An air displacement pipette (also known as a “volumetric pipette” or “mechanical pipette”) is a type of liquid handling tool commonly used in laboratory settings. It uses air displacement to draw a specific volume of liquid into the pipette’s barrel. The volume of liquid is determined by the calibrated volume markings on the barrel of the pipette.

The basic principle of operation is: -The user pulls the piston to the desired volume -This action creates a vacuum inside the pipette that sucks in liquid through the tip -When the user releases the piston, the vacuum is released and the liquid is dispensed

One of the main advantages of air displacement pipettes is their relatively low cost compared to positive displacement pipettes. They are also relatively easy to use and maintain, and can handle a wide range of liquid volumes. However, they are less precise and accurate than positive displacement pipettes and are more susceptible to errors due to variations in liquid viscosity or surface tension.

Air displacement pipettes are commonly found in educational, medical and research laboratories where high precision is not a crucial factor. They come in different types (single channel, multi channel, fixed volume, adjustable volume etc) and volume ranges (microliters to milliliters).

Principle of Air Displacement Pipetting

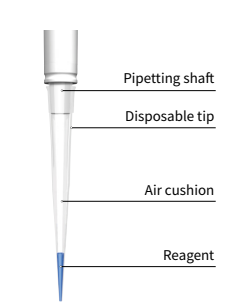

The air displacement principle is mostly utilised in pipettes and allows for precision dispensing and easy handling. By rotating the piston up and down in the pipette shaft, a negative or positive pressure is formed. This results in liquid aspiration into or expulsion from the tip. However, when the pipette is handled properly, the liquid is always separated from the inner piston and the pipette shaft by an air cushion and never comes into contact with the pipette itself. This allows for contamination-free handling that is also simple and precise. However, this is also where the system’s application limitations lie. Media that have a significant effect on the air cushion can impact the precision of the outcome. For instance, high viscosity liquids and very volatile substances make precision work harder.

Air displacement Pipetting Technique

For normal pipetting applications, air displacement pipetting is incredibly accurate. The performance of air displacement pipettes may be affected by temperature, atmospheric pressure, the solution’s specific gravity, and its viscosity.

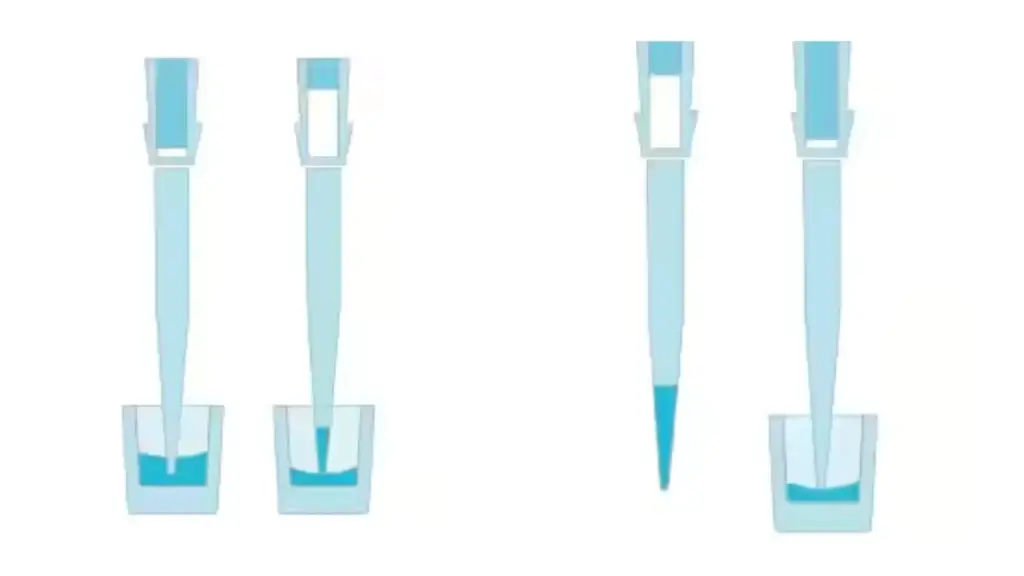

Aspirating the liquid (steps 1–3)

- When the volume is adjusted, the piston moves to its proper place.

- When the button is depressed to the first stop, the piston exhales the same amount of air as indicated by the volume setting.

- After dipping the tip into the liquid, the button is depressed. This generates a partial vacuum, and the specified amount of liquid is drawn into the tip.

Dispensing the liquid (step 4)

- The liquid is dispensed when the operational button is pressed to the first stop again. To completely empty the tip, the button is depressed to the second stop (blow-out).

