Industrial microbiology is the use of microorganisms like bacteria, fungi, and yeast for producing useful materials on a large scale. It is the process where these microbes are grown under controlled conditions so that they can convert raw materials into different products.

It is the process mainly linked with fermentation and other bioconversion methods, and it is used for making substances such as enzymes, antibiotics, vitamins, organic acids, biofuels, and many pharmaceutical compounds. It is the process that began from early activities like brewing and bread making, and later it was explained clearly when it was shown that fermentation is carried out by specific microorganisms.

In modern industries it is done by using improved strains that are obtained by genetic engineering for getting higher yield and stable production. The major aim of industrial microbiology is to obtain a product that is pure, cheap and can be produced continuously in large quantities.

History and Development in industrial microbiology

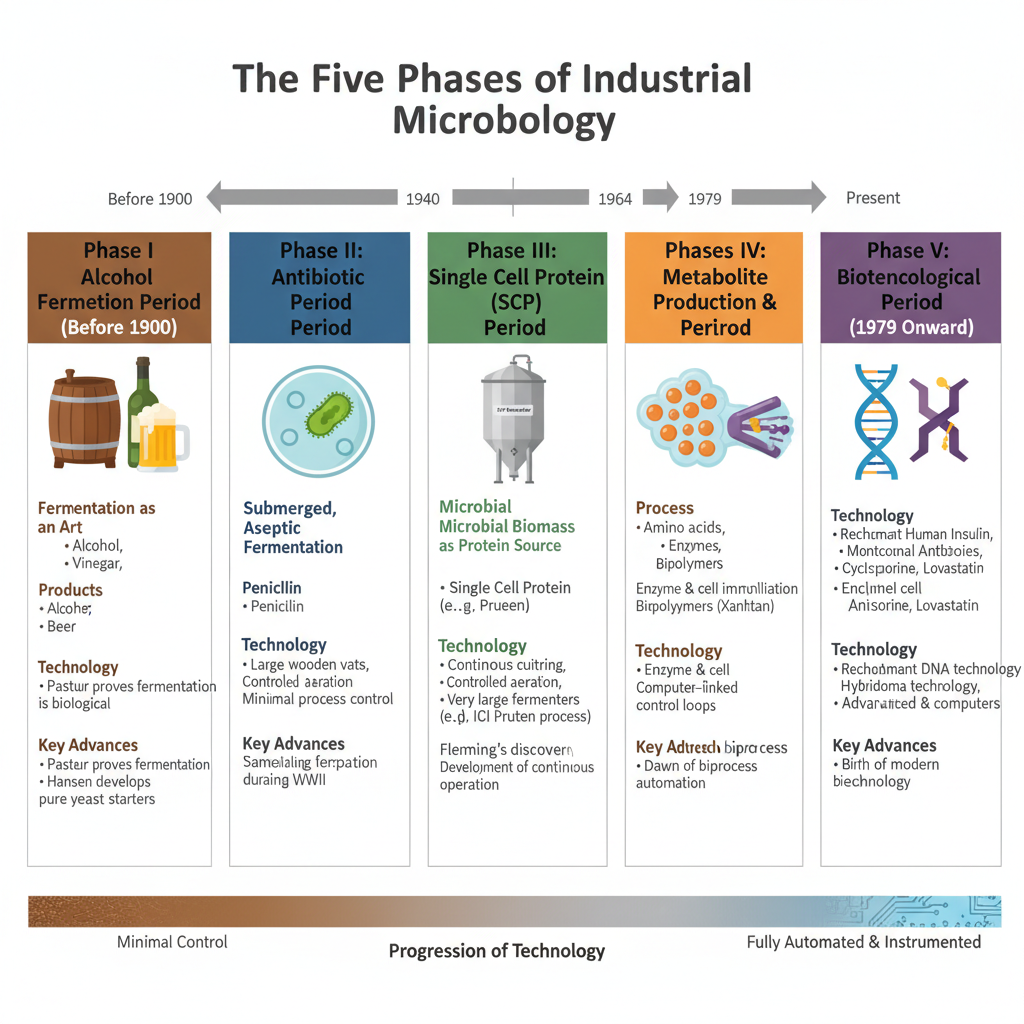

The history of industrial microbiology is usually described in a series of distinct phases, and each phase is marked by a specific type of product and technique that was commonly used. It is the process that first developed as a simple fermentation-based activity, and slowly it turned into a controlled scientific discipline when pure culture methods and aseptic procedures were introduced.

