HACCP, short for Hazard Analysis Critical Control Points, is a practical system designed to keep food safe throughout its production. Rather than relying solely on end-product testing, it tackles potential risks—like harmful bacteria, unwanted chemicals, or even physical hazards—by spotting where things could go wrong during processes like cooking, cooling, or packaging. Once these critical points are identified, specific controls, such as temperature checks or hygiene practices, are put in place to minimize risks. Teams regularly monitor these steps and adjust if something slips off track, ensuring consistent safety. Used everywhere from local eateries to large-scale food factories, HACCP’s proactive approach helps businesses stop problems before they start, keeping food trustworthy and people protected.

What is HACCP (Hazard Analysis and Critical Control Points)?

- Focused on finding, assessing, and managing risks all through the food production process, Hazard Analysis and Critical Control Point (HACCP) is a methodical, scientifically based approach to food safety management. ,

- Three basic kinds of hazards are addressed by HACCP:

- Biological risks including parasites, viruses, and bacteria.

- Chemical dangers including poisons and pollutants.

- Physical risks include glass shards or metal particles.

- Rather than depending just on end-product testing, HACCP’s main objective is to prevent food safety concerns by putting control measures at key stages in the production process.

- NASA first developed HACCP in the 1960s in association with the Pillsbury Company to guarantee food safety for space travellers.

- The approach became well-known in the 1970s when Pillsbury used HACCP ideas to handle a baby food contamination event.

- With regulatory bodies like the FDA and USDA including HACCP into its food safety rules, it evolved as the main food safety method used in the United States in the 1980s and 1990s.

- Established by the FAO and WHO, the Codex Alimentarius Commission endorsed HACCP as a worldwide food safety management benchmark in 1997.

- Because it offers a proactive approach to food safety and lets one find and mitigate possible problems before they might endanger customers.

- From basic production to final consumption, the system is relevant at all phases of the food supply chain and a complete instrument for guaranteeing food safety. Often combined with additional criteria, including ISO 22000, HACCP is acknowledged as a basic component of food safety management systems and helps to improve food safety and quality assurance.

- Through emphasising prevention, HACCP helps lower the foodborne disease incidence and builds customer trust in the safety of food items.

Definition of HACCP

HACCP stands for Hazard Analysis and Critical Control Points. It is a systematic, preventive approach to food safety that identifies, evaluates, and controls biological, chemical, and physical hazards throughout the food production process. The system aims to ensure that food is safe for consumption by preventing hazards before they occur, rather than relying solely on end-product testing.

HACCP is based on seven principles: conducting a hazard analysis, determining critical control points (CCPs), establishing critical limits, monitoring CCPs, establishing corrective actions, verifying the system, and maintaining documentation and records. The implementation of HACCP is essential for food businesses to comply with legal requirements and to demonstrate a commitment to food safety and quality.

Origins and History of HACCP

- Hazard Analysis and Critical Control Points (HACCP) have its roots in the 1960s, when the Pillsbury Company created a food safety system to guarantee astronaut meal safety working with NASA and the U.S. Army Natick Laboratories.

- Moving from conventional end-product testing to a system that recognised and regulated possible dangers at certain moments throughout food manufacturing, the main goal was to develop a proactive approach to food safety.

- The Pillsbury Company formally introduced the method in 1973 when it released the first HACCP plan.

- The approach first became well-known in the 1980s when the U.S. National Academy of Sciences advised its use for food safety control.

- The European Union confirmed its importance in world food safety standards by 1990 when it mandated the application of HACCP in all food companies.

- Beginning their advocacy for HACCP in the 1970s, the Food and Agriculture Organisation (FAO) and the World Health Organisation (WHO) helped to encourage its acceptance all around.

- Establishing worldwide rules for HACCP in 1993, the Codex Alimentarius Commission—a joint effort of WHO and FAO—created a foundation for its implementation anywhere.

- From its beginnings in space food safety to a basic component of food safety management systems worldwide, HACCP has developed throughout time utilised in many areas including agriculture, industry, and food service.

