What is Filtration?

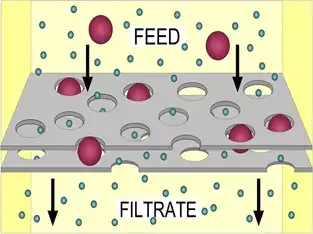

Filtration is utilised to separate a dispersion based on particle size. The filtered mixture is put to an appropriate porous material filter. Particles smaller than the filter’s pores can pass through and enter the filtrate, while larger particles are retained on the filter’s surface.

Filtration is a process that is used to separate particles from a liquid or gas using a filter medium that allows the fluid to pass through, but retains the particles. The particles can be solids, such as sediment or dirt, or they can be liquid droplets, such as oil or moisture. Filtration is used in a wide variety of applications, including water treatment, air purification, industrial processes, and biological research. There are many different types of filtration methods and techniques, including mechanical filtration, chemical filtration, and biological filtration.

What is Filter?

Filters are constructed from a variety of materials. Filtering papers are among the most traditional types of paper; they are porous, unsized, and uncoated. Other materials besides gauze, cotton wool, and glass wool can be used to filter out coarse particles. For the separation of smaller particles, however, specialty membranes composed of, for instance, celulose acetate, PVDF, nylon, or other materials are utilised.

What is the main purpose of filtration?

The main purpose of filtration is to separate a mixture into its components based on the size of the particles or molecules in the mixture. Filtration is often used to remove unwanted impurities or contaminants from a mixture, or to extract only the desired components for a particular use.

There are many different types of filtration, and the specific purpose of the filtration process will depend on the particular application. Some common purposes of filtration include:

- Purifying water: Filtration is used to remove particles, bacteria, and other contaminants from water, making it safe to drink.

- Separating solid and liquid mixtures: Filtration is often used to separate solids from liquids, such as in the production of coffee or in the purification of oil.

- Purifying gases: Filtration can be used to remove impurities from gases, such as in the production of medical oxygen or in the purification of air for breathing.

- Producing pharmaceuticals: Filtration is used in the production of many pharmaceutical products, such as drugs and vaccines, to remove impurities and ensure the purity and quality of the final product.

- Producing food and beverages: Filtration is used in the production of many food and beverage products, such as beer, wine, and fruit juices, to remove impurities and improve the quality and taste of the final product.

Process of Filtration

In the process of filtration, a heterogeneous mixture is distributed over a filter membrane. The holes on the filter membrane or filter media are of a certain size. Particles that are larger in size and dimension than the membrane’s pores cannot travel through the membrane and are trapped on top of the filter membrane.

Simultaneously, smaller particles will move through the membrane pores along with the fluid. Oversized particles will accumulate as a residue on the filter membrane, while liquid will pass through the membrane. Therefore, separating solids and liquids from the heterogeneous mixture. Slurry refers to the suspension of the solid and liquid to be filtered.

The medium used to hold solids is referred to as filter medium. Filter cake is the deposition of solids on the filter. The liquid that remains after passing through a filter is the filtrate. Tea preparation serves as a straightforward illustration of this concept. Using a sieve, we separate the prepared tea from the tea leaves. Tea and dissolved sugar will readily travel through the sieve’s pores, but tea leaves will remain on top of the sieve. The air conditioner’s ability to remove dust particles from the air is another form of filtration.

Based on this understanding, the components of a filtration system’s primary assembly are:

- Filter medium Slurry (or the fluid with suspended solids)

- Filtration motive power (e.g., pressure, gravity, etc.)

- In addition to holding the filter medium and filtrate, this filtration apparatus applies a driving force.

What are the Components of the filtration process?

1. Filter medium

- The ideal filter medium must be durable, have a low resistance to fluid movement, and be unaffected by the slurry’s constituents. Woven materials such as felts or fabrics made of wool, cotton, silk, glass, metals, or synthetic fibres are used as filter media (rayon, nylon, etc.).

- The filtration cloth’s weight and texture may vary. The fabric weave will affect the surface and durability of the filtration cloth.

- Perforated metal sheet is also utilised as a filter media. Pebbles, sand, asbestos, paper pulp, and kieselguhr are examples of granular materials used as filter media, along with gravel, sand, and asbestos. The size of the solids may vary depending on the requirements of the procedure.

- In some cases, a bed of graded particles may be employed as the filter medium to reduce fluid flow resistance through the bed.

- Similarly, porous solids such as sintered glass, sintered metal, earthenware, and porous plastic (e.g., Porvic) are employed as filtration media.