In the first phase, called the alcohol fermentation period, the production of alcohol, vinegar and beer was mainly practiced as an art. It is the period before 1900, when fermentation was not controlled scientifically and large wooden vats were used for operation. It is during this time that the contribution of Pasteur became important because he proved that fermentation is biological and he introduced pasteurization for saving wine from spoilage. Pure yeast starters prepared by Emil Hansen were adopted in brewing during this stage.

The second phase is the antibiotic period. It started in the early 1900s and was strongly influenced by the discovery of penicillin in 1929. The development of large-scale submerged fermentation was carried out when antibiotics were needed in huge amount during the war period. It is the time when mechanical stirring, aeration and pH control were developed clearly. Many antibiotics were isolated especially from Streptomyces species and they were commercialized for general use.

The single cell protein period formed the third phase. It is the period from 1940 to around 1964, when microbial biomass was produced as a cheap protein source. Continuous culture methods were introduced and very large fermenters were established. The ICI Pruteen process with Methylophilus methylotrophus was an important development of this period, although later it faced economic limitations.

The fourth phase is referred to as the metabolite production period. It is the period from 1964 to 1979, when the aim shifted to obtaining amino acids, enzymes, nucleotides and several biopolymers like xanthan and dextran. It is the time when immobilization of enzymes and cells were developed and computer-linked control loops began to regulate the fermentation conditions.

The last phase is the biotechnological period, which started around 1979 and is still continuing. It is the period where genetic engineering and hybridoma technology were introduced, and recombinant proteins like human insulin were produced by engineered microbes. Animal cell culture methods and monoclonal antibodies were used for medical and diagnostic purposes. Secondary metabolites like cyclosporine, lovastatin and ivermectin were also commercialized in this phase.

Throughout these phases, fermenter design, strain selection and aseptic procedures were improved, and the field moved from an art to a complete scientific discipline. Genetic engineering is now applied to improve earlier processes and to create new products, and many modern industries still follow the principles that developed during these historical stages.

