscus viewing during measurement.

- For most general-purpose studies, including measuring chemicals and creating dilutions, volumetric cylinders provide enough precision even though they are less exact than volumetric flasks.

- The design stresses simplicity of reading: by viewing the liquid level at eye level, parallax error should be reduced and more consistent readings guaranteed.

- From as little as 10 mL to over 1 liter, volumetric cylinders fit a wide spectrum of experimental requirements in both research and instructional settings.

- Their strong build and simplicity of cleaning make them a mainstay in laboratories since they offer a sensible mix of precision and simplicity for daily measurements.

Features of Volumetric Flasks and Cylinders

- Volumetric flasks have a pear-shaped body and a long, thin neck with a single calibration point to ensure an accurate volume when filled.

- Borosilicate glass is chemically and thermally resistant, making it appropriate for quantitative analysis standard solutions.

- Volumetric flasks employ stoppers or caps to prevent evaporation and contamination, protecting solution integrity throughout storage and handling.

- Graduated cylinders, often called volumetric cylinders, are tall, thin vessels with several scale increments that measure liquid quantities with intermediate precision.

- Their translucent borosilicate glass or sturdy plastic structure provides precise meniscus reading, minimizing parallax errors during volume estimation.

- In labs, volumetric flasks are ideal for precise measurements and cylinders for common measurements in research and teaching.

Applications of Volumetric Flasks and Cylinders

- Volumetric flasks are essential for accurate solution preparation because its single calibration mark assures the exact volume needed for quantitative analysis.

- Titration studies depend on accurate measurements of solution volume to calculate analyte concentration, making them crucial for consistent findings.

- In addition to standard solution production, volumetric flasks are utilized for instrument calibration and research reference vessels to maintain reagent concentrations.

- Graduated volumetric cylinders are used for everyday liquid measurements because their various scale marks make liquid volume estimation easy and accurate.

- Due to their transparent design, they reduce parallax error and improve measurement accuracy whether moving reagents, diluting solutions, or combining chemicals.

- Volumetric flasks and cylinders are essential in educational laboratories to teach volumetric analysis and chemical experiments.

- Their joint usage standardizes laboratory methods, producing trustworthy and repeatable experimental results across scientific research.

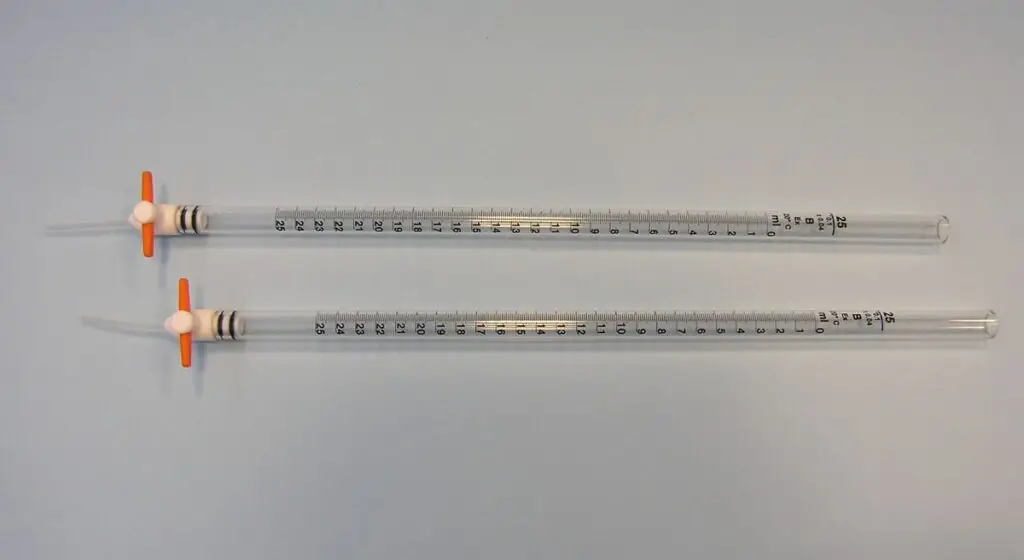

3. Burettes

- Mostly in titration investigations, burettes are precision volumetric tools used to distribute calibrated quantities of liquid.

