Culture medium refers to the nutrient-rich substance that is used in labs to culture microorganisms such as bacteria and fungi. These materials, whether liquid or solid, provide the microbes with needed nutrients, minerals and other factors for growth and reproduction according to step-by-step reports from authoritative sources around the world.

The late 19th century was the time of birth for culture media when examination of micro-organisms became systematic. Louis Pasteur, a French microbiologist, was one of the major figures in this work: he made different media for cultivating characteristic bacteria. Thus, he was able to study the qualities and actions of these tiny forms of life, allowing his successors to appreciate their role in sickness or else decode them for application in new drugs.

The importance of culture media is that it enables micro-organisms to be grown and multiplied in controlled conditions. Hence, scientists are able to study microorganisms in greater depth; they come to understand their characteristics, behavior patterns, and even potential uses. Culture media are also used to manufacture antibiotics, vaccines and other biotechnological products. More important still, the study of microorganisms in cultural medium has become an essential requisite for the fields of medical and veterinary microbiology, agriculture and food safety, environmental science, etc.

What are the basic Components of Culture Media?

Culture media, which support microbe and cell growth, require certain components. Chemical, organic, and synthetic ingredients balance cellular growth and metabolism.

- Carbon Sources

Cellular energy generation requires carbon. Sugars like glucose and fructose or organic acids like lactic acid feed microorganism metabolism and development. Growth is unsustainable without these energy-rich molecules. - Nitrogen Suppliers

Protein and nucleotide synthesis requires nitrogen. Nitrogen from ammonium salts, nitrates, and peptones helps cells develop structural components. - Minerals, trace elements

Zinc, iron, and magnesium are essential even in little levels. Enzymatic processes and survival metabolic pathways need them as cofactors. - pH-buffers

Optimal enzymatic activity and cell stability need pH management. Calcium carbonate, ammonia, and sodium hydroxide buffer the medium to maintain an acceptable range. A pH approaching 7.0 suits most bacteria. - Solidifiers

Solidifying culture medium with agar and gelatin lets researchers analyze specific microbial colonies. These substances are necessary for microorganism isolation and observation. - Growth Factors

Not all cells can thrive without nourishment. Growth factors like vitamins and amino acids are used to promote cell division and replication. - Antimicrobials

The medium may contain antibiotics to avoid contamination. These chemicals inhibit undesirable microbial development, allowing selective culture. - Inorganic Salts

Osmotic balance and membrane potential of cultivated cells are maintained by sodium chloride, potassium chloride, and calcium ions. - Buffered Systems

Natural or manmade buffers stabilize pH:- Natursysteme: Balances between CO₂ and bicarbonate ions are cost-effective but need regulated conditions like incubators.

- Synthetic HEPES buffers are stable yet costly and harmful. The pH is maintained without gaseous control.

- Amino Acids

Nitrogen-rich amino acids like L-glutamine are needed for protein synthesis. These chemicals break down into cell-damaging ammonia. So they’re inserted right before usage. - Peptides, Proteins

Serum-free medium contains albumin and transferrin. Biomolecules eliminate toxins, control transport, and improve cell adhesion. - Vitamins

Vitamins like the B complex supplement culture medium, especially when serum is missing, to support metabolism and development. - Fatty Acids, Lipids

Lipidomes and fatty acids are energy and structural components taken from serum in standard media or added separately in serum-free formulations. - Media Extras

Some cell lines need hormones, growth factors, and other substances. These supplements boost metabolism but change osmolality, therefore balance is needed to avoid growth suppression. - Serum

Serum, a complex mixture of proteins, growth factors, and vitamins, nurtures cells. It reduces mechanical stress and improves adhesion, but its concentration must be managed at 1% to 10%.

General Procedure of Culture Media Preparation

Materials/Equipment Requirement

- Pyrex flask (conical flask) at least double the size of the batch

- Magnetic Stir Bar

- Aluminum Foil

- Weighing machine

- Dehydrated culture media

- Spatula

- Graduated cylinder

- Distilled or deionized water

- Hot plate stirrer

- Autoclave

- Sterile Petri plates,

- Infrared no-touch thermometer

Step By step Procedure

Step 1: Calculation and Weighing

Precision matters. Calculate the correct dehydrated medium amount. Maintain clean balances, tables, and containers to avoid infection. A dry, low-humidity atmosphere is best. Accurate measurements require calibrated precision balances. Avoid irritating exposure by using gloves and glasses when handling. To track lot numbers, preparation dates, and operator initials, log them.

