What is Biosafety Cabinet?

A biosafety cabinet (BSC), also known as a biological safety cabinet or microbiological safety cabinet, is a specialized laboratory workspace designed to handle materials contaminated with or potentially contaminated with pathogens requiring a specific biosafety level. The primary purpose of a biosafety cabinet is to provide a safe working environment for researchers, protect the integrity of the samples or products being handled, and prevent the release of hazardous particles or infectious agents into the surrounding environment.

Biosafety cabinets are available in different types, each offering varying degrees of biocontainment. They were first introduced commercially in 1950. These cabinets are crucial in laboratories and research facilities where the handling of biohazardous materials is a routine part of scientific work.

Biosafety cabinets, or biological safety cabinets, are sometimes referred to as microbiological safety cabinets or tissue culture hoods. They are equipped with a well-ventilated hood that ensures proper airflow and containment of hazardous substances. Unlike laminar flow hoods, which focus solely on protecting the sample being worked with, biosafety cabinets provide comprehensive protection for personnel, products, and the environment.

One of the primary functions of a biosafety cabinet is to maintain the required standards and control the quality of the materials being handled. This is especially important when working with materials that have the potential to be contaminated with pathogens.

Biosafety cabinets serve as the primary barrier protection, shielding individuals and the surrounding environment from aerosols or droplets that may contain biohazardous substances. They offer an efficient containment system for safely handling materials with varying risk levels, ranging from low to high-risk pathogens (Risk Groups 1-3). However, it is crucial to note that the effective and safe use of biosafety cabinets relies on regular maintenance by qualified specialists.

Biosafety cabinets provide three levels of protection:

- Personnel Protection: HEPA (High-Efficiency Particulate Air) filters and an air curtain shield users from biohazardous aerosols generated inside the cabinet, minimizing the risk of exposure.

- Sample Protection: The recirculating and unidirectional airflow within the cabinet, facilitated by HEPA filters, prevents contamination of samples by maintaining a sterile environment.

- Lab/Environmental Protection: The HEPA-filtered exhaust from the top of the biosafety cabinet ensures that any biohazardous aerosols generated inside the cabinet are captured and do not contaminate the laboratory environment.

In summary, biosafety cabinets are essential tools in laboratories and research facilities, providing a controlled and safe workspace for handling biohazardous materials. They offer protection for personnel, prevent cross-contamination of samples, and safeguard the environment from the release of hazardous substances. Routine maintenance and adherence to proper operating procedures are necessary to ensure the effectiveness and reliability of biosafety cabinets in maintaining a safe working environment.

Biosafety Cabinet Definition

A biosafety cabinet (BSC) is a specialized laboratory workspace designed to safely handle and contain biohazardous materials, protecting both personnel and the environment from exposure to pathogens and hazardous particles.

Features of Biosafety Cabinet

Biosafety cabinets (BSCs) are designed to provide a physically and biologically contained workspace for activities involving potentially harmful biological materials. Some key features of BSCs include:

- Physical containment: BSCs are designed to physically contain biological materials and prevent them from escaping into the laboratory environment.

- Biological containment: BSCs are equipped with HEPA filters that remove airborne contaminants from the air flowing into and out of the cabinet, providing an additional layer of protection against the release of biological materials.

- Ventilation: BSCs have an internal ventilation system that constantly circulates filtered air to ensure that the air inside the cabinet is free of contaminants.

- Work surface: BSCs have a work surface that is impervious to liquids and easy to decontaminate, providing a protected space for activities such as cell culture and microbiology.

- Lighting: BSCs are designed with energy-efficient lighting that provide illumination in the cabinet.

- Safety interlock: It has safety interlock switch which prevents the cabinet from being operated if the sash window is not closed properly.

- Type of Biosafety Cabinet: There are different types of BSCs, including Class I, Class II, and Class III, each designed to provide a different level of protection.

- Access port : Some BSCs have access ports for electrical or other connections to devices outside the cabinet, to make it more convenient for the user to perform experiments.

- Large Viewing window : BSCs have large viewing window for observation of the experiments and samples inside.

- Durable construction: BSCs are built to last, with durable construction and materials that are resistant to wear and tear.

Purposes of Biosafety Cabinets /Biological Safety Cabinets

The primary purpose of a biosafety cabinet (BSC), also known as a biological safety cabinet, is to provide a safe working environment for laboratory personnel and protect the surrounding environment from pathogens and hazardous materials. Here are the key purposes of biosafety cabinets:

- Personnel Protection: Biosafety cabinets are designed to safeguard laboratory workers from exposure to pathogens, bacteria, and viruses. The cabinet’s airflow system, along with HEPA (High-Efficiency Particulate Air) filters, ensures that all exhaust air is filtered and free from harmful microorganisms. This protects the operator from inhaling or coming into contact with infectious agents.

- Environmental Protection: Biosafety cabinets prevent the release of hazardous particles and biohazardous materials into the laboratory environment. The HEPA filtration system in the cabinet captures and filters any potentially harmful aerosols or particles, preventing their spread and contamination of the laboratory space.

- Product Protection: Biosafety cabinets help maintain the sterility and integrity of materials being handled inside the cabinet. Whether it is cell cultures, samples, or sensitive equipment, the controlled environment provided by the BSC minimizes the risk of contamination and maintains the quality of the products.

- Containment of Pathogens: Biosafety cabinets are designed to handle materials contaminated with or potentially contaminated with pathogens. They provide a physical barrier that limits the spread of infectious agents, reducing the risk of accidental exposure and cross-contamination.

- Compliance with Biosafety Standards: Biosafety cabinets play a crucial role in meeting regulatory and biosafety standards set by organizations such as the Centers for Disease Control and Prevention (CDC) and the World Health Organization (WHO). They ensure that laboratories adhere to appropriate biosafety levels (BSL) and guidelines for handling hazardous materials.

It is important to note that biosafety cabinets are distinct from laminar flow clean benches or fume hoods. While laminar flow hoods provide a sterile airflow to protect the product, they do not offer the same level of personnel and environmental protection as biosafety cabinets. Fume hoods, on the other hand, are designed for chemical fume containment and do not provide the necessary protection for working with pathogens.

In summary, biosafety cabinets serve multiple purposes, including protecting laboratory personnel, maintaining environmental cleanliness, preserving the integrity of materials, containing pathogens, and ensuring compliance with biosafety standards. These cabinets are essential tools in laboratories working with biohazardous materials, providing a controlled and safe workspace for researchers and maintaining the integrity of both personnel and the environment.

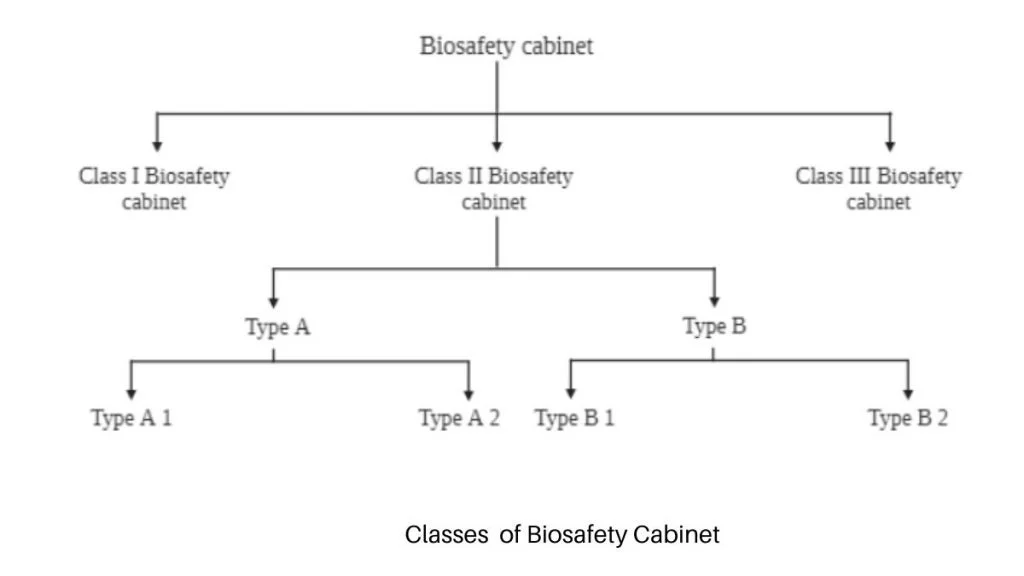

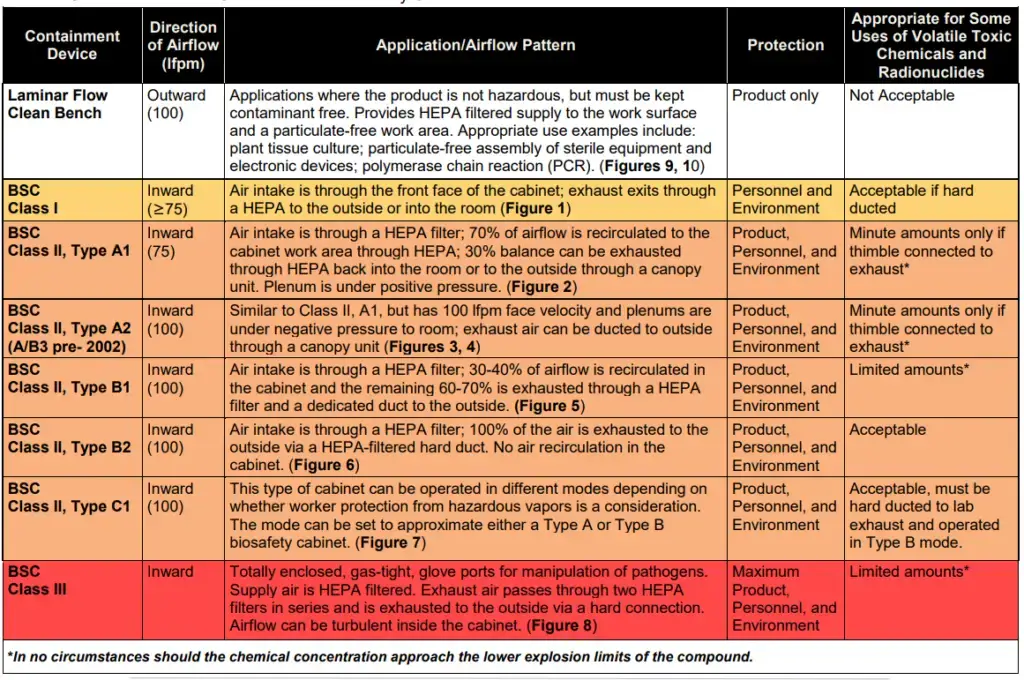

Types of Biosafety Cabinets (Classes of Biological Safety Cabinets)

There are three main classes of biological safety cabinets (BSCs) used in laboratories: Class I, Class II, and Class III. Each class of BSC is designed to provide a different level of protection to the laboratory worker and the environment, depending on the type of biological material being handled and the level of risk associated with the work.

- Class I BSCs, also known as “exhaust BSCs” or “Type A” provide the lowest level of protection. They protect the laboratory worker and environment by drawing in air from the laboratory and passing it through a HEPA filter before expelling the filtered air outside of the laboratory. They are used for work with low-risk biological materials such as bacteria and fungi, and for tasks that do not generate a lot of aerosols or splashes.

- Class II BSCs, also known as “recirculating BSCs” or “Type B1/B2” provide intermediate level of protection. They protect the laboratory worker and environment by recirculating air through a HEPA filter, which removes any contaminants that may be present in the cabinet. They are intended for work with moderate-risk biological materials, such as viruses and human cell lines, and for tasks that generate a moderate amount of aerosols or splashes.

- Class III BSCs, also known as “total containment BSCs” or “Type C” provide the highest level of protection. They are intended for work with high-risk biological materials, such as pathogenic microorganisms and prions. They provide a completely sealed environment, with all of the air being HEPA filtered, both incoming and exhaust. They are used in high-level containment laboratories, and are equipped with additional safety features such as a double-door entry system and special glove ports for access to the work area.

