What is Single Pan or Unequal Arm Mechanical Balance?

- Single pan mechanical balance refers as a type of mechanical weighing device where only one pan is present instead of two, it used widely in laboratories for quick and precise weight measurements.

- In this balance, unequal arms are utilized, one arm is shorter and another is longer, that’s why it called as unequal arm balance, sometimes also known as single beam type.

- The short arm usually carries the pan where object to be weighed is placed, and long arm contains movable weights / riders to balance the mass.

- Principle based on the law of moments, that means, the torque produced by the weights on both sides of the fulcrum must be equal when equilibrium is achieved.

- The working of this balance depend upon lever principle, but arms are designed in unequal length to allow greater convenience and sensitivity during measurement.

- A fixed pointer or index is provided at the center to show the equilibrium position (zero mark) which help user to check the balancing condition.

- When weight of object cause the beam to tilt downward on the pan side, movable rider on the beam is shifted until pointer returns back to zero, this shows equal moments achieved.

- Calibration of the balance done by adjusting the zero screw or balancing nut at the base, sometimes errors may prevail due to friction or misalignment.

- In modern versions, the beam made of lightweight alloy for better stability and less vibration effect, but older ones were made from brass or steel, etc.

- Sensitivity of single pan balance is high compare to double pan, because unequal arm design reduce the movement of mass and hence increase the responsiveness.

- They (the balance) used in many places like chemistry lab, pharmacy, educational institutes, where accurate measurement of small substances required.

- Accuracy usually within ±0.001 g depending on model, though environmental factor like air current or vibration may affect reading slightly.

- Maintenance is necessary, beam should kept clean, knife edges not worn out, and pan free from dust otherwise the reading may become erroneous.

- Unlike two pan balance, single pan required less manipulation since only one object need to place, making the operation more simple and fast.

- The beam is graduated, rider slide along scale to indicate weight directly, so computation become easier and no need for repetitive weighing.

- In some laboratory manuals it also called as Top loading mechanical balance, though principle remain almost same.

- Major advantage is—compact design, portability, time saving and minimal air disturbance effect.

- Disadvantage include—it require careful handling, zero error often occur, and cannot weigh very heavy samples beyond few hundred grams.

- The unequal arms ratio generally about 1:10 or 1:20 depending upon sensitivity required for experiment.

- Hence, single pan mechanical balance serve as a useful and dependable instrument for routine weight determination where electrical balance not available.

Parts of Single Pan/Unequal Arm Mechanical Balance

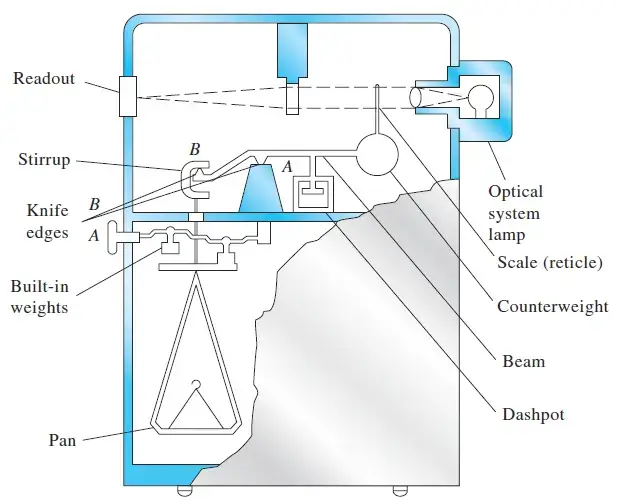

- Beam – The beam is main horizontal lever which supports fulcrum, arms and pointer, it is usually made from light alloy or brass and is balanced for sensitivity.

- Fulcrum – The central knife-edge support is provided by the fulcrum, it must kept sharp and aligned, friction at this point are minimized to increase sensitivity.

- Pan – The pan is attached on short arm, it hold the sample (often stainless-steel ), and is detachable for cleaning.

- Pointer / Index – A fine pointer is fixed to beam that moves over scale to indicate equilibrium, it shows zero position and deflection.