Main HACCP milestones

1960s: NASA, the Pillsbury Company, and the U.S. Army Laboratories collaborated to develop HACCP to ensure the safety of space food.

1971: The HACCP concept was publicly presented at the National Conference on Food Protection.

1972: HACCP principles were used to educate food facilities through a course titled “Food Safety through the Hazard Analysis and Critical Control Point System,” aimed at FDA inspectors for inspecting canned foods.

1974: The FDA applied HACCP principles in regulating low-acid canned foods to eliminate incidences of botulism.

1980s: Major food companies adopted the HACCP approach to enhance food safety.

1991: The National Advisory Committee on Microbiological Criteria for Foods (NACMCF) of the USDA published a report setting forth the basic principles of HACCP.

1993: The Codex Alimentarius Commission adopted guidelines for applying HACCP during its 20th session.

2003: The FAO and WHO were appointed to develop HACCP guidelines for small and less-developed businesses (SLDBs), highlighting potential obstacles and approaches to overcome them.

2020: The Codex General Principles of Food Hygiene were revised, and HACCP was included as an integral part of the text.

HACCP Aim

- To guarantee food safety, the Hazard Analysis and Critical Control Point (HACCP) system primarily seeks to proactively find, assess, and manage biological, chemical, and physical dangers all through the food manufacturing process.

- Unlike depending just on end-product testing, HACCP emphasises on avoiding risks, therefore lowering the risk of foodborne diseases and guaranteeing that food items are safe for consumption.

- Food companies may define quantifiable limits and create key control points by using HACCP, thus allowing them to monitor and manage risks properly, so producing consistent product quality and safety.

- Maintaining high levels of food safety management depends on the system encouraging a culture of food safety inside businesses, therefore fostering responsibility and ongoing improvement among personnel.

- Compliance with HACCP not only guarantees consumer safety but also improves a company’s reputation, promotes customer trust, and provides access to foreign markets needing adherence to acknowledged food safety criteria.

Main characteristics of HACCP

- Designed as a preventative, scientific-based method, HACCP seeks to find, assess, and manage food safety risks all through the food manufacturing process.

- From raw material manufacture to consumption, the system emphasises managing biological, chemical, and physical threats to guarantee food safety at every level.

- Seven fundamental ideas underlie HACCP and offer a methodical means of hazard control:

- Investigate dangers to food safety using a hazard analysis.

- Find key control points (CCPs) from which one may apply control to either prevent or eradicate threats.

- Set crucial limits for every CCP to guarantee under control of dangers.

- Provide monitoring systems to guarantee every CCP remains within its critical limitations.

- Create corrective action plans to follow should monitoring show a departure from set boundaries.

- Create validation protocols to verify the HACCP system is operating as it should.

- Create documentation and record-keeping systems to show the above mentioned actions are applied effectively.

- To provide a strong basis for the HACCP plan, HACCP calls for the adoption of precondition programs including Good Hygienic Practices (GHP).

- To keep control over food safety risks and guarantee the efficiency of the HACCP strategy, the system stresses constant monitoring and validation.

- Promoted by national and regional agencies as a benchmark for food safety management, HACCP is known worldwide.

- From basic manufacturing to ultimate consumption, the method is relevant at all phases of the food supply chain, therefore providing a complete instrument for guaranteeing food safety.

