- A Stage Micrometer can define as a microscope slide which having a precisely engraved scale on it, usually in millimeters (mm) or micrometers (µm).

- It’s mainly used for calibration of an eyepiece micrometer, so that accurate measurement of microscopic objects can be done.

- The scale on stage micrometer is generally 1 mm long, and divided into 100 equal parts, each division representing 10 µm (micrometer).

- It is placed on the microscope stage, and the eyepiece scale is compared with the stage scale to find the calibration factor.

- After that, this factor is used to convert eyepiece readings into actual size of the specimen, under different magnifications.

- The micrometer slide is mostly made of glass or metal, and it is marked using fine precision techniques to maintain uniform spacing.

- Care should be taken that the stage micrometer is clean, as dust or oil may cause reading errors or misalignment of the scale.

- In general, it’s an essential tool in microscopy for quantitative measurements, calibration, and maintaining reliability of observation, etc.

Definition of Stage Micrometer

A stage micrometer is a calibrated slide with a ruled scale used to calibrate microscopes and measure the size of objects under a microscope.

Principle of Stage micrometer

- The Principle of Stage Micrometer is based on calibration of microscope’s measuring system by using a known standard scale.

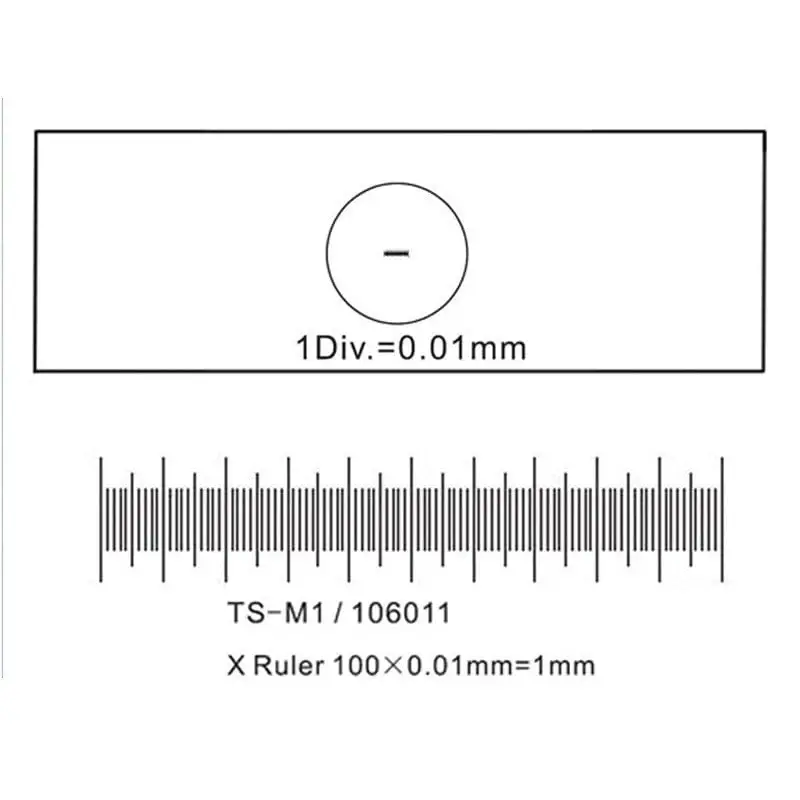

- A fine scale is engraved/etched on a glass slide of known length (usually 1 mm = 100 divisions), which represent each division as 0.01 mm or 10 µm.

- When this micrometer slide is placed on the stage, its scale is viewed at same time with ocular micrometer inside the eyepiece.

- Both scales are superimposed, and comparison is made between the known stage scale and unknown eyepiece scale to find the calibration ratio.

- This ratio tells how many divisions of ocular micrometer are equal to a known real distance on the stage micrometer, under a particular magnification.

- After that, this calculated conversion factor is used for measuring the actual size of microscopic objects—like cells, pollen grains, microorganisms etc.

- The principle therefore rely on direct comparison between real-world distance and microscope scale distance, which make the measurement accurate & reliable.

- Once calibration is done, stage micrometer is removed, and only calibrated eyepiece micrometer is used for measurement purpose.

Parts of Stage micrometer

- Microscope Glass Slide – it acts as base/foundation of the instrument. The fine scale is marked on this surface for calibration purpose.

- Scale – the main measuring reference of stage micrometer. It’s a precisely ruled line scale usually 1 mm long divided into 100 equal divisions (each 0.01 mm or 10 µm). This known division is used to calibrate microscope eyepiece.