Step 2: Mixing with Water and Heating

Start with distilled or deionized water—tap water may have pH fluctuations and contaminants. Add half the water to a borosilicate flask before adding medium powder. Mix carefully. Pre-heat water to 50–60°C for quicker dissolving. Ensure no powder sticks to the flask sides by slowly adding the remaining water. Agar should be heated until transparent, but not boiled, to avoid foaming or uneven mixing.

Step 3: Sterilisation

No negotiation on sterilization. Set an autoclave to 121°C for 15 minutes. Prepare liquid media in bottles or tubes with unfastened tops for steam penetration. After sterilization, cool molten agar to 50°C before putting into Petri plates. Use chemical or biological markers to accurately monitor autoclave cycles to avoid contamination or media degradation.

Step 4: Fine-Tuning

The agar should cool to 45–50°C before adding heat-sensitive additives like vitamins or antibiotics. For sterilization, use membrane filters with holes between 0.2 and 0.45 µm. Check blood quality for haemolysis standards before using it in media. Finally, check pH against manufacturer requirements after sterilization. If sufficient procedures are taken, adjustments are infrequent.

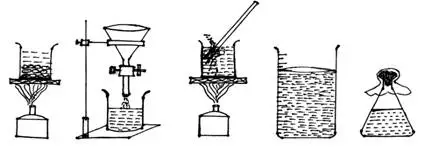

Dispensing of Prepared Culture Media

Cooling Medium– Cool the medium to 45–50°C before dispensing. A water bath or hot plate stirrer works well, but an infrared thermometer is needed. Too much heat can promote evaporation, while too much cooling in a water bath might create precipitation—reheat carefully. Avoid quick chilling with cold water, which can cause flakes or cloudiness.

Glassware Prep– Sterilize glass Petri plates in a 160°C hot air oven for two hours. After finishing, let the oven cool to 50°C before opening to minimize thermal shock. To avoid contamination, cover windows, turn off fans, and operate near a flame or in a biological safety cabinet when distributing the media.

Agar Media Dispensing

Use agar media dispensing plates to fill Petri dishes.

- Flame-sterilize the flask neck before and during filling.

- Swirl the flask gently to mix contents evenly.

- Agar depth is constant when dispensed level.

Most effective antimicrobial susceptibility test depth:

4 ± 0.5 mm agar depth in 90 mm plates (~25 mL each).

Flame or heat the surface to remove air pockets. For accuracy, use sterilized pipettes, syringes, or pumps.

Dispense into tubes:

- Sterile screw-cap tubes with ventilation should not be fully tightened.

- Use autoclavable racks to support tubes.

- Before filling, gently rotate the flask for homogeneity.

After sterilization, tighten caps to avoid contamination during storage or usage.

Drying Media Plates

Completed plates should dry:

- Room temperature for many hours (up to 24).

- Avoid condensation by drying them with lids slightly ajar for less than 30 minutes.

Lid moisture should be removed before shipping. Watch out for cracking from overdrying.

Tubing and Slants

Agar slants should be dried tilted to generate a 2.5–3 cm butt and 2–2.5 cm slope. Use a standardized rack for uniformity. Dry semi-solid or liquid material in vertical tubes on a rack for stability.

Preparation of Common media and cultures

Culture medium preparation is essential to microbiology. It is essential for microbial development. Experimental needs determine whether the medium is liquid or solid. Supplier-prepared media are convenient, but producing them yourself gives you flexibility and control. Sterile conditions are used to prevent media contamination, generally at 121 °C for 15 minutes under 15 lb/in² pressure.

For basic culture preparation, use 15 cm³ agar per Petri dish and 5-10 cm³ broth each McCartney bottle. Sealing cotton wool plugs must be non-absorbent to eliminate moisture retention. Metal or plastic caps are also suitable.

Nutrient Agar:- A typical medium, nutritional agar is made by dissolving 28 grams of material in 1 liter of filtered water. To guarantee thorough dissolve, boil it, then pour it into containers and sterilize.

Nutrient Broth:– Similarly, 13 grams of nutrient broth powder is dissolved in 1 liter of filtered water to make nutritious broth. Well-stirred before sterilization.