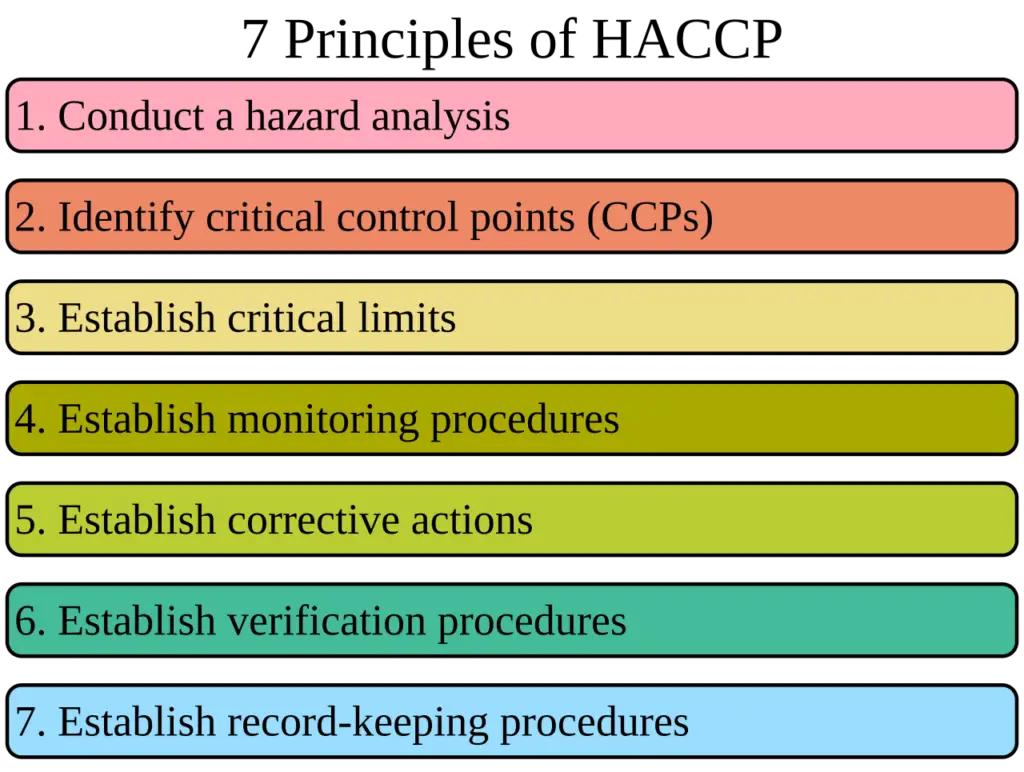

The Seven Principles of HACCP

The principles of the Hazard Analysis and Critical Control Point (HACCP) system provide a structured approach to food safety by identifying and managing risks at critical points in the food production process. Below are the key principles:

- Principle 1 – Conduct a hazard analysis

- The first principle involves determining the food safety hazards—biological, chemical, or physical—that may make food unsafe for human consumption.

- It also involves identifying the preventive measures that can be applied to control these hazards during production.

- Principle 2 – Identify critical control points (CCPs)

- A Critical Control Point (CCP) is a specific step, point, or procedure in the food production process where control can be applied to prevent, eliminate, or reduce a food safety hazard to an acceptable level.

- These points are crucial in ensuring the safety of the final product.

- Principle 3 – Establish critical limits for each CCP

- A critical limit is the maximum or minimum value to which a biological, chemical, or physical hazard must be controlled at each CCP.

- These limits are set to prevent, eliminate, or reduce the hazard to a safe level.

- Principle 4 – Establish critical control point monitoring requirements

- Monitoring is necessary to ensure that each CCP is under control.

- The monitoring procedure, including the frequency, should be clearly defined in the HACCP plan to verify that critical limits are being met.

- Principle 5 – Establish corrective actions

- When monitoring indicates a deviation from the established critical limit, corrective actions must be taken to ensure food safety.

- The corrective actions are designed to prevent hazardous products from entering the market and ensure that no food products are unsafe due to the deviation.

- Principle 6 – Establish procedures for ensuring the HACCP system is working as intended

- Validation: This ensures that the HACCP plan is successful in producing safe food. It requires scientific evidence to prove that the measures implemented are effective in controlling hazards.

- Verification: This involves checking whether the HACCP system is working as intended, which includes reviewing records, conducting microbial testing, and ensuring that the procedures are followed properly.

- Principle 7 – Establish record-keeping procedures

- Comprehensive record-keeping is essential to demonstrate compliance with the HACCP system.