Operation of Air displacement Pipette

These pipettes operate using air displacement driven by a piston. Vertical movement of a metallic or ceramic piston within an airtight sleeve generates a vacuum. The upward movement of the piston, caused by the depressing of the plunger, creates a vacuum in the region the piston vacated. To fill the vacuum, air from the tip rises, which is subsequently replaced by liquid that has been sucked up into the tip and is hence ready for transport and dispensing elsewhere.

The use of sterile method avoids fluids from contacting the pipette itself. Instead, the liquid is sucked into and dispensed from a disposable pipette tip, which is discarded following fluid transfer and replaced for the subsequent transfer. When the tip ejector button is depressed, the tip is removed and safely disposed of in a suitable receptacle without the operator’s intervention. This also protects the substances being monitored from contaminating or causing damage to the calibrated measurement mechanism.

The liquid is both drawn up and dispensed by depressing the plunger. Standard operation involves depressing the plunger button to the first stop while holding the pipette in the air. The tip is then submerged in the liquid to be conveyed, and the plunger is slowly and uniformly depressed. This causes the liquid to ascend into the tip. The equipment is then relocated to the desired area for dispensing. The plunger is depressed to the first stop and then to the second stop, often known as the ‘blowout’ position. This will completely empty the tip and release the liquid. The volume of liquid contained in the tip of an adjustable pipette is variable; it can be altered via a dial or other mechanism, depending on the model. Some pipettes have a tiny window that indicates the current volume setting. The plastic pipette tips are meant for use with aqueous solutions and should not be used with organic solvents that may dissolve the plastics of the tips or pipettes.

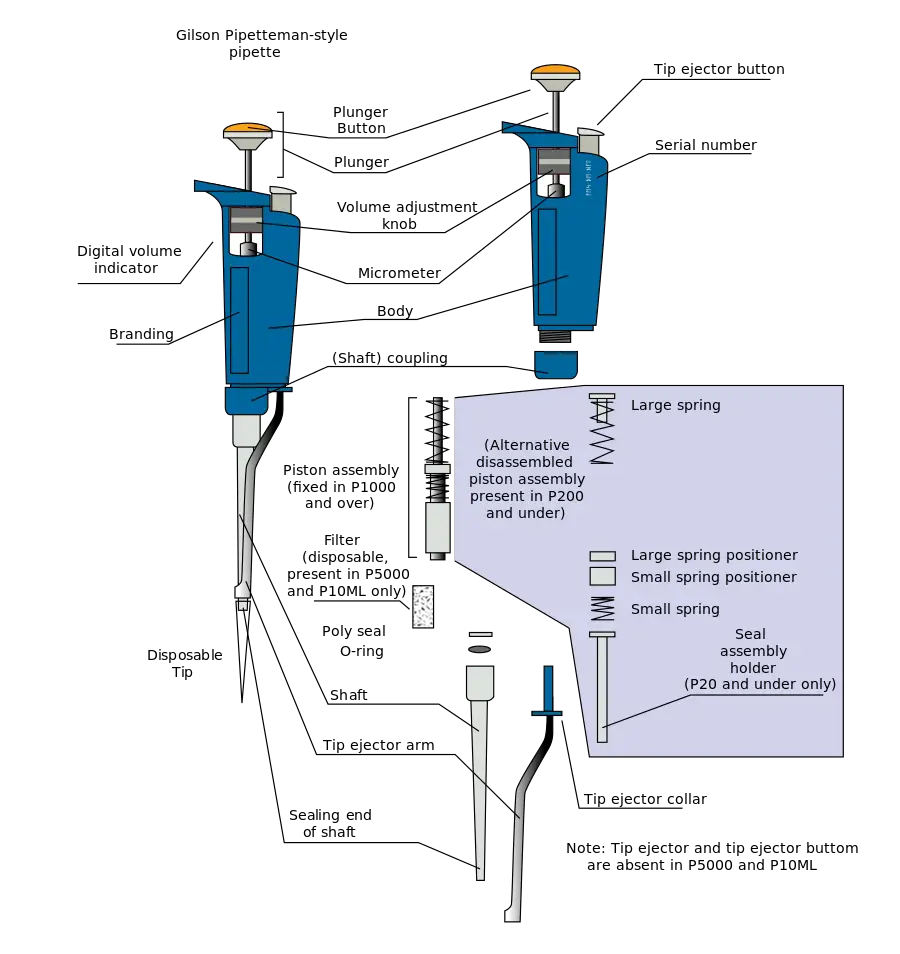

Main parts of a micropipette

A micropipette, also known as a micropipettor, is a precision instrument that is commonly used in laboratory settings to measure and dispense small volumes of liquid. The main parts of a micropipette include:

- The tip: The tip is the part of the pipette that comes into contact with the liquid. It is typically made of plastic or metal, and comes in a variety of sizes and shapes to accommodate different types of liquids and experiments.

