- Vitamin B12 is an essential nutrient for healthy growth in humans and domesticated animals. Humans are required to consume 0.001 mg each day.

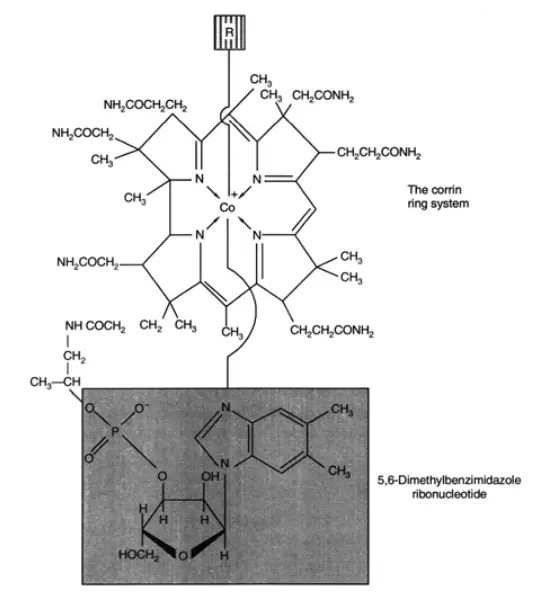

- In terms of its chemistry, vitamin B12 is a complicated chemical molecule with the structural formula illustrated in Figure.

- It is cyanocobalamin, which consists of a cobinamide molecule coupled to a nucleotide.

- Cobalt is connected to a cyanide group in the centre of the cobinamide molecule, which is surrounded by four reduced pyrrole rings united to create a macroring.

- In addition, several carbon atoms have methyl or other substituent groups. The nucleotide is uncommon in that its base is 5, 6-dimethylbenzimidazole instead of purine or pyrimidine.

- Vitamin B12 is exclusively generated commercially through fermentation. Typically, it is produced through primary fermentation.

- In some cases, it is derived from broths predominantly employed in the manufacturing of antibiotics. This is mostly an issue of economics, as maximum antibiotic production and maximum cobalamin production do not typically occur under the same fermentation conditions.

- Its manufacture has become one of the United States’ most important fermentation businesses.

What is Vitamin B12?

- Vitamin B12, sometimes referred to as cobalamin, is a water-soluble vitamin that plays a role in metabolism.

- One of the eight B vitamins. Animals, which utilise it as a cofactor in DNA synthesis, require it for both fatty acid and amino acid metabolism.

- It is essential for the regular functioning of the neural system due to its role in the synthesis of myelin, as well as the maturation of red blood cells in the bone marrow of the circulatory system.

- Cobalamin is not required by plants, which conduct chemical reactions with cobalamin-independent enzymes.

- Vitamin B12 is the most chemically complicated vitamin and the sole vitamin that humans must obtain from animal-derived meals or supplements.

- Only certain archaea and bacteria are able to produce vitamin B12.

- [8] The majority of individuals in affluent nations obtain adequate B12 from meat and other animal-based meals.

- Meat, clams, liver, fish, poultry, eggs, and dairy products are examples of foods that contain vitamin B12.

- Numerous breakfast cereals contain the vitamin. There are various supplements and drugs to treat and prevent vitamin B12 deficiency. For the therapy of deficiencies, they may also be administered via intramuscular injection.

- In industrialised countries, the most prevalent cause of vitamin B12 insufficiency is reduced absorption due to a loss of stomach intrinsic factor (IF), which must be bound to a food source of B12 for absorption to occur.

- A second key factor is the age-related reduction in stomach acid production (achlorhydria), as exposure to acid liberates vitamin-protein complexes.

- People on long-term antacid medication, whether they use proton-pump inhibitors, H2 blockers, or other antacids, are also at elevated risk.

- Vegetarian and vegan diets may not offer adequate B12 unless dietary supplements are utilised.

- A vitamin B12 deficiency may manifest as limb neuropathy or pernicious anaemia, a type of megaloblastic anaemia, causing fatigue, weakness, dizziness, headache, shortness of breath, loss of appetite, abnormal sensations, changes in mobility, severe joint pain, muscle weakness, memory problems, decreased level of consciousness, and brain fog, among other symptoms.

- In newborns with untreated deficiency, brain problems and anaemia may develop. Individual folate levels may influence the progression of degenerative alterations and the symptomatology of vitamin B12 insufficiency.

- Pernicious anaemia, an autoimmune illness in which the blood contains a lower-than-normal amount of red blood cells due to a vitamin B12 deficiency, led to the discovery of vitamin B12. The ability to absorb the vitamin reduces with age, particularly in those older than 60.