Malt Extract Agar:- Fungi grow here. Dissolve 18 grams of agar powder in 1 liter of distilled water and boil. Add 15 grams malt extract per liter and stir well before sterilising.

Mannitol Yeast Extract Agar:- Dissolve 10 grams of agar in 1 liter of filtered water and heat to dissolve for more specialized microbiological growth. To the mixture, K2HPO4, MgSO4·7H2O, NaCl, CaCl2·6H2O, mannitol, and yeast extract are added. Dispense and sterilize the medium after mixing.

Mannitol Yeast Extract Broth:– Instead of agar, Mannitol Yeast Extract Broth is a liquid media.

Glucose Nutrient Broth:- Add 10 grams of glucose per liter to the nutrient broth to make glucose nutrient broth.

Sugar Peptone Water:- In this unique mixture, 10 grams of peptone, 5 grams of NaCl, 5 grams of sugar, and 20 cm³ of Universal indicator are added to 1 liter of distilled water. Adjust the pH to 7.4 and sterilize.

Tributyrin Agar:- Mix 1% tributyrin with nutrition agar and sterilise for lipid-degrading bacteria.

Glucose Yeast Extract Broth:- To make glucose yeast extract broth, combine 10 grams peptone, 5 grams sodium chloride, and 3 grams yeast extract to 1 liter distilled water. Post-preparation sterilisation is typical of media.

Glucose Yeast Extract Lemco Broth:- This soup is identical to glucose yeast extract broth but contains 10 grams of Lemco (meat extract).

Milk Agar:- Prepare nutrient agar with 900 cm³ filtered water. Take 20 grams of dry skimmed milk and dissolve it in 100 cm³ of filtered water. After sterilisation, milk is chilled to 45–50°C and aseptically combined with agar. The finished mix is delivered and sterilised.

Starch Agar:- Mix 15 grams of nutritious agar with 100 millilitres of filtered water and boil. Heat 40 grams of soluble starch in 100 millilitres of filtered water. After preparation, both components are combined, distributed, and sterilised.

Iodine Solution:- Dissolve 1 gram of iodine crystals and 2 grams of potassium iodide in 300 millilitres of filtered water. Starch is typically tested using this solution.

Cellulose Broth (for Trichoderma reesei):– To cultivate Trichoderma reesei, create a cellulose broth by combining CaCl₂, ammonium sulphate, yeast extract powder, asparagine, carboxymethylcellulose, and KH₂PO₄ in 800 cm³ of distilled water. Heat and stir the solution until dissolved, then adjust pH to 6.2.

Maintenance and Preservation of Cultures

Preserving microbial cultures ensures their availability for future research. These methods are essential for preserving organisms over time. Each strategy has benefits and drawbacks that must be considered.

- Refrigeration- Refrigerating bacterial cultures at 4°C is a frequent procedure. The cool temperature reduces cell metabolism, conserving medium and extending preservation. This method has downsides. As cells use medium nutrients, waste products pile up and kill cells. It takes subculturing to overcome this. Fungal cultures need subculturing every three to four months, whereas bacteria need it every two to three weeks. Refrigeration is simple but requires continual monitoring to keep cultures alive.

- Deep Freezing- A longer-term option is deep freezing. This approach mixes microorganisms with glycerol and stores them at -40°C for years. Glycerol protects cells during freezing. Cultures are promptly frozen at -70°C in industrial methylated spirit and carbon dioxide for maximum preservation. They next go into a -40°C freezer. Cultures remain dormant until needed because this procedure dramatically lowers metabolic activity. The frozen cultures are thawed in a water bath before experimentation.

- Freezing Under Liquid Nitrogen – Perhaps the most severe approach is Freezing Under Liquid Nitrogen. Here, cells and bacteria are preserved at -196°C. Putting cells in suspended animation, liquid nitrogen stops all metabolic functions. However, preventing ice crystal formation, which may tear cell membranes and cause irreparable damage, is difficult. Before freezing, glycerol or DMSO is applied to the culture to avoid this. Organisms that cannot be lyophilised prefer this method. Liquid nitrogen may store cultures for decades without affecting viability.

