What is Centrifuge?

- A centrifuge is a piece of equipment that is used to separate components of a sample based on their densities. It works by spinning the sample at high speeds, which causes the heavier components to move towards the outside of the tube or container, while the lighter components remain closer to the center. This process is known as sedimentation, and it allows the components of the sample to be separated and collected for further analysis or testing.

- Centrifuges are commonly used in laboratories and research settings for a variety of purposes, including separating blood cells from plasma, purifying proteins and other biomolecules, and more. They are also used in a number of other industries, including food processing, pharmaceuticals, and chemical manufacturing.

- There are many different types of centrifuges, including benchtop centrifuges, which are small and portable and are commonly used in laboratories; high-speed centrifuges, which are used to spin samples at very high speeds; and large-scale industrial centrifuges, which are used in industrial settings to process large volumes of material.

- Centrifuges may use different types of rotors to hold the samples, including fixed-angle rotors, swing-bucket rotors, and continuous flow rotors. They may also be designed to operate at different speeds and to hold different sizes and shapes of tubes or containers.

What is Centrifuge Balancing?

- Centrifuge balancing is the process of ensuring that a centrifuge is properly balanced and aligned before use.

- Centrifuges are used to separate components of a sample based on their densities by spinning the sample at high speeds. In order to work properly, a centrifuge must be balanced and aligned so that it spins smoothly and evenly.

- If a centrifuge is not properly balanced, it may vibrate or shake excessively, which can cause damage to the equipment and may also result in inaccurate or unreliable results.

- To balance a centrifuge, the weights and distribution of the samples in the tubes must be evenly distributed.

- The tubes must also be properly placed in the centrifuge rotor so that they are evenly balanced.

- The rotor should be carefully inspected for any damage or deformities that could affect its balance, and any necessary repairs should be made before use.

- In addition, the centrifuge itself should be properly leveled and aligned to ensure smooth and even spinning.

- Centrifuge balancing is an important step in the process of using a centrifuge, and failure to properly balance the equipment can result in serious problems.

Why it is important to balance a centrifuge? – Why is centrifuge balanced?

- It is important to balance a centrifuge because an unbalanced centrifuge can cause problems during the separation process and may also result in inaccurate or unreliable results.

- When a centrifuge is not properly balanced, it may vibrate or shake excessively, which can cause damage to the equipment and may also cause the samples to be unevenly separated. This can result in incomplete separation of the sample components, or may cause the components to be mixed together again after separation.

- In addition to these problems, an unbalanced centrifuge can also be dangerous to use. If the centrifuge is not properly balanced, the high speeds at which it spins can cause it to become unstable, which can lead to accidents or injuries.

- Therefore, it is important to carefully balance a centrifuge before use in order to ensure that it functions properly and safely. This may involve carefully distributing the weights and samples in the tubes, checking the rotor for any damage or deformities, and ensuring that the centrifuge itself is properly aligned and leveled. Proper balancing of the centrifuge is essential for accurate and reliable results and for the safe operation of the equipment.

What Happens if a Centrifuge is Unbalanced?

- If a centrifuge is unbalanced, it can cause problems during the separation process and may also result in inaccurate or unreliable results.

- When a centrifuge is not properly balanced, it may vibrate or shake excessively, which can cause damage to the equipment and may also cause the samples to be unevenly separated. This can result in incomplete separation of the sample components, or may cause the components to be mixed together again after separation.

- In addition to these problems, an unbalanced centrifuge can also be dangerous to use. If the centrifuge is not properly balanced, the high speeds at which it spins can cause it to become unstable, which can lead to accidents or injuries.

- Therefore, it is important to carefully balance a centrifuge before use in order to ensure that it functions properly and safely. This may involve carefully distributing the weights and samples in the tubes, checking the rotor for any damage or deformities, and ensuring that the centrifuge itself is properly aligned and leveled.

- Proper balancing of the centrifuge is essential for accurate and reliable results and for the safe operation of the equipment.

How Centrifuge Works?

- A centrifuge is a piece of equipment that is used to separate components of a sample based on their densities. It works by spinning the sample at high speeds, which causes the heavier components to move towards the outside of the tube, while the lighter components remain closer to the center.

- To use a centrifuge, the sample is placed in a tube or container, which is then placed in the centrifuge. The centrifuge has a motor that drives a rotor, which spins the tubes or containers at high speeds. The rotor is typically designed to hold several tubes or containers at once, and can be adjusted to spin at different speeds depending on the specific needs of the sample being separated.