Ancient Origins and Pre-Scientific Use

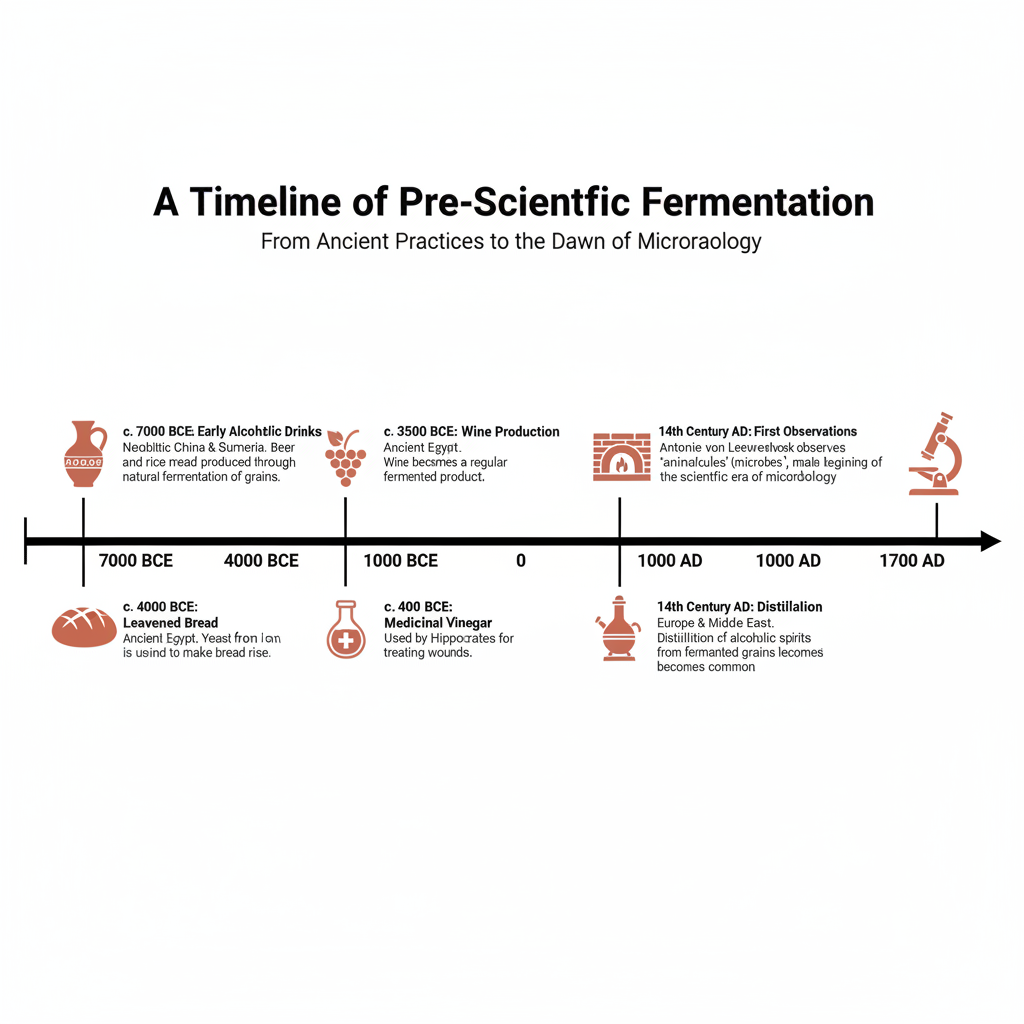

It is the early period when different fermentation practices were applied long before the microbial agents were understood. These practices were developed in many regions, and it is the process where food and beverages were changed by natural activities that were not visible at that time.

In Neolithic China around 7000 BCE, rice mead was prepared and alcoholic fermentation was taking place. It is one of the earliest evidence where grains were converted into fermented drinks although the actual cause behind the change was not known. In Sumeria and Babylonia (7000 BC), beer was produced by natural fermentation and these beverages were a part of daily life and rituals.

By about 4000 BC in ancient Egypt, carbon dioxide released from brewer’s yeast was noticed to make the bread rise, and leavened bread was then produced. This is referred to as one of the first observations where metabolic effects of yeast were used practically. In Assyria around 3500 BC, wine production was being carried out and it was already considered as a regular fermented product.

Vinegar was being used by 400 BC in Assyria for medicinal purposes, and Hippocrates used it for ear and wound treatments. These are early applied uses showing that fermentation products were treated as healing substances. By 100 BC in Ancient Rome, more than 250 bakeries were functioning and leavened bread was produced daily which shows widespread yeast use in daily food.

Milk preservation occurred by lactic fermentation, and products like yogurt, kefyr and koumiss were produced in Asian regions. It is the process where lactic acid bacteria (for example Kluyveromyces species) converted milk into stable products. The Koji process was originated in China by about 2500 BC. In this step molds were used on rice to saccharify starch, and the technique moved to Japan in the 7th century. By 700 AD these molds were used regularly to convert rice starch into sugars for brewing and sauce making.

During the Middle Ages, beer and wine production methods were refined and fermentation was used widely for food preservation. The distillation of alcoholic spirits from fermented grains became common in the 14th century AD and is thought to have originated either in China or the Middle East. Vinegar manufacture in Orleans, France, was established at the end of the 14th century where shallow-tray aeration methods were used.

All these ancient techniques were developed by craft experience. The microbial agents responsible were not understood, yet the processes were maintained by observation and repeated practice. Starter cultures and fermenting methods were transmitted across generations, and most reactions were standardized by habit rather than scientific theory.

In the 17th century Antonie van Leeuwenhoek observed tiny “animalcules” by using simple microscopes. These observations were communicated to the Royal Society (1673–1723). It is the period when invisible organisms were first seen although their direct involvement in fermentation was not immediately confirmed.

The pre-scientific era thus moved slowly toward the scientific era. The empirical practices continued, but the processes were soon to be explained by microbiology. Many preservation advantages were received from these fermentations, and spoilage was attempted to be prevail by salting, acidifying and fermenting.