- Graduated Arm– The longer arm with scale divisions is termed as graduated arm, rider is slided here for fractional weights and direct reading is allowed.

- Rider– A small sliding rider (weight) is used for fine adjustment, it is moved along scale until pointer return to zero, this gives precise fraction reading.

- Pillar– The vertical pillar support is provided to hold fulcrum and beam, it is bolted to base and alignment must checked often.

- Base– A heavy metallic base is provided which gives stability and dampen vibration, it may contain rubber feet for isolation.

- Knife Edges – Knife edges are fitted at fulcrum and at beam bearings, they reduce friction and are hardened steel, their wear will cause error.

- Zero Adjustment Screw– Zero adjustment screw used for correcting initial imbalance, fine tuning is done by this (no load condition).

- Pan Support / Hanger– The pan is suspended by a pan support or hanger (wire/hook), it must be centered and equal length otherwise moment error will occur.

- Protective Case – A transparent protective case is often provided to prevent air currents, drafts are minimized and reading become stable.

- Beam Arrest/ Lock– A beam arrest or lock is provided to lift/hold the beam when not in use, it prevents wear at knife edges and transport damage.

- Weight Box – Standard weights are stored in weight box (5 g, 10 g, etc.), calibration and verification are done with these, they must be certified.

- Scale /Graduation Mark– The scale or graduation marks are printed on beam or near pointer, divisions may be in g or mg and must be checked for wear.

Principle of Single Pan/Unequal Arm Mechanical Balance

- The principle of single pan or unequal arm mechanical balance refers as the law of moments, which state that when a lever is in equilibrium, the product of weight and its arm length on one side equal to that on the other side.

- It work based on the moment balance condition, means— the clockwise moment and anticlockwise moment acting about the fulcrum become equal when balance is achieved.

- Mathematically it expressed as, W₁ × L₁ = W₂ × L₂, where W₁ and W₂ are the weights on two arms and L₁, L₂ are the respective arm lengths.

- The arms of the beam are unequal, one short and another long, so a small weight on long arm can balance larger weight placed on short arm, which increase the sensitivity of instrument.

- The short arm carries pan where unknown mass is placed, and the long arm has a rider which moves along scale to produce variable torque for balancing.

- When torque produced by both sides becomes same, the pointer comes back to its zero position showing that moments are equal and balance is attained.

- The entire operation depend on lever principle, but modified as unequal arm type for convenience and quick determination of mass.

- Sensitivity depend on several factors like knife edge sharpness, beam length ratio and friction at pivot, all these affect accurate balancing.

- The torque equality maintain that, even if beam arms are unequal, the ratio of their lengths is constant, so calibration provide true reading.

- In simple words the unknown mass is calculated indirectly by balancing known moment against it, instead of balancing equal weights like in two pan system.

- When equilibrium disturbed by loading, restoring movement occur until pointer again align to zero, that shows equal moments restored.

- Thus, this balance function by equilibrium of moments, not by equal mass, that’s why it termed as unequal arm mechanical type.

- The main advantage of this principle – smaller movement of weights produce larger balance effect, hence reading become fast and more sensitive.

- This principle applied widely in laboratory instruments for high precision weighing where quick determination required without using double pans.

- Any deviation from zero indicate unbalanced torque, and correction is made by sliding rider or changing standard weight till equal moment achieved again.

Operating Procedure of Single Pan/Unequal Arm Mechanical Balance

- The balance should placed on a firm and vibration-free table before starting, surface must kept level using the spirit level if provided.

- The beam arrest knob is lifted gently to release the beam, pointer should swing freely to both sides, if not then adjustment needed.

- Zero error is checked by observing the pointer position when no load placed on pan, if pointer not at zero then zero adjustment screw is turned until pointer come to rest at center.

- After confirming zero, the beam is again arrested to avoid wear, then the pan is cleaned using soft brush or tissue to remove dust particles etc.

- The object or sample to be weighed is placed carefully on the pan using forceps (never by hand, because moisture/oil may affect weight).