- Usually composed of borosilicate glass, they are long, thin, graded tubes that guarantees chemical resistance and stability under different temperatures.

- By use of a carefully tuned stopcock at the bottom of a burette, the titrant may be delivered under control, drop-by-drop, therefore reducing volume measurement error.

- Determining the end point of a titration depends on users precisely tracking the volume of liquid delivered, so the calibration marks along the burette’s length help them to do this.

- Because of its design and exact calibration, burettes are crucial in quantitative analysis as they guarantee that even small variations in liquid volume might be precisely quantified and identified.

- To preserve the integrity and repeatability of experimental results, a buret should be used properly: thoroughly cleaned, carefully calibrated, and liquid should be released slowly and steadily.

How to use Burettes?

- To assure accurate measurements, make sure the burette is completely cleansed and free of any last traces of chemicals before use.

- To ensure that the inside surfaces of the burette are conditioned to the solution, rinse it first with pure water and then with a little titrant, therefore preventing any diluting impact.

- Clamp the burette securely in an upright posture so that, without parallax error, you may read the meniscus at eye level.

- Using a funnel placed at the top, fill the burette carefully removing the funnel to avoid spillage or contamination; check for air bubbles that might skew the volume measurement.

- To assist remove any trapped air in the tip and verify that the stopcock is running properly, open it just enough to let a few drips flow out.

- Note the meniscus’s lower level at eye level to determine the beginning point for the titration—the initial volume.

- To provide regulated flow that reduces overshooting the endpoint, gently and carefully change the stopcock to release the titrant drop by drop into the analyte.

- To encourage consistent mixing and enable visual observation of any color change or endpoint signal, constantly swirl the solution in the receiving vessel.

- Record the burette’s last volume at the terminus; then, by subtracting the beginning reading from the final value, determine the volume of titrant utilized.

- To prepare the burette for next usage free from cross-contamination, completely rinse and disinfect it following the experiment to eliminate any remaining chemicals.

Applications of Burettes

- Titration investigations require burettes to properly measure unknown solution concentrations by dispensing titrants dropwise.

- They are commonly employed in acid-base, redox, and precipitation titrations to exactly detect even small volume changes for quantitative analysis.

- Burettes standardise solutions in pharmaceutical and environmental labs, providing strict quality control and compliance standards.

- Burettes are essential in research studies that need consistency and accuracy of experimental data because to their precise volume delivery.

- Burettes help students learn volumetric analysis by combining theory with experimentation in educational laboratories.

4. Glass pipettes

- In labs, glass pipettes—thin, cylindrical tools—are used to precisely and highly accurately transfer exact liquid quantities.

- Usually composed of borosilicate glass, which provides outstanding chemical resistance and thermal stability, they guarantee longevity even under severe temperatures or handling of corrosive chemicals.

- Essential for quantitative studies and solution preparations, many glass pipettes have calibration marks throughout their length, enabling accurate measurement and liquid delivery.

- They come in a variety, including volumetric pipettes meant to provide a single, exact amount and graded pipettes showing many volume increases.

- In analytical chemistry, biology, and clinical labs, glass pipettes are extensively employed for activities requiring precise transfer of tiny fluid quantities to guarantee repeatability and accuracy in studies.

- Usually used with pipette bulbs or mechanical pipette fillers, they help to minimize mistakes and contamination risk by enabling seamless liquid aspiration and dispensing.

- Glass pipettes are a dependable and reasonably priced instrument in high-precision laboratory work because of their reusability as well as their simplicity of cleaning and sterilizing.

Pipettors (automatic pipettes, micropipettes, microdispensers).

Automatic pipettes, also known as electronic or motorized pipettes, are laboratory instruments used for dispensing and aspirating precise volumes of liquid. They are commonly used in chemical analysis, clinical laboratory testing, and other fields where accurate and repeatable liquid handling is required.

Automatic pipettes are powered by batteries or an AC adapter and use a motor to control the movement of the plunger, which draws liquid into the pipette and dispenses it out. This makes it much easier and more accurate to dispense precise volumes of liquid compared to manual pipettes, which rely on the user to manually control the plunger.