- As the rotor spins, the centrifugal force generated by the high speeds causes the components of the sample to separate based on their densities. The heavier components move towards the outside of the tube or container, while the lighter components remain closer to the center. This process is known as sedimentation, and it allows the components of the sample to be separated and collected for further analysis or testing.

- Centrifuges are commonly used in laboratories and research settings for a variety of purposes, including separating blood cells from plasma, purifying proteins and other biomolecules, and more. They are also used in a number of other industries, including food processing, pharmaceuticals, and chemical manufacturing.

What is Centrifuge Tube?

- A centrifuge tube is a small, cylindrical tube that is used to store and process small samples in a laboratory or research setting.

- Centrifuge tubes are typically made of a durable material, such as glass or plastic, and are available in a range of sizes and shapes.

- They may have screw caps or snap-on caps to seal the tubes and prevent contamination, and may also have graduated markings on the side of the tube to help measure small volumes of liquid.

- Centrifuge tubes are commonly used in conjunction with a centrifuge, which is a piece of equipment that separates components of a sample based on their densities by spinning the sample at high speeds.

- The tubes are placed in the centrifuge, and the components of the sample are separated as the centrifuge spins. Centrifuge tubes are also used for a variety of other purposes, such as storing small samples, mixing and homogenizing samples, and more.

- There are many different types of centrifuge tubes, including microcentrifuge tubes, which are small tubes designed for use with very small samples; conical bottom tubes, which have a pointed bottom that allows for easy separation of the sample components; and round bottom tubes, which have a round bottom that is suitable for use with a range of sample types.

- Centrifuge tubes are commonly used in laboratories and research settings, and are an essential tool for many scientific and diagnostic applications.

How to balance in different centrifuge?

If you are utilising a portable benchtop instrument, you must ensure that the centrifuge is placed on a firm, level surface. The rotor must then be loaded with tubes so that the centre of gravity remains in the rotor’s centre. To discover how to accomplish this for various instrument kinds and tube numbers, see the sections that follow.

Fixed angle rotor devices

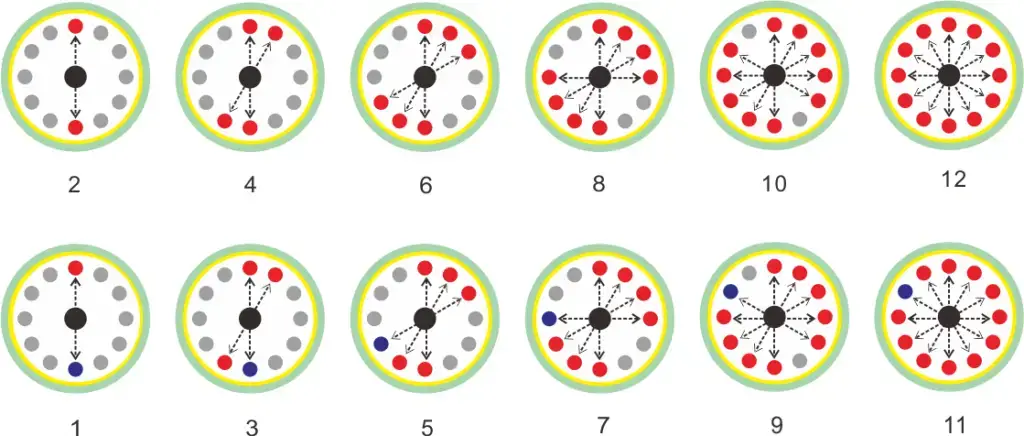

Consider your tubes in pairs and put them across from one another when loading a centrifuge with a fixed-angle rotor. Note that the two tubes positioned opposite one another should have the same mass, which requires that they be filled with identical sample volumes.

If you have an odd number of tubes, position one “balance tube” opposite your “single sample tube.” Please note that when filling it with water to preserve reagents, it does not need to hold the same volume of liquid, but must have the same mass as the sample tube on the opposite side of the rotor.

A fixed-angle rotor centrifuge with an odd number of tubes can also be balanced by uniformly spacing the tubes around the rotor.

