What is Analytical Balance?

An Analytical Balance is a highly sensitive laboratory instrument that used for measuring very small mass with high precision and accuracy.

- It used mainly in analytical chemistry labs where the quantity of substance are required to be measured in milligram (mg) or even microgram (µg) range.

- The balance is enclosed in a transparent glass case (often called a draft shield) to prevent air currents or dust by affecting the measurement, this enclosure help to maintain accuracy.

- Analytical balances usually have readability from 0.1 mg (0.0001 g) or sometimes more precise, depending upon the model or type.

- The weighing pan of balance is very small and delicate, so only clean and dry containers / papers are used for holding the samples.

- Calibration is done frequently, either internal or external, to ensure the accuracy remain consistent during use.

- The balance works on electromagnetic force restoration principle, where force required to balance the load is measured and displayed digitally as weight.

- Temperature, humidity, static electricity and vibration affect the measurement, so they must be controlled during weighing.

- It’s mostly used for preparation of standard solutions, weighing of reagents, and sample preparation for quantitative analysis, etc.

- Analytical balances require regular maintenance and proper leveling (using built-in bubble level) before use.

- In simple words, analytical balance is a precise and sensitive instrument used for measuring tiny mass in laboratory works where accuracy is critical.

Principle of Analytical Balance

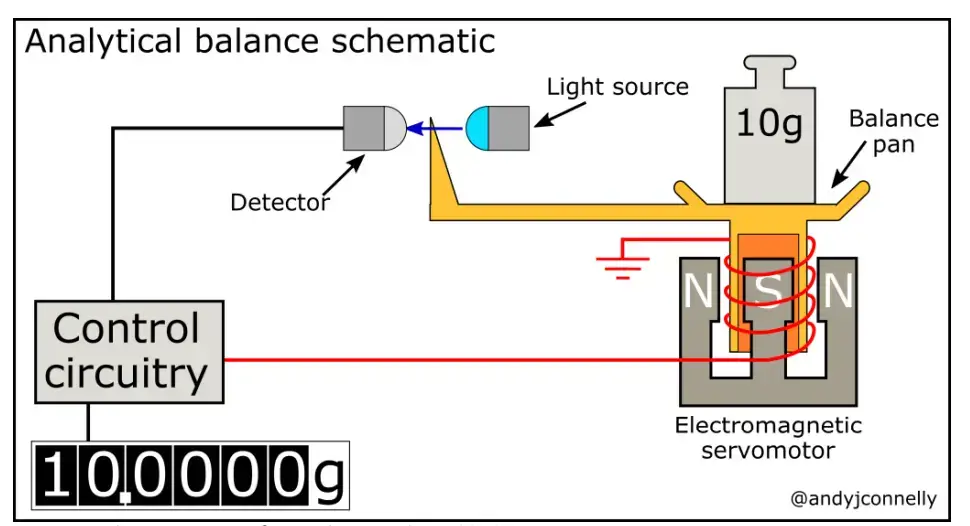

- The principle of analytical balance based on the electromagnetic force restoration method, where the force produced by an electromagnetic coil is used to balance the force of gravity acting on the sample mass.

- In this principle, the object weight is counteracted by an electromagnetic force which generated inside the balance mechanism, and the amount of current required to restore equilibrium is measured.

- This current is directly proportional with the mass of the substance, so by measuring it, the weight can be accurately determined.

- The system work by restoring the balance pan to its original position after sample loading, using electromagnetic coil and position sensor to detect movement.

- A photoelectric sensor or position detector identifies the deflection caused by weight of the sample and send signal to control circuit.

- The control circuit automatically adjusts the current in electromagnetic coil until the beam/pan returns to its neutral position.

- The electric current needed to balance the pan is converted into a digital reading by microprocessor and displayed as mass value.

- Because the measurement is dependent on electromagnetic force instead of mechanical displacement, very high accuracy and sensitivity are achieved.