- The choice of filter material will depend on the type of slurry, its chemical makeup, and the objective of the filtration procedure.

2. Slurry

- The filtration process is affected by the following slurry characteristics:

- The liquid’s characteristics, such as density, viscosity, and corrosiveness

- The characteristics of solids, including particle size, particle size distribution, and rigidity or compressibility.

- The concentration of solids in a slurry.

- In addition, the purpose of the filtration process is to collect liquid or solid; whether the solids must be separated from the liquid effects the entire filtration process, method selection, and rate of filtration.

3. Filtration driving force

The filtration rate is proportional to the difference in pressure between the filter medium and filter cake. The pressure drop or pressure difference can be accomplished in a number of methods, including:

- Gravity: Maintaining the slurry’s head above the filter medium is the simplest way for achieving pressure difference. The pressure difference is caused by the gravitational force of the liquid. The resulting pressure differential will depend on the density of the slurry in this instance.

- Low pressure: By supplying a vacuum pump to the filtrate receiver, the pressure below the filter medium can be decreased below atmospheric pressure, resulting in a pressure differential across the filter. However, this method restricts the pressure differential to 1 bar, as it cannot surpass the atmospheric pressure exerted on the surface of the slurry. Additionally, decreasing pressure decreases the boiling point of liquids, therefore there is a possibility that filtrate will begin to boil in the receiver. Despite this constraint, this way of attaining pressure decrease is the safest and most prevalent filtration technique.

- High pressure: Applying pressure on the surface of the slurry is another widely used filtration technique. Nonetheless, this approach provides a greater pressure difference than lowered pressure.

- Centrifugal force: Centrifugal force is utilised as the driving force in the filtration process. Centrifugation is based on the premise that an item rotating about a centre point at a constant radial distance experiences centrifugal force. This helps the filtration process by creating a pressure differential.

Types of filtration

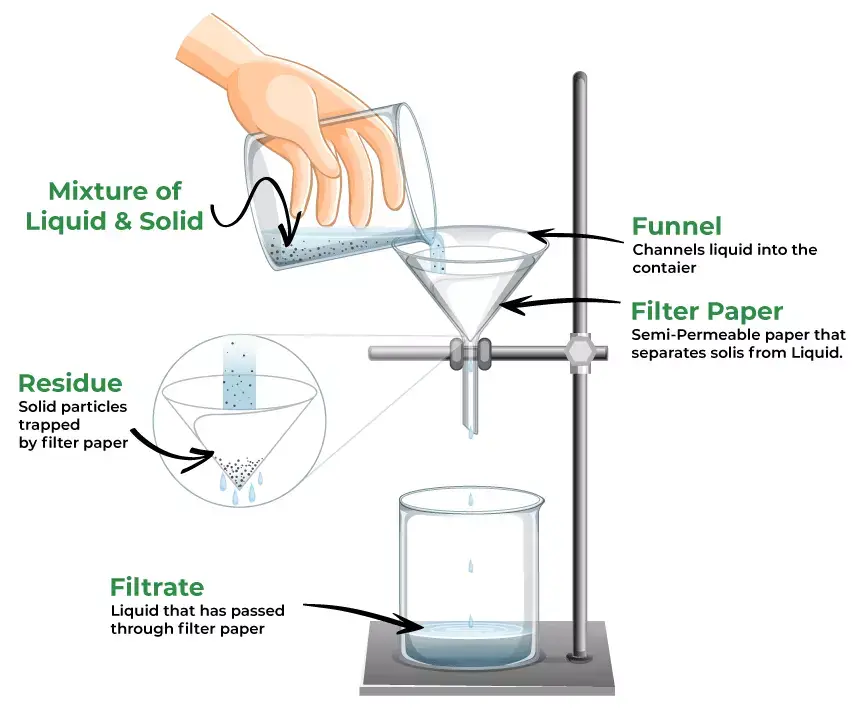

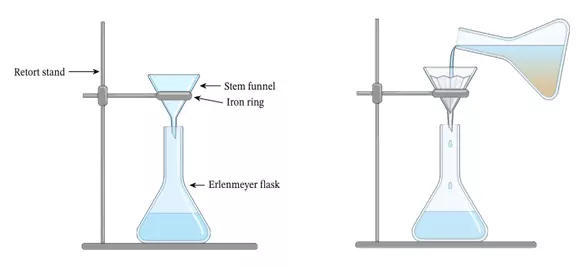

1. Gravity filtration

- Gravity filtration is the simplest type of filtering process, with gravitational force serving as the driving factor. Gravitational filtration is the most often employed filtering method.