- Standard weights from weight box are added one by one on weight carrier or scale pan till near balance is achieved, care must taken not to drop them.

- Beam is released slowly again and pointer movement observed, if pointer deflect to left or right, weights are adjusted until beam oscillate equally on both sides of zero.

- The rider on the graduated arm is then moved to fine tune the balance, small movement of rider correspond to fractional weights (e.g., 0.01 g).

- When pointer rest at zero mark (or oscillate equally), the total of weights + rider reading give the actual mass of the object.

- After recording the reading, the beam should again be arrested using arrest knob and both pan and weights removed.

- The weights are returned to weight box in same position, contamination or loss of weights must avoided by handling them with tweezers.

- The balance is then set back to zero condition again to ensure no residual error has developed during measurement, if deviation seen, recalibration done.

- For accuracy, process repeated 2–3 times and average weight is taken, this helps to prevail random errors caused by air drift or hand vibration.

- The instrument must covered by its glass case or dust cover after use, and should kept in dry area (temperature about 25°C–30°C).

- Overloading of pan or applying jerky load must avoided, as it damage the knife edges and spoil sensitivity of beam permanently.

Factors that affect readings on Single Pan/Unequal Arm Mechanical Balance

1. Air Currents– Movement of air around the balance cause pointer fluctuation, it affect stability of reading, so instrument usually kept in glass case to prevail error.

2. Temperature Changes – Variation of temperature (like 20°C–35°C) lead to expansion of metal beam or weights, this alter arm ratio slightly and change true reading.

3. Friction at Knife Edges – Friction between knife edge and bearing reduce sensitivity, sometimes due to dust or wear, pointer not swing freely causing wrong equilibrium point.

4. Uneven Surface– When base not level, moments are disturbed, one arm appear heavier, and zero reading shifted from center.

5. Zero Error– Improper zero setting before measurement lead to systematic error, result may be always higher or lower than actual mass.

6. Vibration / Shock– External vibration from nearby instruments or table movement make beam oscillate irregularly, reading fluctuate and become uncertain.

7. Magnetic Field – Presence of magnetic field (by electric motor, fan etc.) may influence metallic weights or beam if made of magnetic material.

8. Dirt and Dust – Dust on pan, beam or knife edge add small extra mass or friction, it disturb balance condition, readings become inconsistent.

9. Improper Handling– Rough placing of weights or touching by hand introduce oil or moisture, altering the real mass slightly, this cumulative error seen often in routine labs.

10. Parallax Error – When pointer or scale viewed from wrong angle, observer may read wrong zero mark, human eye position must at same level as pointer.

11. Worn Knife Edges – With long use the knife edges get blunt, friction increase and sensitivity decrease, correction by replacement required periodically.

12. Humidity – High humidity cause adsorption of water vapor on weights or sample, specially for hygroscopic materials, this increase apparent mass.

13. Air Buoyancy – Difference in air density cause buoyant force, particularly affect very light objects or when high precision weighing done.

14. Improper Calibration – If calibration not done with certified standard weights, the indicated readings may deviate from true value, instrument need recalibration at interval.

15. Load Distribution – When sample not placed at center of pan, unequal moment generated, small tilt produce large error due to arm leverage effect.

Uses of Single Pan/Unequal Arm Mechanical Balance

- The single pan mechanical balance used mainly for determination of unknown mass of substances with high sensitivity and accuracy in laboratories.

- It applied widely in chemistry labs for weighing reagents, salts, and solid chemicals before preparation of solutions or performing titration etc.

- The instrument is used for analytical weighing, where small quantity like 0.001 g to 200 g are required to be measured precisely.

- In pharmaceutical laboratories, it used for weighing drug samples, excipients, and formulation ingredients before compounding and mixing.

- Educational institutions use it for demonstration and student practical works because it shows working of lever principle and mechanical balance operation.

- The balance used for calibration of smaller weights, by comparison with standard reference weights in known ratio arms.

- In biological and agricultural studies, it helps to measure dry weight of plant materials, seeds, soil samples etc.

- The instrument used for preparation of standard solution, where exact amount of solute has to weighed for correct molarity.