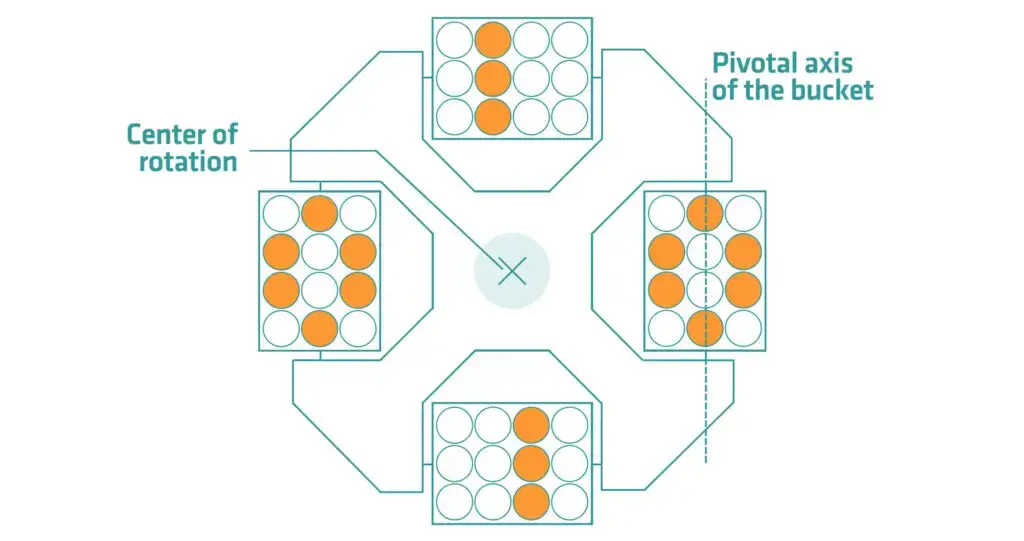

Swinging bucket rotor devices

To load a centrifuge with a swinging bucket rotor, you must equip all rotor positions with buckets, even if they are empty. Operating the instrument without buckets could result in rotor damage. In addition, you must ensure that the buckets can be removed easily.

Ensure that opposing buckets are loaded equally while loading tubes into buckets to prevent an imbalance across the centre of rotation. Additionally, each bucket must be balanced along its pivot axis. Use “balance tubes” if one of these conditions cannot be met with your sample tube number.

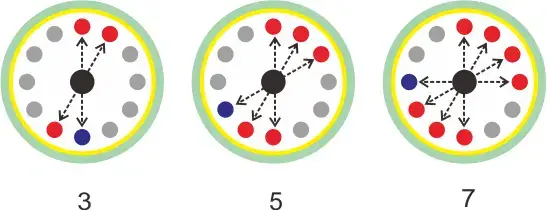

How to balance a three-tube centrifuge?

There are two methods for balancing three pipes. The first approach is to insert three sample tubes beside three equalisation tubes.

Alternately, the sample tubes might be uniformly distributed around the rotor.

How to balance a five-tube centrifuge?

To balance five tubes, make a balance tube and position two sets of three tubes in opposition.

How to equilibrium seven tubes in a centrifuge?

To balance seven tubes, make a balance tube and position two sets of four tubes in opposition.

Tips for Balancing Your Centrifuge

Balance Samples By Mass Not Volume

- If all samples have the same density, the mass and volume of the samples will not match. In this instance, it is possible to visually fill tubes. Nevertheless, it is prudent to weigh tubes for safety’s sake.

- If the density of some materials differs somewhat from that of others, mass, not volume, must be considered.

- Ultimately, the concept of equilibrium that we are discussing here rests entirely on mass. Typically, when it comes to volume, manufacturers will stipulate how full a tube can be. A good example would include no more than two-thirds of its capacity.

Do Not Leave Buckets Out

- If you are utilising a centrifuge with multiple buckets, you may only need to employ a subset of them for your laboratory samples. It may be tempting to leave your empty opposing buckets on the ground.

- However, this is not a good idea, as running without buckets could cause damage to the rotor or perhaps catastrophic failure. Remember this when arranging and balancing scientific equipment.

Use “Dummy Tubes” When Needed

- There will always be instances in which the quantity of samples to be centrifuged does not offer a balanced load. In this instance, “dummy” tubes could be used.

- These may be filled with water or another liquid, but the density of the substance should be comparable to that of your samples. However, tubes should still be weighed and not measured by volume.

Load Your Tubes Symmetrically

- Theoretically, loading tubes symmetrically sounds simple, but for some, it may be a tough notion to grasp, especially when balancing multiple buckets, and especially those that pivot.

- Those centrifuges with a rotor without buckets and a modest number of gaps are the simplest to balance.

Consider a Unit With an Imbalance Sensor

- Even if you believe that you have accurately loaded your samples, there is always the risk of human mistake.

- A gadget with a built-in imbalance sensor is useful in this situation. If it detects an imbalance, the unit will immediately cease operation.

How do you check a centrifuge balance?

There are several steps you can take to check the balance of a centrifuge:

- Check the rotor: Inspect the rotor for any damage or deformities that could affect its balance. Check for cracks, dents, or other imperfections that could cause the rotor to spin unevenly.