- Documentation should include the hazard analysis, the HACCP plan, monitoring activities, verification procedures, corrective actions, and any deviations encountered during production.

- These records should be maintained for regulatory compliance and future audits.

Steps in HACCP Analysis

Here is the steps of HACCP Analysis;

- Stage 1 Assemble the crew

- The team comprises one quality assurance or quality control professional, one manufacturing specialist, one engineer, one buyer, and one operator.

- Stage 2 Establish Terms of Reference

- Terms must specify whether product safety is assessed at the point of consumption or at the time of production, and must provide explicit storage and usage directions.

- Stage 3 Elucidate the product

- Processing procedures for document composition structure, packaging system, storage and distribution circumstances, needed shelf life, and usage instructions.

- Stage 4 Determine the consumer’s intended usage

- Detail the manner and individuals responsible for utilising the product, including any vulnerable groups.

- Stage 5 Develop a flowchart.

- Detail each processing phase sequentially, commencing from the receipt of raw materials to the final delivery.

- Stage 6 On-site validation of flowchart

- Examine the operation to verify that the diagram appropriately reflects the real process flow.

- Stage 7 List all hazards and control measures

- Identify biological, chemical, and physical dangers at each stage and enumerate strategies to mitigate them.

- Stage 8 Utilise the HACCP decision tree to determine important control points.

- Utilise a logical flow or decision tree to identify stages where controls can mitigate, diminish, or eradicate dangers.

- Stage 9 Establish target levels and tolerances for each CCP

- Establish quantifiable factors such temperature, time, pH, moisture, or chemical thresholds for each control point.

- Stage 10 Establish a monitoring system for each CCP

- Detail the monitoring parameters, frequency, accountable parties, and record-keeping methods.

- Stage 11 Formulate a remedial action plan

- Outline the procedures to follow when monitoring indicates a deviation, encompassing product disposal and documentation requirements.

- Stage 12 Implement record-keeping and documentation

- Document the quality of raw materials, team assignments, product descriptions, flow diagrams, and associated dangers. Critical limitations of CCPs rectifying discrepancies in cleaning logs and implementing remedial measures

- Stage 13 Verification

- Perform internal audits Examine discrepancies in market surveys and reaffirm important thresholds to guarantee system efficacy.

- Stage 14 Review HACCP plan

- Periodically reassess the entire HACCP system and update plan to reflect process changes new hazards or regulatory updates

Applications of HACCP

- Food manufacturing and processing:

- In food processing and manufacturing, HACCP is extensively used to guarantee product safety by means of hazard identification and management at pivotal stages in the production process.

- It applies to meat, dairy, fish, and canned goods as well as consumer safety depends on limiting biological, chemical, and physical dangers.

- To guarantee food safety, meat facilities must, for example, follow and preserve hygienic practices grounded on HACCP ideas.

- Food Service and Catering:

- By means of control mechanisms established throughout food handling, preparation, and storage, HACCP aids in addressing food safety hazards in food service enterprises like restaurants and catering services.

- HACCP used in these environments guarantees that food presented to consumers is safe and free of infection.

- Retail and Distribution:

- HACCP is applied by distributors and retailers to track and manage food safety hazards during food product transit and storage.

- Using HACCP in retail and distribution guarantees food goods stay safe from the point of origin to the customer.

- Export and International Trade:

- Many times, exporting food items to foreign markets requires HACCP certification as it shows a dedication to food safety and adherence to international guidelines.

- For imported food goods, countries and areas may demand HACCP certification to guarantee they satisfy safety criteria.

- Regulatory Compliance:

- Many nations have mandated the use of HACCP as a legal obligation for food companies in order to guarantee public health and food safety.

- For instance, food companies in the UK have to follow and keep hygienic practices grounded on HACCP concepts.

- Small and Medium Enterprises (SMEs):

- Providing a methodical way to control food safety hazards, HACCP is flexible enough for companies of all kinds—including small and medium ones.

- MyHACCP tools let SMEs create and apply food safety management systems based on HACCP, catered to their particular requirements.

