What is Toolmakers Microscope?

The Toolmaker’s Microscope is referred to as a compact Precision optical device that is utilized for measurement rather than ordinary viewing, and it projects a magnified shadow-image of a component’s contour in to an eyepiece or screen.

It is considered to be contactless equipment, which is necessary for measuring very thin or delicate part’s without adding pressure, however, the overall handling sometimes feels sturdy and hardy.

The instrument’s structure consists of an optical head mounted on a vertical column, And that head is adjusted for focus using various micrometer assemblies.

A movable XY stage is applied beneath the optics, and the stage is shifted in two perpendicular direction’s using micrometer screw’s, resulting in linear readings that can be recorded with around 0.01 mm accuracy.

During this process, the operator aligns the crosshair with one feature of the object, then the micrometer value is noted, which leads to dimension estimation after the stage is moved to the next point.

Angular measurement is generated using a rotatable eyepiece protractor that turns 360°, although the angle dial sometimes shows small spacing noise around markings etc.

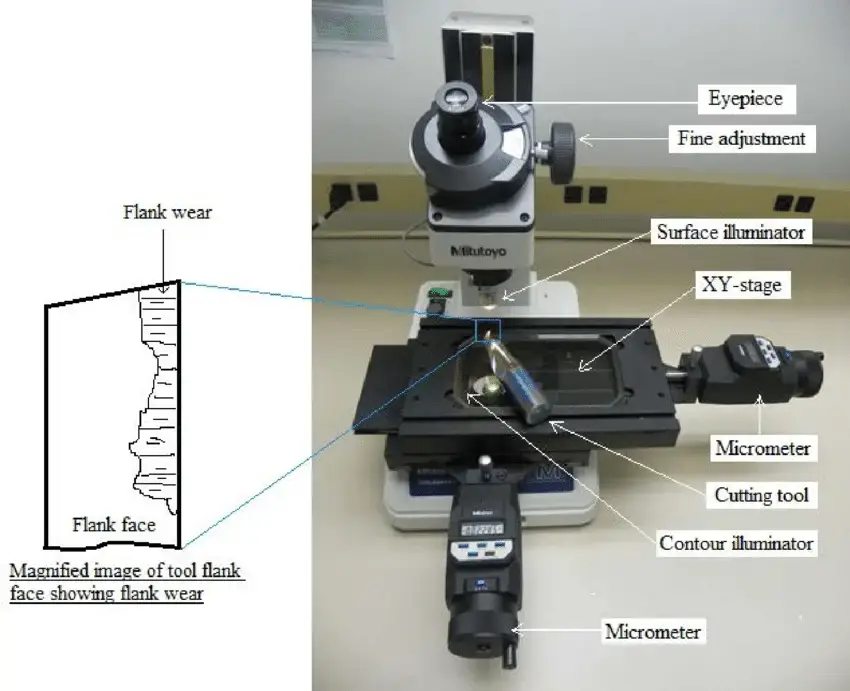

The device is widely regarded as being useful for analyzing tool angles like rake angle or relief angle, and these angles are measured by aligning the feature’s edge with the rotated crosshair.

Screw-thread parameter’s (e.g., pitch / thread angle / major–minor diameter) are measured, and this technique involves a method that gives a look into the reaction between the thread flank’s geometry and the optical contour.

Linear and angular readings are monitored for pieces like gear teeth,milling cutters, punches, and the jigs / fixtures that are used in workshop’s.

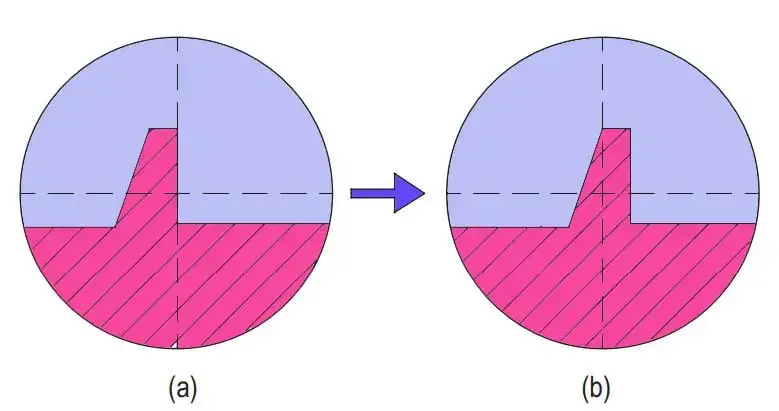

Two main measurement method’s are recognized: the “shadow-image method”, which is applied for general contour checking, and the axial-reaction method, which is known to be more sensitive for thread’s, producing clearer edge definition.