There are several different types of automatic pipettes available, each designed for specific applications. One common type is the single-channel pipette, which is designed for dispensing one specific volume of liquid at a time. Another common type is the multi-channel pipette, which can dispense multiple aliquots of the same volume at once.

Micropipettes, also known as micromanipulators, are similar to standard automatic pipettes but are designed to handle very small volumes of liquid, typically in the range of microliters (μL) to nanoliters (nL). These are commonly used in molecular biology, genetic engineering, and other fields where small volumes of liquid are used.

Microdispensers, also known as nanolitre dispensers, similar to micropipettes which specifically handle even smaller volume (nanoliters) and are used in advanced biotech research, protein crystallography, and for high-throughput screening assays. These dispensers have the ability to dispense and aspirate very small volumes of liquid with high precision and accuracy.

In summary, automatic pipettes, micropipettes, and microdispensers are laboratory instruments used for precise and accurate liquid handling. They are powered by batteries or an AC adapter, and use a motor to control the movement of the plunger. They are commonly used in fields such as chemical analysis, clinical laboratory testing, molecular biology, genetic engineering and biotechnology.

How to use Glass pipettes?

- Attach a pipette bulb or pipette filler firmly to the top of the glass pipette so that, for regulated liquid aspiration, it forms an airtight seal.

- Holding the pipette vertically at eye level, dip the tip into the liquid without contacting the container sides to stop air bubbles from developing or contamination.

- Keeping the tip submerged, gently squeeze the bulb to remove any trapped air and then gradually relax the pressure to progressively pull the liquid up into the pipette.

- Beforehand, rinse the pipette with the liquid to condition its inner surface and reduce residual contaminant-related measurement mistakes.

- Carefully expelling a tiny bit will help you to change the liquid level so that the meniscus exactly lines the intended graduation point on the pipette.

- To prevent splashing, slant the tip toward the inner wall of the receiving container slightly and let the liquid flow gently.

- Throughout both aspiration and dispensing, use a steady hand and fluid motions to avoid bubbles and guarantee the accuracy of the transferred volume.

- To get the pipette ready for future usage, wipe its outside surface with a fresh, lint-free lab cloth and give it a thorough wash.

How to use Automatic pipettes?

- Using a motorized piston to aspirate and distribute liquid, automatic pipettes are electronic tools offering exact and repeatable readings.

- Start by turning on the pipette and using the digital display to select the appropriate volume; be sure the set volume is within the pipette’s ideal working range.

- Maintaining precision and avoiding leaks during liquid handling depend on a good fit, which guarantees a strong attachment of a disposable pipette tip.

- Press the plunger button to the first stop and submerge the tip into the sample; then, gently release the button to automatically draw the pipette the proper volume.

- Holding the pipette upright, let the liquid settle within the tip for a moment before moving it to the receiving vessel.

- After positioning the tip into the destination container, press the plunger; the motor of the pipette will regulate the dispense speed; if necessary, typically a blow-out step will be used to release any remaining liquid.

- Many automated pipettes let you programmed procedures, including reverse pipetting or repeat dispensing, so configure these settings based on your experimental requirements.

- Use the tip ejector feature to securely remove and discard the used tip after dispensing; then, if necessary, clean the pipette before turning off the power.

- Continuous precision and dependability in high-throughput applications depend on regular calibration and appropriate automated pipette maintenance.

Applications of pipettes

- Chemical labs need pipettes to measure and transfer exact liquid quantities for solution production, reagent mixing, and dilution series.

- They ensure uniformity in PCR, qPCR, and other nucleic acid amplification experiments by handling tiny quantities of DNA, RNA, enzymes, and buffers.

- Clinical laboratories employ pipettes to treat blood or serum samples for ELISA and immunoassays, where even slight volume mistakes might alter findings.

- High-volume genomics, drug discovery, and high-throughput screening applications benefit from automated pipetting systems using electronic pipettes.

- Pipettes precisely add and remove medium and nutrients in cell culture, ensuring sterility and reducing cross-contamination.