- It can used in industrial laboratories to check purity and quality control by measuring small mass differences during formulation.

- The single pan design make it suitable for rapid routine weighing, since only one side need to load and equilibrium achieve faster.

- The balance sometimes used for density determination, when combined with displacement method or double weighing approach.

- It is used also for scientific research where comparative weights or sample-to-sample mass variation are studied.

- Some field laboratories employ portable versions of it because it not require electricity and still provide reliable accuracy.

- The instrument used for recalibration of old weights and checking wear of standard mass sets in metrology labs.

Advantages of Single Pan/Unequal Arm Mechanical Balance

- The single pan balance provide faster operation since only one pan required to load sample, hence weighing time is reduced almost half compare to double pan system.

- High sensitivity achieved because of unequal arm design, small rider movement produce large torque difference that makes reading more accurate.

- Less manual handling needed, as no need to transfer weights repeatedly between two pans, this also minimize error due to human operation.

- It require smaller working space, compact design make it portable and suitable for small laboratory benches or field use.

- The balance can used for quick routine measurement, particularly in chemical and pharmaceutical labs where many samples weighed daily.

- Calibration process are easier since only one beam ratio need to verified, that reduce maintenance effort and time.

- Friction error are minimized due to light beam construction and fewer moving parts, so instrument remain stable for long time.

- The mechanical design not depend on electricity, hence can used in areas without power or during power failure conditions.

- Accuracy remain high (±0.001 g for standard models) when properly maintained, suitable for analytical purpose.

- Less chance of air disturbance since only one pan exposed, that improve precision for light samples or volatile substances.

- It’s economical and durable, made of sturdy and hardy metals, maintenance cost usually very low compare to electronic balances.

- The pointer movement allow clear visual indication of equilibrium which help student to learn concept of moment and torque balance easily.

- Unequal arm mechanism make possible to balance heavy sample by small counter weight, thus extending usable range of instrument.

- Because of simple construction and long-term reliability, it preferred in educational, research, and industrial laboratories for general weighing etc.

Limitations of Single Pan or Unequal Arm Mechanical Balance

- The single pan balance not suitable for very large weights, capacity usually limited to few hundred grams only, beyond that accuracy lost.

- It is affected easily by vibration, air current, and temperature change which alter the equilibrium condition during weighing.

- Zero error frequently occur, and it must checked before each use, otherwise the readings become inconsistent and unreliable.

- The knife edges wear out with time, due to constant use or dust deposition, which reduce sensitivity and produce permanent error.

- Readings depend on human observation, parallax error often arise when pointer not viewed straight to the scale, so operator skill influence result.

- The process of weighing is slow compare to electronic balances, since user has to adjust rider and wait for pointer stabilization each time.

- Calibration require standard weights, and any error in weights directly transfer to measurement making balance inaccurate.

- Not convenient for volatile, hot, or magnetic samples, as air convection or magnetic field disturb the moment balance condition.

- The beam arrest and release system can damage if handled roughly, once knife edge bent, instrument lose precision completely.

- Friction at pivot and improper lubrication cause damping variation, so sometimes pointer not reach zero properly even if balance is true.

- Due to manual manipulation, small random error appear each time, repeatability of same sample reading may differ slightly.

- The balance need careful leveling and clean environment; dust or moisture affect both beam and weights easily.

- Maintenance cost low but frequent adjustment required, so it not ideal for very high precision analytical works (like micro weighing).

- Because of mechanical parts and external factors, accuracy often limited around ±0.001 g, which is lesser than modern digital balances.

Precautions of Single Pan/Unequal Arm Mechanical Balance

- The balance must always kept on stable and vibration-free surface, uneven or shaky tables cause fluctuation in readings.

- Before using, the zero error should checked carefully, pointer must rest at central zero when beam released without load.

- The beam arrest knob must used while placing or removing weights, otherwise knife edges may get damaged permanently.

- Weights should never touched directly by hand, forceps or tweezers are used because fingerprints or moisture change actual weight.

- The pan should clean properly before every use, any dust, chemical particle, or residue can affect measurement.