In reality, the instrument may be linked to Z-height determination, because the focusing motion can influence apparent height differences, thereby producing additional dimensional insight.

Modern digital TMM’s may be equipped with camcorder sensor’s, and the captured frame is interpreted by Image-processing software, allowing higher repeatability, though some user’s still prefer the analog feel.

Principle of Toolmakers Microscope

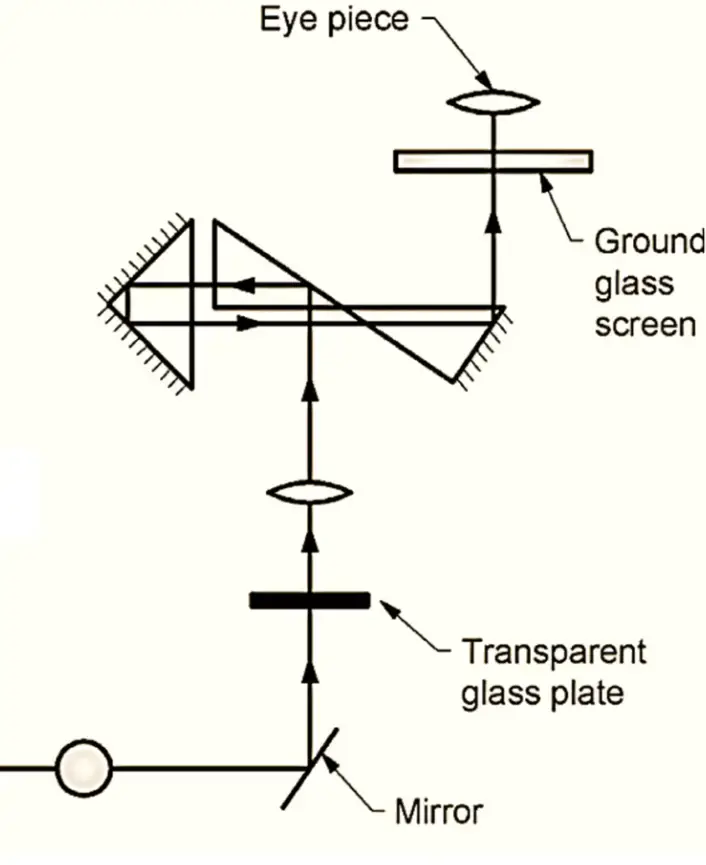

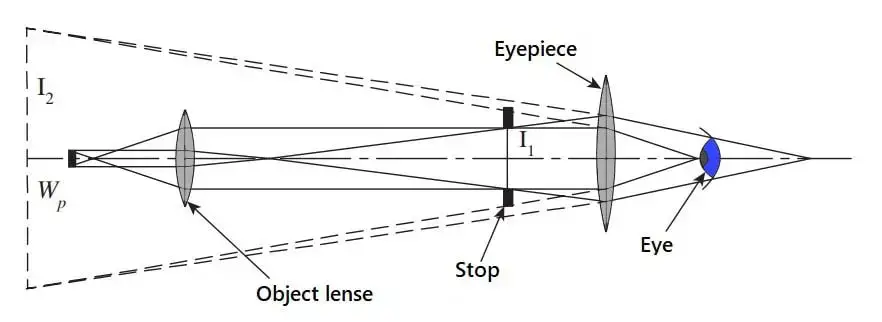

The fundamental principle is based on forming a magnified shadow-type “Contour Image”, which is produced when the part is placed on a transparent stage and light is passed from under it, resulting in a projected outline that’s used for very precise dimensional reading.

In this technique the illumination is often directed upward in to the glass plate, and the workpiece’s edges are observed to be blocking this beam, causing a silhouette that is carried through the Optical Head, which is considered a vital feature for evaluating tiny tool’s profiles.

Measurement is achieved when the object is translated on the XY-table by micrometer screw’s, however,the displacement recorded from these micrometer heads give the actual size in a non-contact approach, leading to measurements that are preserved without deformation of thin piece’s.

The crosshair in the eyepiece is utilized as the reference mark, and the operator aligns one edge with it, then moves the stage until another feature meet’s that same line, producing a run-on reading that is measured directly, which can be an indication of its accuracy.