- In this process, filter paper is inserted into a funnel secured with an iron clamp. Next, the liquid is put over filter paper. As a result of gravitational pull, the liquid moves downward.

- Thus, it is collected as filtrate in the beaker positioned below the funnel. Simultaneously, the residue is placed upon the filter paper.

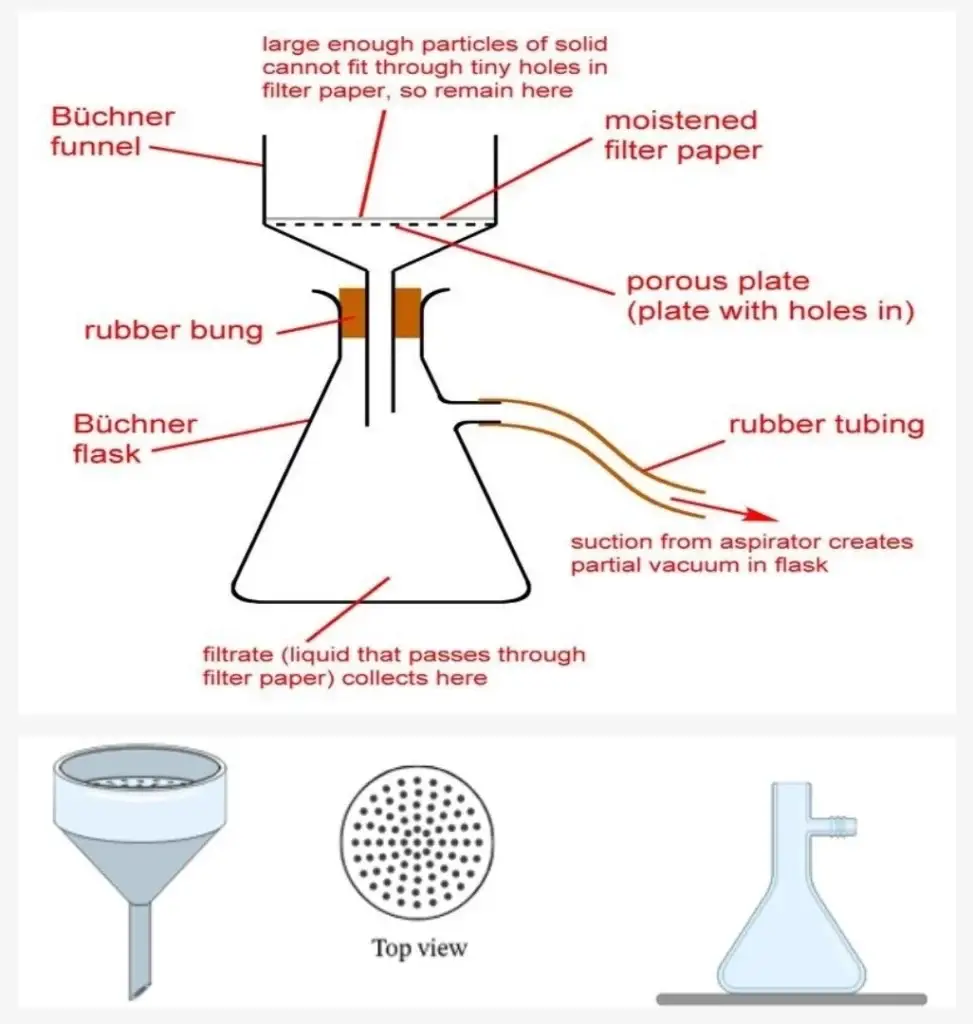

2. Vacuum filtration

- Similar to gravity filtration is vacuum filtration. In vacuum filtration, the liquid travels through a funnel containing filter paper. However, the driving force of filtration is the applied vacuum. Therefore, the use of vacuum makes this procedure more efficient than gravity filtering.

- The apparatus for vacuum filtering comprises of a Buchner flask, funnel, and vacuum pump. Buchner’s flask is utilised for vacuum filtration. When the Buchner flask is linked to a vacuum, the liquid is forced to pass through the filter paper and into the flask.

3. Centrifugal filtration

- The centrifugal force drives centrifugal filtering. The inertial force experienced by an object travelling in a round path is centrifugal force. Moving in a circular orbit, centrifugal force pushes the material outward or away from the centre of revolution.

- The slurry is poured through a rotating drum that makes up the instrument. The liquid is propelled out of the drum by centrifugal force, while the filtrate is held on the walls of the drum.