- The barrel: The barrel is the main body of the pipette. It contains the piston and other mechanical parts of the pipette. The volume markings are usually displayed on the barrel, which can be read by the user when setting the volume.

- The piston: The piston is the part of the pipette that is used to draw in and dispense liquid. It is typically made of plastic, metal or glass and is located inside the barrel. It is moved up and down by the thumb or fingers of the user to change the volume of liquid in the pipette.

- The thumbrest: This is the part of the pipette where the thumb of the user would rest during operation of the micropipette. It helps to provide a secure grip during operation

- The volume display: A digital or mechanical volume display that gives the user the volume of liquid in the pipette.

- The ejector button: A button that when pushed causes the tip to be ejected from the pipette.

- The tip ejector: The part of the pipette that when actuated causes the tip to be ejected from the micropipette.

- Calibration feature: Micropipettes are calibrated for precision, This calibration feature is found on some micropipettes, mostly electronic ones. It could either be factory or user calibrated.

Different types and models of micropipettes may have slightly different parts or design features, but these are the main components that are typically found in most micropipettes.

Different Types of Air displacement pipettes

Several different type of air displacement pipettes exist:

- adjustable or fixed

- volume handled

- Single-channel or multi-channel or repeater

- adjustable tip spacing

- conical tips or cylindrical tips

- standard or locking

- manual or electronic

- manufacturer

1. Adjustable or fixed volume

- Micropipettes have a minimum volume capacity of 0.2 µL and a maximum volume capacity of 10,000 µL. (10 mL). Consequently, they are utilised for smaller-scale transfers than equipment such as graduated pipettes, which are available in 5, 10, 25, and 50 mL volumes.

- Adjustable pipettes are the most frequent form because they can be tuned to a specific volume within their operational range. These pipettes typically bear a label indicating their volume range, such as “10–100 µL.” These limitations are indeed the limits, as exceeding them would result in pipetting system damage. Pipettes with a set volume cannot be altered. Since there are fewer moving components, the mechanism is simpler, resulting in more precise volume measurement.

- In 1972, many University of Wisconsin–Madison researchers (primarily Warren Gilson and Henry Lardy) improved the fixed-volume pipette by developing the variable-volume pipette. Based on this innovation, Warren Gilson formed Gilson, Inc.

2. Volume

- Every pipette provider offers a wide variety of capacities for efficient use. A pipette with a narrow volume range, such as 10–100 µL, is significantly more accurate than one with a vast range, such as 0.1–1,000 µL.

- Regarding the volume being transferred, the smallest pipette capable of handling the necessary volume should be used. This is significant since accuracy reduces as the set volume approaches the minimal capacity of the pipette.

- For instance, if 50 µl are administered using a pipette that holds 5,000 µl, the results will be subpar. Using a 300 µl pipette will produce superior results, while a 50 µl pipette would be optimal.

Tips

- Two components are required for the pipetting process: the pipette and disposable tips. The tips are disposable plastic instruments. Typically, they are composed of Polypropylene. Depending on the size of the pipette, the user requires certain tip sizes, such as 10 µL, 100 µL, 200 µL, and 1,000 µL, as well as non-standard sizes such as 5,000 µL (5 mL) and 10,000 µL. (10 mL). The majority of tips are color-coded for easier identification, such as natural (colourless) for small volumes (0.1–10 µL), yellow (10–100 µL), and blue (100–1,000 µL). The colour code for the appropriate pipette is displayed on the pipette.

- For unique applications, filter-tips are offered. The upper conus of these tips is lined with a small piece of foam plastic to prevent sample aerosols from contaminating the pipette.

- In general, all tips are housed vertically in 8 x 12 boxes for 96 pieces. The tip spacing in these boxes is typically standardised for multichannel pipette compatibility across a variety of manufacturers.

Commonly available pipette volumes

| Name | Min. volume (µL) | Max. volume (µL) | Color on Gilson | tip size (µL) |

|---|---|---|---|---|

| P2 | 0.2 | 2 | Orange | 10 |

| P10 | 1 | 10 | Red | 10 |

| P20 | 2 | 20 | Lemon | 200 |

| P100 | 20 | 100 | Salmon | 200 |

| P200 | 50 | 200 | Yellow | 200 |

| P1000 | 200 | 1000 | Blue | 1000 |

| P5000 | 500/1000 | 5000 | Purple | Purple |

| P10000 | 1000 | 10000 | Sky | Sky |

Two major tip systems exist, called conical or cylindrical, depending on the shape of the contact point of the pipettes and the tip.