Phase I — Alcohol Fermentation Period (Before 1900)

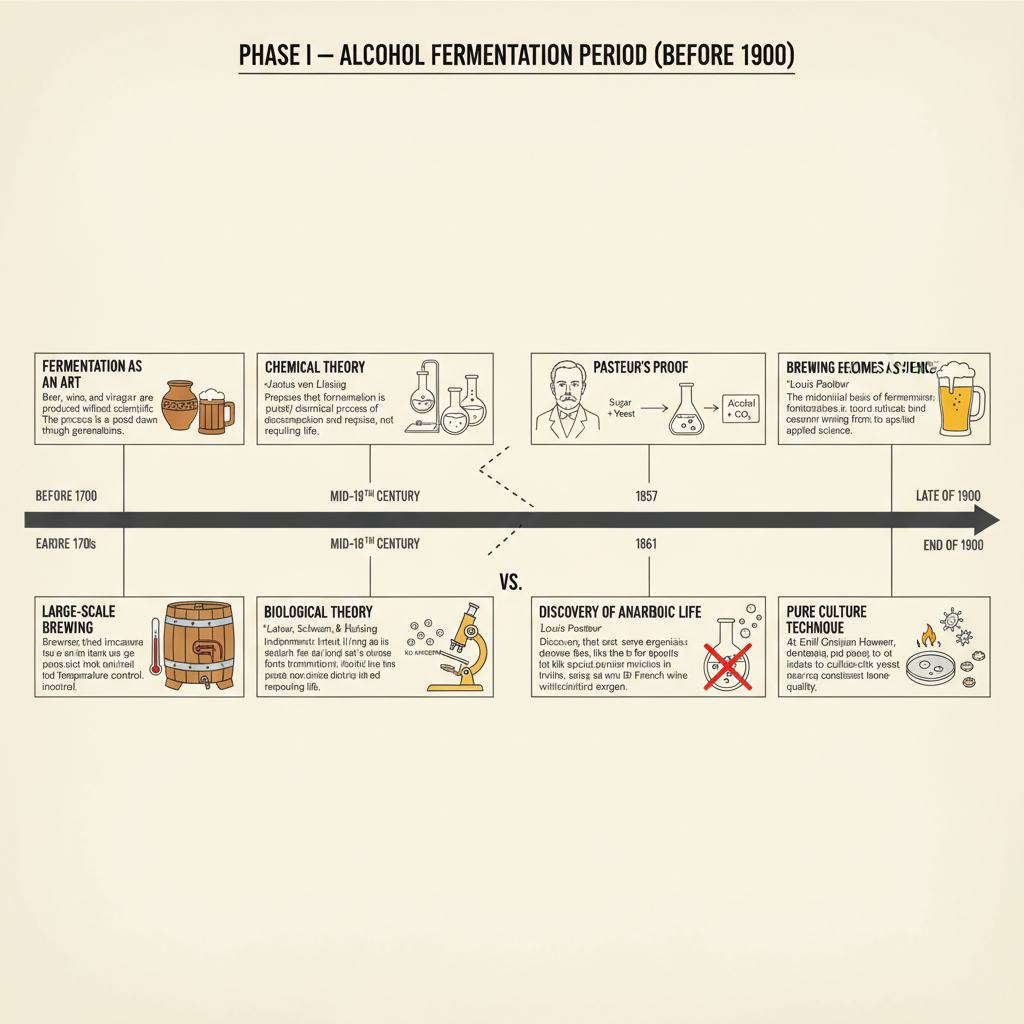

This is the earliest phase in the development of Industrial Microbiology, and it is the period when alcohol, beer and vinegar were produced without understanding the biochemical basis. It is the process where fermentation was treated more like an art and not as a scientific operation.

Beer represent the first phase of this fermentation period. Ancient Egyptians produced beer on small scale, but large-scale brewing started in the early 1700s. In this step, big wooden vats of nearly 1500-barrel capacity were used and temperature was controlled by thermometers and heat exchangers. These tools helped in regulating heat during fermentation, because heat affects the quality of the final product.