Angular checking is carried out when the protractor or the angle-dial is rotated, and the crosshair is observed to match different flank’s or Tool Angles, however—the image itself may be rotated instead, both ways giving a look into the orientation of the part.

A second principle known as the axial-reaction method is sometimes applied for threads, where knife-edge contact is not used but is simulated optically, and the thread-section is viewed along its axis to allow more dependable readings, which leads to reduced parallax error’s.

The whole system is referred to as a contactless measuring Microscope, and its function is to maintain integrity of delicate items’ surfaces, also the stage/ illumination/ optics arrangement are linked with each other to form the measurement chain, though tiny spacing noise around optics / mechanics often appear in operator’s notes.

Parts of a Toolmakers Microscope

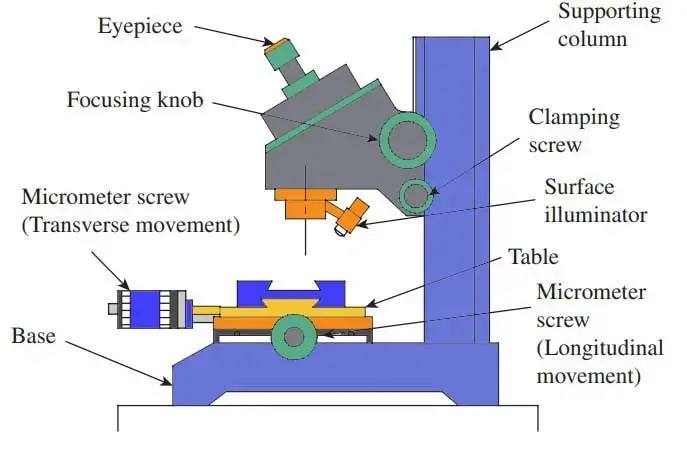

The toolmakers microscope is a precision measuring instrument that consists of several essential parts working together to provide accurate and reliable measurements. Each component plays a crucial role in the functionality and versatility of the microscope.

1. Hollow Base– the sturdy hollow base is referred to as the main foundation of the instrument, which is utilized to keep the whole frame stable and also houses the illumination unit below, producing a firm support even during slight vibration’s.

2. Circular Stage Surface– a transparent Glass stage is placed on top of the base, and it can rotate 360° allowing precise positioning of the object, resulting in better angle observation in many situations.

3. Vertical Column – the upright column support’s the optical head and is considered to be the central structural Backbone for Z-direction adjustments, though sometimes the height alignment is slightly drifted.

4. Carrier Arm – this arm holds the optical head and it is moved in the vertical direction by a focusing mechanism, which in this case is usually a rack-and-pinion system used/ needed for fine focusing.

5. Objective Lens – the objective lens (e.g., 2X standard) is utilized to magnify the specimen image, causing the first major enlargement step that gives a look into the tiny feature’s on the part.

6. Eyepiece – the eyepiece (15X often) is placed at the top and further enlarges the magnified view, And it carries the cross-hair reticle, which leads to more accurate alignment of edges.

7. Diopter Adjustment Ring – this ring is added around the eyepiece, and it is adjusted to correct user eye accommodation, though its setting’s are sometimes left slightly off-center.

8. Angle Dial / Eyepiece Protractor – a 360° rotating dial is mounted on the optical tube allowing angular measurements, which are recorded with a vernier sometimes, giving rise to fine angle reading’s.

9. XY Stage (Co-ordinate Measuring Table) – the stage is used to hold the workpiece on a transparent glass plate and also moves in X/Y directions, forming the Core measurement platform for linear displacement.

10. Micrometer Screws – two micrometer screw’s provide the Longitudinal and lateral motions of the stage, and each screw is measured in small divisions, thereby producing precise coordinate displacement.

11. Transmitted Illumination Unit – a contour light source is placed below the stage glass, often with a green filter, and light is passed upward, allowing edge profiling in this technique.

12. Surface Illuminator – an oblique incident-light system is located near the objective, and it is applied for surface inspection, leading to clear reflection from small scratches, etc.

13. Ground Glass Screen – this screen is located at the top region and acts as the focusing surface where the image is projected, and sometimes the image is observed here before final reading.

14. Control Panel – a small panel is utilized to manage illumination intensity/ direction, And in certain cases it also switches between transmitted and reflected modes.