- Distribute the weights evenly: Make sure that the weights and samples in the tubes are evenly distributed in the rotor. This will help to ensure that the centrifuge is balanced and will reduce the risk of vibration or shaking.

- Level the centrifuge: Place a level on top of the centrifuge to ensure that it is properly aligned. If the level indicates that the centrifuge is not level, make adjustments to the feet or base of the centrifuge until it is level.

- Spin the centrifuge at low speeds: Run the centrifuge at low speeds and observe the rotor for any signs of imbalance, such as vibration or shaking. If the rotor appears to be spinning smoothly and evenly, you can increase the speed of the centrifuge to the desired level.

- Use a balancing device: Some centrifuges are equipped with a built-in balancing device that can help to ensure that the rotor is properly balanced. Follow the manufacturer’s instructions for using this device.

By following these steps, you can help to ensure that your centrifuge is properly balanced and ready for use. It is important to carefully balance the centrifuge before each use in order to ensure accurate and reliable results and to ensure the safety of the equipment.

What to do if a centrifuge is unbalanced?

If a centrifuge is unbalanced, it can vibrate excessively, potentially causing damage to the equipment and creating a safety hazard. Here are some steps you can take if you suspect that your centrifuge is unbalanced:

- Stop the centrifuge immediately: If you notice that the centrifuge is vibrating excessively, it is important to stop the machine immediately to prevent further damage.

- Check for any visible problems: Look for any visible issues, such as an unbalanced load, damaged rotor, or broken parts.

- Check the rotor and samples: Make sure that the rotor is properly seated in the machine and that the samples are evenly distributed in the tubes or buckets.

- Check the machine and environment: Make sure that the machine is properly leveled and that the environment is free from vibrations.

- Consult the manufacturer: If you are unable to identify and resolve the problem, you should contact the manufacturer for further assistance. They may be able to provide additional troubleshooting guidance or suggest repairs that need to be made.

It is important to follow the manufacturer’s guidelines for operating and maintaining the centrifuge to ensure that it is running smoothly and safely. If you are unsure about how to use the machine or how to address any problems that arise, you should consult the manufacturer or a qualified technician.

How do you balance an uneven centrifuge?

Here are some steps you can take to balance an uneven centrifuge:

- Check the rotor and samples: Make sure that the rotor is properly seated in the machine and that the samples are evenly distributed in the tubes or buckets.

- Check the machine and environment: Make sure that the machine is properly leveled and that the environment is free from vibrations.

- Check for any visible problems: Look for any visible issues, such as an unbalanced load, damaged rotor, or broken parts.

- Consult the manufacturer: If you are unable to identify and resolve the problem, you should contact the manufacturer for further assistance. They may be able to provide additional troubleshooting guidance or suggest repairs that need to be made.

It is important to follow the manufacturer’s guidelines for operating and maintaining the centrifuge to ensure that it is running smoothly and safely. If you are unsure about how to use the machine or how to address any problems that arise, you should consult the manufacturer or a qualified technician.