- Substrate Material – usually made from thin glass or sometimes opal material, which give clear visibility of scale under light microscope.

- Scale Image / Pattern – it’s the etched pattern of lines made on the surface. For transmitted light (bright field) it appears as dark lines on clear background, while for reflected light it’s reversed (clear lines on dark).

- Image Coating – a thin layer (like chrome coating) is applied during manufacturing to create durable and visible markings on scale.

- Glass Disc – a small circular plate (around 16 mm dia) on which the scale or reticule pattern is centered.

- Cover Glass (Coverslip) – placed over the scale to protect it from dust, scratches, and damage, also it helps in simulating actual specimen viewing condition.

- Slide Mount / Frame – standard slide size 75 mm × 25 mm.

- ‘S’ series mount made of black anodised aluminum for regular calibration.

- ‘PS’ series mount made of stainless steel, used when ISO certification or traceable result is needed.

- Engraved Serial Number – present in ‘PS’ type slide; important for traceability in quality control and ISO documentation.

- Reticule (Pattern) – a grid or line pattern which helps in aligning the stage micrometer correctly on the microscope stage.

- Mounting Hole – the central hole used for fixing/holding the micrometer slide firmly on the microscope stage.

- Calibration Mark – the specific point on scale used as reference to check calibration accuracy during measurement.

- Nanometer / Micrometer Scale – some advanced micrometers have additional finer divisions allowing measurement in nm or µm ranges.

- Storage Box – protective case, made of plastic or polished wood (depending on S or PS series) for safe storage and transport.

Types of Stage Micrometer

A. Based on Scale Design / Measurement Function

- Linear Stage Micrometer – it is the most common and simple type. Have a straight linear scale divided into equal known units (µm or nm). Used mainly for general calibration and linear measurement of specimen length.

- Rotary Stage Micrometer – this type has a rotatable scale, so angle or direction can be changed without shifting the stage. Commonly used in optical setups, materials science for angular calibration purpose.

- • Crossed-Line Stage Micrometer – consist of two perpendicular lines forming a cross pattern. Useful for measuring objects which are not parallel to main axis of the micrometer.

- • Crossed-Graduated Stage Micrometer – contain two full scales at right angles, which permit measurement in both X and Y directions (2D measurement).

- • Multi-Scale Stage Micrometer – have multiple scales printed/etched on one slide, sometimes with different units, giving more flexibility in measurement.

- • Specialized Stage Micrometer – designed for very specific or research purpose like analyzing particle size, surface defects, etc.

- • Digital Stage Micrometer – advanced type having a digital display unit. It provide high accuracy reading, mostly used where precision calibration is essential.

B. Based on Physical Construction/ Traceability

- ‘S’ Series (Standard Type) – made for everyday calibration work. The glass disc is fixed in black anodised aluminum slide (75 mm × 25 mm). No serial number, so it’s not traceable but economical and durable, usually kept in plastic box.

- ‘PS’ Series (Precision Type) – meant for ISO/NIST traceable calibration. The disc is mounted in stainless-steel frame and engraved with unique serial number for identification. Usually stored in polished wooden box for safe keeping.

C. Based on Light Type Used

- Transmitted (Brightfield) Light Micrometer – used when light comes from below specimen. Have positive image i.e., dark opaque lines on clear background.

- Reflected (Incident) Light Micrometer – used for top illumination microscopes, like metallurgical types. Have negative image pattern (clear lines on opaque background).

How to Use Stage micrometer – Procedure of Stage micrometer

- First, the objective lens of the microscope is chosen (10X, 40X, etc.) because calibration depends on the magnification used.

- After that, the ocular micrometer (reticle) is inserted into the eyepiece by removing the top lens carefully. It should fit properly on the circular shelf.

- The ocular micrometer normally has 100 equal divisions (0–100) but they are not any real units yet. These divisions remain the same for all objectives.

- Now the stage micrometer slide (known scale) is placed on the microscope stage, above the light source, and fixed properly by stage clips.

- By using coarse and fine focus the stage micrometer scale is made to be seen clearly and is brought to the center of the field of view. Always work with the low power objective first.

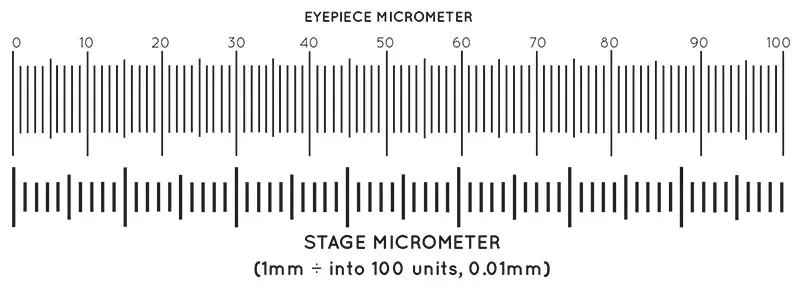

- The lines on the eyepiece scale and stage scale should be parallel. For that, the eyepiece may be slightly rotated and the stage adjusted until the lines look aligned.

