What is a water distiller?

- A water distiller removes impurities by heating water until it turns to steam and subsequently condensing that vapor back into liquid.

- By preventing non-volatile contaminants—such as heavy metals, bacteria, viruses, and dissolved salts—from evaporating, the boiling process guarantees their stay in the boiling chamber.

- This approach replics the natural hydrologic cycle, whereby water evaporates from surfaces, condenses in the sky, and precipitates as rain, therefore producing very pure water.

- Many water distillers include extra filtration—activated carbon filters, for example—to trap volatile organic compounds that might vaporize alongside the water.

- Although the produced distilled water is almost free of contaminants, it lacks minerals, which would cause a flat taste unless minerals are added for flavor and nutritional balance.

- Usually producing one gallon of distilled water every 4 to 6 hours, countertop devices need regular cleaning to avoid limescale buildup—especially in hard water locations.

- Water distillers are used in a variety of applications, from providing safe drinking water and food preparation to running devices like humidifiers, car batteries, and laboratory equipment. Though the distillation process is energy-intensive and slower than methods like reverse osmosis, it offers one of the most complete contaminant removal techniques available.

- Maintaining the long-term effectiveness and safety of the system depends on regular maintenance including descaling the boiling chamber and changing filters as needed.

- Despite the more initial energy use, utilizing a water distiller over time may be affordable and ecologically favorable compared to buying bottled distilled water.

Definition Water distiller

A water distiller is a device that purifies water by heating it to produce steam, then cooling and condensing the steam to remove impurities. This process helps remove contaminants such as bacteria, viruses, heavy metals, and minerals, resulting in purified and distilled water.

Principle of Water Distiller – How Does a Water Distiller Work?

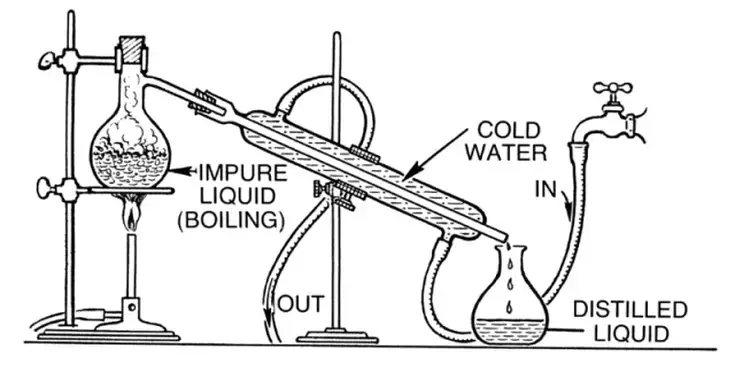

- The principle of a water distiller revolves around the processes of evaporation and condensation. Adding thermal energy to water—still in its liquid form—start the distillation process. This energy gives the water molecules sufficient kinetic energy to separate from molecules of other compounds that may be diluted or combined with it.

- The water evapes and turns into vapor as it heats. Then, focused toward a condenser, this vapor—which just consists of water molecules—is The condenser is used to chill the water vapor, therefore losing thermal energy and bringing it back into liquid form.

- Distilled water results from the water vapor changing back into liquid form during the condensation process. Separate tank or container holds the gathered condensed water droplets. Since it is free of the contaminants from the original water supply, this distilled water is quite pure.

- The idea behind a water distiller is that other contaminants including bacteria, viruses, minerals, heavy metals, and other pollutants do not change into vapor. Either dumped during the distillation process or left behind in the boiling chamber are these contaminants. Consequently, the distilled water generated by a water distiller is fit for many uses that call for clean water as it shows perfect properties and is basically devoid of contaminants.