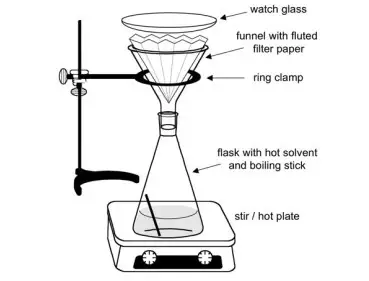

4. Hot Filtration

- Liquids that tend to crystallise quickly are filtered using the hot filtration process. In such instances, crystals form rapidly and obstruct the filtration assembly. In such instances, the liquids’ temperature is increased to prevent crystallisation. To prevent crystal formation, the entire filtration procedure is conducted swiftly and at high temperatures.

- For hot filtration, a stemless filter funnel and fluted filter sheets are required. Hot gravity filtration refers to the transport of hot filtration under the gravitational driving force. Typically, an Erlenmeyer flask, filter paper, a stemless funnel, and a hot plate are used. Hot gravity filtering serves to remove insoluble contaminants from a hot solution.

5. Cold Filtration

- This procedure is the antithesis of cold filtering, and crystallisation is desired. The creation of protein clumps, which is widely employed in the beer industry, is began by lowering the temperature and eventually separating the crystals from the residual liquid.

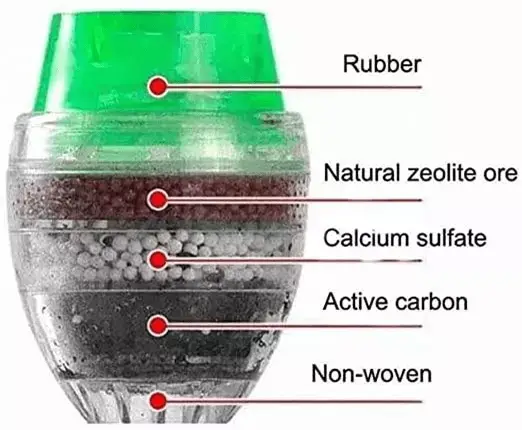

6. Multilayer Filtration

- Water purification is an illustration of multilayer filtration, in which water is passed through various layers of filters (sand, gravel, charcoal, etc.) to remove contaminants.

- The water is filtered through various media layers. At each stage of filtration, contaminants are removed based on the particle size. Filtration through extra layers of filters improves filtration effectiveness and ensures the purity of water.

7. Mechanical Filtration

- Utilizing a mechanical force in the form of a pressure pump, mechanical filtration employs a mechanical force. On a large scale, this filtration is utilised by industries.

8. Conventional Filtration

- Since the beginning of time, conventional filtration has been used to purify water by passing it through layers of sand, rock, and granules.

9. Chemical Filtration

- Chemical filtration utilises carbon or chemical resins to remove impurities from water. Until the point of saturation, activated carbon filter removes pollutants from water.

- However, your filtration system’s activated carbon filters must be periodically replaced.

10. Biological Filtration

- Biological filtration is the process by which beneficial bacteria degrade ammonia and nitrite and convert them into the far safer nitrate molecule.

- Beneficial bacteria must exist in oxygen-rich water as well as on surfaces such as rocks and sand on which they can adhere. With so few fish, this could be sufficient to sustain the aquarium. All aquariums must incorporate biological filtration.

Examples Filtration

We rely on the filtration process in our daily lives, as illustrated by the following examples.

- Water purification techniques that eliminate pollutants. Depending on the eventual use of the water, several filters are employed to remove pollutants. Potable water for residential use is often purified using granular-activated carbon filters, metallic alloy filters, depth filters, carbon block resin filters, microporous ceramic filters, ultrafiltration membranes, and microfiltration membranes.

- HEPA (high-efficiency particulate air) filters are commonly used to remove allergies, germs, and pollutants from the air. Through a mesh of varying pore diameters, anti-microbial layer panels, and UV light panels, allergies, bacteria, and particulate matter are removed from the air. HEPA filters are 99.9% effective at purifying the air. Additionally, these filters are present in vacuum cleaners.

- Air Filter, Cabin Filter, Fuel Filter, and Oil Filter are examples of automotive filters that remove particulate matter from fuel & air and prolong the life of the vehicle.

- Mechanical filtration, biological filtration, and chemical filtration are the three forms of filtration found in aquarium filters. Mechanical filters eliminate big contaminants based on the idea of size. The mechanical filters consist of gravel, sponges, or foam. Beneficial bacteria transform toxic ammonia and nitrite into safe nitrate molecules. In an aquarium, chemical filters are activated charcoal or carbon that absorb toxic substances from the water. Combining these three types of filters helps maintain a clean and hospitable aquarium environment for aquatic life.