- The next step is the superimposition of zero points – the zero lines of both scales are matched exactly at one side. This mark will be considered as a reference.

- If you don’t change the position, look for the next line on the ocular micrometer that corresponds to a line on the stage micrometer (farthest on the right side usually).

- Count the number of Ocular Divisions (OD) between the two points that coincide. Also, count how many Stage Micrometer Divisions (SMD) are between them.

- The value of each SMD is 10 µm (0.01 mm), so the total known distance = No. of SMD × 10 µm.

- Then find 1 OD value (conversion factor) by calculating:

- 1 OD (µm) = (No. of SMD × 10 µm) ÷ No. of OD

- For example, when 40 OD corresponds to 60 SMD:

- total known distance = 60 × 10 = 600 µm;

- value of 1 OD = 600 / 40 = 15 µm.

- This conversion factor is kept for each objective lens separately (low, high, oil immersion). If the objective/eyepiece is changed calibration must be done again.

- After the calibration, the stage micrometer is taken out carefully and the actual specimen slide is put in its place.

- Focus on the specimen and determine how many divisions of the ocular scale the cell or microorganism has covered.

- To get the real size (length, breadth, diameter, etc.) in micrometers just multiply the number of divisions by the factor that was calculated earlier.

- By all means, a microscope and micrometers must be kept clean and properly aligned, otherwise calibration errors can be made quite easily.

Calibration of Eyepiece Graticule with stage micrometer Video

Precaution of Stage micrometer

- The Stage Micrometer must be handled carefully, because it is made of thin glass that easily get cracked or chipped.

- It should always be cleaned with soft tissue / lens paper, never by rough cloth or finger touching.

- Before use, the scale surface must be checked that no dust or oil spots are present, otherwise reading error occur.

- The micrometer slide should not be placed upside-down; correct orientation is ensured before focusing.

- After use it is advised that the slide is kept inside its storage box (plastic or wooden) to avoid scratch and contamination.

- It should not be exposed to direct sunlight or strong heat for long, because scale coating (chrome or metal film) may get damaged.

- Always make sure the microscope stage is dry and clean before mounting the micrometer, moisture can make it slip slightly.

- During calibration, both stage and ocular micrometer must be well focused — mis-focusing can produce wrong coincidence.

- Do not use excessive pressure while fixing the slide clips; gentle placement is enough to hold it firmly.

- The objective lens should never touch the micrometer surface; contact may cause scratch on both lens & scale.

- When changing objectives, the micrometer should be refocused slowly to avoid sudden collision.

- Calibration results must be written down immediately after measurement, because human memory not always reliable.

- It is better to repeat calibration time to time, as alignment may drift with regular usage of microscope.

- The slide number / series (S or PS) should be verified if traceable calibration is needed for ISO or quality purpose.

- Overall, the Stage Micrometer is delicate and must be treated like a permanent standard, not like normal slide.

Applications of Stage micrometer

- The Stage Micrometer is mainly used for calibration of the ocular micrometer, so that accurate measurement of microscopic objects can be done.

- It is applied for determining actual size (length, width, or diameter) of cells, microorganisms, pollen grains, etc. after calibration.

- Used in biological laboratories for standardizing measurement between different microscopes or users.

- Applied in material science and metallography for size estimation of metal grains, crystals, and surface defects.

- The micrometer help to check the magnification accuracy of different objective lenses, which sometimes vary slightly from nominal values.

- It is used for instrument validation and routine maintenance of optical systems (quality control / ISO procedures).

- The stage micrometer assist in comparing calibration between different light types (transmitted or reflected) during microscope alignment.

- It can also be used for training purpose, allowing students to understand relation between stage and ocular measurement scales.

- Sometimes it is used in research imaging calibration, to match pixel size of digital camera with real physical distance.

- The micrometer helps in establishing traceability of microscope measurement results with international standard values.

- It’s also useful for testing focus accuracy and optical alignment of microscope lenses.

- In pathology and microbiology labs, it aids in morphometric studies, where small structures like spores, nuclei, or fibers are measured.

- It can be used for demonstration of calibration principle during microscopy practicals in teaching institutes.