Parts of a Water Distiller

The primary pieces of a water distiller work together to purify water. Parts include:

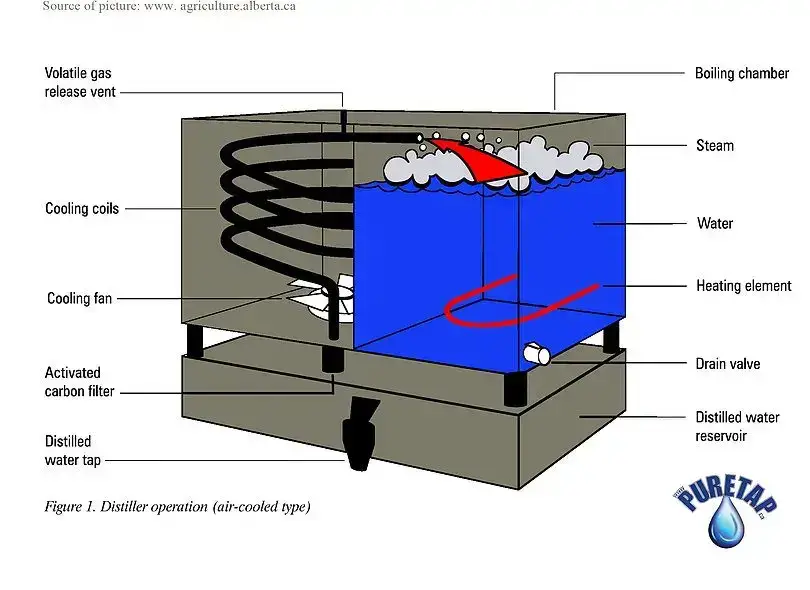

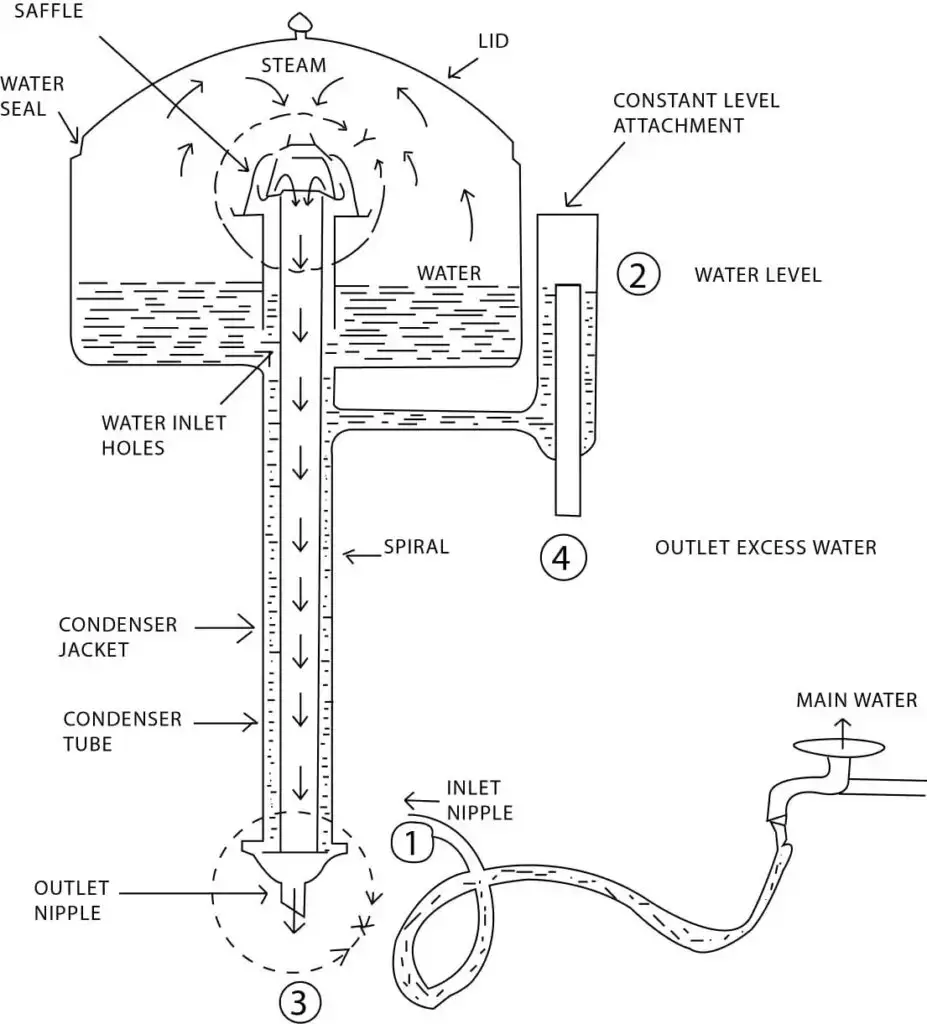

- Vapour generator/Boiling tank- Stores distilled water. Small-volume distillers employ glass, whereas bigger ones use stainless steel with copper, tin, or titanium coatings.