- Class I

- Class II

- Type A

- Type A1

- Type A2

- Type B

- Type B1

- Type B2

- Type A

- Class III

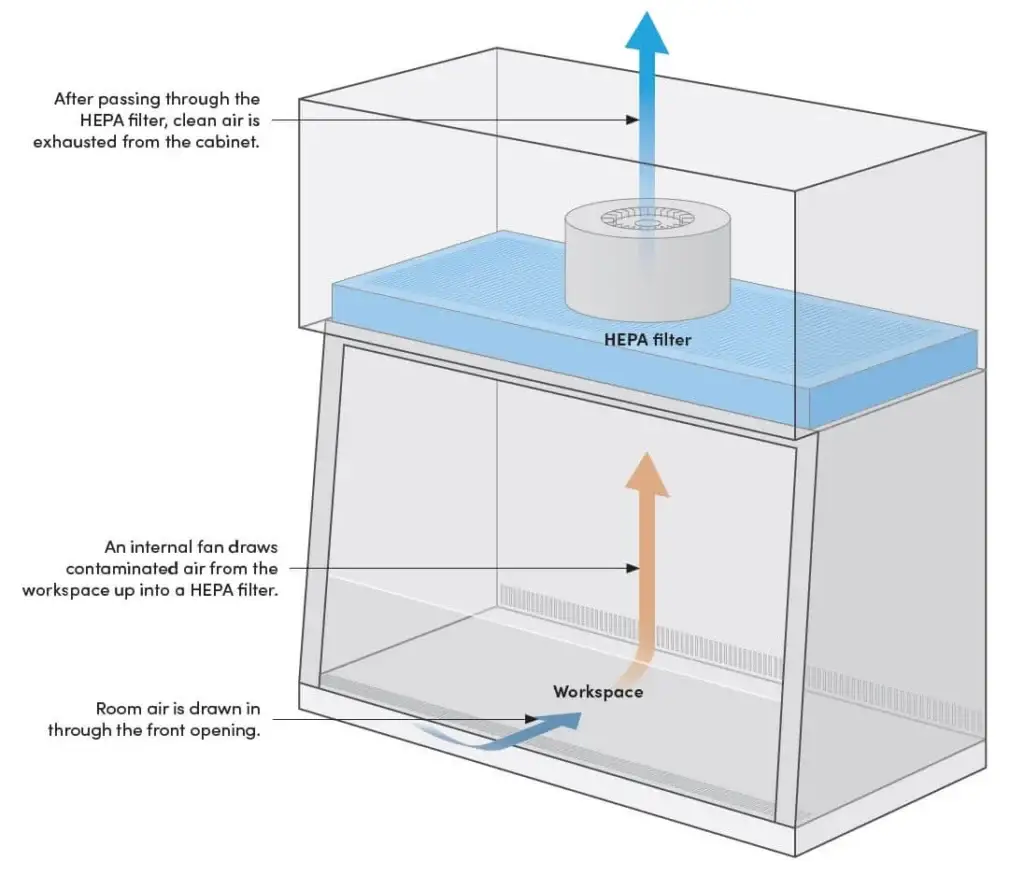

1. Class I Biosafety Cabinet (BSC)

A Class I biosafety cabinet (BSC) is the most basic type of safety cabinet used in laboratories. Here are the key characteristics and features of a Class I BSC:

- Objective: The main objective of a Class I BSC is to provide protection to personnel and the environment in a cost-effective manner. It offers basic containment measures but does not provide defense against sample contamination.

- Open Front and Negative Pressure: Class I BSCs have an open front, allowing easy access to the workspace. They operate under negative pressure, which means that air is drawn into the cabinet from the laboratory or the outside environment.

- Air Exhaust: The air exhaust from a Class I BSC is either ducted (connected to the building exhaust system) or unducted (recirculating filtered exhaust back into the laboratory).

- Handling of Biological Materials: Class I BSCs can handle biological materials from Risk Groups 1, 2, and 3 (RG1, RG2, and RG3). However, they are not suitable for working with research materials that require sterile conditions, as the incoming air is not filtered.

- Containment Level: Class I cabinets can be used safely with agents requiring Biosafety Level 1, 2, or 3 containment measures. They provide personnel and environmental protection but do not offer product protection.

- Airflow and Aerosol Containment: Class I BSCs maintain inward airflow at a minimum velocity of 75 ft/min (0.38 m/s). They are commonly used to enclose specific equipment or procedures that may generate aerosols, such as centrifuges or aerating cultures.

It is important to note that while Class I BSCs provide some level of protection to personnel and the environment, they do not provide a sterile working environment or protect the samples from contamination. These cabinets are suitable for basic containment needs and handling of lower-risk biological materials.

In summary, a Class I biosafety cabinet is a basic safety cabinet that prioritizes personnel and environmental protection. It operates with an open front, negative pressure ventilation, and offers containment for biological materials of different risk levels. However, it lacks product protection and should not be used for materials that require sterile conditions.

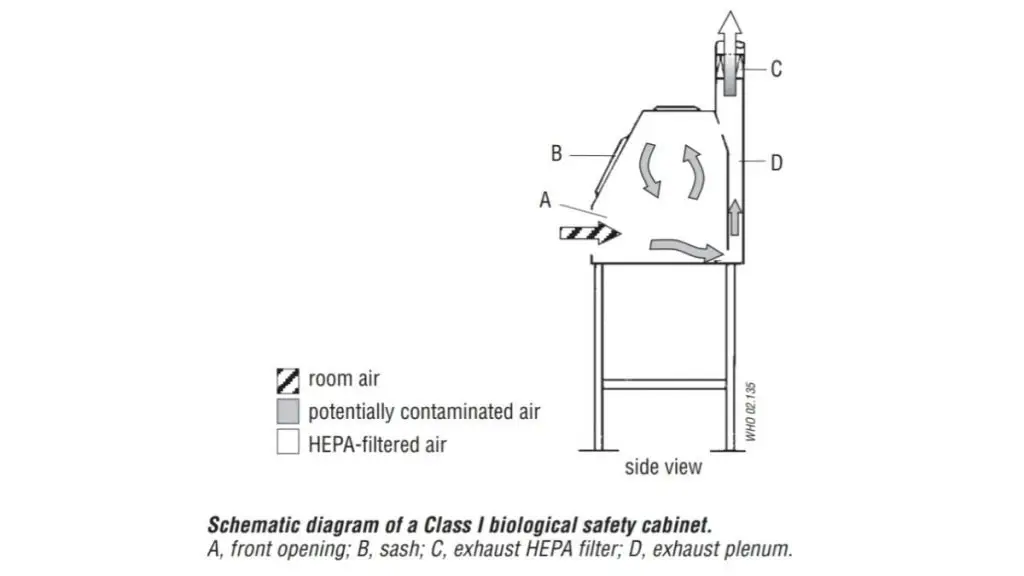

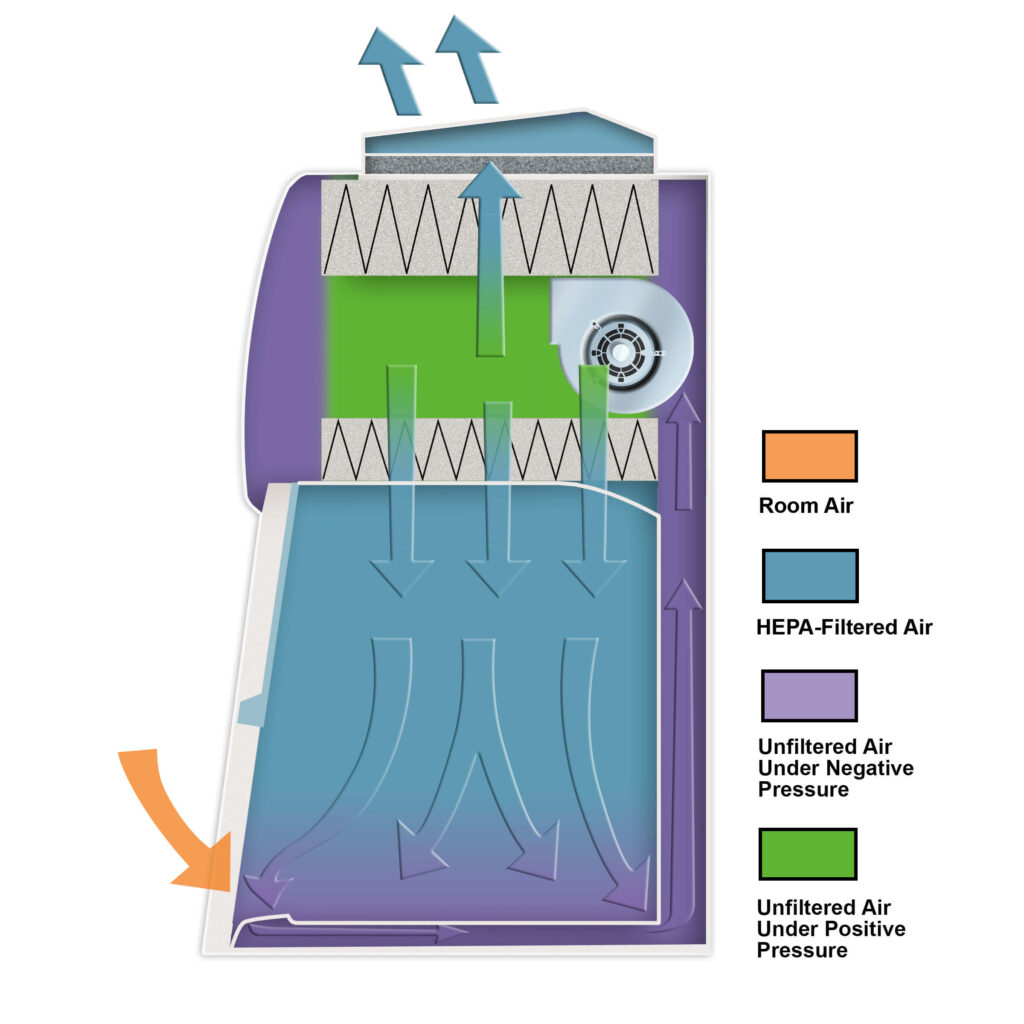

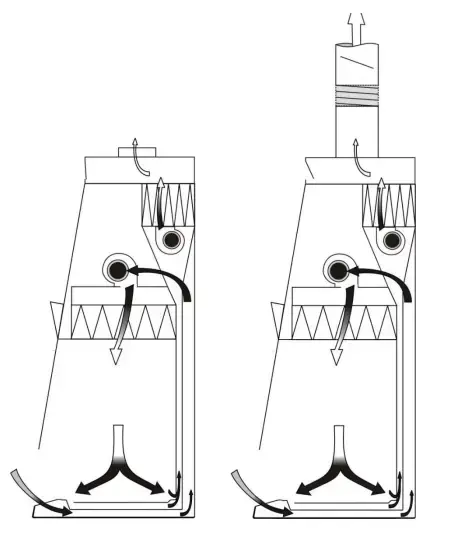

Working Mechanism of Class I Biosafety Cabinet

The working mechanism of a Class I biosafety cabinet (BSC) involves the flow of air to create a protective environment for personnel and the surrounding area. Here is an overview of how a Class I BSC operates:

- Airflow Direction: A Class I BSC operates by creating inward airflow. The air enters the cabinet through the front entrance or opening, which serves as the primary intake. The air then moves over the workspace, providing a protective barrier between the user and the potentially hazardous materials.

- Air Velocity: The inward airflow in a Class I BSC is maintained at a minimum velocity of 0.38 m/s (75 ft/min). This ensures that there is a consistent flow of air moving into the cabinet, preventing the escape of aerosols and other contaminants into the laboratory or surrounding environment.

- Aerosol Containment: As the inward airflow moves over the workspace, it effectively carries away and captures any aerosols or particles generated during microbiological manipulations. This helps to prevent the release of potentially harmful substances into the laboratory and protects the personnel working inside the cabinet.

- Filtration System: The air that is drawn into the Class I BSC passes through a filtration system before being released back into the environment. The filtration system typically consists of two main components:

- Pre-Filter: The pre-filter is the first stage of filtration that captures larger particles and debris from the incoming air. It helps to extend the lifespan and efficiency of the main HEPA filter.

- HEPA Filter: The High-Efficiency Particulate Air (HEPA) filter is a critical component of the Class I BSC. It is designed to trap and remove airborne particles, including microorganisms and contaminants, with a high level of efficiency. The HEPA filter ensures that the air leaving the cabinet is clean and free from any harmful substances.

By combining the inward airflow, aerosol containment, and filtration system, a Class I BSC creates a controlled and protected working environment. It allows the user to work with potentially hazardous materials while minimizing the risk of exposure to pathogens and preventing the release of contaminants into the laboratory or surrounding area.

It’s important to note that a Class I BSC primarily focuses on personnel and environmental protection and does not provide product protection or sterile conditions.

Features of Class I Biosafety Cabinet

Class I biosafety cabinets (BSCs) have specific features that contribute to their functionality and ensure the safety of personnel and the environment. Here are some key features of Class I BSCs:

- Front Opening: Class I BSCs have an open front design that allows easy access to the workspace inside the cabinet. The front opening provides a clear view and facilitates the manipulation of materials or equipment within the cabinet.

- Exhaust Plenum: Class I BSCs are equipped with an exhaust plenum, which is a chamber located at the back of the cabinet. The exhaust plenum collects and directs the air from the workspace towards the exhaust system.