- Gas filters feature distinct filters for distinct gas types. Consequently, a gas filter connected to a gas generator or purifier will have a filter for each type of gas. For instance, the air purifier will include separate oxygen and carbon dioxide filters. Air is a mixture of pollution, carbon dioxide, and oxygen. Therefore, purified air will contain a minimum of two filters that will release the pure oxygen. In addition, an oxygen-free gas filter will be utilised to separate carbon dioxide and contaminants from the cleansed air.

- Belt filters are utilised in the mining, apple cider vinegar, and wine industries.

- Coffee and tea filters

- Reverse osmosis

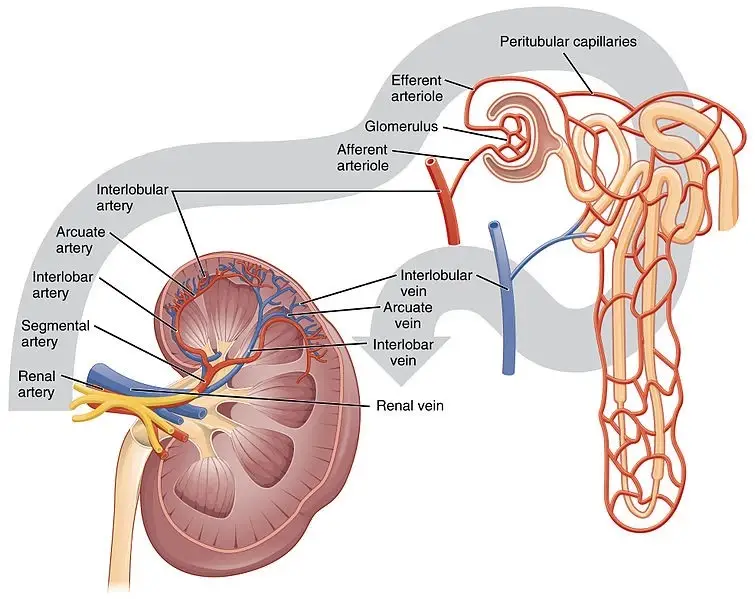

- Dialysis. The kidneys are biological filters that remove toxins from the body through urine and retain and reabsorb important nutrients through glomerular filtration. However, when kidneys malfunction or stop functioning, the body’s poisons are no longer filtered out. This can result in the deadly accumulation of toxic poisons in the body. For the elimination of these poisons, dialysis becomes necessary. During dialysis, bodily fluid is passed over a semipermeable membrane with variable pore size, resulting in filtration and the removal of undesirable substances. Dialysis functions as artificial kidneys and aids in the elimination of toxins from the body.

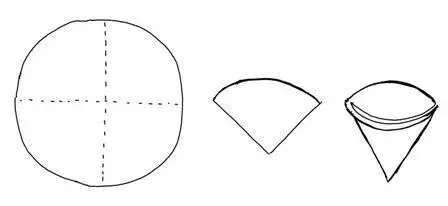

Filtering through a Paper Filter

- A filter paper circle is folded into quarters. The paper is then unfurled to make a cup.

- The cup is positioned within a funnel. Frequently, it must be hydrated (usually with distilled water).

- During filtration, the funnel’s stem should be in contact with a container wall. The fluid that has been filtered is put onto three layers of filter paper.

- The filtered mixture must be slowly introduced. It must never reach or even exceed the top of the filtration paper.

Physical Processes Involved in Filtration

- Filtration is used to separate particles and fluid in a suspension, with the fluid being a liquid, gas, or supercritical fluid. One or both of the components may be separated, depending on the application.

- As a physical process, filtration permits the separation of substances with distinct chemical compositions. A solvent is selected that dissolves one component, but not the other. By dissolving the mixture in the selected solvent, one component will enter the solution and pass through the filter, while the remaining component will be retained.

- In chemical engineering, filtration is commonly used. It can be integrated with other unit operations to process the feed stream, such as in the biofilter, a filter and biological digesting device.

- In sieving, separation happens at a single perforated layer, whereas in filtration, separation occurs at many perforated layers (a sieve). In sieving, particles too large to pass through the sieve’s holes are kept (see particle size distribution). In filtration, a multilayer lattice holds particles incapable of following the filter’s tortuous pathways. Oversize particles may form a cake layer on the filter surface and may also obstruct the filter lattice, preventing the fluid phase from passing through the filter (blinding). Commercially, the word filter is applied to membranes whose separation lattice is so thin that the surface becomes the primary zone of particle separation, despite the fact that these products might also be referred to as sieves.