- Water Level Gauge – Regulates vapour generator water quantity. When the boiling tank water level drops, the gauge recovers evaporated liquid.

- Control valve – Control valves mechanically or electromechanically direct water to the vapour generator tank.

- Immersion resistors – When electrical current travels through immersion resistors, they create heat. Ceramic covers and metal plates shield them from the outside.

- Refrigerator water outlet – This pipe condenses water vapor to chill distillation.

- Condenser – The condenser loses thermal energy to cool and liquidify the vapor. This process is accelerated by forced convection of low-temperature fluids like water or air surrounding the vapor flow line.

- Filter – Water distillers commonly have activated carbon filters at the condenser or collector outflow. They eliminate flavors and particles from condensed vapor.

- Distilled water container– This holds distilled water. Distilled water should be stored in plastic containers to avoid ionic contamination. Polytetrafluoroethylene, polyethylene, and polypropylene containers are prevalent.

Other popular water distiller parts are:

- Boiler or heating element – The distiller’s bottom boiler or heating element heats water to boiling.

- Boiling chamber – The boiling chamber contains the water to be boiled and distilled above the boiler or heating element.

- Collection chamber or bottle – The collection chamber or bottle above the condenser gathers purified water.

- Pre-filter – Some distillers use a pre-filter to remove bigger particles and impurities from water before distillation.

- Carbon filter – Some distillers use a carbon filter to remove chlorine, pesticides, and other contaminants from water before distillation.

Types of Water Distillers

Water distillers can be classified into different types based on their configuration and usage. Let’s explore these types:

- Manual Distiller Systems – Users of manual distiller systems must personally replenish the device following every distillation cycle. Usually generating one gallon of distilled water every cycle, they are appropriate for personal or small-scale usage. The water the system can distill in an hour determines its capacity.

- Automatic Distiller Systems – Designed for continuous operation, automatic distiller systems are coupled straight to a water supply. They stop output when the storage tank fills up and automatically control water intake and outflow. Capacities vary; storage reservoirs usually carry three to twenty-five liters of distilled water.

- Countertop Distillers – Perfect for domestic usage, countertop distillers are small and portable. They are simple to use and sit on kitchen countertops; they need hand refilling. Travelers or people seeking distilled water anywhere will find them handy because of their mobility.

- Plumbing Distillers – Integrated right into the plumbing system of a building, plumbing distillers offer a constant supply of distilled water on demand. Although they are more difficult to install, they are appropriate for homes or businesses needing plenty of distilled water because of their convenience and increased capacity.

- Commercial Distillers– Designed for large-scale operations, commercial distillers fit labs, medical facilities, and industrial uses. They can meet the needs of settings where great purity water is required by generating daily large amounts of distilled water.

- Non-Electric Distillers – Designed for use over external heat sources such as stoves or open flames, non-electric distillers are appropriate for circumstances in which power is not accessible. They are frequently seen in places with restricted power supplies or in emergency situations.

Operating Procedure of Water Distiller

- Before usage, make sure the distiller is correctly put together, the boiling chamber is clean, and all components lack scale and residue.

- Without going over the maximum fill line, fill the boiling chamber with water up to the required amount to avoid overheating or damage.

- Connect the device to a suitable power source to verify that all operational and safety features—such as anti-dry protection or automatic shutoff—are working.

- Turn on the distiller’s electricity to start the heating element and bring the water to boiling temperature.

- Let the water boil so it turns into steam; in this phase, non-volatile contaminants stay in the boiling chamber while water molecules evaporate.

- Direct the produced steam into the condenser or cooling section, where it cools and condenses back into liquid form producing filtered water.