- Exhaust HEPA Filter: A high-efficiency particulate air (HEPA) filter is installed in the exhaust plenum of a Class I BSC. The exhaust air from the cabinet passes through this filter, which is designed to capture and remove airborne particles, including microorganisms and contaminants. The HEPA filter ensures that the air released from the cabinet is clean and free from harmful substances.

- Sash: Class I BSCs often have a movable sash or window at the front opening. The sash serves as a physical barrier between the operator and the materials inside the cabinet. It can be raised or lowered to control the airflow and provide additional protection by minimizing the potential for cross-contamination and aerosol escape.

- Airflow and Ventilation: Class I BSCs operate with inward airflow to contain and capture aerosols generated during manipulations. The airflow typically moves from the front opening towards the exhaust plenum, ensuring that any potentially hazardous particles or substances are carried away from the user.

- Negative Pressure: Class I BSCs maintain negative pressure within the cabinet, meaning that the pressure inside the cabinet is lower than the surrounding environment. This helps to prevent the escape of contaminants into the laboratory or workspace.

- Lighting and Power Outlets: Class I BSCs are equipped with lighting fixtures that provide adequate illumination for the workspace. They may also include power outlets within the cabinet to support the operation of equipment or devices used during procedures.

These features collectively contribute to the functionality and safety of Class I BSCs. They enable the containment of hazardous materials, the removal of airborne contaminants, and the protection of personnel and the environment during microbiological manipulations.

Uses of Class I Biosafety Cabinet

Class I biosafety cabinets (BSCs) have various applications in different laboratory settings. Here are some common uses of Class I BSCs:

- Cell Culture and Bacterial Handling: Class I BSCs are commonly used for the handling and culturing of cell cultures and bacteria. They provide a controlled and sterile environment for working with these biological materials, protecting both the operator and the samples from contamination.

- Sample Preparation for PCR: Class I BSCs are utilized for preparing and handling samples for polymerase chain reaction (PCR). PCR is a sensitive technique used to amplify DNA, and the use of a BSC helps minimize the risk of contamination during the preparation process.

- Microbiological Assays: Class I BSCs are employed for the preparation and handling of samples for various microbiological assays. These assays include the testing and analysis of microorganisms, such as bacteria and fungi, for research or diagnostic purposes.

- Serological Assays: Serological assays involve the testing of blood serum for the presence of specific antibodies or antigens. Class I BSCs are used to prepare and handle samples for these assays, ensuring a controlled environment and minimizing the risk of contamination.

- Handling of Low-Risk Biological Materials: Class I BSCs are suitable for handling low-risk biological materials, such as plant and animal tissue samples. They provide a safe and controlled workspace for processing and manipulating these samples.

- Handling of Small Volumes of Hazardous Chemicals: In addition to biological materials, Class I BSCs can also be used for the safe handling of small volumes of hazardous chemicals. The enclosed and ventilated workspace protects the operator and the environment from potential exposure to these chemicals.

- Fermenters and Centrifuge Housing: Class I BSCs can be used to enclose specific equipment, such as fermenters and centrifuges, that have the potential to generate aerosols. The BSC provides a containment area to prevent the release of aerosols and protect the operator and the environment.

Class I BSCs are commonly found in medical, research, and industrial laboratories where low- to moderate-risk microbiological studies are conducted. They provide personnel, product, and environmental protection by filtering the air through HEPA filters, ensuring a controlled and contaminant-free workspace.

Advantages of Class I Biosafety Cabinet

Class I biosafety cabinets (BSCs) offer several advantages in laboratory settings. Here are some key advantages of Class I BSCs:

- User, Sample, and Environmental Protection: Class I BSCs provide a high level of protection for the operator, samples, and the surrounding environment. The negative pressure ventilation system and HEPA filters ensure that harmful biohazardous aerosols and particles are contained within the cabinet, minimizing the risk of exposure to the user and preventing contamination of the laboratory and the external environment.

- Ease of Use and Maintenance: Class I BSCs are relatively easy to use and maintain. They have a simple design with a front opening and exhaust plenum, making it convenient for operators to access and work with the samples. The HEPA filters and exhaust system can be easily replaced and maintained to ensure optimal performance and safety.

- Versatility in Laboratory Procedures: Class I BSCs can be used for a wide variety of laboratory procedures. They are suitable for handling and culturing cell cultures, bacteria, and other microorganisms. They are also used for sample preparation for techniques like PCR and microbiological assays. Their versatility makes them a valuable tool in different laboratory applications.

- Cost-Effective Solution: Compared to other types of biosafety cabinets, Class I BSCs are generally less expensive. This makes them a cost-effective option for laboratories that require basic containment and protection for low- to moderate-risk biological materials. Their affordability allows laboratories with limited budgets to implement appropriate safety measures without compromising on user and environmental safety.

Overall, the advantages of Class I BSCs make them a practical choice for laboratories working with biohazardous materials. They offer robust protection, ease of use, versatility, and cost-effectiveness, ensuring the safety of personnel, samples, and the environment during laboratory procedures.

Disadvantages of Class I Biosafety Cabinet

While Class I biosafety cabinets (BSCs) offer certain advantages, they also have some limitations and disadvantages. Here are some of the disadvantages associated with Class I BSCs:

- Limited Protection Level: Class I BSCs do not provide the same level of protection as higher-level biosafety cabinets, such as Class II or Class III cabinets. They primarily focus on protecting the product, environment, and samples, but they do not provide comprehensive operator protection. This means that users may still be exposed to biohazards during procedures, especially if working with highly infectious or dangerous materials.

- Unsuitability for Highly Infectious Materials: Due to their limited containment capabilities, Class I BSCs may not be suitable for working with highly infectious or hazardous materials. These cabinets are generally designed for low- to moderate-risk microbiological studies and may not offer adequate protection when handling highly virulent pathogens or dealing with procedures that generate high-level aerosols.

- Filter Maintenance and Airflow Issues: Class I BSCs rely on HEPA filters to remove airborne particles and maintain a clean working environment. However, these filters require periodic replacement, and there may be challenges such as filter leakage or issues with maintaining appropriate air velocities. Failure to properly maintain the filters can compromise the cabinet’s effectiveness in providing a clean and safe working environment.

- Limited Protection for Large Volumes of Hazardous Materials: Class I BSCs may not offer sufficient protection when working with large volumes of hazardous materials. The inward airflow in these cabinets is not designed to handle significant quantities of hazardous substances, potentially increasing the risk of exposure for the operator.

- Limited Application Scope: Class I BSCs have specific application limitations. They are not suitable for working with airborne biohazards or procedures that generate high-level aerosols. These cabinets are typically used for low-risk procedures and samples, and their usage requires careful consideration and adherence to appropriate safety protocols.

It is crucial to evaluate the specific requirements of the laboratory and the materials being handled to determine if a Class I BSC is the appropriate choice. For high-risk procedures or highly infectious agents, higher-level biosafety cabinets should be considered to ensure optimal operator protection and containment of biohazards.

2. Class II Biosafety Cabinet

A Class II Biosafety Cabinet (BSC) is a specialized laboratory enclosure designed to provide protection for personnel, the environment, and the product being handled. Here are some key features and characteristics of Class II Biosafety Cabinets:

- Application and Usage: Class II BSCs are commonly found in clinical, life science, hospital, pharmaceutical, and research laboratories that work with tissue culture or handle infectious agents classified in Risk Groups 2, 3, and 4 (when positive-pressure suits are worn). They offer a higher level of containment compared to Class I BSCs and are suitable for handling a broader range of biohazardous materials.

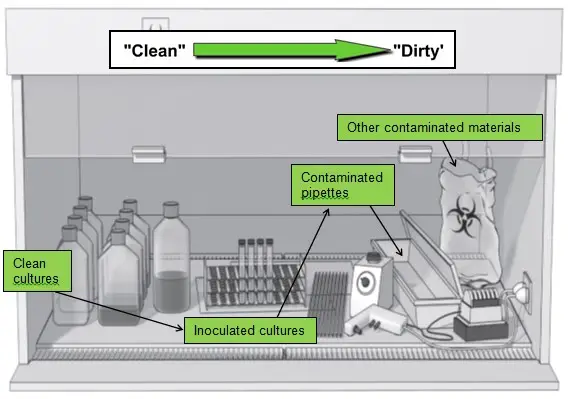

- Airflow and Containment: Class II BSCs utilize a combination of negative pressure and laminar airflow to create a controlled working environment. Unlike Class I cabinets, Class II cabinets feature an airfoil that generates a vacuum and directs air beneath the work surface. This creates a barrier of clean, filtered air at the front of the cabinet, protecting the user from potential airborne contaminants.

- Types and Classifications: Class II BSCs are further classified into different types based on their construction, ventilation, and exhaust systems. The most common types include A1, A2, B1, B2, and C1. Each type has specific design features and airflow patterns to meet different requirements for personnel and product protection.

- Three Key Features: Class II BSCs have three primary features to ensure protection:a. Product Protection: The downward HEPA-filtered unidirectional or laminar airflow creates a sterile work area, preventing contamination of the samples or materials being handled. This feature ensures the integrity and purity of the product.b. Personnel Protection: The open front design of Class II BSCs incorporates carefully regulated inward airflow to shield the operator from exposure to hazardous agents. The inward airflow captures and filters any potential contaminants generated during manipulations.c. Environmental Protection: The exhaust air from the BSC is HEPA-filtered and directed towards a room or facility exhaust system. This prevents the release of biohazardous particles into the environment, safeguarding the surrounding area from contamination.

Class II BSCs offer a higher level of protection compared to Class I cabinets, providing containment for a broader range of biohazardous materials. They are designed to meet specific safety requirements and ensure the safety of personnel, the environment, and the handled products. The choice of a particular type of Class II BSC depends on the level of containment needed for the specific application and the types of pathogens or materials being handled.

Uses of Class II Biosafety Cabinet

Class II Biosafety Cabinets (BSCs) are widely used in various laboratory settings for handling a range of biological materials and hazardous substances. Here are some common uses of Class II Biosafety Cabinets:

- Microorganism Handling: Class II BSCs are commonly employed for the handling and culturing of microorganisms, including bacteria, viruses, and fungi. These cabinets provide a controlled and sterile environment to prevent contamination and protect the operator from potential exposure to these pathogens.

- Biological Material Manipulation: Class II BSCs are utilized for the manipulation of biological materials such as blood, tissues, and body fluids. These cabinets provide a safe and controlled workspace for processing and handling these samples, minimizing the risk of cross-contamination and protecting the operator from potential biohazards.

- Animal Research: In research settings, Class II BSCs are often used for working with live animals. These cabinets provide a controlled environment for tasks such as administering treatments, collecting samples, and conducting experiments, ensuring the safety of both the animals and the researchers.

- Sample Preparation: Class II BSCs are crucial for the preparation of biological samples for analysis, including DNA and RNA extraction. These cabinets offer a clean and sterile workspace with laminar airflow, minimizing the risk of sample contamination and ensuring accurate and reliable results in molecular biology experiments.

- Hazardous Material Handling: Class II BSCs are also utilized for handling hazardous materials, including biological toxins and other chemicals that pose a risk of exposure. The cabinets provide an enclosed and controlled environment that protects the operator and prevents the release of hazardous substances into the laboratory or the environment.

- Research and Development: Class II BSCs are widely used in research and development laboratories across various fields, including pharmaceuticals, biotechnology, and medical research. These cabinets provide a safe and controlled environment for conducting experiments, testing hypotheses, and developing new products or therapies.

Class II Biosafety Cabinets are versatile and essential tools for ensuring safety and maintaining sterility in laboratory work involving a range of biological materials and hazardous substances. Their use is critical in preventing contamination, protecting personnel, and complying with biosafety guidelines and regulations.

Advantages of Class II Biosafety Cabinet

Class II Biosafety Cabinets offer several advantages that make them a preferred choice for working with biological materials and hazardous substances. Here are some key advantages of Class II Biosafety Cabinets:

- Worker Protection: One of the primary advantages of Class II Biosafety Cabinets is that they provide a physical barrier between the worker and the biological materials or hazardous substances being handled. The cabinet’s design and airflow patterns help minimize the risk of exposure to infectious agents or other harmful materials, protecting the operator from potential contamination and reducing the chances of occupational hazards.

- Air Filtration and Containment: Class II BSCs are equipped with high-efficiency particulate air (HEPA) filters that filter and capture airborne contaminants, including biological particles, dust, and aerosols. These filters effectively remove pathogens and hazardous substances, ensuring that the air inside the cabinet remains clean and free from potential contaminants. The exhaust system then safely removes the filtered air from the cabinet, minimizing the risk of laboratory or environmental contamination.

- Environmental Protection: Class II BSCs not only protect the operator but also provide a controlled environment that prevents the release of potentially hazardous materials into the laboratory or the surrounding area. The filtered exhaust air from the cabinet is directed through appropriate ventilation systems, ensuring that any contaminants are effectively removed before being released into the environment.