Microorganisms used for B12 Productions

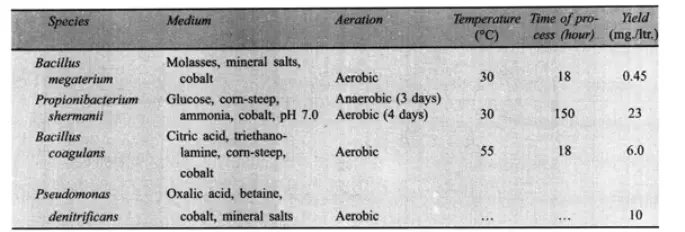

Streptomyces griseus, S. olivaceus, Bacillus megaterium, B. coagulans, Pseudomonas denitrificans, Propionibacterium freudenreichi, P. shermani, and a mixed fermentation of a Proteus spp. and a Pseudomonas spp. may be used in the industrial manufacture of vitamin B12. Typically, Vitamin By is produced via the submerged-culture method. The producing medium must be aerated and stirred vigorously. Typically, these fermentations last between 3 and 5 days.

Vitamin B12, production using Streptomyces olivaceus NRRL B-1125

In this article, the parameters that influence Streptomyces olivaceus NRRL B-1125-vitamin fermentation are described briefly.

Preparation of inoculum

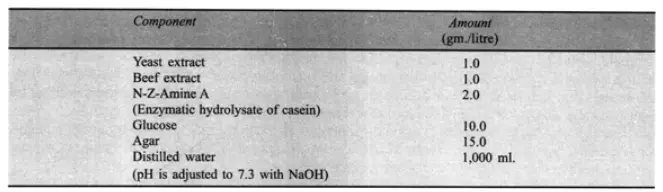

- A pure agar slant culture of Streptomyces olivaces NRRL B-1125 is inoculated and cultured in 100 to 250 ml of inoculum medium housed in Erlenmeyer flasks during the establishment of the inoculum.

- During incubation, these flasks should be placed on the platform of a mechanical shaker to aerate the media.

- The flask cultures are then used to inoculate greater quantities of inoculum media stored in a succession of inoculum tanks.

- Typically, two or three subsequent transfers are necessary to obtain the necessary quantity of inoculum culture.

- It has been demonstrated that inoculating the production tank with approximately 5% of the production medium volume is adequate.

Production medium

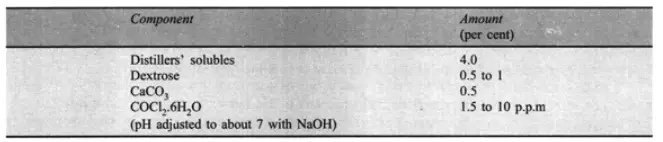

- Typical production media for this fermentation include carbohydrates, proteinaceous material, a cobalt supply, and other salts.

- In Table, a typical production medium is provided. Under optimal conditions, the majority of distillers’ solubles, soya bean meal, yeast, casein, etc. are deemed good. Cobalt must be added to the medium in order to maximise cobalamin yields.

- Cobalt has nothing to do with the growth of S. olivaceus, it should be mentioned. In certain instances, it is necessary to add cyanide to the medium in order to facilitate the conversion of other cobalamins to vitamin B12. By- The medium can be sterilised in batches or in a continuous manner.

- In batchwise sterilisation, the production tank’s medium is heated at 250°F for one hour. In the latter method, the production tank is charged (e.g., at 330 degrees Fahrenheit for thirteen minutes) by mixing it directly with live steam.

- Steam is blown into apertures during sterilisation, and all transfer lines are filled with live steam while not in use to ensure sterility.

Temperature

- During fermentation, a temperature of 80°F in the production tanks is acceptable.

pH

- During the first 24 hours of fermentation, there is a pH drop of a few tenths of a unit and a rapid consumption of sugar.

- After two to four days, mycelium lysis commences, resulting in an increase in pH.

- To stabilise the mash, sulfuric acid is used to lower the pH to about 5 and a little amount of a reducing agent is added (e.g. sodium sulphite).

Aeration and agitation

- The streptomycete strain’s growth rate is dependent on the aeration and agitation rates.

- Greater than optimal aeration rates result in excessive foaming. The optimal aeration rate is around 0.5 volume air/volume medium per minute.

- Activated charcoal is typically used to sterilise air by passing it through columns.

Antifoam agents

- Foam formation is a significant issue with this fermentation, particularly at the beginning and end of the process.

- There are numerous antifoaming compounds that can be used to prevent the creation of foam. Soybean oil, corn oil, lard oil, and silicones are significant defaming agents.

- Depending on the need, a defaming agent in its sterile form is given to the medium during foaming.

- In some circumstances, an antifoaming agent is included during the production medium formulation process.

Prevention of contamination

- Sterility must be maintained until the fermentation is complete, as contamination invariably results in extremely low yields.

- All equipment must therefore be sterile. Moreover, transfers are conducted under aseptic circumstances.

Yields

- The yields of cobalamin in fermented broth are typically between 1 and 2 mg per litre.

Recovery

- Throughout the majority of fermentation, the majority of cobalamin is connected with the mycelium. However, a substantial amount of cobalamin remains in the solution at the conclusion of the fermentation time.