- Lyophilization or Freeze-Drying – Another popular approach for long-term culture storage is lyophilization or freeze-drying. The culture is immediately frozen at -70°C and dehydrated under vacuum. The dried, dormant culture can be kept in vacuum-sealed vials at 4°C away from light. This method is good for long-term preservation of bacteria, fungi, and viruses. Rehydrating the organism with liquid media before moving it to a growth medium revives the culture. Lyophilisation is one of the best ways to preserve cultures without affecting their genetic or metabolic features.

Examples of Culture Media Preparation

Nutrient Broth (NB) and Nutrient Agar (NA)

- All steps of nutrition broth (NB) and nutrient agar (NA) preparation must be precise. These media are used to culture many microorganisms in microbiology investigations. Examine preparation in detail.

- Make sure your workstation is clean and hygienic. Wipe the lab bench with disinfectant to avoid infection. Measure 250 ml distilled water in a 1L graduated cylinder. A 60°C water bath warms the water to the optimum temperature for optimal component dissolution.

- Put the water in a 1L flask. Add 1.5g beef extract and 2.5g peptone. You must wash and dry your spatula between ingredients to avoid cross-contamination. Never put excess stuff back in its container; trash it. Wash any powder on the flask’s edges with 100ml of water to mix it in.

- A Bunsen burner on low heat should be used to properly stir the mixture. Mix until all solids are dissolved. Pour the solution back into the graduated cylinder and fill it to 500ml with warm water. Return liquid to flask.

- Checking pH is crucial next. Make sure the medium’s pH is 7.0 with a pH meter. Small quantities of HCl or NaOH can be used to modify the pH, however adding agar will not change it.

- Distribute the mixture into test tubes. Pipette 10 ml of broth into ten test tubes and place them on a rack. The broth can now be solidified into agar for use.

- Add 6g agar to the flask for the following step. A cheesecloth-wrapped Styrofoam stopper taped to the flask seals it. Boil the mixture slowly, stirring regularly, for 1-2 minutes. Without boiling, agar will not dissolve and become transparent. After dissolving, let the flask cool before pipetting 10ml of agar into each test tube.

- Seal these test tubes with Morton caps, making sure they’re thoroughly depressed—otherwise, they may pop off during autoclaving. Place test tubes and flask in autoclave to sterilize medium. Place autoclave in slow exhaust mode and sterilize for 15 minutes at 121°C and 15 lb/in² pressure.

- Remove autoclave media after sterilization. Cool the broth at room temperature. Slant racks should hold NA tubes so the medium solidifies into a long slant and short butt. Put the flask in a 48°C water bath.

- Prepare petri plates carefully after medium solidifies. After drying the petri dish foundation, gently fill each dish with prepared agar, little over the entire line on the side. This prevents medium drying during incubation.

- Let the plates firm for 15 minutes after filling. Label the plates and invert them overnight at 37°C to check for microbiological contamination.

- Final task: cleaning. Place all glassware on paper towels by the sink after a thorough hot water rinse.

Potato dextrose agar (PDA) Preparation

Mostly used for isolating and growing fungus for additional study, potato dextrose agar (PDA) is PDA is prepared by multiple painstaking stages that guarantee the finished product is free of pollutants and provides the best conditions for fungal development. Let’s stroll through the procedure.

- First, wash and peel 250 grammes of potatoes. Cut the potato into little bits; these will cook in 500 ml of water. Cook the slices for thirty minutes regardless of the pot you decide on—open or pressure cooker. This facilitates the extraction of the nutrients required for fungal growth.

- Strata the potato extract through muslin cloth or a net filter to remove the solid particles once the potato has boiled. Your medium will be built using this filtered extract. Next, dissolve twenty grammes of agar in 500 millilitre of water and boil it for another thirty minutes. The agar will dissolve totally to produce a transparent, molten solution.

- Then stir the potato extract with twenty grammes of dextrose. By offering a sugar supply, this injection of dextrose supports the development of the fungus. To guarantee complete mixing, gently stir this with the melted agar mixture. Now the total amount should be changed to one liter using filtered water.

- Using pH indicator paper, now find the pH of the combination. Using a glass rod, gently stir the medium; dip a tiny piece of pH paper into the liquid. Match the produced color to the pH range. Add several drops of 0.1N hydrochloric acid (HCl) to decrease the pH from above 7 to a neutral pH. If the pH is excessively acidic—that is, below 7—add 0.1N sodium hydroxide (NaOH) to increase it. Retest for neutrality after every change; always stir fully.