- Controlled Work Environment: Class II BSCs create a controlled and sterile workspace, particularly important when working with sensitive biological materials such as cell cultures or live animals. The laminar airflow within the cabinet helps maintain a consistent and sterile environment, reducing the risk of contamination and ensuring the integrity of the samples or organisms being manipulated.

- Reduced Contamination Risk: The design and features of Class II Biosafety Cabinets significantly reduce the risk of contamination during manipulations of biological samples. The controlled airflow, combined with features like glove ports and access openings, allows researchers to perform experiments, analysis, and measurements with minimal risk of contamination, ensuring reliable and accurate results.

- Compliance with Biosafety Guidelines: Class II BSCs are designed to meet specific biosafety standards and regulations. By using these cabinets, laboratories can ensure compliance with biosafety guidelines and regulations, promoting a safe working environment and reducing the potential risks associated with handling biological materials and hazardous substances.

Class II Biosafety Cabinets provide a range of advantages, including worker protection, air filtration, environmental protection, controlled work environment, and reduced contamination risk. These advantages make them an indispensable tool in laboratories, research facilities, and healthcare settings where biological materials and hazardous substances are handled.

Disadvantages of a Class II Biosafety Cabinet

While Class II Biosafety Cabinets offer significant advantages, they also have certain disadvantages that should be considered. Here are some key disadvantages of Class II Biosafety Cabinets:

- Cost: Class II Biosafety Cabinets can be expensive to purchase, and the initial investment required for their installation and setup can be significant. Additionally, ongoing maintenance, including filter replacements and certification, adds to the overall cost. The expense involved may pose a challenge for laboratories with limited budgets.

- Infrastructure Requirements: Installing a Class II Biosafety Cabinet often requires specific electrical, plumbing, and ventilation connections. These requirements may involve additional costs and the need for specific building modifications to meet the necessary infrastructure criteria. Ensuring proper installation and compliance with regulatory guidelines can be a complex and time-consuming process.

- Space and Size Limitations: Class II BSCs, particularly larger models, can be bulky and require a considerable amount of space in the laboratory. This can limit the available workspace and make it challenging to accommodate other equipment or samples. It is essential to consider the available space and the specific requirements of the laboratory before installing a Class II Biosafety Cabinet.

- Noise and Communication: Class II BSCs can generate noise due to the operation of fans and filtration systems. The noise levels may interfere with communication between workers in the laboratory, which can impact collaboration and coordination. Adequate measures should be taken to minimize noise disturbance and maintain effective communication channels.

- Maintenance and Certification: Class II Biosafety Cabinets require regular maintenance and certification to ensure their proper functioning and compliance with safety standards. This includes periodic filter replacements, calibration of airflow, and performance verification. The maintenance and certification processes can be time-consuming and may involve additional costs, including the involvement of qualified technicians or third-party service providers.

- Training Requirements: Proper training is crucial for the safe and effective use of Class II Biosafety Cabinets. Users need to be trained on the correct procedures for operating the cabinet, maintaining aseptic conditions, and preventing contamination or exposure. Training programs should be implemented to ensure that all personnel working with the cabinet are knowledgeable and competent in its use.

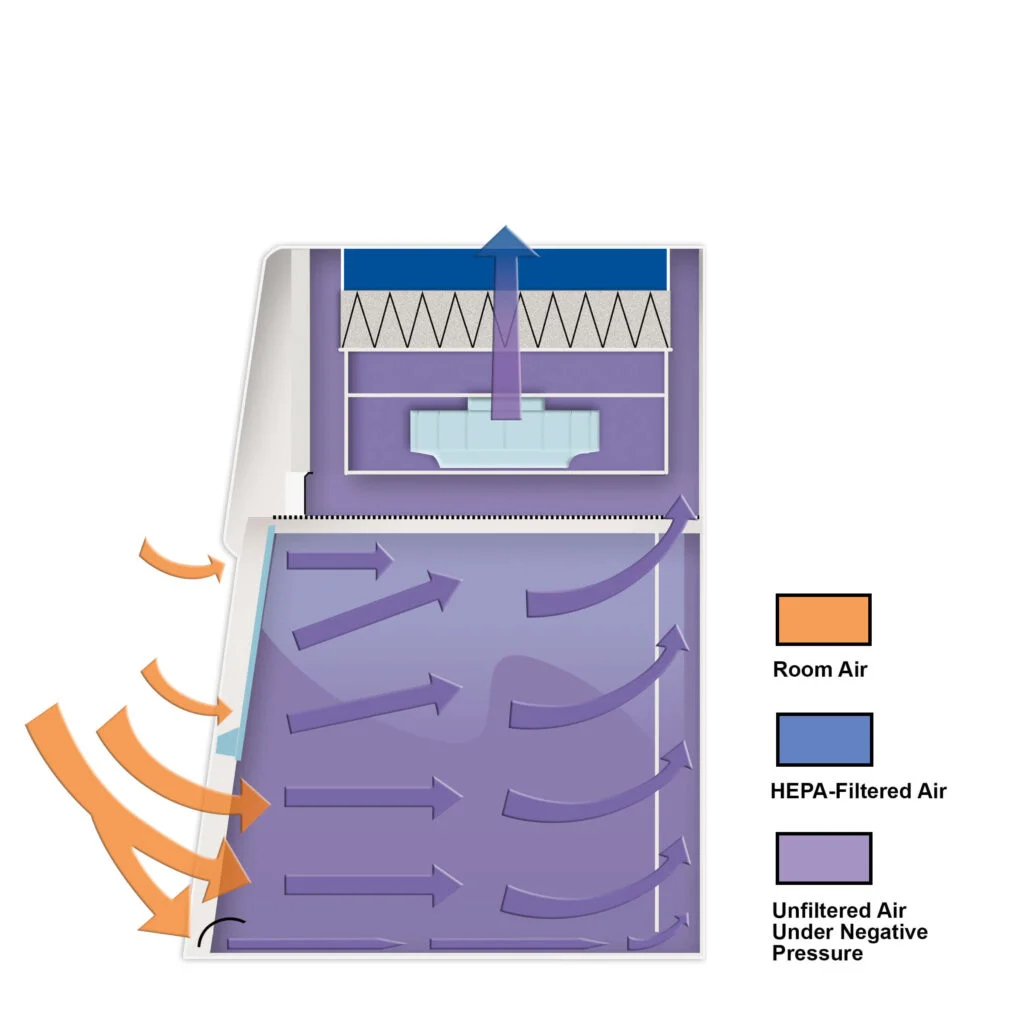

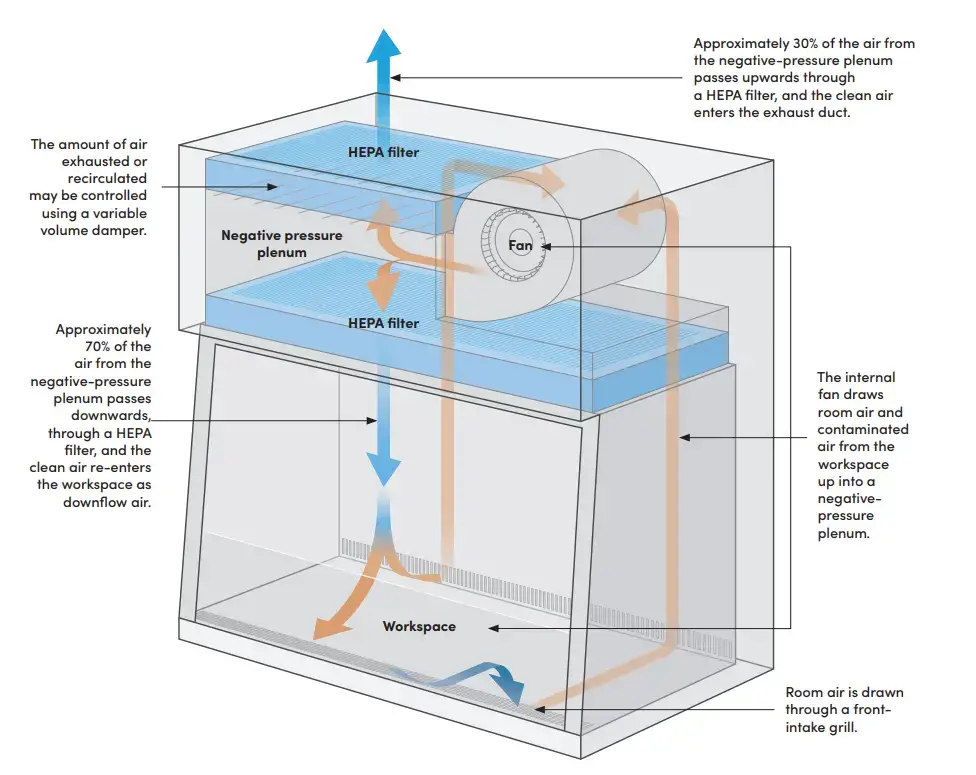

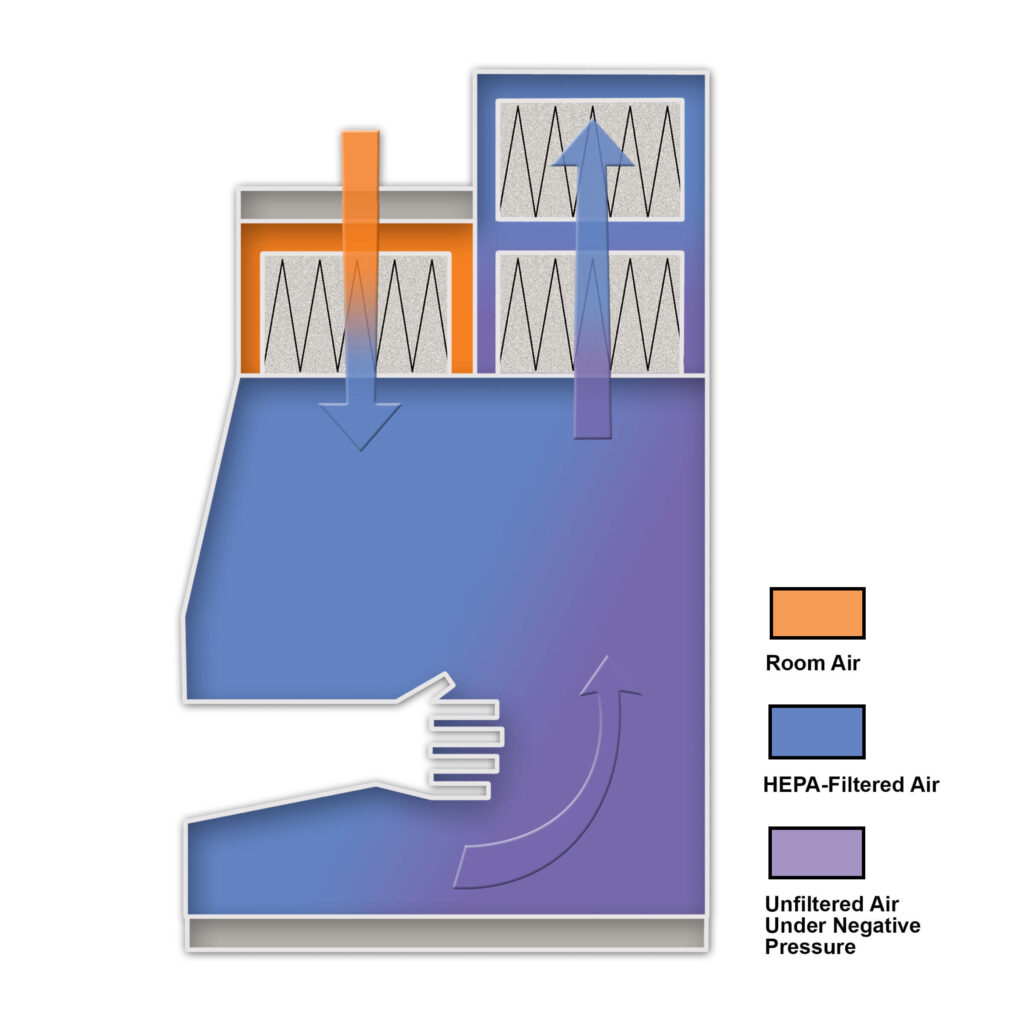

General Working Principle of Class II Biosafety Cabinet

The general working principle of a Class II Biosafety Cabinet involves a combination of inward airflow, downward laminar airflow, and exhaust filtration to provide protection for personnel, the product, and the environment. Here is a breakdown of the working mechanism:

- Inward Airflow: The cabinet is designed with an open front and inward airflow to ensure personnel protection. The air enters the cabinet through the front opening with a velocity of 0.38 m/s. This inward airflow creates a barrier that prevents contaminants from escaping the cabinet and reaching the user.