In the mid-18th century, Justus von Liebig described fermentation as chemical breaking down of starch or sugars into alcohol. This explanation was supported by chemists like Berzelius and Bertholet, who believed that life was not required for fermentation. However, Cagniard Latour, Schwann and Kutzing observed that yeast, which is a unicellular fungus, was actually responsible for the process and it is the living agent.

The debate ended when Louis Pasteur proved experimentally that fermentation is a biological process. In 1857, Pasteur demonstrated that not only yeasts, but also other organisms convert sugars into lactic acid. It is the process showing that different microorganisms carry out different types of fermentations. Later in 1861, during his study on butyric acid fermentation, he found that some organisms grow and work without oxygen. This introduced the idea of anaerobic life. The organism for butyric fermentation was later named Clostridium butyricum.

Pasteur’s findings made a major change because microorganisms were divided broadly into aerobic and anaerobic groups, which became an important concept. During this time the French wine industry faced spoilage called “souring.” The French Government requested Pasteur to investigate. He found that unwanted microorganisms were contaminating wine and were changing its taste. Pasteur suggested heating the juice below boiling point to destroy spoilage organisms. This process was called Pasteurization. It saved the wine industry and later was used for milk and other beverages.

Pasteur fully disproved the chemical theory of fermentation by proving that living microorganisms are essential for every type of fermentation. In the late 19th century, Emil Christian Hansen at Carlsberg Brewery developed a method to produce pure yeast cultures. These pure cultures removed problems of mixed fermentation and produced stable and uniform beer. It is the step where brewing shifted from craft to controlled microbiological process.

By the end of the nineteenth century, microbial involvement in fermentation and its control were well understood, and brewing became an applied scientific field.

Phase II — Antibiotic Period (1900–1940)

This phase is the period when many important advancements were developed in industrial microbiology, mainly in fermentation control and antibiotic production. It is the stage where microbial processes started to become more organised and scientifically managed.

During this period, large-scale production of baker’s yeast was improved. It is the process where growth of yeast in alcoholic fermentation was controlled by adding wort slowly in small amounts. This method is called fed-batch culture. It helped in preventing oxygen-limiting conditions because slow feeding allowed cells to grow without sudden depletion of oxygen. Aeration was also improved by using air sparging tubes, which helped air reach deeper into the medium and made yeast culture more efficient.

Another progress was the development of acetone–butanol fermentation by Weizmann. It was considered as one of the first truly aseptic and anaerobic fermentations. This process was a major step forward, and from this technology, production of organic solvents such as glycerol, citric acid, and lactic acid became possible. These fermentations later shifted into aseptic aerobic systems for better control.

A remarkable discovery in this phase was Penicillin, found by Alexander Fleming in 1929. It saved many soldiers’ lives in World War II. Production of penicillin is an aerobic process using submerged culture under aseptic conditions. In this step sterile air is sparged into viscous broth. Mixing a large volume of this broth was difficult at first and contamination was a serious problem. After solving these difficulties, penicillin fermentation opened the way for new processes like production of vitamins, amino acids, enzymes and steroid transformations.

Around this time, Dubos at Rockefeller Institute found several antimicrobial products from microorganisms, which were useful in treating human diseases. Later, S. A. Waksman and his team, who were soil microbiologists, discovered many antibiotics from Streptomyces species living in soil. Examples include Streptomyces griseus, St. fradiae, St. rimosus, etc.

The list of antibiotics discovered in this period includes Penicillin (1929) by Fleming, Tyrothricin (1939) from Bacillus, and Griseofulvin (1939) from Penicillium griseofulvum. More antibiotics continued to be discovered in the 1940s–1950s.

These achievements changed industrial microbiology from solvent fermentation to therapeutic drug manufacturing on industrial scale. This period is also called the golden beginning of the antibiotic age because microbial products started to be seen as lifesaving medicines.

Phase III — Single Cell Protein (SCP) Period (1940–1964)

This is the period when microbial biomass started to be produced as protein-rich food material. It is the process where microorganisms were used directly as protein source, and later the material was called Single Cell Protein (SCP). During this time, large-scale production of microbial protein began because the cost of final product was very low, and industrial interest increased very quickly.

