Filtration is the most popular method to sterilize heat sensitive liquid and gases, without exposure to denaturing temperatures. Instead of killing microorganisms that cause contamination the process simply eliminates them. It is the process of choice to sterilize chemical solutions for antibiotics radioisotopes, toxic chemicals or vaccines, as well as carbohydrates, all of which are sensitive to heat.

The gas or liquid is filtered through which has pores that are too small to allow passing through microorganisms however, large enough to permit the flow of gas or liquid. The filters are made from various substances;

| Materials | Name of the filter |

| Asbestos pad | Seitz filter |

| Diatomaceous earth | Berkefeld filter |

| Procelain | Chamberland-Pasteur filter |

| Sintered glass disks | Sintered glass filter |

| Cellulose | Membrane filter |

| Borosilicate glass fiber | HEPA filter |

| Clay, mud | Candle filter |

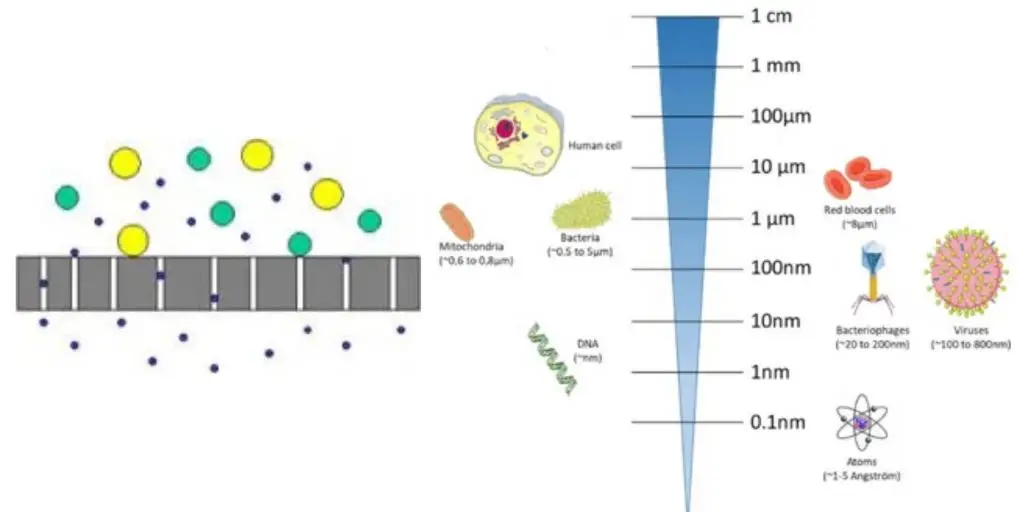

The selection of the filters to be sterilized must consider the dimensions of the contaminants that need to be eliminated. The most popular filter is made of nitrocellulose with an pore size of 0.22mm. The size of bacteria is between 0.3 to 0.5 millimeters, while the size of viruses ranges from 20nm to 0.36 millimeters. Therefore, a filter of 0.22mm keeps all spores and bacteria however it does not contain all virus.

Solutions for intravenous use can be free of pyrogens by filtration. The sterilization process of these solutions can kill organisms, but the endotoxins that are resistant to heat (lipopolysaccharide of Gram-negative bacteria) can persist and cause fever.

Working Principle of Filtration Sterilization

Filters function by physically trapping particles that are larger than the size of the pore and retaining smaller particles by electrostatic attraction of particles to the filter. Apart from porosity, various other aspects influence the effectiveness of filtration. These include:

- The filter is charged with electricity.

- the electric charge carried by organisms

- nature of the filtering fluid

The liquids are filtered through either pushing the solution through a cellulose acetate membrane using the aid of a vacuum (i.e applying negative pressure on the membrane filter) or by pushing the solution into the filter paper by applying pressure over the liquid.

The air filtering process is carried out by using high-efficiency particulate (HEPA) filters that are designed to eliminate organisms greater than 0.3 millimeters from operating rooms and biological safe cabinets.