- Downward Laminar Airflow: Once inside the cabinet, the air passes through a supply High-Efficiency Particulate Air (HEPA) filter. The filtered air then moves downward in a laminar flow pattern over the work surface. This downward airflow provides a clean and sterile environment for handling samples or conducting experiments, minimizing the risk of cross-contamination.

- Aerosol Capture: As the downward airflow reaches the work surface, it splits into two directions. Approximately half of the airflow passes through the front exhaust grill, while the other half passes through the rear exhaust grill. This airflow configuration allows for the effective capture and removal of aerosols generated during work, ensuring maximum product protection.

- Filtration and Exhaust: The captured aerosols and contaminated air are then directed to the space between the supply and exhaust filters located at the top of the cabinet. The supply HEPA filter recirculates approximately 70% of the air within the cabinet, while the remaining 30% is exhausted through the exhaust filter. Both the supply and exhaust filters are HEPA filters, which effectively remove airborne particles and contaminants, ensuring a clean and safe working environment.

By combining the inward airflow, downward laminar airflow, and HEPA filtration, the Class II Biosafety Cabinet creates a controlled and sterile workspace. It provides personnel protection by preventing the escape of contaminants, product protection by maintaining a clean environment for sample handling, and environmental protection by filtering and removing potentially contaminated air before it is released into the surrounding space.

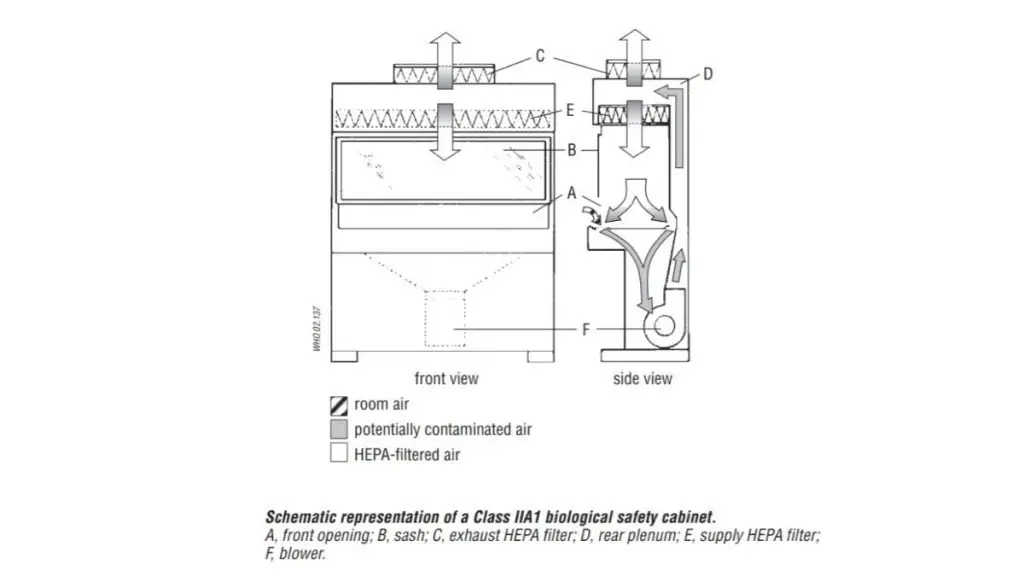

A. Class II Type A1 Biosafety Cabinet

A Class II Type A1 Biosafety Cabinet is a specific type of biosafety cabinet that offers personnel, product, and environmental protection. Here are some key characteristics and features of the Class II Type A1 Biosafety Cabinet:

- Face Velocity: The Class II Type A1 Biosafety Cabinet operates with a face velocity of 75 feet per minute (fpm). This refers to the speed at which air moves across the opening of the cabinet. The face velocity ensures proper containment and minimizes the escape of contaminants.

- Air Recirculation: Approximately 70% of the air inside the cabinet is recirculated through a High-Efficiency Particulate Air (HEPA) filter. This recirculation helps maintain a clean and controlled working environment by removing airborne particles and contaminants.

- Air Exhaust: About 30% of the air is exhausted from the cabinet after passing through the HEPA filter. The exhaust air undergoes filtration to ensure that any potentially hazardous or contaminated particles are effectively removed before being released into the environment.

- Limitations on Use: Class II Type A1 Biosafety Cabinets are not suitable for working with radio nucleotides and toxic chemicals. These cabinets are primarily designed for Biosafety Levels 2 and 3, which involve handling moderately hazardous biological materials.

- Protection Provided: The Class II Type A1 Biosafety Cabinet offers personal, product, and environmental protection. Personnel working inside the cabinet are shielded from exposure to harmful agents. The laminar airflow and HEPA filtration create a sterile environment that protects samples and sensitive materials from contamination. Additionally, the exhaust system ensures that potentially contaminated air is effectively filtered before being released into the surrounding environment.

It is essential to adhere to appropriate safety protocols and guidelines when working with a Class II Type A1 Biosafety Cabinet. Regular maintenance, certification, and proper training are necessary to ensure its effective operation and to safeguard the well-being of personnel, protect the integrity of products, and maintain a safe laboratory environment.

Working Principle of Class II Type A1 Biosafety Cabinet

The working principle of a Class II Type A1 Biosafety Cabinet involves a series of airflow patterns and filtration systems to ensure personnel, product, and environmental protection. Here is a breakdown of the working principle:

- Face Velocity: The cabinet operates with a face velocity of 0.38 m/s or 75 feet per minute (fpm). This controlled speed of the incoming airflow helps contain contaminants and minimize their escape from the cabinet.

- Supply HEPA Filter: The incoming airflow passes through a supply High-Efficiency Particulate Air (HEPA) filter. This filter is designed to capture and remove airborne particles, including microorganisms and contaminants, ensuring a clean and sterile working environment.

- Downward Airflow: The filtered air travels in a downward direction across the work surface. This downward airflow helps prevent contaminants from rising and coming into contact with the operator or samples.

- Airflow Split: At a distance of 6-18 cm from the work surface, the downward airflow “splits” into two directions. Half of the airflow passes through the front exhaust grill, while the other half passes through the rear exhaust grill. This division of airflow helps capture and remove aerosols generated during work, maximizing product protection.

- Recirculation and Exhaust: The air is released into the space between the supply and exhaust filters located at the top of the cabinet. The supply HEPA filter recirculates approximately 70% of the air back into the cabinet, maintaining a clean and controlled environment. The remaining 30% of the air is directed through the exhaust filter and expelled into the room or connected ventilation system. The ratio of recirculated air to exhaust air is determined by the size and specifications of the respective filters.

- Limitations: It’s important to note that Class II Type A1 Biosafety Cabinets should not be used when working with toxic substances or radioactive nucleotides. These cabinets are not designed to provide the necessary level of protection for handling such materials.

By adhering to proper protocols and maintenance, the working principle of the Class II Type A1 Biosafety Cabinet ensures a safe and controlled environment for handling biological materials, minimizing the risk of contamination and protecting both personnel and products.

Class II Type A1 Biosafety Cabinet Features

A Class II Type A1 Biosafety Cabinet possesses several distinct features that contribute to its functionality and the level of protection it offers. Here are the key features of a Class II Type A1 Biosafety Cabinet:

- Front Opening: The cabinet is equipped with a front opening that allows the operator to access the workspace inside. The size of the front opening may vary depending on the specific model and design.

- Sash: The cabinet features a sash, which is a transparent protective barrier that can be raised or lowered. The sash acts as a shield between the operator and the materials being handled inside the cabinet, reducing the risk of contamination and exposure.

- Exhaust HEPA Filter: The Class II Type A1 Biosafety Cabinet incorporates an exhaust High-Efficiency Particulate Air (HEPA) filter. This filter is responsible for capturing and removing any contaminants or hazardous particles present in the exhaust air before it is released into the environment or connected ventilation system. The exhaust HEPA filter ensures the safe disposal of potentially harmful substances.

- Rear Plenum: The rear plenum is a compartment located at the back of the biosafety cabinet. It serves as a space for housing various components such as the blower, exhaust system, and filters. The rear plenum facilitates the airflow management within the cabinet and contributes to maintaining the necessary containment and protection levels.

- Supply HEPA Filter: The Class II Type A1 Biosafety Cabinet also includes a supply HEPA filter. This filter ensures that the air entering the workspace is clean, filtered, and free from contaminants. The supply HEPA filter plays a crucial role in maintaining a sterile and controlled environment for working with sensitive biological materials.

- Blower: The blower is an integral component of the biosafety cabinet’s ventilation system. It generates the necessary airflow and directs it through the filtration system, ensuring the proper circulation and filtration of air within the cabinet. The blower helps maintain the required airflow velocity and containment performance.

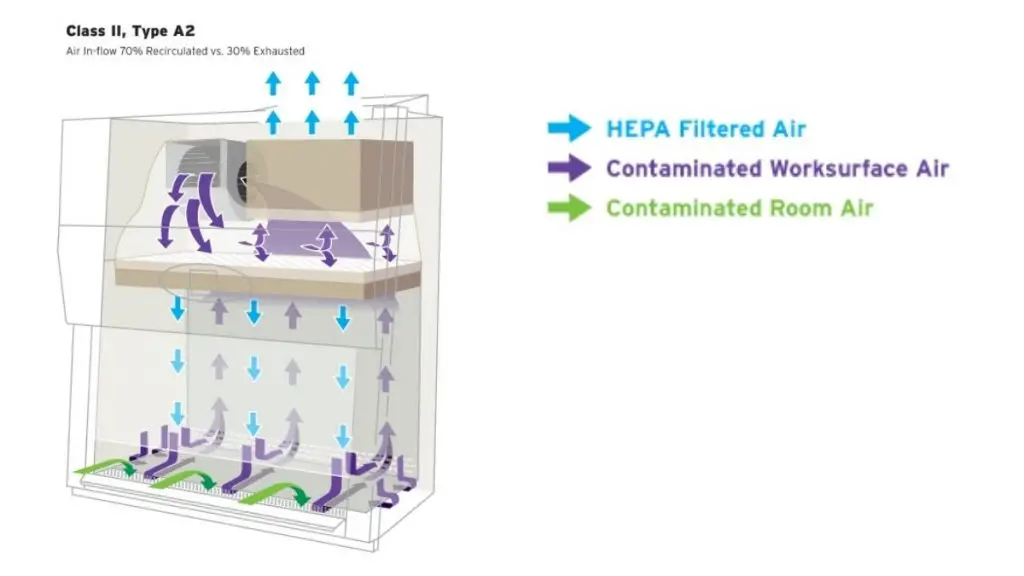

B. Class II Type A2 Biosafety Cabinet

The Class II Type A2 Biosafety Cabinet is a specialized laboratory equipment designed to provide a safe working environment for handling biohazardous materials. Here are the key features and characteristics of a Class II Type A2 Biosafety Cabinet:

- Downward Velocity: The cabinet maintains a downward airflow velocity of 100 feet per minute (fpm). This consistent and controlled airflow helps to prevent the escape of airborne contaminants from the cabinet and provides an added layer of protection for the operator and the environment.

- Air Recirculation and Exhaust: Approximately 70% of the air within the cabinet is recirculated through a High-Efficiency Particulate Air (HEPA) filter. This recirculation helps maintain a clean and controlled environment within the cabinet. The remaining 30% of the air is exhausted through another HEPA filter to ensure the safe disposal of any contaminants.

- Compatibility with Radio Nucleotides and Toxic Chemicals: The Class II Type A2 Biosafety Cabinet is specifically designed to handle hazardous materials such as radio nucleotides and toxic chemicals. This type of cabinet provides the necessary containment and protection levels required for working with these substances safely.

- Biosafety Levels 2 and 3: The Class II Type A2 Biosafety Cabinet is suitable for use in laboratories working with Biosafety Levels 2 and 3. These levels indicate the degree of risk associated with the biological materials being handled and the corresponding precautions and safety measures required.

- Product and Environment Protection: The primary function of the Class II Type A2 Biosafety Cabinet is to provide protection for the operator, the products being handled, and the surrounding environment. The downward airflow and HEPA filtration system ensure that any contaminants or hazardous particles are captured and removed, minimizing the risk of exposure and cross-contamination.

- Negative Pressure and Hard Ducted Exhaust: The Class II Type A2 Biosafety Cabinet operates under negative pressure, meaning that air is drawn into the cabinet and exhausted to the external environment. The exhaust air is directed through a hard ducted system, ensuring that contaminants are expelled safely outside the room and away from the operator and laboratory environment.

Overall, the Class II Type A2 Biosafety Cabinet offers a high level of protection, allowing for the safe handling of hazardous materials, including radio nucleotides and toxic chemicals. It ensures the containment of contaminants, provides a controlled environment, and maintains the safety of the operator and the surrounding laboratory space.