Production of proteinaceous food from microorganisms was considered an efficient method to overcome shortage of protein foods. It is the process mainly used for animal feed and sometimes also suggested for human use. To obtain huge biomass, very large fermenters were developed. These fermenters were mechanically stirred and had capacity ranging from 80,000 to 1,50,000 liters, sometimes even larger. They needed to operate continuously for many days to remain economical.

For this purpose, continuous culture fermentation was developed. In this step the culture is maintained in a steady condition by supplying fresh medium continuously, and cells are harvested at the same time. It is the system where balanced growth is maintained, allowing very high productivity compared to earlier batch or fed-batch systems.

The most successful continuous culture process was the ICI Pruteen Process. It used Methylophilus methylotrophus, a methylotrophic bacterium growing on methanol as carbon source. This process was mainly used for animal feed production and it became a model for future SCP programs. Later it was replaced by cheaper substrates and new microbial species, but it remained one of the important developments.

During this phase, single-cell protein became an important research field where microbiology, fermentation engineering and nutrition science were combined. It is the time when industrial microbiology shifted towards food biotechnology and large-scale biomass production instead of focusing only on metabolite formation.

Phase IV — Metabolite Production Period (1964–1979)

This phase is marked by the development of new microbial processes aimed at producing different metabolites. It is the period where amino acids, nucleosides and several high-value microbial products were synthesized by controlled fermentations.

In Japan, new fermentation methods were developed for the synthesis of amino acids and 5′-nucleosides. These compounds were used as flavour augmenters in food industries. It is the process that became important because chemical synthesis of such compounds was costly and also not environmentally suitable.

During this time, many enzyme-production processes were improved for industrial, analytical and medical uses. Techniques for enzyme immobilization and cell immobilization were also developed. In this step enzymes were attached onto solid surfaces or trapped inside matrices so that they could be reused for long durations. It allowed better operational stability of biocatalysts and reduced production cost. These methods also made enzymatic processes suitable for continuous operation.

Commercial-scale production of microbial biopolymers like Xanthan and Dextran also started during this period. Xanthan gum was produced from Xanthomonas campestris and Dextran from Leuconostoc mesenteroides. These compounds were used as stabilizers, thickeners and additives in food and pharmaceutical industries.

Microorganisms were also applied in tertiary oil recovery, where microbial metabolites such as surfactants helped in extracting more oil from old wells. This is the process showing how microbial products improved recovery of petroleum by reducing surface tension and releasing trapped oil.

Thus, this phase represented a shift toward high-value metabolite production and specialty chemicals, moving industrial microbiology beyond bulk biomass and antibiotic production.

Phase V — Biotechnological Period (1979 onward)

This period is the era when very fast progress occurred in industrial microbiology. It is the stage mainly shaped by the invention of genetic engineering and the hybridoma technique, which changed the direction of microbial technology completely.

By using genetic engineering, manipulation of genes became possible in-vitro. It is the process where human or mammalian genes were inserted into microorganisms so that they could express those proteins. This was a major breakthrough. The first important product obtained was Human Insulin, which helped in treating the increasing disease diabetes. After this, several other human proteins were produced such as Human Growth Hormone (HGH), Erythropoietin (EPO) and Colony Stimulating Factors (CSFs). These are the proteins that control formation and proliferation of blood cells. Erythropoietin is used for treating renal failure, anemia and platelet deficiency in cancer patients, while G-CSF is used in cancer therapy and in recovery after chemotherapy.

The hybridoma technique, used for monoclonal antibody (mAb) production, also developed during this time. In this step, a hybrid cell line was formed by fusing antibody-producing cells with myeloma cells. These monoclonal antibodies became extremely important because they helped in disease diagnosis and were also used as targeted drugs for tumor cells. They became essential tools in modern medicine.

Besides recombinant DNA works, fermentation of secondary metabolites was improved further. This led to large-scale industrial production of many new microbial compounds. Examples of such metabolites released into the market include:

– Cyclosporine – an immunoregulant drug used to prevent rejection of transplanted organs.

– Imipenem – a modified carbapenem with broad antibacterial activity.

– Lovastatin – a drug used to reduce cholesterol levels.

– Ivermectin – an antiparasitic drug that prevented African River Blindness (caused by Onchocerca volvulus).