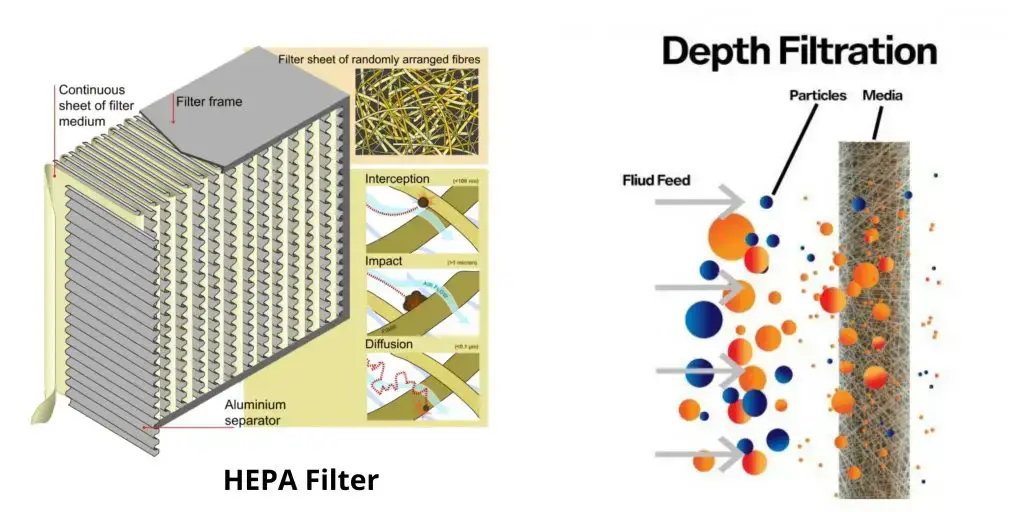

Depth Filters

It is an elongated layer or mat that is made of an array of random overlapping sheets of paper, or even the borosilicate (glass) fibrous material. The depth filter collects particles inside the web of fibers within the structure.

Applications of Depth Filters

- Sterilization of air filters in industrial processes

- Forced air cooling and heating systems that are used in homes have a simple filter that traps dust, spores and allergens

- Utilization in biosafety-related applications, like biosafety cabinets. The cabinets for biological safety contain the HEPA, or high-efficiency particle air (HEPA) filter it is a form of depth filter.

HEPA filter

An average HEPA filter is one piece of borosilicate glass that is treated with water-repellent binding agent. The filter, which has been pleated to increase the surface area, is encased in an unbreakable, sturdy frame. HEPA filters are available in different sizes and shapes, ranging from a few square centimeters for vacuum cleaners up to many square meters for biological containment hoods, as well as rooms air system.

Control of airborne particles by using HEPA filters can allow the building of “clean rooms” and isolation rooms to prevent quarantine, and also specific diagnostic and research labs. HEPA filters are typically used to eliminate 0.3 millimeters of test particles with an efficiency of 99.97 percent, including the majority of microorganisms from the airstream.

Membrane filters

Membrane filters comprise the commonly used kind of filter employed for liquid sterilization in microbiology labs. Membrane filters are made of high-tensile strength polymers like cellulose acetate, polysulfone or cellulose nitrate. Membrane filters are made in the form of circular membranes that measure around 150mm in thickness. They contain millions of tiny pores of uniform diameters. The size of which is adapted according to the requirements in the process of polymerization.

The pores of membrane filters vary between 0.1mm to 10mm. The most popular membrane filter comes with a pores that is between 0.22mm or 0.45mm.

The membranes are stored in special holders , and usually preceded by depth filters comprised from glass fibers, which remove larger particles that could block the filter. The solution is pushed or pulled through the filter, and then stored in sterilized containers.

Application of membrane filter

- Sterilization of fluids (pharmaceuticals Ophthalmic solutions as well as antibiotics and other substances that are sensitive to heat in labs and in industries

- Enumeration and identification of microorganisms.

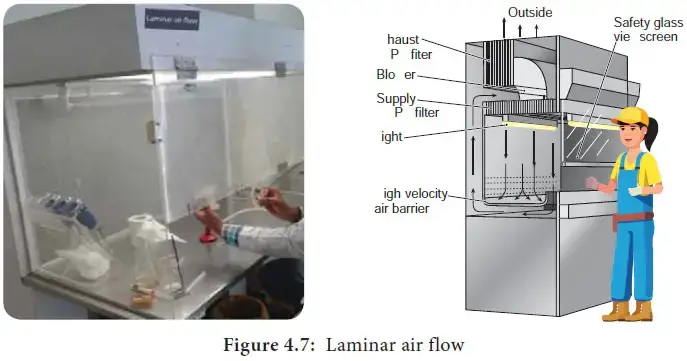

Air filtration Method

Air can also be cleaned through filtering. The air is cleared of disease by passing it through a the High Efficiency Particle Arrester (HEPA) filter. Laminar flow biological safety cabinets are among the most crucial air filters (Figure 4.7). They use HEPA filters that eliminate 99.97 percent of 0.33mm particles of 0.33mm in size. Certain operating theaters and rooms that are occupied by patients with burns are filtered to reduce the number of microbes that are a part of the air. HEPA filters can eliminate almost all microorganisms that are greater than 0.3mm within diameter.

Advantages of Filtration Sterilization

- Capital intensive, but less

- It is suitable for liquids sensitive to heat (infusions and vaccines, hormones and more).

- Large volumes of liquids can be easily filtered

Limitations of Filtration Sterilization

- Only gases and liquids can be sterilized through this method.

- Filters can be expensive to replace, particularly nano-filters.

- The inherent limitations of the filters’ materials impact the efficiency of this method i.e breakage of glass filters breakage of membrane filter, and absorption of filtrate through a Sietz filter

- The process of clogging can occur.