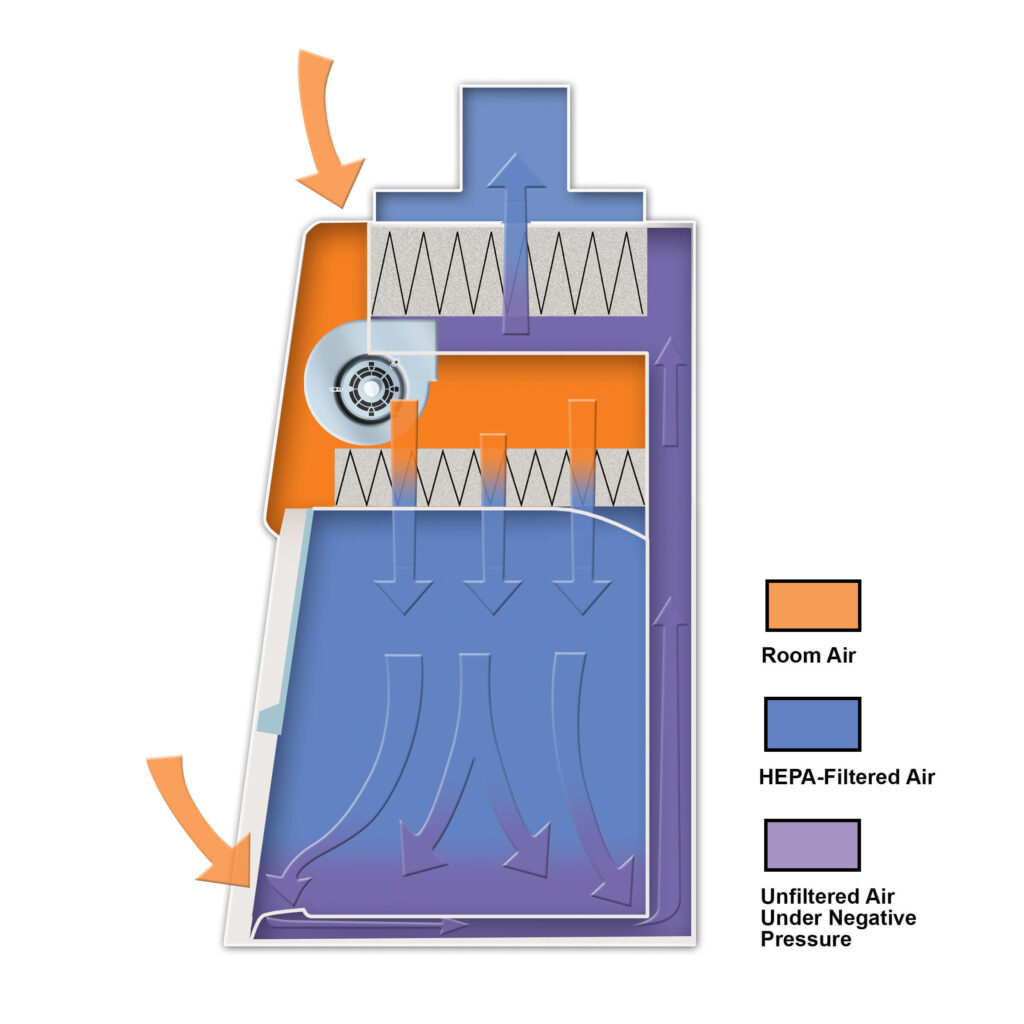

Working Principle of Class II Type A2 Biosafety Cabinet

The Class II Type A2 Biosafety Cabinet operates on a specific working principle to ensure the containment and protection of the operator, products, and environment. Here is an overview of the working principle of a Class II Type A2 Biosafety Cabinet:

- Airflow Direction: The cabinet utilizes a downward laminar airflow pattern to maintain a controlled environment. The ambient air is drawn into the cabinet through the front grill, and a motor blower pulls the air through a plenum located at the rear wall, beneath the work surface.

- Exhaust and Recirculation: A small portion (30%) of the contaminated air is expelled from the top of the cabinet through a HEPA filter. This exhaust air is directed into the central plenum and expelled out of the biosafety cabinet. The remaining air (70%) is recirculated back into the work zone through another HEPA filter.

- Air Division: The recirculated air divides on the work surface, creating a laminar or unidirectional airflow. A portion of the air is drawn through the front airflow grill, while the rest is pulled back through the rear wall grill. This airflow design helps capture and contain any airborne contaminants or hazardous particles generated during the work process.

- Airflow Underneath and Around Work Surface: The airflow continues underneath the work surface, circulating around its edges and underneath. This helps maintain a clean and controlled workspace, minimizing the risk of cross-contamination and ensuring the protection of the operator and the products being handled.

- Compatibility with Radio Nucleotides and Toxic Chemicals: The Class II Type A2 Biosafety Cabinet is specifically designed to handle hazardous materials, including radio nucleotides and toxic chemicals. The working principle and airflow design of the cabinet, along with the HEPA filtration system, provide the necessary containment and protection levels required for working with these substances safely.

By adhering to this working principle, the Class II Type A2 Biosafety Cabinet effectively controls the airflow, captures contaminants, and provides a safe working environment. It allows for the use of radio nucleotides and toxic chemicals while maintaining the integrity of the operator, products, and surrounding environment.

Class II Type A2 Biosafety Cabinet Features

The Class II Type A2 Biosafety Cabinet is a specialized laboratory equipment designed to provide enhanced protection for both the operator and the environment. It incorporates several important features to ensure efficient containment and control of hazardous substances. Here are the key features of a Class II Type A2 Biosafety Cabinet:

- Front Opening: The cabinet is equipped with a front opening that allows easy access to the work area. It provides a clear view and convenient entry for the operator to perform tasks while maintaining a controlled environment.

- Sash: The sash is a movable transparent panel located at the front of the cabinet. It acts as a physical barrier between the operator and the work zone, helping to prevent the escape of contaminants and maintaining a safe working space.

- Exhaust HEPA Filter: The exhaust system of the biosafety cabinet includes a High-Efficiency Particulate Air (HEPA) filter. This filter captures and removes any potentially hazardous particles or microorganisms from the exhaust air, ensuring that only clean air is released into the environment.

- Supply HEPA Filter: The supply air entering the cabinet passes through a HEPA filter as well. This filter removes airborne contaminants and provides a clean and sterile airflow over the work surface, minimizing the risk of contamination during procedures.

- Positive Pressure Plenum: The Class II Type A2 Biosafety Cabinet incorporates a positive pressure plenum. This plenum ensures a controlled and uniform airflow within the cabinet, creating a barrier against the entry of external contaminants and maintaining a clean working environment.

- Negative Pressure Plenum: The cabinet also features a negative pressure plenum. This plenum helps contain any potentially hazardous materials within the cabinet, preventing their release into the laboratory or surrounding environment.

C. Class II Type B1 Biosafety Cabinet

The Class II Type B1 Biosafety Cabinet is a specialized laboratory containment device designed to provide a safe working environment for handling hazardous substances. It incorporates specific features to ensure both the protection of the operator and the integrity of the surrounding environment. Here are the key features of a Class II Type B1 Biosafety Cabinet:

- Downward Velocity: The cabinet maintains a downward airflow velocity of 100 feet per minute (fpm). This controlled airflow helps to minimize the dispersion of airborne contaminants and ensures efficient containment within the workspace.

- HEPA Filter Recirculation: Approximately 30% of the air inside the cabinet is recirculated through a High-Efficiency Particulate Air (HEPA) filter. This recirculation helps maintain a clean and controlled environment by removing hazardous particles and microorganisms from the air.

- HEPA Filter Exhaust: About 70% of the air within the cabinet is exhausted through a HEPA filter. This exhaust system efficiently removes any captured contaminants, ensuring that clean air is released into the laboratory or the facility’s ventilation system.

- Suitable for Radio Nucleotides and Toxic Chemicals: The Class II Type B1 Biosafety Cabinet is designed to handle low levels or volatile forms of radio nucleotides and toxic chemicals. This allows for safe manipulation and containment of these hazardous substances during laboratory procedures.

- Biosafety Levels 2 & 3 Users: The cabinet is specifically designed to accommodate Biosafety Levels 2 and 3, indicating its capability to handle moderate to high-risk biological materials and pathogens. It provides an enhanced level of protection for users working with these potentially hazardous agents.

- Product and Environment Protection: The Class II Type B1 Biosafety Cabinet ensures the protection of both the products being handled and the surrounding environment. The controlled airflow, HEPA filtration, and exhaust system work together to prevent the escape of hazardous materials, safeguarding both the operator and the laboratory.

By incorporating these features, the Class II Type B1 Biosafety Cabinet provides a safe and controlled environment for working with hazardous substances. Its downward airflow, HEPA filter recirculation, and exhaust system contribute to the containment and removal of contaminants, while its compatibility with radio nucleotides and toxic chemicals expands its versatility. Designed for Biosafety Levels 2 and 3, it offers comprehensive protection for users working with moderate to high-risk biological materials.

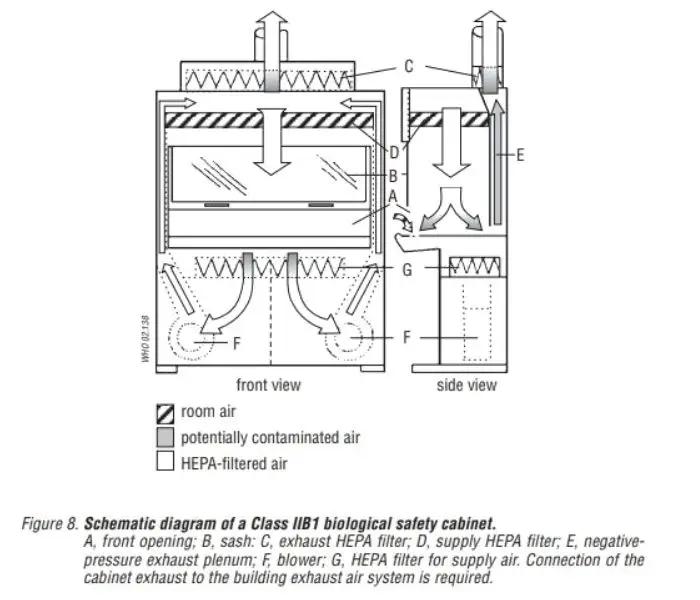

Working Principle of Class II Type B1 Biosafety Cabinet

The working principle of a Class II Type B1 Biosafety Cabinet combines elements of both Type A2 and Type B2 cabinets, offering a unique airflow system to ensure operator and environmental protection. Here is an overview of its working principle:

- Inflow and Front Downflow: Similar to a Type A2 cabinet, the incoming air enters through the front airflow grill and is directed towards a region beneath the work surface. From there, the air flows towards the back of the cabinet.

- Vertical Path and Supply HEPA Filter: The airflow proceeds up a vertical path, reaching a plenum. This plenum is connected to a supply High-Efficiency Particulate Air (HEPA) filter located below it. The supply HEPA filter directs the filtered air downward into the work area, ensuring a clean and controlled environment for handling hazardous materials. Approximately 30% of the air passing through the cabinet is part of this circuit.

- Internal Blower Motor: The air circulation within the cabinet is facilitated by an internal blower motor. This motor drives the air circuit described above, helping to maintain the desired downward airflow and proper filtration.

- External Exhaust Blower: Simultaneously, an external exhaust blower operates to power a second air circuit. This blower pulls the back portion of the cabinet’s downflow into another airflow grill, which leads to a second plenum located at the back of the work zone.

- Exhaust HEPA Filter: The second plenum at the back of the cabinet is connected to an exhaust HEPA filter. This filter captures and removes contaminants from the air, ensuring the safe extraction of approximately 70% of the air from the cabinet.

By combining these airflow systems, the Class II Type B1 Biosafety Cabinet effectively controls the circulation of air within the workspace. The supply HEPA filter provides clean air for the working area, while the exhaust HEPA filter removes any potentially hazardous materials. The dual blower system ensures the proper functioning of both air circuits, allowing for efficient air filtration and extraction.

Overall, the working principle of the Class II Type B1 Biosafety Cabinet aims to maintain a safe and controlled environment for handling hazardous substances. The airflow pattern and filtration mechanisms contribute to the protection of both the operator and the surrounding environment, ensuring the containment of hazardous materials within the cabinet.

Features of Class II Type B1 Biosafety Cabinet

The Class II Type B1 Biosafety Cabinet is equipped with several key features designed to ensure operator safety and environmental protection. Here are the main features of this type of biosafety cabinet:

- Front Opening: The cabinet has a front opening that allows easy access to the work area. The front opening provides a barrier between the operator and the materials being handled, minimizing the risk of exposure to hazardous substances.

- Sash: The sash is a transparent protective barrier located at the front of the cabinet. It can be raised or lowered to control the airflow and create a physical barrier between the operator and the work area.