Key Notes

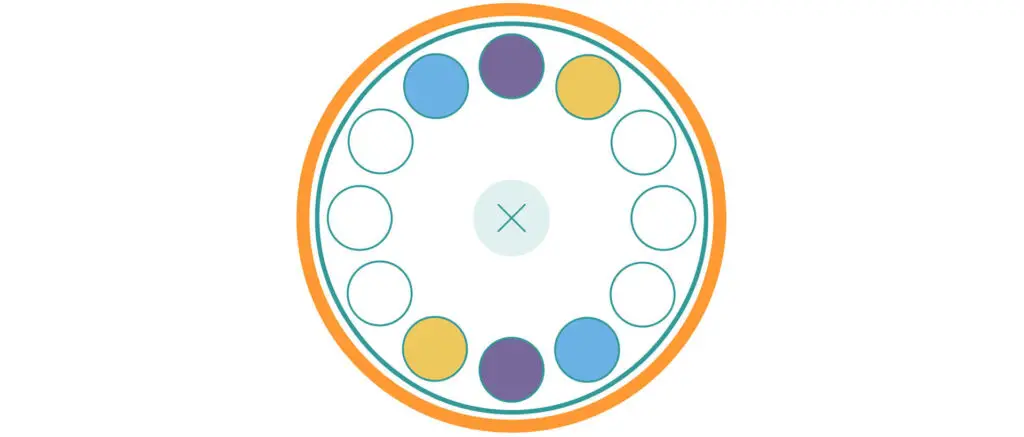

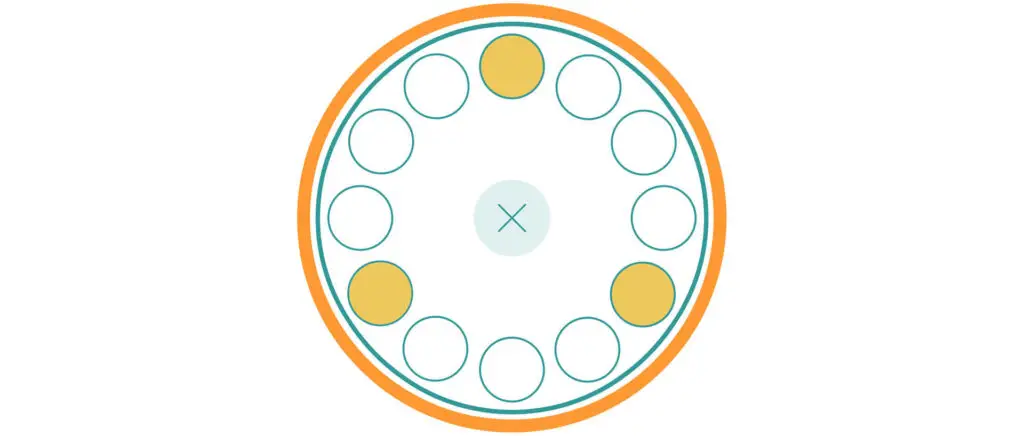

Consider a 12-tube angle rotor as an illustration. No matter how many centrifuge tubes you need to centrifuge, always position them symmetrically around the centre of the rotor, as depicted in the image below.

- Ensure that all samples in centrifuge tubes are equally distributed; often, low-speed centrifuge samples can be visually inspected.

- While weighing and adding the test solution in the centrifuge tube of the high-speed centrifuge.

- If additional tubes are required for balancing, fill them with water or a liquid of comparable density to the sample and ensure that the mass is balanced to the closest gramme. If sample volume is unequal, a strong vibration will result.

- For each tube pushed into the rotor, add an opposing tube of equal weight. This will ensure that the rotor’s centre of gravity remains centred.

- If applicable, tighten the rotor cover and recheck the balance of the test tube and the tightness of the screws.

FAQ

Why is it important to balance samples to be centrifuged within 0.1 g?

Balancing samples to be centrifuged within 0.1 g is important because an unbalanced load can cause the centrifuge to vibrate excessively, potentially causing damage to the equipment and creating a safety hazard. In addition, an unbalanced load can result in uneven separation of the samples, which can affect the accuracy and reliability of the results.

To ensure the safety and accuracy of the results, it is important to balance the samples as evenly as possible. This may involve weighing the samples and adjusting the volume or mass of the samples to ensure that they are balanced within the specified tolerance.

The manufacturer of the centrifuge may provide guidelines for balancing samples, and it is important to follow these guidelines to ensure the safe and efficient operation of the machine. If you are unsure about how to balance the samples, you should consult the manufacturer or a qualified technician.

References

- https://www.labmanager.com/product-focus/the-basics-of-centrifuge-operation-and-maintenance-1433

- https://onunicornsandgenes.blog/2016/06/11/balancing-a-centrifuge/

- https://www.beckman.com/resources/technologies/centrifugation/principles/rotor-balancing

- https://www.integra-biosciences.com/global/en/blog/article/how-balance-centrifuge-and-which-tubes-use

- https://labcentrifuges.net/blogs/blog/balancing-samples-in-lab-centrifuge

- https://vetlabsupplies.co.uk/blog/how-and-why-to-balance-your-centrifuge/

- https://www.labnetinternational.com/blog/2018/12/3-tips-balancing-your-centrifuge

- https://www.separatorsinc.com/blog/how-to-balance-your-centrifuge

- https://www.kethink.com/how-to-balance-a-centrifuge.html

- https://microbiozindia.com/how-do-you-make-sure-a-centrifuge-is-balanced/

- https://www.labpeople.com/blog/greatest-practices-for-balancing-your-samples-in-a-lab-centrifuge/

- https://demonstrations.wolfram.com/BalancedConfigurationsOfMultislotCentrifuges/

- https://www.codingame.com/training/hard/the-balanced-centrifuge-problem

- Text Highlighting: Select any text in the post content to highlight it

- Text Annotation: Select text and add comments with annotations

- Comment Management: Edit or delete your own comments

- Highlight Management: Remove your own highlights

How to use: Simply select any text in the post content above, and you'll see annotation options. Login here or create an account to get started.