- Filtration is distinct from adsorption, which relies on surface charge for separation. Commercially, some adsorption devices incorporating activated charcoal and ion-exchange resin are referred to as filters, despite the fact that filtration is not their primary mechanical function.

- Because there is no filter medium, filtration varies from magnetic removal of magnetic impurities from fluids (usually lubrication oil, coolants, and fuel oils). Magnetic filters are sold commercially, however their name does not accurately depict their operation.

- In biological filters, particles of excessive size are captured and ingested, and the resulting metabolites may be discharged. In animals (including humans), for instance, renal filtration removes waste from the blood, and in water treatment and sewage treatment, undesired elements are removed by adsorption into a biological film developed on or within the filter media, as in slow sand filtration.

7 Stages of Water Filtration

The precise methods for water treatment depend exclusively on the composition of the raw water and the desired water quality standard for business and households. General purifying procedures for drinking water include:

- Aeration of Water: Raw water is gathered in a big aeration tank for aeration. By means of perforated pipes, air is introduced into the water. Aeration eliminates smells and CO2. Some undesirable metals, such as manganese and iron, can be removed from water by precipitating them as hydroxides.

- Storage or Settling of Dust and Wastes: Aerated water is stored for 10 to 15 days in a settling tank. This procedure allows sediments and heavy metals to sink to the bottom of the tank, which clarifies the water. During storage, pathogenic microorganisms and a portion of the organic stuff in the water are oxidised.

- Coagulation Tank: The water is subsequently introduced into the coagulation tank. Lime, alum, and other precipitating agents are added to the water. These agents precipitate from Aluminium hydroxide, Al(OH)3, when combined with water. Thus, the suspended solids absorbed by the lime/alum particles precipitate out of the water and settle to the bottom of the tank.

- Filtration: The water is subsequently filtered by passing it through sand in a gravity filter. Here, approximately 98% of bacteria and contaminants are removed. Gravity water filtration tank consists of three fundamental layers:

- Top Layer: It is a thin layer of 1 m in thickness.

- Middle Layer: It consists of coarse sand particles and has a thickness of 0.3 to 0.5 metres.

- Bottom Layer: It is about 0.3 and 0.5 metres thick and consists of white gravel.

- Collection Tank: A collection tank gathers the filtered water at the bottom of the filter bed.

- Water Disinfection: Disinfectants such as chlorine kill pathogens and other germs in water.

- Overhead Storage Tank: Water for home distribution is pumped into this tank for storage.

Applications of Filtration

- Water treatment: Filtration is used to remove particles, bacteria, and other contaminants from water, making it safe to drink.

- Food and beverage production: Filtration is used in the production of many food and beverage products, such as beer, wine, and fruit juices, to remove impurities and improve the quality and taste of the final product.

- Medicine: Filtration is used in the production of many pharmaceutical products, such as drugs and vaccines, to remove impurities and ensure the purity and quality of the final product.

- Air purification: Filtration is used to remove impurities from air, such as dust, pollen, and allergens, to improve air quality in homes and other buildings.

- Swimming pools: Filtration is used to remove contaminants from swimming pool water, such as sweat, urine, and dirt, to keep the water clean and safe to swim in.

- Automotive: Filtration is used in the automotive industry to remove impurities from oil, fuel, and other fluids to improve the performance and lifespan of vehicles.

- Industrial processes: Filtration is used in many industrial processes, such as the production of chemicals and the purification of gases, to remove impurities and improve the quality of the final product.

- Aquaculture: Filtration is used in aquaculture to remove waste and excess nutrients from water, to maintain the health and quality of the water for aquatic life.

- Wastewater treatment: Filtration is used in wastewater treatment to remove solid particles and other contaminants from wastewater, to make it safe to discharge into the environment.

- Environmental remediation: Filtration is used in environmental remediation to remove contaminants from soil, water, and air, to restore the environment to a healthy state.

Advantages of filtration

Filtration is a process that is used to separate particles and materials from a liquid or gas based on their size, shape, and/or other characteristics. There are several advantages to using filtration, including:

- Efficiency: Filtration can be a very efficient way to separate materials, especially when compared to other separation methods such as sedimentation or decantation.

- Versatility: Filtration can be used to separate a wide variety of materials, including solids, liquids, and gases. It can also be used to remove contaminants from water, air, and other substances.

- Cost effectiveness: Filtration is often a cost-effective method for separating materials, especially when compared to other methods that may require more energy or specialized equipment.