- The entire weighing process happens inside enclosed chamber to avoid disturbance by air, temperature fluctuation or vibration.

- Therefore, the analytical balance work on the principle that— the electromagnetic force required to balance an object weight is directly proportional to its mass.

Types of analytical balance

1. Mechanical Analytical Balance – This type of balance works on beam and knife-edge mechanism. The sample weight is compared against known standard masses. It operated manually and used earlier before digital balances. Accuracy is high but not convenient for fast weighing.

2. Electronic Analytical Balance – It works on electromagnetic force restoration principle. The load on pan is balanced by electromagnetic force generated inside the balance. The reading displayed digitally with very high precision up to 0.0001 g. These are most widely used in modern labs.

3. Single Pan Analytical Balance– Only one weighing pan is used, and weights are electronically adjusted or automatically calibrated. The operation is faster than double-pan type and suitable for routine analytical works.

4. Double Pan Analytical Balance– It contains two pans, one for sample and another for reference weight. Comparison between both sides gives accurate measurement. It’s less used nowadays but still preferred in teaching labs for demonstration.

5. Semi-Micro Analytical Balance– It designed for weighing very small quantities, usually with readability of 0.01 mg (0.00001 g). Used for micro analytical work where tiny mass is involved.

6.Microbalance / Ultra-microbalance– These balances used when extremely minute mass (like 1 µg or less) is to be measured. They have enclosed weighing chamber to prevent air or vibration effect.

Each type have its own advantages / limitations, but all are based on same principle of balancing gravitational force with electromagnetic or mechanical restoring force for accurate mass determination.

Parts of Analytical Balance with Functions

1. Balance plate (Pan) – The balance plate (pan) is used to bold the sample material for mass measurement, it is usually made of stainless steel and should be kept clean, dry.

2. Weights – Standard weights are used for calibration and verification of accuracy, these are kept aside (calibration masses) and sometimes they are called reference weights, they are traceable to standards.

3. Power button (On/Off) – The power button is pressed to activate or deactivate the balance, it allows the instrument to start up and to shut down safely.

4. ‘Re-zero’ / ‘Tare’ button – The re-zero or Tare button is used to rebalance the system and bring it back to neutral (zero), so container weight is removed from final result.

5. Mode button – The Mode button is used to change measurement units or functions (g, mg, oz, ct ), it configures the conversion system and user settings, sometimes multiple modes are provided.

6. Draft shields / Enclosure – Draft shields are incorporated into design to protect from air currents, dust and temperature fluctuation, they must be closed during weighing to obtain stable readings.

7. Level adjustment feet – The leveling feet (movable legs) are used to bring the balance to reference position, and leveling is checked by bubble (spirit) level or plumb bob, they are adjusted until centered.

8. Level indicator – The level indicator checks that the balance is in level, the bubble must be centered (or reading shown) before weighing is started.

9. Display panel / Screen – The display panel shows the mass reading, error messages, tare value and function status, it also provide prompts during calibration and other operations.

10. Electromagnetic coil – The electromagnetic coil generate restoring force to counteract sample weight, the required current is measured and converted to mass by the processor.

11. Photo/position sensor – A photo sensor or position detector is used to sense deflection of pan/beam, it sends signal to control circuit for correction and stabilization.

12. Control circuit / Processor – The control circuit is used to process signals, adjust coil current and convert analog data into digital reading, microprocessor control is provided for improved speed and accuracy.

13. Weighing chamber door – The chamber door (sliding or hinged) is provided to allow sample placement and must be closed while weighing, air disturbance will otherwise spoil precision.

14. Base and housing – The base/housing support internal parts and minimize vibration, it also protect electronics, they contribute to stability and durability of the balance.

15. Power supply / Adapter – The power supply (internal battery or external adapter) is used to provide electrical energy to balance, without stable power the readings are not reliable.

16. Accessories (like gloves, tweezers, weighing boats) – Small accessories are used to handle samples, they are recommended to avoid contamination and static, they help to get accurate results.