- Sample or object to weigh must placed at center of pan, if not, unequal moment generated and accuracy lost.

- Air currents / drafts should avoided, balance must enclosed in glass case or shield when working with light objects.

- The rider should moved slowly and gently on the graduated arm, sudden movement cause jerky oscillation of beam.

- After every weighing, beam must arrested back, leaving it free can cause continuous strain on knife edges.

- Calibration must done regularly using standard weights (certified) to maintain reliability of reading.

- Never overload the pan beyond its capacity (usually 200–300 g), excess weight will bend arm and spoil alignment.

- The balance should kept away from magnetic field, fan, or heat source, as they disturb equilibrium condition.

- Level adjustment screw must checked time to time, since even small tilt of base can prevail correct moment ratio.

- Avoid weighing hot substances, wait until they cool to room temperature (25°C approx), heat cause air convection and mass variation.

- After completion of work, both pan and beam should cleaned with soft brush and instrument covered with dust cover.

- During transport, the arrest mechanism must locked tightly and balance carried in upright position to avoid damage.

- All readings should taken with eye level same as pointer, to prevent parallax error in scale observation.

- Periodic servicing required to maintain knife-edge sharpness, friction surfaces must not oiled unnecessarily.

- Moisture and corrosion should prevented by keeping silica gel or drying agent nearby the instrument cabinet.

- Thus by following these precautions, accuracy and longevity of single pan / unequal arm mechanical balance can maintained properly for long period etc.

FAQ

What is a single pan/unequal arm mechanical balance?

A single pan/unequal arm mechanical balance is a weighing instrument used to determine the mass of an object. It consists of a pan where the object is placed, and a pointer that indicates the weight on a graduated scale.

How does a single pan/unequal arm mechanical balance work?

The balance operates on the principle of equilibrium. The weight of the object on the pan causes the pointer to deflect, and the balance is adjusted by adding standard weights to the opposite arm until equilibrium is reached, indicating the weight of the object.

What are the advantages of using a single pan/unequal arm mechanical balance?

Some advantages include its simplicity, affordability, and ease of use. It does not require electricity or batteries and can provide accurate measurements for small to medium-sized objects.

What are the weight capacity and readability of a single pan/unequal arm mechanical balance?

The weight capacity and readability can vary depending on the specific model and brand. It is important to check the specifications provided by the manufacturer for the particular balance being used.

Can a single pan/unequal arm mechanical balance measure both solids and liquids?

Yes, a single pan/unequal arm mechanical balance can measure both solids and liquids. However, it is essential to ensure that liquids are contained in suitable vessels to prevent spillage or damage to the balance.

How do I calibrate a single pan/unequal arm mechanical balance?

Calibration methods may differ depending on the manufacturer’s instructions. Generally, calibration involves placing known standard weights on the pan and adjusting the balance until the pointer indicates the correct weight. Follow the manufacturer’s guidelines for specific calibration procedures.

Can I use a single pan/unequal arm mechanical balance for legal or trade purposes?

No, a single pan/unequal arm mechanical balance is not typically used for legal or trade purposes. It is more commonly employed in educational, laboratory, or general weighing applications where high precision is not necessary.

What precautions should I take when using a single pan/unequal arm mechanical balance?

Precautions include placing the balance on a level surface, avoiding vibrations and air currents, not overloading the balance, handling weights carefully, and keeping the balance clean from dust and dirt. Refer to the precautions mentioned earlier for more detailed information.

How do I clean a single pan/unequal arm mechanical balance?

Cleaning involves using a soft, lint-free cloth to wipe the balance and remove any dust or dirt. It is essential to avoid using harsh chemicals or abrasive materials that could damage the balance. Follow the manufacturer’s cleaning instructions for specific guidance.

Can I use a single pan/unequal arm mechanical balance for highly precise measurements?

Single pan/unequal arm mechanical balances are generally not designed for extremely precise measurements. If high precision is required, other types of balances, such as analytical balances, may be more suitable. Consult the balance’s specifications and intended use to determine its precision capabilities.