- Environmental benefits: Filtration can be used to remove pollutants and contaminants from water, air, and other substances, which can have positive environmental impacts.

- Safety: Filtration can be used to remove potentially dangerous materials, such as pathogens or toxins, from liquids or gases, making them safer to consume or use.

What material is used in filtration?

There are many different materials that can be used in the filtration process, depending on the specific application and the properties of the mixture being filtered. Some common materials used in filtration include:

- Filter papers: Filter papers are thin sheets of porous material, usually made from cellulose or other natural fibers. They are used for mechanical filtration, and can be used to separate particles based on size.

- Mesh screens: Mesh screens are made from wire or other materials and have openings of a specific size. They are used for mechanical filtration, and can be used to separate particles based on size.

- Membranes: Membranes are thin layers of porous material that can be used for membrane filtration. They can be made from a variety of materials, including polymers, ceramic, or metal. Membrane filtration is used to separate particles based on size, charge, or other properties.

- Sand: Sand is a common material used for mechanical filtration, particularly in the purification of water. Sand can be used to remove particles larger than a certain size from a mixture.

- Activated carbon: Activated carbon is a porous material that is highly adsorbent. It is often used in chemical filtration to remove impurities from gases or liquids by adsorbing them onto the surface of the carbon.

- Biological filters: Biological filters use living organisms, such as bacteria or algae, to remove contaminants from a mixture. They are often used in wastewater treatment and aquaculture.

Why filtration is a better method?

Filtration is a common method for separating mixtures into their components, and it has several advantages over other separation techniques. Here are a few reasons why filtration may be a better method:

- It is relatively simple and inexpensive: Filtration does not require complex equipment or chemicals, and it is generally a low-cost method for separating mixtures.

- It is gentle on the components being separated: Filtration does not involve the use of heat or other potentially damaging processes, making it a good choice for separating sensitive or heat-sensitive materials.

- It is capable of separating a wide range of particle sizes: Filtration can be used to separate particles over a wide range of sizes, from very small molecules to large particles.

- It can be used to purify liquids and gases: Filtration can be used to remove impurities from both liquids and gases, making it a versatile separation method.

- It is a continuous process: Filtration can be carried out continuously, with the mixture being fed continuously into the filter and the separated components being collected continuously on the other side. This makes it an efficient method for separating large volumes of material.

Which filters are most commonly used?

There are many different types of filters that can be used for a variety of purposes. Some of the most commonly used filters include:

- Sand filters: These are widely used in water treatment plants to remove particles and impurities from water. Sand filters work by trapping contaminants in the spaces between the sand grains.

- Carbon filters: These are commonly used to remove chlorine, taste, and odor from water, as well as to remove some types of contaminants such as pesticides and industrial chemicals. Carbon filters work by adsorbing (trapping) contaminants on the surface of the carbon particles.

- Ceramic filters: These are similar to sand filters, but they use a ceramic material instead of sand. Ceramic filters are effective at removing particles, bacteria, and other contaminants from water.

- Membrane filters: These are thin, porous filters that are used to remove very small particles from liquids or gases. They are commonly used in reverse osmosis systems and in the production of pharmaceuticals and other products.

- Metal filters: These are used to remove metal ions or particles from liquids or gases. They are commonly used in the chemical and food processing industries.

- Glass fiber filters: These are made of thin fibers of glass and are used to remove very small particles from liquids or gases. They are commonly used in laboratories and in the production of electronic components.

How is filtration effective?

Filtration is effective at separating particles and materials from a liquid or gas based on their size, shape, and/or other characteristics. The effectiveness of filtration depends on several factors, including the size of the particles being filtered, the type of filter material being used, the flow rate of the liquid or gas being filtered, and the operating conditions (such as pressure and temperature).

To be effective, the filter material must be able to trap or remove the particles or materials that are being targeted. This can be achieved in several ways, including:

- Physical entrapment: The particles or materials are physically trapped in the pores or on the surface of the filter material.

- Adsorption: The particles or materials are attracted to and held on the surface of the filter material by forces such as van der Waals forces or chemical bonding.

- Chemical reactions: The particles or materials react with the filter material, forming a new compound that is either retained by the filter or can be easily removed.

In general, filtration is most effective when the filter material is carefully chosen to match the size and characteristics of the particles or materials being filtered, and when the operating conditions are optimized for the specific application.

FAQ

What is filtration and examples?

In computer science and data processing, filtering is the process of selecting a subset of data from a larger set, based on specified criteria. Filtering is often used to remove unwanted data, or to extract only the data that is needed for a particular purpose.