- Evaporation and air cushioning in air-displacement models cause inaccuracies when handling viscous, volatile, or corrosive liquids. Positive displacement pipettes avoid these problems.

- Pipettes are essential for teaching volumetric measurement, solution preparation, and laboratory technique in educational laboratories.

- Serological, repeater, and adjustable-tip pipettes are designed for repeating dispensing and exact volume transfer in high-consistency experiments.

- Pipettes provide precise standard and control solution preparation in analytical labs, supporting quality control and calibration.

- Pipettes accurately distribute chemicals into lab-on-a-chip devices for biomedical engineering and nanotechnology research.

5. Microsyringes

- Usually spanning microliters to a few milliliters, microsyringes are small syringes designed to precisely measure and distribute extremely small quantities of liquid.

- Often equipped with ultra-fine needles or tips to enable microinjection or exact reagent administration, they comprise a tiny, perfectly graded barrel with a finely controlled plunger mechanism.

- Made from premium materials like glass or specialty polymers, microsyringes have great chemical resistance and endurance for usage with many different compounds, including viscous or volatile liquids.

- Their design reduces dead volume, therefore guaranteeing that almost all of the aspirated liquid is delivered—a vital consideration in research and clinical environments using costly or limited reagents.

- Microsyringes find extensive usage in research labs for uses including precision dosage in pharmacological investigations, microinjection in embryology, sample collecting in analytical chemistry and microfluidic experiments.

- With syringe pumps, they can be manually driven or combined into automated systems to provide high-throughput and repeatable dispensing in challenging procedures.

- Correct use calls for frequent calibration, cautious handling to preserve sterility, and choosing a suitable needle size to fit the experiment’s viscosity and volume needs.

- Microsyringes are essential instruments for both academic research and clinical diagnosis as their accuracy and dependability allow even small volume differences to greatly affect outcomes.

How to use Microsyringes?

- To guarantee accurate measurements and prevent contamination, make sure the microsyringe is disinfected, correctly calibrated, and free of defects before use.

- If a needle is needed, firmly connect the ultra-fine needle or tip meant for microscale quantities such that no leaks arise during dispensing or aspiration.

- Remove any protective caps and, if necessary, pre-wet the needle or internal surfaces by drawing a little sample to condition the syringe for more exact volume absorption.

- If the design requires for a tiny air gap, gently depress the plunger; then, submerge the needle tip into the liquid sample at the proper depth—usually just below the surface—to stop drawing in air.

- Release the plunger slowly to aspirate the liquid into the microsyringe; adjust your rate to let the liquid fill the barrel uniformly without creating air bubbles.

- Examining the drawn volume for bubbles, gently tap the syringe or release a minute extra volume back into the original container to release any trapped air.

- Position the needle tip at the target spot or in the receiving vessel; then, gently lower the plunger to precisely dispense the measured volume.

- Following your lab’s safety procedures, correctly expel or discard the needle tip after dispensing; clean the microsyringe should it be meant for reusing.

- In tests requiring handling extremely tiny amounts, accuracy depends on regular maintenance and occasional microsyringe recalibration.

Applications of Microsyringes

- Microsyringes are widely employed in embryology and gene editing to inject small amounts of genetic material into cells.

- They allow precision dosing in preclinical pharmacological trials, administering tiny amounts of medicines or reagents.

- In analytical chemistry and microfluidics, microsyringes provide controlled liquid sampling and dispensing for reaction monitoring and lab-on-a-chip applications.

- They are crucial in material science and nanotechnology, where extremely tiny liquid volumes are needed for device manufacture or surface modification.

- Clinical research uses microsyringes to deliver imaging agents or biomarkers, improving diagnostic accuracy and safety.

- Microsyringes integrated with syringe pumps enable high-throughput screening and repeatable experimental processes in contemporary labs.