15. Accessory Holding Jigs – optional tools like V-blocks or Swivel center supports are inserted on the stage, which assists in holding cylindrical part’s securely during measurements.

Construction and Working of Tool Maker’s Microscope

CONSTRUCTION –

- The microscope system consists of a vertical Supporting Column that is considered the main load-bearing part, and it keeps the instrument’s stability even when the measuring head’s weight are shifting in up–down direction.

- The XY Stage is utilized for translatory motion in two principal direction’s, and this table can be moved precisely with micrometer head’s, which is necessary for getting the linear displacement during this process.

- The Measuring Head carries the Optical Tube, And it is moved along the supporting column by a focusing knob, leading to a controlled focusing that’s required for locating small feature’s on workpiece.

- A clamping screw’s system is applied for locking the head in to a fixed position, however, sometimes the user forget to tighten it which leads to slight drift during measurement.

- There is an Angle Dial around the eyepiece, which provides angle reading’s and is known to be helpful in orientation study , but it may be sensitive to parallax error’s.

- A Surface Illuminator is generated at the base region, producing a sharp beam on the object’s surface, and also giving a look into the edges / contour lines of components etc.

- The instrument usually include sturdy and hardy base, although minor vibration’s could be observed during rough bench setups.

WORKING PRINCIPLE –

- The Reticle inside the eyepiece is referred to as the main datum line, which forms a reference for linear and angular measurement, resulting in a clear alignment pathway.

- In linear measurement, a feature point is aligned with the reticle crosswire, then R1 is recorded using XY Table micrometer head’s, and next the table is moved before aligning the second point, however,R2 reading’s are sometimes misread due to operator fatigue.

- The difference R2–R1 is considered to be the actual dimension, which can be affected by backlash, leading to operator repeating the step.

- Some microscope’s have Vernier Scales instead of micrometers; it is applied for reading smaller division’s, but, the vernier interpretation requires attention to avoid parallax.

- The Dioptre adjustment ring is observed on the eyepiece mount (often overused), and it can influence visual comfort because it bring’s the crosswire into focus.

- The focusing knob moves the optical tube up/down, allowing proper image sharpening, which is linked to the table height indirectly.

- Alignment of Workpiece is required so the measuring direction match the stage traversal direction, In practice, misalignment causes small skew error’s that are difficult to prevail.

- Surface illumination is used widely, and different modes (direct/oblique / diffused) can be applied, giving rise to contrast improvement that’s vital when the objects have dull finish.

- The overall working of the microscope is considered a very effective process for dimensional metrology, although slight user-dependent variation’s are common.

How to Use a Measuring Microscope

- Setup and Preparation

- The microscope is placed on a clean stable table, and the illumination is switched on at the needed level.

- The stage and the lens system is checked so that dust is not present, and calibration condition is confirmed.

- Mounting the Specimen

- The specimen is kept on the glass stage, and it is held with the clamp or jig provided with the instrument.

- The stage is moved by the micrometer heads and the object is brought at the center of the viewing field.

- Initial Focusing

- The eyepiece is aligned vertically and the image is focused by using coarse and fine adjustment knobs.

- The illumination angle and intensity is adjusted until a clear contrast is obtained.

- Alignment of Measuring Features

- The crosshair reticle is rotated with its knob so that it match the edge or reference point of the specimen.

- For angular checking, the reticle or the specimen is turned to match the required flank or tooth angle.

- Dimensional Measurement

- The X and Y micrometer heads is moved carefully so the crosshair come exactly on the starting and ending point of the feature.

- Readings are taken from the micrometer heads, and the difference is the diameter, length or thickness measured.

- For angular reading, the vernier or dial scale is used.

- Repeat and Verify

- The measurement is repeated two or more times for confirming the value.

- When more than one feature is measured, the same alignment and micrometer steps is followed.

Additional Notes

- It is seen that the crosshair and stage movement is in proper alignment for correct measurement direction.

- Backlash error is avoided when the stage is clamped before taking any reading.

- After the work is finished, the illumination is turned off and the microscope is covered to stop dust entry.

Simple Experiments

Pitch measurement of a hacksaw blade

- The Microscope Light is switched on at the beginning, and proper illumination is considered essential because it create’s a clear field that allow the blade’s profile to stand out.

- A suitable Lens is selected for precision operation, although operator’s sometimes over-choose magnification, leading to narrower field-of-view and slight difficulty in positioning.