Operating Procedure of Analytical Balance – Weighing Procedure of an Analytical Balance

- Before starting, the analytical balance should be placed on a firm and vibration free surface, and the level indicator checked for correct position of bubble, by adjusting the leveling feet if needed.

- The balance must switched ON by pressing the power button, and it should be allowed to stabilize for few minutes before use, so that internal electronics reach steady condition.

- The draft shield doors are kept closed when not in use, and opened only when placing the weighing container or sample, to avoid air disturbance by the chamber.

- A clean weighing paper or container is placed on the balance pan, and after the reading stabilized, the Tare / Re-zero button pressed to set display to zero value.

- The sample to be weighed is carefully transferred into the container using spatula or tweezers (to avoid contamination), and the draft shield is immediately closed after addition.

- The balance display is observed until the reading become stable, then the mass value is recorded. If balance has automatic stability indication, the final value will blink or hold.

- After recording, the sample is removed, and again Tare is pressed to check if the display return to zero, this ensures no drift or static error during process.

- During weighing procedure, no object or hand should touch balance table, because vibration or body heat can prevail stable readings.

- All weighing must be done under same temperature (around 20–25°C) and humidity controlled area, since moisture absorption or evaporation affect accuracy.

- After completion of weighing, the weighing pan is cleaned with soft brush, and the draft shield doors are closed, balance turned off by power button to save energy.

- For very fine measurements, the balance is recalibrated using standard weights before next session to maintain accuracy and reliability of result.

- The procedure mainly rely on principle that electromagnetic force generated within the balance restore equilibrium position proportional to sample mass, hence following the stepwise process ensures consistent precision in analytical measurement.

Calibration Procedure of Analytical Balance

- Before starting calibration, the analytical balance should be placed on a stable and vibration-free surface, and checked that it is properly leveled by observing the level indicator bubble in center position.

- The balance is switched ON, and allowed to warm up for about 30–60 minutes depending on model, this stabilization time helps the electronics to reach steady temperature condition.

- The weighing chamber and pan must cleaned with soft brush or tissue to remove dust or residues, since even tiny particles can cause deviation of calibration result.

- Calibration should always performed in controlled environment, at constant temperature (20–25°C) and humidity, without strong air flow, sunlight or vibration, otherwise error will prevail in readings.

- The draft shield doors are kept closed during calibration process to prevent air turbulence and maintain steady reading on display.

- There are two types of calibration methods used:

- a) Internal calibration – The balance has built-in standard weight which automatically used when calibration mode activated.

- b) External calibration – A separate certified standard weight (traceable to OIML or NIST) is placed manually on pan for calibration purpose.

- For internal calibration, the calibration button (sometimes marked as CAL or CAL/MODE) is pressed, balance perform automatic process by itself, after few seconds it display “End” or “OK” when calibration completed.

- For external calibration, the following steps are followed –

- Press the calibration mode key on display panel.

- The balance show the required weight value (like 100 g or 200 g).

- Place that exact standard weight carefully on the weighing pan, wait until reading stabilize.

- The balance automatically adjust internal factors, then display confirmation message when completed.

- After calibration, remove the standard weight and check zero reading by pressing Tare/Re-zero, to confirm that system is correctly adjusted back to neutral.

- Calibration must be done regularly – daily before use, or after relocation of balance, or after drastic temperature change, to ensure accuracy remains within permissible limit.

- The calibration weights must handled by tweezers or gloves to avoid contamination from finger oils and moisture, which can affect the true mass value.

- Periodically, calibration certificates of standard weights should be verified by metrology laboratory to maintain traceability and compliance with GLP / ISO standards.

- Finally, after calibration, a short verification check is done by weighing a known object to confirm reading is within ± tolerance range, if deviation found then recalibration or servicing may required.