- Exhaust HEPA Filter: The cabinet is equipped with an exhaust High-Efficiency Particulate Air (HEPA) filter. This filter captures and removes airborne contaminants, ensuring that the exhaust air released into the environment is clean and free from potentially hazardous particles.

- Supply Plenum: The supply plenum is a chamber located within the cabinet that distributes filtered air from the supply HEPA filter. It helps to maintain a consistent flow of clean air throughout the work area.

- Supply HEPA Filter: The supply HEPA filter is responsible for filtering the incoming air before it enters the work area. It removes airborne contaminants, such as bacteria, viruses, and other particles, ensuring a clean and sterile environment for handling hazardous materials.

- Blower: The blower, often an internal motorized blower, is responsible for circulating the air within the cabinet. It helps to maintain a controlled airflow pattern, ensuring that the air is properly filtered and directed to the work area.

- Negative Pressure Exhaust Plenum: The negative pressure exhaust plenum is a chamber located at the back of the cabinet. It facilitates the extraction of air from the cabinet, creating negative pressure within the workspace. This negative pressure helps to contain any potential contaminants within the cabinet, preventing their release into the surrounding environment.

These features work together to provide a safe and controlled working environment for handling hazardous materials. The Class II Type B1 Biosafety Cabinet offers both operator protection and environmental safety, ensuring that the risk of exposure to hazardous substances is minimized, and potential contamination is contained within the cabinet.

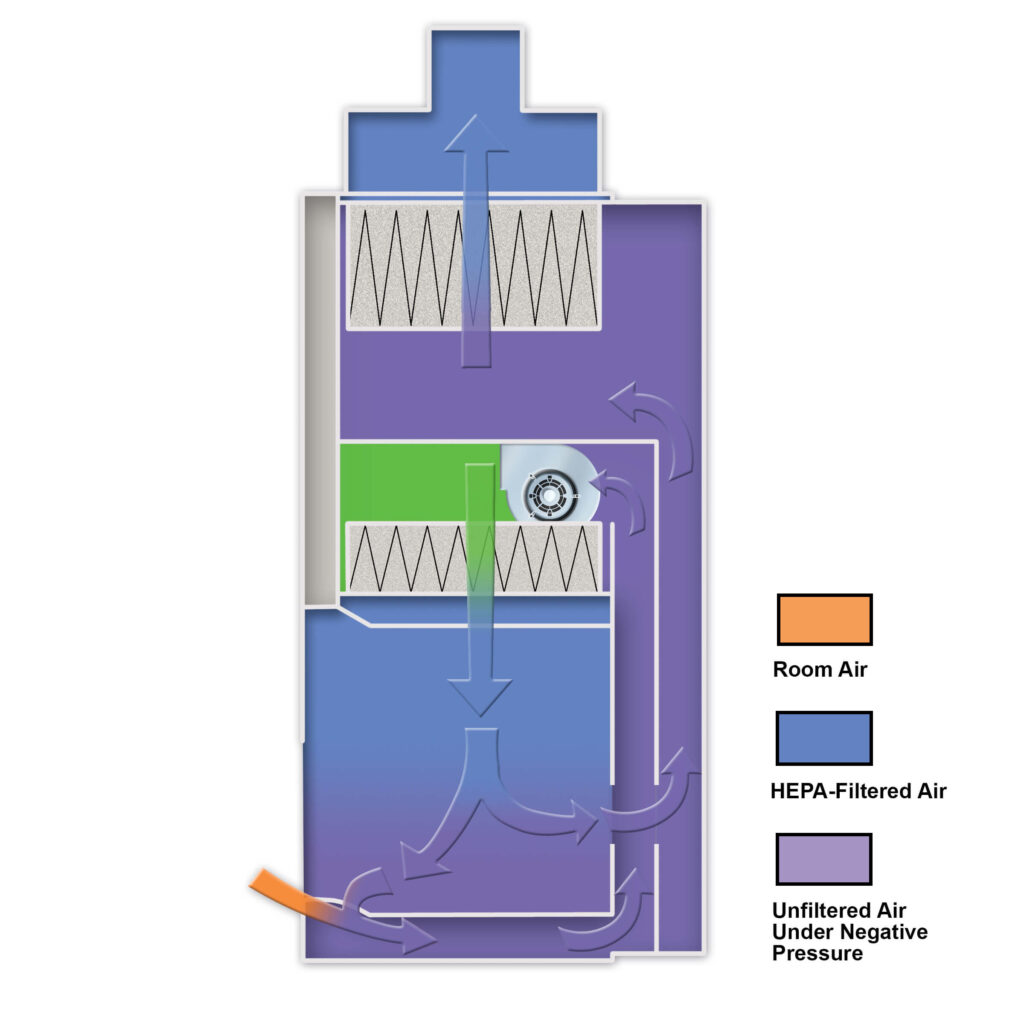

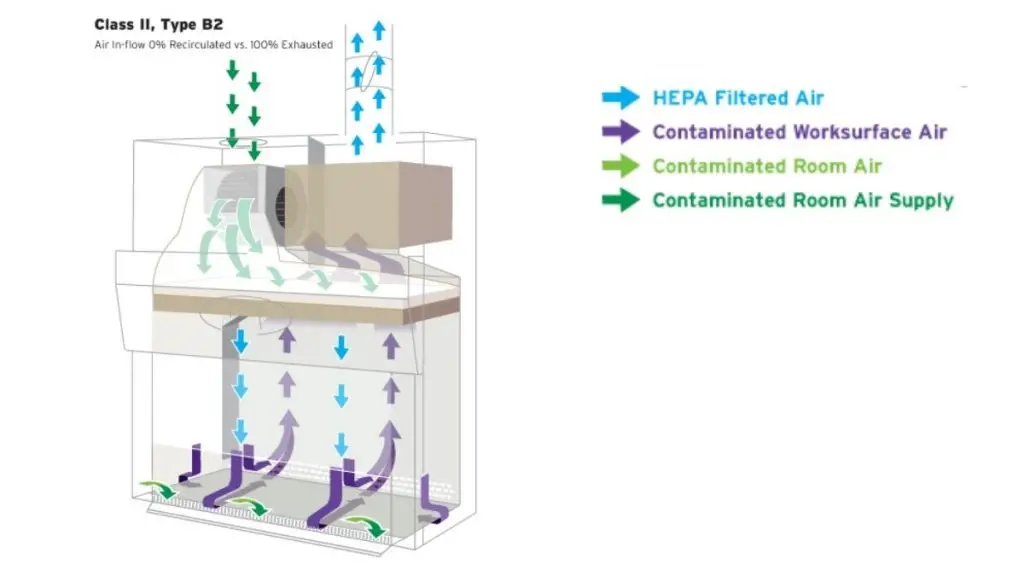

D. Class II Type B2 Biosafety Cabinet

The Class II Type B2 Biosafety Cabinet is specifically designed to provide maximum protection for both the operator and the environment. It incorporates various features and operating principles to ensure a high level of safety. Here are the key aspects of the Class II Type B2 Biosafety Cabinet:

- Downward Velocity: The cabinet maintains a downward airflow velocity of 100 feet per minute (fpm). This controlled airflow helps to create a barrier between the operator and the work area, minimizing the risk of contaminants escaping the cabinet.

- 100% Air Exhausted Through HEPA Filter: Unlike other Class II cabinets, the Type B2 cabinet does not recirculate any air within the cabinet. All of the air is exhausted through a High-Efficiency Particulate Air (HEPA) filter. This ensures that any hazardous particles or contaminants are effectively captured and filtered out before being released into the environment.

- Suitable for Radio Nucleotides and Toxic Chemicals: The Class II Type B2 Biosafety Cabinet is designed to handle hazardous materials, including radio nucleotides and toxic chemicals. It provides a safe and controlled environment for working with these substances, minimizing the risk of exposure to the operator and preventing their release into the surroundings.

- Biosafety Levels 2 & 3: This type of biosafety cabinet is suitable for Biosafety Levels 2 and 3, which involve working with moderate to high-risk biological agents. It meets the necessary requirements to provide a secure containment environment for handling these types of hazardous materials.

- Product and Environment Protection: The Class II Type B2 Biosafety Cabinet offers comprehensive protection for both the products being handled and the surrounding environment. The downward airflow and HEPA filtration system help prevent cross-contamination within the cabinet and ensure that any potentially harmful particles are captured and removed from the exhaust air before it is released.

- Exhaust HEPA Filtered: The exhaust air from the cabinet passes through a HEPA filter. This filter effectively traps and removes contaminants, ensuring that the exhaust air is clean and free from hazardous particles.

- Exhaust Hard Ducted Out: The exhaust air is directed outside the laboratory through a hard duct system. This setup ensures that any exhaust air containing hazardous materials is safely and efficiently removed from the working area, minimizing the risk of contamination.

Overall, the Class II Type B2 Biosafety Cabinet is a specialized cabinet designed for high-level containment and protection. It provides a controlled and secure environment for working with hazardous materials, offering operator safety, product protection, and environmental integrity.

Working Principle of Class II Type B2 Biosafety Cabinet

The Class II Type B2 Biosafety Cabinet operates on a unique working principle that distinguishes it from other types of biosafety cabinets. Here is an overview of its working principle:

- Internal Motor and Supply HEPA Filter: The Type B2 cabinet contains an internal motor that drives the airflow. This motor pushes the air past the supply HEPA filter, which helps to remove contaminants and maintain clean air within the cabinet.

- Downflow and Air Intake: The air pushed by the internal motor creates a downward flow or downflow within the cabinet. This downflow combines with the air drawn into the front access aperture, which serves as the intake for the external environment.

- External Exhaust Blower: The Type B2 cabinet is dependent on an external exhaust blower to function properly. The external exhaust blower creates a negative pressure environment by continuously pulling air from the front of the cabinet and through the ductwork, ensuring a controlled airflow.

- Prevention of Contamination: The primary purpose of the external exhaust blower is to maintain a constant airflow that prevents the escape of hazardous particles from the work zone towards the operator. In the event of a failure of the external exhaust blower, the internal motor ceases to force air down into the work zone to prevent the potential release of contaminants.

- No Recirculation: Unlike other biosafety cabinets, the Class II Type B2 does not recirculate any air within the cabinet. It operates on a 100% exhaust principle, meaning all the air inside the cabinet is exhausted through HEPA filters and expelled out of the system.

- Chemical Vapor Emission: Class II Type B2 cabinets are particularly suitable for operations involving the emission of chemical vapors. As there is no recirculation of air within the cabinet, these cabinets minimize the risk of re-circulating chemical vapors and help maintain a safer working environment.

In summary, the Class II Type B2 Biosafety Cabinet operates with an internal motor to drive downflow and relies on an external exhaust blower for proper airflow and containment. It offers effective protection against hazardous particles and is especially suitable for applications involving chemical vapor emissions due to its 100% exhaust design.

Class II Type B2 Biosafety Cabinet Features

The Class II Type B2 Biosafety Cabinet offers several key features that contribute to its effective functionality and safety. Here are the main features of a Class II Type B2 Biosafety Cabinet:

- Front Opening: The cabinet is equipped with a front opening that allows access to the workspace. This opening can be adjusted using a sash, which provides flexibility in working with various materials and equipment.

- Exhaust HEPA Filter: The cabinet is equipped with an exhaust HEPA (High-Efficiency Particulate Air) filter. This filter is responsible for capturing and removing harmful particles, microorganisms, and contaminants from the air before it is expelled from the cabinet.

- Supply Plenum: The supply plenum is a component within the cabinet that helps direct the airflow. It ensures that the filtered air is evenly distributed throughout the workspace, providing a clean and controlled environment for handling sensitive materials.

- Supply HEPA Filter: The supply HEPA filter is located within the cabinet and plays a crucial role in purifying the incoming air. It removes particles and contaminants, ensuring that only clean and filtered air is supplied to the workspace.

- Blower: The blower is an internal motor that drives the airflow within the cabinet. It creates the necessary negative pressure environment and maintains a continuous flow of air from the supply plenum to the exhaust system.

- Negative Pressure Exhaust Plenum: The negative pressure exhaust plenum is responsible for capturing and containing the exhaust air from the cabinet. It helps prevent the escape of hazardous particles or contaminants into the surrounding environment.

- Container Supply Blower: Some Class II Type B2 Biosafety Cabinets may include a container supply blower. This blower is designed to provide additional airflow specifically for containers or vessels within the cabinet, ensuring proper containment and protection.

- Filter Screen: The filter screen is an additional feature that can be found in Class II Type B2 Biosafety Cabinets. It acts as a protective barrier, preventing large particles or objects from entering the cabinet and potentially interfering with the airflow or workspace.

These features collectively contribute to the effectiveness and safety of the Class II Type B2 Biosafety Cabinet. They provide a controlled environment, efficient filtration, and containment of hazardous materials, ensuring both user and environmental protection.