- The Hacksaw blade is placed on the Glass Table (stage), and it is required that the blade stay steady during this process , which is necessary for avoiding drift error’s.

- The focusing wheel on the right side is rotated until the tooth edges form a sharp outline, however, slight vibration may blur the image for a moment, producing a need to refocus again.

- The Cross line (reticle) is aligned so that it coincide with the first visible tooth edge, and this step is observed to be the critical alignment phase.

- An Initial Reading is recorded on the ground glass screen, but sometime the reading’s are misread due to glare on the screen, however,it usually take’s only a second attempt to correct.

- Then the Table is rotated slowly until the next tooth edge is brought in to view, resulting in a new alignment against the same reticle line.

- A Second Reading is taken from the scale/glass screen, and this value is linked to the new stage position, giving a look into how far the stage moved.

- The Pitch is calculated as (Second reading – Initial reading) , and this difference is considered to be the tooth spacing , although minor human error can influence it.

- The measurement is repeated several time’s, forming an averaged value that’s more sturdy and hardy for quality checking, and occasionally small deviation’s are noticed between trials.

Obtaining the angle of the hacksaw teeth

- The Hacksaw blade is positioned on the Glass Table (stage), and the teeth region is required to be clearly visible, which is necessary for accurate angle observation.

- The blade is kept steady , however slight sliding sometimes occur’s if the table isn’t cleaned properly, resulting in repeated repositioning.

- The Screen of the microscope is rotated until a highlighted reference line appear’s, and this step is considered the starting alignment phase that give a look into the angular setup.

- An Initial Angular Reading is observed on the scale, although occasional glare on the viewing window may cause small difficulty in reading the number’s.

- Then the Screen is rotated again, bringing the same highlighted line toward the opposite flank of the tooth, and this motion is influenced by the gearing / rotation knob arrangement.

- A Second Angular Reading is taken once the flank coincide with the line, forming the second reference position, but the operator may misread if the pointer drift slightly.

- The Angle is calculated as (Second – Initial) reading , leading to the tooth-angle value, and this calculation is often straightforward, although myopia of the operator might prevail the clarity.

- The measurement is repeated on several tooth’s, producing an averaged value that’s sturdy for inspection purposes, also helping to reduce random error’s from handling.

Handling Precautions

- It is always moved with two hands, supporting from the base and the arm, and the stage or optical tube is not used for lifting.

- It is placed on a flat surface free from vibration, and a clean environment is needed to avoid dust and misalignment.

- It is covered with a dust cover after use so that dust does not gather on the optical or mechanical parts.

- The lenses, eyepiece and objectives are not touched with fingers, and only lens paper or a soft cloth is used for cleaning.

- No force is applied during focusing or stage movement because the gears can get damaged.

- It is unplugged before shifting or cleaning, and it is not handled with wet hands to avoid electrical risk.

- It is calibrated at regular intervals, and alignment is checked before important measurement work.

- The illumination condition is checked so that the viewing and measurement remain clear.

- Readings are taken from the front to avoid parallax error, and the setup is not disturbed during measurement.

- After using immersion oil or chemicals, the optics are cleaned properly to stop residue formation.

Applications of Tool Maker’s Microscope

- It is used for linear and angular measurement of small parts, and the measurement is taken for diameters, radii and thread angles with high accuracy.

- It is applied for checking the profile and contour of workpieces like gears, cams, punches and cutting tools where no contact is required to avoid damage.

- It is used in examining screw threads and gear teeth, and the pitch and spacing is inspected for quality control.

- It helps in studying tool edges, and the wear of milling cutters, dies and templates is observed for maintenance.

- It is used to measure the center-to-center distance between holes or bores in a given plane which is important for assembly works.

- It is used in finding the relative position of different points on an object, supporting alignment and calibration activities.

- It is applied in observing delicate or miniature parts in electronics and biomedical fields where accurate measurement is required without deformation.

- It is used in mechanical and electronic industries for tool development and precision inspection.

- It is used in light industries for checking component dimensions and surface characters.

- It is used in metrology labs, research centers and academic institutions for calibration, study and teaching purposes.

Advantages of Tool Maker’s Microscope

- It is used for taking very high precision measurement, and micron-level accuracy is obtained for linear, angular and diametric dimensions.

- It allows non-contact measurement, so there is no deformation of delicate or thin materials during observation.

- It is versatile because lengths, angles, diameters, pitch, thread forms and profiles are measured, and shapes are also compared directly.