- Quality Management Systems:

- To offer a complete strategy to control food safety and quality, HACCP may be combined with other quality management systems as ISO 9000 series.

- This integration guarantees that food safety is kept in line with other quality criteria, therefore enhancing the whole quality of the products.

- Training and Education:

- Training food industry employees in food safety procedures is based on HACCP, which guarantees staff members’ expertise on hazard identification and control strategies.

- Maintaining successful HACCP systems and adjusting to new food safety concerns depend on continuous education and training.

Advantages of HACCP

- Enhances operational efficiency through a thorough review of food production and handling operations to optimise procedures and eradicate extraneous stages.

- Concentrates food safety resources on essential control points, diminishing dependence on expensive and laborious end-product inspection and testing.

- Reduces product recalls by prioritising preventative control methods that identify and address safety concerns prior to product distribution.

- Reduces medium- and long-term operational expenses for small and underdeveloped enterprises (SLDBs) via enhanced personnel allocation, optimised documentation systems, and minimised product waste.

- Establishes a legal defence framework and may lower insurance prices by evidencing due diligence and compliance with preventative safety requirements.

- Augments the competitiveness of HACCP-compliant enterprises in local and international markets by indicating compliance with elevated safety requirements.

- Facilitates regulatory inspections by the maintenance of systematic documentation and monitoring records that evidence process control and compliance.

- Facilitates commerce by enhancing consumer and buyer trust in food product safety, thereby broadening market access.

- Enhances international trade by conforming to globally acknowledged, science-based safety standards and synchronising safety requirements across nations.

Disadvantages of HACCP

- Effective HACCP implementation is much hampered by staff members without experience and training. Many staff members could not completely grasp HACCP ideas or how to spot and handle important control points (CCPs), which would result in incorrect implementation and maybe food safety hazards.

- High implementation costs present difficulties particularly for small and medium-sized businesses (SMEs). Training, equipment, and paperwork associated expenses might be costly, therefore restricting the capacity of these companies to implement HACCP systems.

- Complexity in creating and keeping a HACCP strategy may overwhelm companies. Thorough hazard analysis, risk assessment, and frequent updates—all of which are part of the process—can be time-consuming and financially taxing.

- Insufficient resources and infrastructure impede good application. Certain facilities could lack the required physical infrastructure or tools to implement HACCP procedures, therefore posing difficulties in hazard monitoring and management.

- Adoption of HACCP might be hampered inside companies by resistance to change. Management and staff members might be hesitant to change accepted procedures, particularly if they believe the new approach is complicated or onerous.

- HACCP implementation is complicated by different standards and regulatory difficulties throughout areas. Variations in food safety rules and standards can lead to uncertainty and contradictions, therefore challenging companies’ ability to comply properly.

- Food company owners’ limited knowledge of HACCP adds to its underuse. Ignorance of the advantages and requirements of HACCP might keep companies from appreciating it and applying it correctly.

- Requirements for records and documentation might be onerous. While HACCP compliance depends on maintaining accurate and comprehensive records, for companies with limited administrative resources this can be time-consuming and difficult.

- Constant improvement of the HACCP system and ongoing maintenance need for persistent effort. Regular evaluations, upgrades, and training help to guarantee that the system is efficient—which can be challenging for companies.

- HACCP efficacy can be influenced by environmental variables and supply chain variance among other external elements. Within a HACCP system, variations in raw material quality, transportation problems, and environmental variables including temperature and humidity can create risks difficult to manage.

- Legal and legal issues might discourage companies from using HACCP. Organisations may be determented from implementing thorough food safety management systems by fear of more responsibility and possible legal consequences.

Foods under the control of HACCP

Meat and Poultry Products: Mandatory HACCP plans are required for meat and poultry manufacturers under U.S. regulations, specifically 9 CFR part 417.

Juices: Juice manufacturers must implement HACCP plans in accordance with 21 CFR part 120 to ensure safety.