3. Single-channel and multi-channel pipettes

- There is a distinction between single-channel and multi-channel pipettes based on the number of pistons within the pipette. For manual high-throughput applications such as filling a 96-well microtiter plate, the multi-channel pipette is used by the majority of researchers.

- This type of pipette includes 8 parallel pistons, allowing a row of 8 wells to be handled in parallel rather than individually.

4. Adjustable tip spacing pipettes

- Some manufacturers offer pipettes with adjustable tip spacing. These allow for the concurrent transmission of many samples between diverse labware formats.

5. Electronic pipettes

- Electronic pipettes were designed to improve the ergonomics of pipettes by decreasing the required force. The physical movement of the piston is replaced by a battery-powered electric motor.

- Manual pipettes require a thumb movement of up to 3 cm, whereas electronic pipettes have a primary button.

- The pipette is often programmed using a control wheel and other buttons. All configuration options are provided on a tiny display. Electronic pipettes can reduce the likelihood of RSI injuries.

6. Repeaters

- Repeaters are specialised pipettes that are optimised for repeated working processes, such as dispensing 20 µL many times from a greater volume with a single aspiration.

- In general, they have specific tips that are incompatible with standard pipettes. Using standard tips, certain electronic pipettes are able to do this operation.

7. Locking mechanism

- Some air displacement pipettes can be equipped with a locking mechanism (referred to as “locking pipettes”) to allow for more precise volume adjustments while maintaining precision.

- By locking the volume setting while completing many identical pipetting motions, inadvertent volume adjustments are prevented.

- Typically, the lock mechanism is a mechanical toggle adjacent to the pipette setting controls that prevents the setting mechanism from moving. However, some pipettes have dials for setting the individual volume numbers that can only be modified when the plunger is depressed and rotated.

Calibration

Pipettes should be calibrated periodically to ensure sustained precision and consistent, repeatable performance. These intervals vary based on the following variables:

- The proficiency and education of the operators. Skilled operators typically operate the instrument more precisely and make fewer errors that compromise precision.

- The liquid that the pipette dispenses. Even under optimal operating conditions, corrosive and volatile liquids tend to generate vapours that climb into the pipette shaft and can corrode the metal piston and springs, as well as the seals and o-rings that form an airtight seal between the piston and the surrounding sleeve.

- Careful and proper handling. The accuracy of pipettes that are often dropped, subjected to negligent handling or horseplay, or improperly kept in a horizontal posture can diminish over time.

- The required precision of the instrument. Applications that require utmost precision require more frequent calibration. In general, instruments used for solely academic or research purposes require less frequent calibration.

Most pipettes can be calibrated semi-annually (every six months) and work satisfactorily under normal settings. Institutions governed by the GMP/GLP regulations of the Food and Drug Administration typically benefit from quarterly calibration, or every three months. Critical applications may demand monthly service, but research and academic institutions may only require annual service. The calibration interval should be determined with care, taking into account the pipette in issue (some are more dependable than others), the pipette’s operating conditions, and the pipette’s operators.

Typically, gravimetric analysis is utilised for the purpose of calibration. This requires dispensing samples of distilled water into a vessel atop a precision analytical balance. The density of water is a well-established constant, therefore the mass of the dispensed sample offers an accurate indication of the dispensed volume. Typically, relative humidity, ambient temperature, and barometric pressure are integrated in a complex formula and computed as the Z-factor to determine the measurement’s precision. This Z-factor is then utilised to alter the raw mass data output by the balance and provide a more precise measurement.

The colorimetric approach employs exact concentrations of coloured water to influence the measurement and calculate the dispensed volume. A spectrophotometer is used to accurately quantify the colour change between the sample before and after aspiration. Given the expense of the coloured reagents, this method is more expensive than the more usual gravimetric method, but it is suggested when maximal precision is desired. It is also advised for extremely low-volume pipette calibration, in the range of 2 microliters, as the inherent errors of the gravimetric approach, done with standard laboratory balances, become excessive at such low volumes. For gravimetric examination of low-volume micropipettes, properly calibrated microbalances capable of reading in the range of micrograms (106 g) can also be used efficiently, but only provided ambient conditions are strictly controlled. Six-place balances and environmental controls significantly enhance the expense of these calibrations.

- Text Highlighting: Select any text in the post content to highlight it

- Text Annotation: Select text and add comments with annotations

- Comment Management: Edit or delete your own comments

- Highlight Management: Remove your own highlights

How to use: Simply select any text in the post content above, and you'll see annotation options. Login here or create an account to get started.