- It combines inspection and measurement in one instrument, and surface quality, tool wear and defects are observed together with quantitative values.

- It can be attached with camera systems, and images are recorded for documentation and data export.

- It is adaptable for different specimens since the stage and optical parts are adjustable for various sizes and shapes.

- It has easy working steps, and digital micrometers or software are used for direct measurements without difficult setup.

- It is important for quality assurance where components must match required specifications.

- It is useful in research and development for quick and accurate checking of new designs.

- It is applied in teaching and calibration work in laboratories, helping in improving technical skills.

Limitations of Tool Maker’s Microscope

- It is designed for specific works, and some models cannot adapt to wider applications.

- It requires skilled handling, and careful alignment and focusing is needed to avoid errors.

- It is limited only to surface features, and internal parts of opaque materials cannot be examined.

- It has restricted depth of field, and only one plane normal to the optical axis is measured clearly at a time.

- It needs proper illumination, and poor lighting conditions reduce clarity and may cause errors.

- It depends on manual stage movement, and many steps are slow and can introduce human error.

- It has high cost and maintenance because of precision optics and illumination systems.

- It is not suitable for high-volume production since the measurement process is not rapid or automated.

FAQ

What is a toolmaker’s microscope, and what sets it apart from a conventional microscope?

A toolmaker’s microscope is a precision measuring instrument used to inspect and measure small mechanical and electronic parts. Unlike a conventional microscope, it is designed specifically for accurate measurements and can measure up to 1/100th of a millimeter.

What are the main applications of a toolmaker’s microscope?

Toolmaker’s microscopes are widely used in various industries for shop floor inspection of screw threads, gears, and small machine parts. They are also used for precision measurement of test tools in tool rooms and for determining dimensions of small holes and tapers.

How does a toolmaker’s microscope achieve magnification and accurate measurements?

Toolmaker’s microscopes use optical systems with high magnification capabilities, allowing users to view and measure small parts with precision. They also incorporate reticles or scales to provide reference points for accurate measurements.

Can a toolmaker’s microscope be used for non-destructive testing of materials?

No, a toolmaker’s microscope is not suitable for non-destructive testing. Its primary purpose is precise measurement and inspection of small components rather than assessing material properties or flaws.

What are the advantages of using a toolmaker’s microscope over other measuring instruments?

A toolmaker’s microscope offers advantages like z-axis height information, linear scale integration, and adaptability for various applications. It is also ideal for measurements of hardness test indentations and surface finish verification.

Can a toolmaker’s microscope measure angles of components?

Yes, a toolmaker’s microscope can measure angles of various components. It is equipped with an angle dial or reticle, enabling users to accurately determine the angles of objects being observed.

Is it necessary to calibrate a toolmaker’s microscope regularly?

Yes, regular calibration is essential to maintain the accuracy and reliability of a toolmaker’s microscope. Calibrating at recommended intervals ensures that the instrument provides consistent and precise measurements.

Can a toolmaker’s microscope be used for photo documentation?

Yes, many toolmaker’s microscopes can be adapted with cameras and CCTV systems for photo documentation requirements. This allows users to capture images and videos of the observed components for documentation and analysis.

What precautions should be taken while using a toolmaker’s microscope?

Handling precautions include maintaining a clean environment, covering the microscope when not in use to prevent dust accumulation, and ensuring stable installation to avoid vibrations.

Is it possible to perform both absolute and comparative measurements with a toolmaker’s microscope?

Yes, a toolmaker’s microscope allows for both absolute and comparative measurements. By using reference points and scales, it facilitates precise measurements of individual components and comparisons between different parts to assess their dimensions and features.

References

- https://www.microscopemaster.com/toolmakers-microscope.html

- https://www.keyence.co.in/ss/products/measure-sys/measurement-selection/type/microscope.jsp

- https://extrudesign.com/tool-makers-microscope/?expand_article=1

- https://electricalworkbook.com/tool-makers-microscope/

- https://www.holmarc.com/tool_makers_microscope.php

- https://www.radicalindia.com/toolmaker-microscope.php

- https://www.india-tools.net/toolmakers-microscope.html

- Text Highlighting: Select any text in the post content to highlight it

- Text Annotation: Select text and add comments with annotations

- Comment Management: Edit or delete your own comments

- Highlight Management: Remove your own highlights

How to use: Simply select any text in the post content above, and you'll see annotation options. Login here or create an account to get started.