Seafood: Seafood manufacturers are required to have HACCP plans under 21 CFR part 123 to address potential hazards.

Dairy Products: Dairy items such as milk, cheese, and yogurt are subject to HACCP controls due to risks like microbial contamination.

Eggs and Egg Products: Raw and cooked eggs, as well as dishes containing eggs, require HACCP oversight to prevent salmonella risks.

Cooked Rice and Pasta: These foods are susceptible to bacterial growth and require time-temperature controls under HACCP.

Cut Fruits and Vegetables: Items like cut melons, leafy greens, and tomatoes need HACCP management to prevent microbial hazards.

Ready-to-Eat Foods: Sandwiches, salads, and similar ready-to-eat items are under HACCP control to mitigate contamination risks.

Canned Foods: Low-acid canned foods are regulated under HACCP principles to prevent botulism and other risks.

Fresh Produce: Certain fresh produce items may require HACCP plans, especially when cut or processed, to ensure safety.

Foods with High Moisture and Protein Content: Foods that are moist and protein-rich are particularly vulnerable to microbial growth and are thus controlled under HACCP.

Foods with pH Between 4.6 and 7.5: These foods, due to their pH level, can support the growth of pathogens and require HACCP management.

Foods Requiring Time-Temperature Control: Any food that needs to be kept at specific temperatures to prevent microbial growth is subject to HACCP.

Foods with Potential for Toxin Formation: Certain foods can support the formation of toxins if not properly controlled and are thus under HACCP oversight.

Foods with Specific Water Activity (a_w) and pH Combinations: Foods with certain a_w and pH values may require HACCP plans to prevent microbial hazards.

Foods with Modified Atmosphere Packaging (MAP): Foods packaged in modified atmospheres need HACCP controls to ensure safety.

Foods with Extended Shelf Life: Products designed for longer shelf life require HACCP management to prevent spoilage and contamination.

Foods with Specific Storage and Use Temperature Ranges: Foods that must be stored and used within specific temperature ranges are controlled under HACCP to maintain safety.

Foods with Preservatives or Antimicrobials: Foods containing added preservatives or antimicrobials may still require HACCP plans to ensure they remain safe for consumption.

Foods with Specific Packaging Types: Certain packaging types, like vacuum-sealed or hermetically sealed containers, require HACCP oversight to prevent contamination.

Foods with Specific Shelf Life and Use Conditions: Foods with defined shelf life and use conditions are subject to HACCP to ensure they are consumed within safe time frames.

Foods with Specific Temperature Ranges for Storage and Use: Maintaining specific temperature ranges for storage and use is critical for certain foods under HACCP control.

Foods with Specific Intrinsic and Extrinsic Factors: The combination of intrinsic factors (like pH) and extrinsic factors (like storage conditions) can determine the need for HACCP plans.

Foods with Specific Product Assessments: Some foods require product assessments to determine if they need HACCP plans based on their characteristics.

Foods with Specific Food Safety Risks: Any food identified with specific food safety risks necessitates a HACCP plan to manage those risks effectively.

Foods with Specific Food Safety Management Systems: Implementing food safety management systems, including HACCP, is essential for foods with identified risks.

Foods with Specific Food Safety Regulations: Compliance with food safety regulations, including HACCP requirements, is mandatory for certain foods.

Foods with Specific Food Safety Standards: Adhering to food safety standards, such as HACCP, ensures the safety of specific foods.

- https://iufost.org/iufostftp/sadc_sec4_mod14_haccp.pdf

- https://food.unl.edu/article/haccp-seven-principles/

- https://openknowledge.fao.org/server/api/core/bitstreams/a56f938c-7e92-4ffe-a901-f4494a2eeb64/content

- https://seafoodacademy.org/pdfs/haccp-training-folder-contents-v2.pdf

- https://unacademy.com/content/kerala-psc/study-material/food-microbiology/hazard-analysis-critical-control-point-haccp/

- https://www.fda.gov/food/hazard-analysis-critical-control-point-haccp/haccp-principles-application-guidelines