E. Class II Type C1 Biosafety Cabinet

The Class II Type C1 Biosafety Cabinet introduces unique features and capabilities that distinguish it from other biosafety cabinet types. Here are the key characteristics of a Class II Type C1 Biosafety Cabinet:

- Inflow Velocity: The Class II Type C1 cabinet maintains an average inflow velocity of at least 105 feet per minute (fpm) through the sash aperture. This high velocity ensures efficient containment and protection by preventing the escape of airborne contaminants from the cabinet.

- Recirculating and Exhausting Modes: The C1 cabinet is designed to operate in two modes. In the recirculating mode, it functions as a Type A cabinet, providing personnel and environmental protection through HEPA filtration. In the exhausting mode, it functions as a Type B cabinet, allowing for direct exhaust of hazardous substances and ensuring enhanced containment.

- Mode Switching: The Class II Type C1 Biosafety Cabinet offers the capability to switch between recirculating and exhausting modes rapidly. By connecting or disconnecting the exhaust system and having the cabinet recertified, the C1 cabinet can seamlessly transition between the two modes to accommodate different experimental requirements.

- Direct Exhaust Work Area: The C1 cabinet includes a dedicated work area for direct exhaust applications involving radionuclides or hazardous vapors. This area is specifically designed to handle and exhaust such substances, ensuring their safe containment and preventing their dispersion into the laboratory environment.

- Distinct Workspace and Storage Areas: The Class II Type C1 Biosafety Cabinet is equipped with a demarcated work area that is clearly separated from storage and filing sections. This separation helps maintain organization and prevents cross-contamination between the workspace and stored materials.

The Class II Type C1 Biosafety Cabinet is a versatile and innovative solution for laboratory settings. Its ability to switch between recirculating and exhausting modes, combined with the designated direct exhaust work area, provides researchers with flexibility and safety when working with hazardous materials. The cabinet’s high inflow velocity and clear workspace demarc

Working Principle of Class II Type C1 Biosafety Cabinet

Working mechanism (Not connected to building exhaust)

The working mechanism of a Class II Type C1 Biosafety Cabinet, when not connected to a building exhaust, operates through a carefully designed airflow system to ensure containment and protection within the cabinet. Here is an overview of the working mechanism:

- Air Entry: Room air is drawn into the Class II Type C1 Biosafety Cabinet through the front aperture, which is located under the sash. This incoming air serves as the primary source of airflow for the cabinet.

- Air Division: Once inside the cabinet, the air in the working area is divided into two streams. One portion of the air is directed back towards the supply blower and supply filter, while the other portion is routed through an exhaust blower and exhaust HEPA filter.

- Supply Blower and Filter: The air that is directed back to the supply blower and supply filter undergoes filtration to remove particulates and contaminants. This filtered air is then recirculated within the cabinet to maintain a clean and controlled working environment.

- Exhaust Blower and Filter: The remaining portion of the air is channeled through an exhaust blower and exhaust HEPA filter. This exhaust system ensures that any hazardous particles or contaminants present in the cabinet are captured and filtered out before being released into the room.

- HEPA Filtration: Both the supply and exhaust air streams pass through HEPA filters, which are highly efficient filters capable of capturing microscopic particles, including biological agents and other hazardous substances. HEPA filtration plays a crucial role in maintaining a safe and clean working environment by preventing the escape of contaminants.

By utilizing this working mechanism, the Class II Type C1 Biosafety Cabinet creates a controlled and contained environment for working with biological materials. The combination of supply and exhaust systems, along with HEPA filtration, ensures that airborne contaminants are effectively captured and filtered, providing personnel and environmental protection. It is important to note that when not connected to a building exhaust, the exhaust air is filtered through HEPA filtration before being released into the room, minimizing the risk of contamination.

Working mechanism (Connected to building exhaust)

When a Class II Type C1 Biosafety Cabinet is connected to a building exhaust system, its working mechanism involves both internal airflow control and connection to the external exhaust. Here’s an overview of how it operates:

- Air Entry: Room air enters the Class II Type C1 Biosafety Cabinet through the front aperture, located beneath the sash. This serves as the primary source of air for the cabinet’s working area.

- Air Division: Inside the cabinet, the incoming air is divided into two streams. One portion of the air is directed back to the supply blower and supply filter, while the other portion is routed through the exhaust blower and exhaust HEPA filter.

- Supply Blower and Filter: The air directed back to the supply blower and supply filter undergoes filtration to remove particles and contaminants. This clean air is recirculated within the cabinet, creating a controlled working environment.

- Exhaust Blower and Filter: The remaining portion of the air is channeled through the exhaust blower and exhaust HEPA filter. This exhaust system ensures that any hazardous particles or contaminants present in the cabinet are captured and filtered before being expelled.

- Connection to Building Exhaust: Instead of releasing the exhaust air into the room, the Class II Type C1 Biosafety Cabinet is designed to be connected to the building’s exhaust ductwork. A canopy opening or gap at the upper front of the cabinet allows room air to bypass the cabinet and enter the building exhaust ductwork. Optional flexible ducting connects the cabinet’s exhaust duct to the facility’s exhaust system.

- HEPA Filtration: Prior to entering the building exhaust system, the air from the exhaust blower passes through an exhaust HEPA filter. This ensures that any remaining contaminants or hazardous particles are effectively filtered out, preventing their release into the building or environment.

By connecting the Class II Type C1 Biosafety Cabinet to the building exhaust system, the cabinet’s internal airflow is supplemented by the external exhaust, providing an additional level of containment and preventing the escape of contaminants. The HEPA filtration in both the supply and exhaust systems contributes to maintaining a safe and controlled working environment while ensuring the protection of personnel and the surrounding environment.

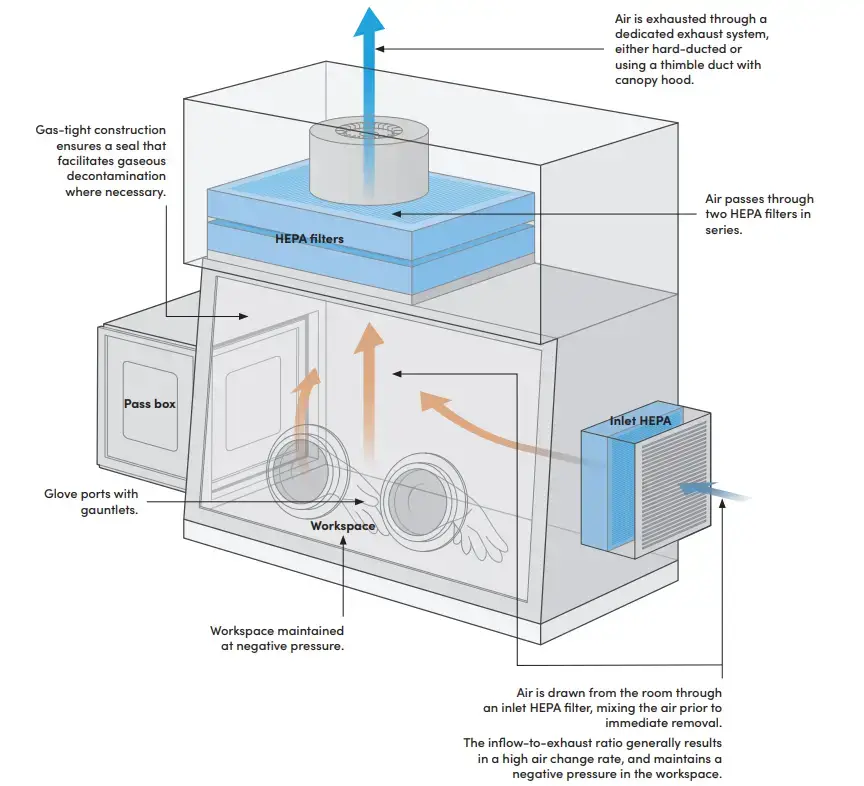

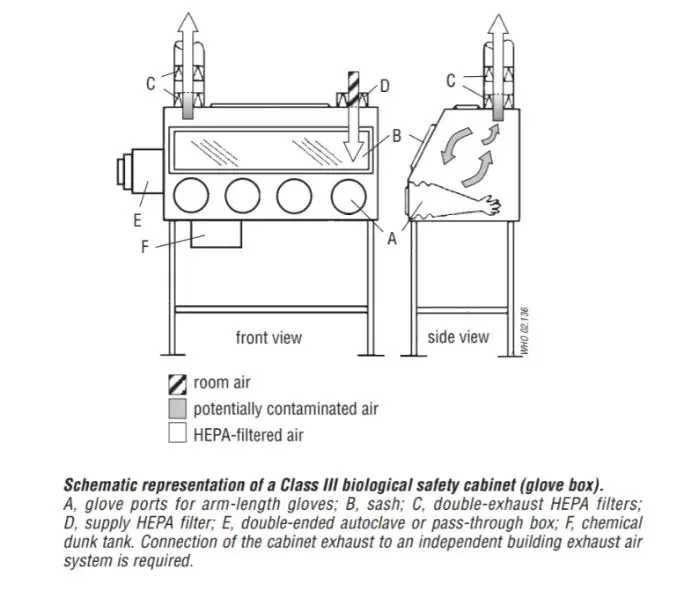

3. Class III Biosafety Cabinet

A Class III Biosafety Cabinet, also known as a total containment cabinet or microbiological safety cabinet, is a specialized laboratory equipment designed to offer the highest level of security for individuals, products, and the environment. Here are the key features and functions of a Class III Biosafety Cabinet:

- Maximum Containment: Class III Biosafety Cabinets provide complete containment by creating a sealed, non-opening enclosure that is aerosol-tight. This ensures that there is no risk of exposure to highly infectious or dangerous biological agents.

- Exhaust System: These cabinets are connected to an exhaust system that captures and filters all the air released from the cabinet. This exhaust system effectively removes any contaminants or hazardous particles, ensuring the protection of the environment and preventing the escape of infectious agents.

- Positive Pressure Work Area: The work area inside the Class III Biosafety Cabinet is maintained at a slight positive pressure relative to the surrounding room. This positive pressure helps prevent the leakage of the agent outside the cabinet and ensures that any potential contaminants are contained within the cabinet.

- Sealed Glove Ports: Operators work inside the Class III Biosafety Cabinet through sealed glove ports that are attached to the front access opening. These glove ports allow the operator to manipulate samples, reagents, or equipment inside the cabinet while maintaining a high level of containment.

- Personal Protective Equipment (PPE): Operators working with Class III Biosafety Cabinets must wear appropriate personal protective equipment (PPE), including gloves, suits, and respiratory protection, to minimize the risk of exposure to hazardous agents.

- Pathogenic Pathogens: Class III Biosafety Cabinets are specifically designed for use with biological agents assigned to Risk Group 4 (RG4), which include highly infectious pathogens such as Ebola virus and Lassa virus. They provide the necessary level of containment and protection when working with these dangerous pathogens.

- Hazardous Materials: In addition to biological agents, Class III Biosafety Cabinets may also be used for handling toxins, dangerous chemicals, or radioactive materials when required by specific laboratory procedures. This allows for the safe manipulation of these hazardous substances within a controlled and contained environment.

Class III Biosafety Cabinets are primarily found in high-security laboratories, research facilities, and specialized containment areas. They are operated by trained and certified personnel who adhere to strict protocols and procedures to ensure maximum safety. These cabinets play a critical role in safeguarding both laboratory personnel and the surrounding environment when working with highly infectious or dangerous biological agents.

Working Principle of Class III Biosafety Cabinet

The working principle of a Class III Biosafety Cabinet involves the following steps:

- Pressure Testing: Class III Biosafety Cabinets undergo pressure testing to ensure that no particles or contaminants can escape and enter the surrounding area. These cabinets are designed to maintain a negative pressure inside the cabinet, creating a secure containment environment.

- HEPA Filtration: HEPA filters are used to filter the supply air entering the cabinet, ensuring that it is free from contaminants. In addition, two HEPA filters are employed to filter and release the exhaust air into the atmosphere, further preventing the escape of any hazardous particles.

- Sealed Enclosure: Class III Biosafety Cabinets are constructed as metal-welded, gas-tight chambers. The front cabinet is equipped with heavy-duty rubber glove apertures, allowing the operator to work inside the cabinet while maintaining a sealed environment. Multiple glove boxes can be connected to expand the work surface area.

- Negative Pressure: The cabinet’s interior is maintained at a negative pressure through a dedicated exhaust system located outside the cabinet. This negative pressure helps prevent the release of any hazardous agents from the cabinet into the laboratory or surrounding environment.

- Autoclave and Sterilization: Class III Biosafety Cabinets may have an attached double-door autoclave. This autoclave is used to decontaminate all materials entering or leaving the cabinet, ensuring that no hazardous agents are inadvertently transmitted.