Advantages of Stage micrometer

- The Stage Micrometer provide a known reference scale, which makes accurate calibration of microscope possible.

- It is very simple to use and can be applied with almost any light microscope without modification.

- The calibration done by stage micrometer is reliable and repeatable, ensuring consistency between different microscopes.

- Because of its fixed known divisions (usually 10 µm each), it allows true size measurement of microscopic specimens.

- The device is durable and reusable, if handled carefully, so it can serve for many years in routine work.

- It help to detect magnification errors among objectives and correct them easily.

- It is cost-effective compared with electronic calibration tools or digital measurement systems.

- The stage micrometer can be used for both transmitted / reflected light microscopes, depending on scale design.

- It doesn’t require any complex maintenance—only cleaning and safe storage are sufficient.

- The traceable versions (PS series) support ISO / NIST quality verification and provide high-level measurement confidence.

- It offers a visual demonstration of calibration principle, useful for teaching and laboratory training purpose.

- Calibration once done helps in saving time during multiple specimen measurement sessions.

- It is lightweight, portable, and fits in normal microscope slide holder, no extra attachment needed.

- The stage micrometer acts as a universal standard, applicable across biological, industrial, and research microscopy fields.

Limitations of Stage micrometer

- The Stage Micrometer is very delicate, made of thin glass, and can break or scratch easily if mishandled.

- Calibration must be repeated for each objective lens, which takes extra time and may cause error if skipped.

- The accuracy of result highly depend on proper alignment between stage and ocular scales, which sometimes not achieved perfectly.

- It can’t be used directly for specimen measurement — only after calibration of ocular micrometer, which add extra step.

- The scale divisions may become unclear or faded after long use or due to improper cleaning chemicals.

- Dust or oil particles on scale may create parallax or blurry lines, leading to wrong readings.

- Slight focusing error during calibration can make large measurement deviation, especially under high magnification.

- It provide linear calibration only, not suitable for measuring curved or irregular-shaped specimens.

- The micrometer cannot compensate for optical distortions caused by microscope lenses or misalignment.

- It require skilled handling — beginners may miscount coinciding lines or mix up scales easily.

- The resolution limit is fixed by its engraving (usually 10 µm); finer calibration below that not possible with standard slide.

- It is not convenient for digital image-based systems, unless the image scale is separately calibrated again.

- The temperature or humidity can slightly affect metal coating or cause glass expansion, reducing precision.

- Frequent calibration using same slide may wear the coating or mark, lowering accuracy over time.

- In some microscope with small stage size, proper mounting of micrometer slide may be difficult or unstable.

FAQ

What is a stage micrometer?

A stage micrometer is a precision measurement tool used in microscopy to calibrate eyepiece graticules and measure the size of objects viewed under a microscope.

How does a stage micrometer work?

A stage micrometer consists of a calibrated scale divided into known units, typically micrometers (µm) or nanometers (nm). When placed on the microscope stage, the divisions on the scale are used as a reference to measure the size of objects observed through the eyepiece.

What are the common units of measurement on a stage micrometer?

Stage micrometers typically have scales calibrated in micrometers (µm) or nanometers (nm). Some may offer additional units like millimeters (mm) or microns.

How do I use a stage micrometer to calibrate a microscope?

To calibrate a microscope, place the stage micrometer on the stage, focus on the scale, and count the number of divisions that match a specific length on the eyepiece graticule. Then, use the known length of the stage micrometer to determine the magnification of the eyepiece graticule.

Can I use a stage micrometer with any microscope?

In most cases, yes. Stage micrometers are compatible with various microscopes that have a standard stage size and an adjustable eyepiece graticule.

Are stage micrometers fragile?

Yes, stage micrometers are delicate instruments, usually made of glass or plastic. Proper handling and care are essential to prevent damage.

How accurate are stage micrometers?

The accuracy of a stage micrometer depends on its quality, calibration, and the user’s skill in making precise measurements. Generally, they offer high accuracy in measuring microscopic objects.

Can I measure moving objects with a stage micrometer?

While it is possible to measure moving objects with a stage micrometer, it can be challenging to keep the micrometer in focus during the measurement process.

What are the main applications of stage micrometers?

Stage micrometers are widely used in biology, chemistry, physics, engineering, and quality control to measure the size of microscopic objects and calibrate microscopes.

How do I clean and store a stage micrometer?

Clean the stage micrometer with a soft cloth and avoid using harsh chemicals or solvents. Store it in a safe, clean place away from dust, dirt, and moisture to ensure its longevity and accuracy.