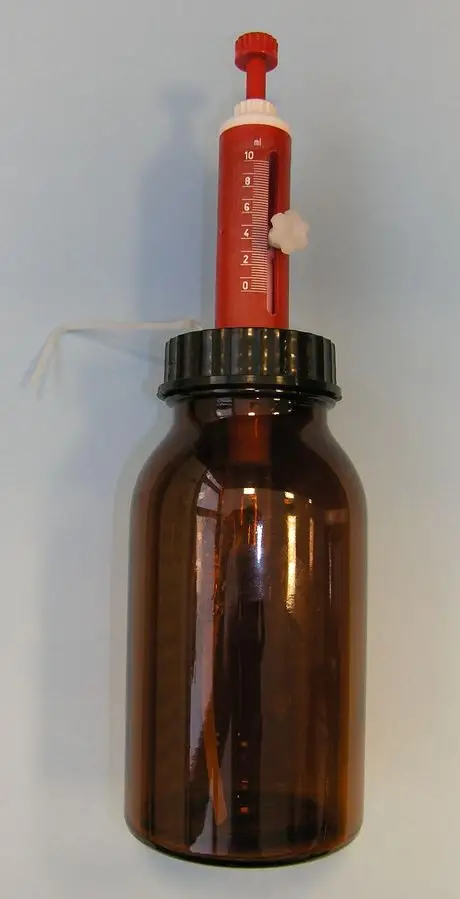

6. Piston dispensers

- Automated or manual instruments using a piston mechanism to precisely measure and distribute predefined amounts of liquid or gel materials are piston dispensers, often known as piston dosing dispensers.

- In applications, they ensure great precision and repeatability by operating a piston inside a cylinder where the stroke length and internal parameters of the cylinder define the volume dispensed.

- Built from glass, PTFE, or strong polymers, piston dispensers fit for handling a variety of media, including adhesives, resins, and other viscous or particulate-loaded materials.

- Their design minimizes dead space and lowers product waste, hence they are perfect for uses where regular dosage and reagent economy are vital.

- Common uses are adhesive bonding, potting, encapsulating, sealing, and thermal management—especially in sectors like electronics, automotive, medical technologies, and construction.

- Either stand-alone manual devices or incorporated into digital-controlled automated systems, piston dispensers provide perfect integration into high-throughput manufacturing or research settings.

- By guaranteeing constant dosage less influenced by changes in material viscosity or environmental conditions, they offer benefits over alternative dispensing systems that guarantees dependable process performance in difficult industrial and laboratory environments.

How to use Piston dispensers?

- First make sure the dispenser is clean and correctly calibrated; next, to assure constant dosage, check that all seals, pistons, and adapters are intact and free from residue.

- Make sure the suitable adapter fits your reagent bottle, then fill the dispenser chamber with the material, being careful to exclude any air pockets during the filling operation.

- Actuating the piston softly helps the system to prime it by releasing trapped air and guarantees that the piston moves smoothly inside the cylinder, therefore defining a correct baseline volume.

- Depending on the model, set the appropriate dispensing volume using the volume adjustment mechanism—a dial, digital control, or fixed-volume setting—then confirm that the chosen volume is within the dispenser’s ideal range.

- Position the nozzle above the target receptacle when ready to dispense; activate the trigger or control button; the piston will force the material out in a volumetric, under control way.

- Applying equal, smooth pressure during the dispensing cycle will help you to keep a constant functioning and prevent pulsating or uneven output.

- If at all possible, do a quick post-dispense cycle—such as a blow-out or purge step—to guarantee that any remaining material in the nozzle is cleaned, therefore preserving precision for next use.

- To maintain long-term accuracy and dependability in your applications, lastly follow manufacturer recommendations for cleaning the dispenser components and plan frequent maintenance and recalibration.

Applications of Piston dispensers

- Piston dispensers properly administer adhesives, resins, and sealants in potting, encapsulating, and adhesive bonding applications in electronics, automotive, and construction.

- Their precise dispensing makes them excellent for viscous or abrasive materials, where volume consistency is crucial to product quality and process dependability.

- Research and development labs use these dispensers to manage reactive or hazardous substance distribution, reducing waste and enhancing safety during formulation and testing.

- Production lines use automated piston dispensing systems to boost productivity and provide consistent, calibrated dosages for complicated assembly processes including insulation, sealing, and thermal control.

- Their sturdy design, which uses piston stroke mechanical volume control, guarantees performance stability across various temperatures and material viscosities, making them suitable for industrial and laboratory applications.