These developments showed how biotechnology transformed microbiology into a multi-disciplinary science combining genetics, medicine and fermentation engineering together. Truly, the statement of Foster (1949) that “Never underestimate the power of microbes” became justified again during this remarkable period.

Importance of Industrial Microbiology

- It help to produce useful products like antibiotics, enzymes, vitamins, amino acids, and organic acids.

- It helps in large-scale fermentation for making food items such as bread, cheese, yogurt and beverages.

- It provides methods for producing vaccines and therapeutic proteins which are essential in medicine.

- It is used for wastewater treatment, because microorganisms degrade harmful wastes.

- It helps in bioconversion, where cheap raw materials changed into valuable products.

- It supports agriculture by producing biofertilizers, biopesticides, and plant-growth promoters.

- It is important for creating microbial biomass like Single Cell Protein for animal feed.

- It helps in energy production through biogas and bioethanol fermentations.

- It plays role in mining processes, where microbes extract metals from low-grade ores.

- It contributes to environmental protection by biodegradation of pollutants.

QNA Section

What is industrial microbiology?

Industrial microbiology is the branch of microbiology where microorganisms are used for producing large-scale substances. It is the process in which microbes are cultured under controlled conditions so that different biochemical reactions occur for forming useful industrial products. It is applied in food, pharmaceuticals, enzymes, biofuels and many related fields.

What is the history of industrial microbiology?

The history started when fermentation was used in ancient times for preparing alcohol and fermented foods even before microbes were known. After Antonie van Leeuwenhoek observed microorganisms, the scientific basis was created. Louis Pasteur explained that fermentation is carried out by living organisms, which changed the understanding of industrial processes. During the early 20th century, pure cultures, aseptic handling and fermenter design improved the production system. The large-scale production of penicillin is considered an important starting point of modern industrial microbiology.

What are the major developments in industrial microbiology?

Some of the major developments are–

– Use of pure culture technique.

– Introduction of sterilization and aseptic processes.

– Development of industrial fermenters.

– Production of antibiotics.

– Application of submerged fermentation.

– Introduction of genetic engineering for strain improvement.

– Large-scale production of enzymes, acids and metabolic products.

What are the applications of industrial microbiology?

It is used for producing fermented foods, beverages, antibiotics, vitamins, organic acids, amino acids and enzymes. It is also applied in making vaccines, biofertilizers, solvents and biofuels. It is used in waste treatment and bioremediation.

What products are produced using industrial microbiology?

These are alcohols (ethanol, butanol), organic acids (citric acid, lactic acid), antibiotics (penicillin), enzymes (amylase, protease), fermented foods, amino acids, vitamins, steroids, vaccines, and microbial polysaccharides.

How has industrial microbiology evolved over time?

It evolved from simple natural fermentation to controlled fermentation with pure cultures. Later the development of bioreactors improved production. After the discovery of antibiotics, industrial fermentation expanded widely. With the introduction of genetic engineering, microbial strains were modified for higher yields. Presently, automated bioreactors and metabolic engineering are used.

What are the different phases of industrial microbiology history?

The phases are–

- Traditional fermentation phase.

- Discovery phase with microbial studies.

- Antibiotic production era.

- Biotechnology and genetic engineering phase.

- Modern automated industrial phase.

What microorganisms are used in industrial microbiology?

The microorganisms used include bacteria like Bacillus spp., Lactobacillus spp., Streptomyces spp., yeasts like Saccharomyces cerevisiae, molds such as Aspergillus spp. and Penicillium spp., and many genetically modified microbial strains.

What are the key concepts and technologies used in industrial microbiology?

The important concepts are– microbial growth kinetics, aeration, agitation, sterilization, substrate utilization and downstream processing. The technologies used are bioreactors, continuous fermentation, immobilized cells, strain improvement and sensor-based automatic control systems.

What is the role of fermentation in industrial microbiology?

Fermentation is the central principle. It is the process in which microorganisms convert substrates to final products. It is used for alcohol production, antibiotics, enzymes, acids and several metabolites. The major source of industrial chemicals is formed in this biochemical process.

Who are the key figures in the history of industrial microbiology?