- Transfer 15 ml of the medium into each clean boiling tube after the pH is exactly right. To stop contamination, wrap every tube with non-absorbent cotton wool. The tubes ought then to be arranged in a wire basket and covered with a layer of waste paper. Cotton thread will help you to tightly tie the paper.

- Sterilisation comes next in importance. Put the tube-filled wire basket into a pressure cooker or autoclave. Run for twenty minutes using the autoclave set to fifteen pounds of pressure. Release the steam and take off the tubes after the sterilising operation is finished.

- Let the sterilised tubes slant cool down now. For the purpose of growing fungus, this will enable the agar placed into a slanted shape to be used. The tubes should be returned into the wire basket once the agar has set and kept in a neat, regulated surroundings.

- Especially in controlling temperature, pH, and sterilization conditions, potato dextrose agar (PDA) production calls for accuracy. Nonetheless, the outcome is a consistent habitat for developing fungus, therefore offering a strong basis for study or culture of fungal species.

Some of the commonly used media

Potato dextrose agar (PDA)

| Potato | 250 g |

| Dextrose | 20 g |

| Agar agar | 20 g |

| Distilled water | 1000 ml. (pH : 7) |

Oatmeal agar (OA)

| Oatmeal | 30 g |

| Agar agar | 20 g |

| Distilled water | 1000 ml. (pH : 7) |

Wheat meal agar (WMA)

| Wheat grain | 30 g |

| Agar agar | 30 g |

| Distilled water | 1000 ml. (pH : 7) |

Malt extract agar (MEA)

| Malt extract | 25 g |

| Agar agar | 20 g |

| Distilled water | 1000 ml. (pH : 7) |

Yeast potato dextrose agar (YPDA)

| Yeast granules | 1 g |

| Potato | 200 g |

| Dextrose | 20 g |

| Agar agar | 20 g |

| Distilled water | 1000ml (pH: 7) |

Most Common Errors and Possible Causes during Culture Media Preparation

- Dehydrated Culture Media Clustering

One of the primary reasons dehydrated media clumps is too high humidity during storage. Lumps can develop if the container is left open for too long or if it is not securely shut after use as moisture will leak in. Using expired dehydrated media is another element that could influence later development as it might not dissolve correctly. - Uncorrect pH Levels

Inaccurate pH readings can readily come from an incorrectly calibrated pH meter. If not closely examined, this is a common error that could go unnoticed. Testing pH on a very hot medium—usually over 25°C—may also provide erroneous findings. Another offender may be utilizing chemically polluted containers or less than perfect water. The pH reading could also be impacted if the medium is not completely mixed or if it is just poorly dissolved. At last, past-due dried media could not be able to keep the predicted pH values. - Uncomplete Solubility

Incomplete solubility of the culture media can be caused by several elements. Using too little water is a common problem as it makes it harder for the components to dissolve completely. In the same vein, insufficient heating or providing too little time for dissolution might keep the medium from totally dissolving. Furthermore insufficient may be mixing, particularly in cases when the flask employed is too small to enable appropriate convection and complete mixing. - Inadequate Agar or Gelling

One typical error in agar preparation is choosing a wrong product-to—-to–water ratio. One might get this via overdilution or a weighing mistake. Agar may not gel if it isn’t dissolved enough or if mixing is inadequate. The gelling qualities of the agar may be damaged if the medium is kept at 50°C for too long or repeatedly reheated. Furthermore preventing appropriate gelling is overheating the medium, particularly at a low pH. - Caramelization or darkness

Darkening or caramelizing of the media is mostly caused by overheating. This can arise from too rigorous sterilization or from media kept at 50°C for long durations. Media repeated remelting might also caramelize, particularly in cases of too high temperatures. Furthermore contributing to the discolouration might be inadequate dissolution of the medium. - Precipitation or Turbidity

Often the cause of turbidity or precipitation is either inadequate dehydrated medium or the use of contaminated water or containers. Should the medium be warmed, particularly during sterilization, this might lead to a precipitate. Likewise, this can be caused by too lengthy media maintenance at 50°C, repeated remelting, or overheating at high temperatures. Furthermore causing turbidity might be improper pH, incomplete dissolution or mixing. Further issues may arise from the loss of water resulting from evaporation of prepared medium. - Inadequate Development or Variance in Differential Properties

Problems with quality control (QC) usually blame cultures failing to develop or maintain their unique characteristics. Incorrect or poorly maintained QC organisms might produce either poor or inconsistent findings. Likewise, microbiological development can be stopped by overheating, extended high temperature storage, or regular remelting. Furthermore contributing to bad cultural performance are inadequate mixing and disintegration of the medium. Furthermore upsetting development might be components in the water, containers, or inoculum; improper pH can stop ideal microbial activity.