- After gathering the distilled water in the specified storage container, discard the first batch if advised to eliminate any remaining contaminants from the system.

- Track the process to make sure the boiling chamber’s water level stays sufficient and that the condenser runs effectively all through the distillation cycle.

- Turn off the device and let it cool once the intended quantity of distilled water is gathered before starting any maintenance or cleaning activities.

- Use suitable cleaning chemicals to descale the boiling chamber, condenser, and filters on a regular basis to preserve best performance and water purity.

- Periodically record operational metrics including conductivity measurements or water clarity to confirm that the distillation process regularly satisfies quality criteria.

Applications of Water Distiller

- Laboratory studies and chemical analyses make use of distilled water as its great purity removes interference from extraneous ions, therefore guaranteeing precise reflection of the desired chemical processes.

- Distilled water is essential for creating reagents, formulations, and sterile solutions in pharmaceutical manufacture, therefore maintaining strict standards of patient safety and quality control.

- Medical uses for distilled water in CPAP humidifiers, sterilizing techniques, and in the preparation of intravenous fluids—where patient care depends critically on the absence of pollutants.

- Distilled water is used in industrial operations including boiler operations, lead-acid battery maintenance, and cooling systems to prevent scale development and corrosion, so improving general system lifetime and efficiency.

- Distilled water helps household appliances—including humidifiers and steam irons—minimizes mineral deposits that could compromise device performance and lower maintenance needs.

- By removing fluctuating mineral content, hydroponics uses distilled water to offer a consistent and regulated medium for fertilizer delivery, therefore enabling ideal plant development.

- Since distilled water lacks contaminants, which helps to prevent inadvertent changes in taste, appearance, or safety, the food and beverage sector employs it to preserve consistency in product quality.

- Distilled water is a favored solvent in sensitive applications as cosmetic and personal care formulations include it to guarantee product stability and lower the risk of skin irritation.

Advantages of Water Distiller

- Water distillers successfully remove a broad spectrum of pollutants, including heavy metals, chemicals, and microbiological diseases, by evaporating water and leaving impurities behind

- Chemical additions are not necessary in the distillation process; so, the generated water stays chemically neutral and is fit for delicate laboratory and medicinal uses.

- The fundamental simplicity of water distillers permits speedy installation and routine maintenance, giving a cost-effective alternative to more complicated filtering systems

- Distilled water is devoid of dissolved minerals and shows great consistency in purity, therefore avoiding scaling and extending the lifetime and efficiency of domestic appliances and industrial machinery.

- The manufacturing of premium distilled water supports important uses in food processing and hydroponics, where exact water quality is necessary for best results of the products.

- Reducing possible pollutants in water helps to improve health results by minimizing exposure to elements that might compromise skin integrity and general physiological performance.

Limitations of Water Distiller

- Water distillers require a constant source of power for operation, resulting to significant energy consumption and rising operational expenses over time

- The distillation process eliminates both pollutants and vital minerals, resulting in water that frequently has a flat or bland flavor due to the absence of natural elements

- Because distillation includes heating, boiling, and condensing water—which might restrict its efficiency in rapidly creating huge volumes—it is intrinsically sluggish.

- Frequent maintenance is important as mineral deposits (scaling) form in the boiling chamber, possibly lowering efficiency and needing regular cleaning or descaling

- The combination of high energy use and the necessity for continuing maintenance might make water distillers less inexpensive compared to alternative water purifying technologies in high-demand applications

Precautions Should be taken When Operating a Water Distiller

- Make sure the water distiller is set up correctly following manufacturer recommendations to avoid possible hazards and operational mistakes.

- Check that the boiling chamber’s water level stays within the advised range; overfilling might cause overheating and damage.

- To prevent short circuits and electrocution hazards, make sure the electrical supply matches the rated voltage and power needs of the unit.

- Verify that before starting the distillation process all built-in safety mechanisms—such as automatic shutdown and anti-dry protection—are operational.

- Keep constant control to guarantee the effectiveness of the cooling system and to keep the distillation process inside reasonable limits.