- Therefore the calibration procedure ensures that the analytical balance give reliable, consistent and traceable mass measurement, eliminating systematic error and instrument drift caused by environmental or mechanical factors.

Types of Calibration

1. Internal Calibration – This type of calibration is performed automatically by the balance itself. The balance has a built-in standard weight fixed inside, which is used whenever calibration mode is activated. No external weights are needed in this type. The balance internally measure deviation between measured value and the internal standard and then adjust it automatically. It is very convenient for frequent calibration and reduce human error, but internal standard must verified periodically for accuracy.

2. External Calibration – In this type, calibration is done using an external certified standard weight which is traceable to OIML / NIST standards. The operator manually places the required standard weight (like 100 g, 200 g, etc.) on weighing pan after pressing calibration mode key. The balance then compare the measured value with the standard one and adjust internal calibration factor. This method ensures high accuracy and traceability but require regular handling and proper maintenance of external weights.

3. Automatic Calibration– Some modern balances are equipped with fully automatic calibration systems which perform calibration at fixed time intervals or when environmental changes (like temperature drift) are detected. The balance sense deviation and initiate calibration automatically without user intervention. It ensures constant precision even during long operations.

4. Semi-Automatic Calibration – This calibration is partially automated where the user has to initiate calibration manually by pressing a key, but the rest of the procedure is performed automatically by the balance. It is simpler than external method and faster too.

5. Temperature / Time Triggered Calibration– These are specialized automatic calibrations where calibration is triggered either after specific time interval (like every 2 hours) or when temperature variation exceed a pre-set limit (for example ±2°C). This help to minimize drift caused by environmental fluctuation.

Rules/Precautions For Analytical Balances

- The analytical balance should always be placed on a firm, vibration free table and kept away from direct sunlight, air conditioner vents or door drafts, since such disturbances affect accuracy of weighing.

- Before use, the balance must checked for correct leveling by adjusting leveling feet until bubble in the level indicator comes at center position, improper leveling cause reading error.

- The balance should be calibrated daily or before important measurement, either by internal or external standard weights, to ensure reliable performance.

- The draft shield doors must remain closed during weighing operation, they are only opened for placing or removing the sample, this helps to avoid air movement effect.

- All sample containers, spatulas, and papers used must be completely clean and dry, any moisture or residue can alter true mass.

- Never weigh directly on the balance pan, always use weighing paper, boat or container to protect the pan surface and to prevent contamination.

- The object to be weighed must be at same room temperature as the balance, because hot or cold items cause air convection inside chamber leading to unstable readings.

- Do not touch the sample or standard weights with bare hands, they should handled using forceps or gloves, since oil and moisture from fingers change the actual weight.

- The sample should be added gently without spilling powders or liquids inside chamber, any spillage must cleaned immediately with soft brush or lint-free tissue.

- During weighing process, do not lean or rest hands on table surface, vibration and heat transfer from body can prevail balance stability.

- Always wait till the display reading becomes steady or stability mark appear before recording the measurement, otherwise the value may fluctuate.

- If static electricity suspected (especially for dry powders or plastics), use antistatic device or ionizer to neutralize charge before weighing.

- Keep surrounding area of balance free from clutter, unnecessary items may block airflow or generate vibration by movement.

- The balance pan and chamber should cleaned after each use, dust accumulation reduce sensitivity and precision over time.

- Do not overload the balance beyond its maximum capacity, it may damage electromagnetic system permanently.

- Regular preventive maintenance should performed, and balance serviced periodically according to manufacturer instruction.

- The balance must always be turned OFF when not in use for long time, and covered with dust cover to protect from environment.

- Observing these precautions ensure the analytical balance remain accurate, stable and long lasting for critical laboratory applications etc.

Factors that affect readings on analytical balances

- Air Currents – The movement of air inside or around the weighing chamber cause fluctuation in balance reading. This is why draft shield are used to isolate the weighing pan from external airflow.