Among the important figures are Antonie van Leeuwenhoek, Louis Pasteur, Robert Koch, Alexander Fleming, Chaim Weizmann and many scientists who contributed to fermentation technology and industrial strain development.

How has genetic engineering impacted industrial microbiology?

Genetic engineering improved microbial strains so that product yield becomes higher. It allows the insertion of new genes and metabolic pathways. Many recombinant microbes now produce insulin, vaccines, enzymes and different metabolites. It is the process that transformed modern industrial microbiology.

What are the recent trends in industrial microbiology?

The recent trends include metabolic engineering, synthetic biology, CRISPR-based strain modification, biofuel development, microbial bioplastics, environmental biotechnology and modern biorefineries.

What are the challenges and future outlook of industrial microbiology?

Some challenges are contamination, maintaining stable strains, cost of production and regulatory issues. In future, more engineered microbes will be used. Renewable raw materials and automation are expected to increase. Industrial microbiology will expand in energy, environment and material production.

What is the importance of industrial microbiology?

It is important because it produces many essential food, medicine and biochemical products. It supports agriculture, environment and energy sectors. It is the process that uses microorganisms as small factories producing valuable substances in an efficient way.

- 1. American Chemical Society. (2025). Insulin Development and Commercialization.

- Benson, A. K., & Breting-Garcia, V. M. (2024). Industrial applications of genetic engineering. EBSCO Research Starters.

- BOC Sciences. (2025). Submerged Fermentation: Principles, Technologies, and Applications Across Industries.

- Cave, A. (2024, July 9). Asilomar Conference (1975). Embryo Project Encyclopedia.

- EBSCO Research Starters. (n.d.). Eli Lilly Releases the First Commercial Genetically Engineered Medication. EBSCO.

- EBSCO Research Starters. (n.d.). Pasteur Begins Developing Germ Theory and Microbiology. EBSCO.

- Eikmanns, B., Eikmanns, M., & Paddon, C. J. (n.d.). Historical overview and future perspective. In (n.d.). Industrial Microbiology (1st ed.). Wiley-VCH.

- Gallo, G., & Aulitto, M. (2024). Advances in extremophile research: Biotechnological applications through isolation and identification techniques. Life, 14(9), 1205. https://doi.org/10.3390/life14091205

- Gaynes, R. (2017). The Discovery of Penicillin—New Insights After More Than 75 Years of Clinical Use. Emerging Infectious Diseases, 23(5), 849–853. https://doi.org/10.3201/eid2305.161556

- Gerberi, D. (2024). Alexander Fleming: a second look. Journal of the Medical Library Association, 112(1), 55–59. https://doi.org/10.5195/jmla.2024.1780

- Genome.gov. (2013, April 26). 1972: First Recombinant DNA.

- Hanišáková, N., & Vítězová, M. (2022). The Historical Development of Cultivation Techniques for Methanogens and Other Strict Anaerobes and Their Application in Modern Microbiology. Microorganisms, 10(2), 412. https://doi.org/10.3390/microorganisms10020412

- Jiang, X., Ji, J., et al. (2025). Key Technologies of Synthetic Biology in Industrial Microbiology. Microorganisms, 13(10), 2343. https://doi.org/10.3390/microorganisms13102343

- Liu, L., Wang, F., et al. (2025). Addressing challenges in microbial manufacturing: Systematic microbial biotechnology. Xinn, 6(6), 100871. https://doi.org/10.1016/j.xinn.2025.100871

- Maxam, A. M., & Gilbert, W. (1977). A new method for sequencing DNA. Proc. Natl. Acad. Sci. USA., 74(2), 560–564. https://doi.org/10.1073/pnas.74.2.560

- Microbiology Class. (n.d.). Approaches To Microbial Strain Improvement For Industrial Applications.

- Mullis, K. B., & Faloona, F. A. (1987). Specific synthesis of DNA in vitro via a polymerase-catalyzed chain reaction. Methods Enzymol., 155, 335–350.

- Text Highlighting: Select any text in the post content to highlight it

- Text Annotation: Select text and add comments with annotations

- Comment Management: Edit or delete your own comments

- Highlight Management: Remove your own highlights

How to use: Simply select any text in the post content above, and you'll see annotation options. Login here or create an account to get started.