- Before doing any maintenance or cleaning, let the unit cool totally to lower the burn and other injury risk.

- Adhere to frequent cleaning and descaling operations with manufacturer-recommended products to minimize mineral accumulation that might impede efficiency

- To protect human and environmental health, dispose of waste water including concentrated pollutants in line with local environmental rules.

- Minimise heat and steam exposure by using suitable personal protective gear including eye protection and heat-resistant gloves.

- To keep best performance and avoid unnecessary mechanical strain on the system, avoid surpassing the capacity of the unit.

How to clean your water distiller?

- Before starting any cleaning projects, unplug the water distiller and let it cool entirely to avoid burns or electrical dangers.

- To make sure every component—including the storage container, boiling chamber lid, and any filters—is reachable for complete cleaning—disassemble everything.

- To remove the last of the water from the unit, drain any stagnant water that can cause scale development or harboring of pollutants during the cleaning operation.

- Prepare a cleaning solution using a dilute acid, such as a 5% hydrochloric acid or a mild vinegar solution, as recommended by the manufacturer to dissolve mineral deposits and accumulated impurities

- To properly break down scale and residue from extended use, fill the boiling chamber with the cleaning solution and let it sit for the recommended period—usually around 12 hours.

- Several times rinse the unit completely with pure tap water to guarantee that all traces of the cleaning solution and dislodged deposits are totally eliminated, so preventing contamination of next distillate.

- Carefully reassemble the water distiller, run a preliminary cycle, discard the first batch of distilled water to remove any residual cleaning agent possibly compromising water quality.

- Establish a regular cleaning program depending on the frequency of usage and the hardness of the feed water to ensure maximum performance and durability of the unit

- Record every cleaning cycle and any maintenance done in a log to track system performance over time and assist academic or business environments’ quality control systems.

Water Distiller Examples

Here is a list of top and best water distiller systems for laboratory use, along with a brief description of each:

- Millipore ELIX Essential Water Distiller: This distiller is designed for use in laboratories and produces high-purity water with a resistivity of up to 18.2 MΩ·cm. It has a compact design and is easy to use, with a user-friendly LCD display and automatic shut-off feature.

- Pure Water Mini-Classic CT Countertop Water Distiller: This countertop distiller produces high-purity water with a resistivity of up to 18.2 MΩ·cm. It has a compact design and is easy to use, with a user-friendly LCD display and automatic shut-off feature.

- H2O Labs Countertop Water Distiller: This countertop distiller produces high-purity water with a resistivity of up to 18.2 MΩ·cm. It has a compact design and is easy to use, with a user-friendly LCD display and automatic shut-off feature.

- Water Wise 4000 Countertop Water Distiller: This countertop distiller produces high-purity water with a resistivity of up to 18.2 MΩ·cm. It has a compact design and is easy to use, with a user-friendly LCD display and automatic shut-off feature.

- Pure Water Countertop Water Distiller: This countertop distiller produces high-purity water with a resistivity of up to 18.2 MΩ·cm. It has a compact design and is easy to use, with a user-friendly LCD display and automatic shut-off feature.

- AquaNui Classic Water Distiller: This water distiller produces high-purity water with a resistivity of up to 18.2 MΩ·cm. It has a compact design and is easy to use, with a user-friendly LCD display and automatic shut-off feature.

- WaterWise Water Distiller: This water distiller produces high-purity water with a resistivity of up to 18.2 MΩ·cm. It has a compact design and is easy to use, with a user-friendly LCD display and automatic shut-off feature.

- WaterWise Model 8800 Water Distiller: This water distiller produces high-purity water with a resistivity of up to 18.2 MΩ·cm. It has a compact design and is easy to use, with a user-friendly LCD display and automatic shut-off feature.

- Megahome Countertop Water Distiller: This countertop distiller produces high-purity water with a resistivity of up to 18.2 MΩ·cm. It has a compact design and is easy to use, with a user-friendly LCD display and automatic shut-off feature.

- Durastill Water Distiller: This water distiller produces high-purity water with a resistivity of up to 18.2 MΩ·cm. It has a compact design and is easy to use, with a user-friendly LCD display and automatic shut-off feature.