Here are some examples of filtering:

1. Removing spam emails from a mailbox: A filter can be used to identify emails that are likely to be spam, based on certain characteristics such as the sender, the subject line, or the content of the email. The filter can then move these emails to a separate folder or delete them automatically.

2. Extracting data from a database: A filter can be used to select only certain records from a database, based on specified criteria such as a particular date range, a specific location, or a specific product.

3. Removing noise from an audio signal: A filter can be used to eliminate unwanted frequencies from an audio signal, such as background noise or static.

4. Removing contaminants from water: A filter can be used to remove particles, bacteria, and other contaminants from water, making it safe to drink.

5. Blocking content on the internet: A filter can be used to block access to certain websites or types of content, based on specified criteria such as keywords, domain names, or categories.

What are 2 examples of filtration?

Here are two examples of filtration:

1. Removing spam emails from a mailbox: A filter can be used to identify emails that are likely to be spam, based on certain characteristics such as the sender, the subject line, or the content of the email. The filter can then move these emails to a separate folder or delete them automatically.

2. Extracting data from a database: A filter can be used to select only certain records from a database, based on specified criteria such as a particular date range, a specific location, or a specific product. For example, a database of customer orders might be filtered to show only orders placed in the last month, or only orders for a particular product.

What is filtration process?

The filtration process involves the separation of a mixture into its components based on the size of the particles or molecules in the mixture. There are several different types of filtration, including mechanical filtration, which uses a physical barrier to separate particles based on size, and biological filtration, which uses living organisms to remove contaminants from a mixture.

In the filtration process, a mixture is passed through a filter medium, which may be a porous material such as a filter paper or a mesh screen. The larger particles or molecules in the mixture are unable to pass through the pores of the filter medium, and are retained on one side of the filter. The smaller particles or molecules, on the other hand, are able to pass through the filter medium, and are collected on the other side.

The filtration process is used in a wide range of applications, including purifying water, separating solid and liquid mixtures, and purifying gases. It is also used in the production of many products, including pharmaceuticals, food and beverages, and chemicals.

What is the meaning of word filtration?

The word “filtration” refers to the process of separating a mixture into its components based on the size of the particles or molecules in the mixture. Filtration is often used to remove unwanted impurities or contaminants from a mixture, or to extract only the desired components for a particular use. There are several different types of filtration, including mechanical filtration, which uses a physical barrier to separate particles based on size, and membrane filtration, which uses a porous membrane to separate particles based on size or other properties. Filtration is used in a wide range of applications, including purifying water, separating solid and liquid mixtures, and purifying gases.

What is the principle of water filtration?

The principle of water filtration is that the filter material is able to remove contaminants from the water by trapping them within its pores or on its surface. The size of the pores in the filter material determines which contaminants can be removed. For example, a filter with smaller pores will be able to remove smaller contaminants, such as bacteria and viruses, while a filter with larger pores may only be able to remove larger particles, such as sediment and dirt.

Which type of filtration is the most important and why?

It is difficult to say which type of filtration is the most important, as the importance of different types of filtration can vary depending on the specific application. Some types of filtration may be more important for certain industries or applications, while others may be more important for others.

For example, in the water treatment industry, sand and ceramic filters may be very important for removing particles and contaminants from water, while carbon filters may be important for removing taste, odor, and certain types of contaminants. In the food processing industry, metal filters may be important for removing metal ions or particles from food products, while in the pharmaceutical industry, membrane filters may be important for removing very small particles from liquids or gases.

In general, the importance of a particular type of filtration will depend on the specific contaminants or materials that need to be removed and the desired level of purity.

References

- https://www.sciencedirect.com/topics/chemistry/filtration

- https://www.biologyonline.com/dictionary/filtration

- https://www.toppr.com/guides/chemistry/is-matter-around-us-pure/filtration/

- https://www.geeksforgeeks.org/filtration/

- https://www.aakash.ac.in/important-concepts/chemistry/filtration

- https://www.vedantu.com/chemistry/filtration

- https://biologydictionary.net/filtration/

- https://www.lenntech.com/chemistry/filtration.htm

- https://collegedunia.com/exams/filtration-definition-types-uses-and-drawbacks-chemistry-articleid-1762

- https://www.thoughtco.com/filtration-definition-4144961

- Text Highlighting: Select any text in the post content to highlight it

- Text Annotation: Select text and add comments with annotations

- Comment Management: Edit or delete your own comments

- Highlight Management: Remove your own highlights

How to use: Simply select any text in the post content above, and you'll see annotation options. Login here or create an account to get started.