- The cobalamin is quantitatively released from the mycelium by boiling the mixture at a pH of 5 or lower. Depending on the type of product to be manufactured, cobalamin-containing broth undergoes further processing.

- To obtain crystalline vitamin B12, the process begins with filtration to eliminate mycelium, followed by cyanide treatment of the filtered broth to convert cobalamin to cyanocobalamin.

- Alternately, this conversion may also be performed once a certain concentration has been achieved during fermentation.

- By passing the solution through packed columns of an adsorbing agent, the cyanocobalamin is removed from the solution.

- There are numerous adsorbents available for this function, including activated charcoal, bentonite, fuller’s earth, and ion-exchange resins.

- Lastly, cyanocobalamin is eluted from the adsorbent using an aqueous solution of materials ranging from organic bases to hydrochloric acid.

- Several substances, including water, water-acetone, and solutions of sodium cyanide or sodium thiocyanate, have been reported for this function.

- Typically, some type of extraction is then performed. It might be a countercurrent distribution of cresol, amylphenol, or benzyl alcohol with water, or a single extraction into an organic solvent (e.g. phenol). Copper or zinc cyanide-cyanocobalamin complex precipitation has been recorded.

- A further purification procedure applicable to aqueous concentrates involves dissolving a zinc salt in a slightly acidic solution and then increasing the pH to precipitate zinc hydroxide, which removes several contaminants.

- Typically, the procedure concludes with chromatography on alumina and crystallisation from methanol-acetone, ethanol-acetone, or acetone-water.

- In order to generate a vitamin B12 concentration for use as a feed additive, the final fermented broth is evaporated to dryness. First, these final broths containing around 3% solids are evaporated under vacuum to a solids concentration of 15 to 20%.

- The syrups are then drum- or spray-dried. These cobalt-supplemented fermentation concentrates may include between 10 and 30 mg/lb of cobalamin.

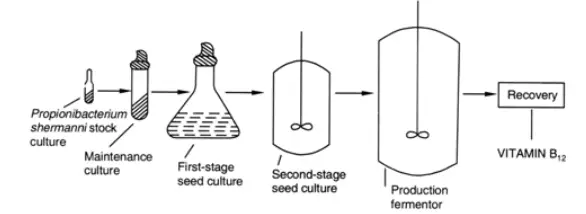

Vitamin B12, production using Propionibacterium freudenreichii

- It has been discovered that Propionibacterium species provide the highest vitamin B12 outputs. It has been claimed that P. freudenreichii produces 20 milligrammes per litre.

- It has been demonstrated that the production medium including glucose, corn-steep, betaine, and cobalt is adequate.

- The medium is supplemented with betaine to provide methyl groups. Betaine likely achieves this by acting as a methyl donor during the production of methionine.

- The betaine concentration in the medium is 0.5%. In relation to the utilisation of cobalt, its medium concentration is crucial.

- It has been demonstrated that a cobalt concentration of Sug./ml is optimal. Cobalt in excess inhibits the synthesis of cobinamide.

- Adjusting the pH of the manufacturing medium to 7.5. The temperature of 30 degrees Celsius has been deemed acceptable.

- This fermentation is comprised of two fermentation cycles: a 70-hour anaerobic fermentation cycle and a 50-hour aerobic fermentation cycle.

- Cobinamide is exclusively synthesised in the anaerobic cycle because oxygen inhibits cobinamide biosynthesis.

- In addition, the pH decreases from 7.5 to 6.5 before increasing to 8.5. Due to the inability of P. freudenreichii to synthesis 5,6-dimethylbenzimidazole, it is required to add 0.1% of this base to the production medium.

- The nucleotide is produced during the subsequent aerobic fermentation cycle. This nucleotide then binds to the previously synthesised cobinamide to produce cobalamin.

- Consequently, the yield obtained was less than 20ug/ml. In the continuous culture variant of the method, two large fermentation tanks are utilised in sequence, each with a 60-hour retention period; the first is anaerobic and the second is aerobic, and 5, 6-dimethylbenzimidazole is introduced continually. Consequently, a yield of 15ug/ml is achieved.

Vitamin B12, production using other microorganisms

- In addition to Streptomyces olivaceus and Propionibacterium freudenreichii, Table lists several commercially significant microorganisms used in the industrial manufacture of vitamin B 2 along with brief process information.

- On hydrocarbon media, Japanese researchers have discovered that diverse species of Corynebacterium, Mycobacterium, and Nocardia may synthesise vitamin B. However, the yields produced by these microorganisms are negligible, amounting to a few milligrammes per litre.

- Text Highlighting: Select any text in the post content to highlight it

- Text Annotation: Select text and add comments with annotations

- Comment Management: Edit or delete your own comments

- Highlight Management: Remove your own highlights

How to use: Simply select any text in the post content above, and you'll see annotation options. Login here or create an account to get started.