It is important to note that the purity and resistivity of the water produced by these distillers may vary depending on the specific model and the source water being used. It is always a good idea to thoroughly research and compare different models to find the one that best meets your needs and budget.

Alternatives to Water Distillers

While water distillers are effective in producing purified water, several alternative methods can also provide high-quality water for various applications:

- Reverse Osmosis (RO) Systems: These systems employ a semipermeable membrane to remove pollutants, including dissolved salts, bacteria, and other impurities, producing water purity equivalent to distillation.

- Deionization (DI) Units: DI systems eliminate ionized salts and minerals from water by ion-exchange resins, yielding highly pure water appropriate for laboratory and industrial uses.

- Carbon Filtration: Activated carbon filters efficiently diminish chlorine, volatile organic compounds (VOCs), and specific pesticides, enhancing taste and odor, although they may not eliminate all dissolved solids.

- Ultraviolet (UV) Purification: UV systems disinfect water by inactivating bacteria, viruses, and other microbes, making them excellent for providing microbiologically clean water without modifying its mineral composition.

- Bottled Water: Commercially accessible bottled water, encompassing filtered and mineral types, offers a handy option; nonetheless, it is crucial to ascertain the source and treatment procedures to guarantee quality.

FAQ

How long does it take to distill water?

The time it takes to distill water will depend on the size of the distiller and the amount of water being distilled. In general, a small countertop water distiller will take about 4-6 hours to distill one gallon of water. Larger, more industrial-sized distillers may be able to produce one gallon of distilled water in as little as one hour.

It’s important to note that the time it takes to distill water can also be affected by factors such as the purity of the water being distilled, the temperature of the water, and the humidity level in the environment. In general, it will take longer to distill water if the water is dirty or contaminated, or if the temperature or humidity is high.

To get a more accurate estimate of how long it will take to distill a specific amount of water, it’s best to consult the manufacturer’s instructions or guidelines for your particular water distiller.

What does a water distiller remove?

A water distiller removes impurities from water by using the process of distillation. Distillation involves heating water to its boiling point so that it turns into steam. As the steam rises, it leaves behind any impurities that are dissolved in the water, such as minerals, bacteria, and other contaminants.

The steam is then collected and cooled, resulting in pure, distilled water. Because the distillation process removes impurities from the water, it is an effective way to produce pure, clean drinking water.

However, it’s important to note that while distillation can remove many types of impurities, it may not be effective at removing certain contaminants, such as certain chemicals or heavy metals. To ensure that your water is as pure as possible, it may be necessary to use other methods in addition to distillation, such as carbon filtration or reverse osmosis.

Does boiling water distill it?

Boiling water can produce distilled water if the steam produced is collected and condensed back into a liquid. This is the process of distillation.

When water is heated to boiling, it produces steam, which is a mixture of water vapor and air. As the steam rises, it comes into contact with a cooled surface, such as a condenser coil or a cooled glass tube. As the steam cools, it condenses back into a liquid, and the resulting liquid is pure water with any impurities left behind.

To collect the distilled water, the condensation must be collected in a clean container. This container should not be made of a material that can leach contaminants into the water, such as plastic or metal. Glass or ceramic containers are best for collecting distilled water.

While boiling water can produce distilled water, it is not the most efficient method of distillation. It is also not suitable for producing large quantities of distilled water. For these purposes, a more sophisticated distillation system is typically used.

Can I distill water myself?

Yes, it is possible to distill water yourself at home using simple equipment and materials. Here is a basic outline of the process:

1. Collect the materials you will need: a large pot or kettle, a smaller pot or jar, a clean cloth or coffee filter, and some ice.

2. Fill the large pot with water and bring it to a boil.

3. Place the smaller pot or jar on top of the large pot, making sure that it is not touching the water.

4. Cover the smaller pot or jar with the cloth or coffee filter and secure it in place with a rubber band.

5. As the water boils, steam will rise and collect on the cloth or coffee filter. As the steam cools, it will condense and drip into the smaller pot or jar.