MCQ on Culture Media

1. What is the primary purpose of culture media?

a) To provide nutrients for microorganisms

b) To sterilize microorganisms

c) To inhibit the growth of microorganisms

d) To differentiate between different types of microorganisms

2. What is the most common method of sterilizing culture media?

a) Filtration

b) Chemical sterilization

c) Autoclaving

d) Incineration

3. What type of culture media is best for growing bacteria?

a) Solid (agar-based)

b) Liquid

c) Semisolid

d) Both A and C

4. What is the ideal storage condition for culture media?

a) Room temperature

b) Warm and humid

c) Cool and dark

d) Cold and dry

FAQ

What is culture media and why is it important?

Culture media is a nutrient-rich solution used to grow microorganisms, such as bacteria and fungi. It is important because it provides the necessary nutrients for the microorganisms to grow and multiply.

What are the different types of culture media?

There are many different types of culture media, including: solid (agar-based), liquid, and semisolid. Each type of media is formulated to support the growth of a specific type of microorganism.

How do you prepare culture media?

Culture media is typically prepared by mixing a dehydrated powder with water and sterilizing the mixture by autoclaving. Some media can also be purchased ready-to-use.

How do you sterilize culture media?

Culture media is typically sterilized by autoclaving, which uses high pressure and temperature to kill any microorganisms present. Other methods of sterilization include filtration and chemical sterilization.

How do you store culture media?

Culture media should be stored in a cool, dark place to preserve its nutrient content. Once opened, it should be used as soon as possible or stored in a refrigerated environment.

How do you select the appropriate culture media for your microorganism?

The appropriate culture media for a microorganism depends on its growth requirements. Factors to consider include pH, temperature, oxygen requirements, and the presence of specific nutrients.

What is the difference between selective and differential culture media?

Selective culture media is formulated to favor the growth of a specific type of microorganism, while inhibit the growth of others. Differential culture media is formulated to differentiate between different types of microorganisms based on their growth patterns or metabolic by-products.

Can culture media be reused?

Culture media should not be reused as it can lead to contamination with other microorganisms and also decrease the nutrient level.

Can you use tap water to prepare culture media?

Tap water should not be used to prepare culture media as it may contain microorganisms and other contaminants. Instead, it is recommended to use distilled or sterile water.

Can you add antibiotics to culture media?

Yes, antibiotics can be added to culture media to inhibit the growth of unwanted microorganisms or to select for specific microorganisms that are resistant to the antibiotic. However, it should be done under the guidance of a professional and in compliance with the local regulations.

- https://www.sigmaaldrich.com/IN/en/applications/microbiological-testing/microbial-culture-media-preparation

- https://www.mt.com/in/en/home/applications/Laboratory_weighing/Culture-Media-Preparation.html

- https://www.rpcau.ac.in/wp-content/uploads/2020/03/Media-and-their-composition.pdf

- https://www.thermofisher.com/blog/food/five-tips-for-culture-media-preparation-success/

- https://www.sigmaaldrich.com/IN/en/applications/cell-culture-and-cell-culture-analysis/cell-culture-by-technique/cell-culture-media-preparation

- http://www.cabri.org/guidelines/micro-organisms/M203Ap1.html

- https://www.sas.upenn.edu/LabManuals/biol275/Table_of_Contents_files/2-PreparationOfMedia.pdf

- https://agritech.tnau.ac.in/farm_enterprises/Farm%20enterprises_%20Mushroom_Culture%20media.html

- https://labassociates.com/how-to-prepare-culture-media-for-plant-tissue-culture

- https://conductscience.com/how-to-prepare-culture-media-and-preserve-cultures/

- https://microbiologyonline.org/teachers/preparation-of-media-and-cultures

- https://microbeonline.com/preparation-of-culture-media/

hi thank you very much