6. To increase the efficiency of the process, you can place ice on top of the cloth or coffee filter. This will help to cool the steam and cause it to condense more quickly.

7. Continue boiling the water until you have collected as much distilled water as you need. Be sure to keep the water level in the large pot topped up so that it does not boil dry.

This is a simple, low-tech way to produce small quantities of distilled water at home. However, it is not the most efficient or effective method for producing large quantities of distilled water. For these purposes, a more sophisticated distillation system is typically used.

Is it safe to drink distilled water?

Distilled water is safe to drink. In fact, it is one of the purest forms of water available and is often used in laboratories and medical settings where high levels of purity are required.

During the distillation process, impurities such as minerals, bacteria, and other contaminants are removed from the water, leaving behind pure H2O. Distilled water does not contain any minerals or other contaminants, which makes it ideal for certain uses, such as preparing infant formula or filling lead-acid car batteries.

However, it is important to note that while distilled water is safe to drink, it can also be less beneficial to drink on a regular basis because it lacks the minerals and other substances found in most other types of water. Some experts recommend drinking mineral water or fortified water to help ensure that you are getting enough minerals in your diet.

In summary, distilled water is safe to drink, but it may not be the best choice for everyday consumption due to the lack of minerals and other substances found in most other types of water.

Is distilling water better than boiling?

Distillation is generally considered to be a more effective method of purifying water than boiling, because it removes a wider range of impurities and contaminants.

During the distillation process, water is heated to the point of vaporization, and the steam that is produced is collected and condensed back into a liquid. This process removes impurities such as minerals, bacteria, and other contaminants, leaving behind pure water.

Boiling water can also kill bacteria and other microorganisms, but it is not as effective at removing other contaminants such as minerals and chemicals. Boiling water is also less efficient at producing purified water, as it requires a lot of energy and time to bring the water to a boil and maintain it at that temperature.

In summary, distillation is generally considered to be a more effective and efficient method of purifying water than boiling, as it removes a wider range of impurities and contaminants. However, boiling can still be useful for killing bacteria and other microorganisms in water, and it can be a simple and effective way to produce small quantities of purified water at home.

Why can’t adults drink distilled water?

There is no inherent reason why adults cannot drink distilled water. Distilled water is safe to drink and is often used in medical settings and laboratories due to its high level of purity.

However, it is important to note that distilled water lacks minerals and other substances that are found in most other types of water. These minerals and substances, such as calcium and magnesium, can be important for maintaining good health and can be beneficial when consumed as part of a balanced diet.

While it is generally safe for adults to drink distilled water, it may not be the best choice for everyday consumption due to the lack of minerals and other substances. Some experts recommend drinking mineral water or fortified water to help ensure that you are getting enough minerals in your diet.

In summary, there is no inherent reason why adults cannot drink distilled water, but it may not be the best choice for everyday consumption due to the lack of minerals and other substances found in most other types of water.

- https://dashappliances.com/what-is-a-water-distiller/

- https://www.wqpmag.com/softening-conditioning/distiller-equipment-components/article/10956704/what-are-water-distillers-how-do-they-work

- https://www.pharmaceuticalsky.com/2021/08/sop-for-distilled-water-still.html

- https://slidetodoc.com/maintaining-a-water-distiller-o-principles-of-operation/

- https://www1.agric.gov.ab.ca/$department/deptdocs.nsf/all/agdex715/$file/716d62.pdf

- https://www.freshwatersystems.com/blogs/blog/what-is-a-water-distiller-and-how-does-it-work

- https://advancedwaterinc.com/water-distillation-work/

- https://puretap.ca/information-on-water-distillers/

- http://www.i4at.org/surv/distill.htm

- https://www.megahome-distillers.co.uk/what-does-a-water-distiller-do

- https://www.pharmaguideline.com/2007/02/distillation-basic-principle-and-mehodology-of-simple-distillaion.html

- Text Highlighting: Select any text in the post content to highlight it

- Text Annotation: Select text and add comments with annotations

- Comment Management: Edit or delete your own comments

- Highlight Management: Remove your own highlights

How to use: Simply select any text in the post content above, and you'll see annotation options. Login here or create an account to get started.