- Temperature Variation – Changes in room temperature or sample temperature create convection currents and thermal expansion of materials, which affect mass readings. Weighing should done after both balance and sample reach same temperature equilibrium.

- Humidity – High humidity or moisture condensation on the sample, especially hygroscopic substances, lead to increase in apparent weight, while low humidity cause evaporation losses.

- Static Electricity – Accumulation of static charge on containers or samples (especially plastics and powders) repel or attract particles, which disturb the force on weighing pan and lead to unstable readings.

- Vibration – Vibrations from nearby equipment, footsteps or floor movement disturb the electromagnetic system and cause noise in readings, hence balances are placed on anti-vibration tables.

- Magnetic Fields – Strong magnetic or electric fields near balance (from motors or other devices) may induce currents in electromagnetic circuit, altering balance sensitivity.

- Air Buoyancy Effect – Difference in air density at different temperatures or pressures produce buoyancy effect on the sample, resulting in small but measurable mass deviation, especially at micro-level.

- Handling Error – Touching the sample or standard weights by hand cause transfer of oil, moisture and heat, which slightly change mass reading, therefore weights must handled using tweezers.

- Sample Condition – Volatile liquids, hygroscopic or static-prone samples give unstable readings because they either evaporate or absorb moisture during weighing.

- Balance Leveling – If the balance not properly leveled, the electromagnetic force distribution becomes uneven, leading to systematic measurement error.

- Overloading – Placing load above balance capacity cause mechanical strain or deformation of weighing mechanism, which alter calibration and accuracy.

- Environmental Disturbances – Noise, light vibration from centrifuges, or electrical fluctuation in power supply also affect stability of digital display reading.

- Operator Technique – Rapid placement of sample, open chamber door, or poor cleaning after weighing lead to minor deviations or drift in readings.

- Altitude and Pressure Variation – At higher altitudes, reduced air pressure change buoyancy correction factor, causing small change in apparent weight for very precise measurements.

Use of analytical balance

- The analytical balance used for accurate determination of mass of substances in laboratory experiments where precision is highly required.

- It mainly used in quantitative chemical analysis, to weigh reagents before preparation of standard solutions, titration, or dilution processes.

- The balance is used in pharmaceutical laboratories for formulation of drugs, weighing of active pharmaceutical ingredients (API) and excipients in precise quantity.

- In analytical chemistry, it helps in gravimetric analysis, where the mass of precipitate is measured to calculate concentration of analyte.

- It used in research laboratories to measure small samples of organic/inorganic compounds for synthesis, testing or calibration purpose.

- The balance also used in food industry to measure nutritional ingredients, flavoring agents, or additives in accurate proportions for quality control.

- In biological laboratories, it used to weigh biological samples like tissues, enzymes or powdered extracts before experimental analysis.

- Analytical balance used for preparation of calibration standards for instruments like spectrophotometer, chromatograph etc.

- It used in material testing laboratories for measuring small metal or polymer samples during density or moisture content determination.

- The balance is used in forensic analysis for measuring very small evidence materials (powders, fibers, residues) where even slight error is significant.

- It used for checking purity of compounds by comparing theoretical and actual weight during chemical reaction yield determination.

- Analytical balance also serve in educational laboratories for student experiments to understand principle of precision weighing and data accuracy.

- In environmental laboratories, it used for measuring filter paper weights before and after sampling of dust or particulate matter for air pollution analysis.

Advantages of Analytical Balance

- The analytical balance provides very high accuracy and precision in mass measurement, even up to 0.0001 g or 0.1 mg, which make it suitable for scientific and research works.

- It used for small quantity measurement with minimal error, that’s why it is preferred in analytical chemistry and pharmaceutical labs.

- The design includes draft shield that protect the weighing chamber from air currents, ensuring stability and consistency of readings.

- It allows quick response time, since readings are displayed digitally and stabilized within few seconds without manual adjustment.

- Analytical balances are equipped with automatic calibration systems, which reduce human error and maintain continuous accuracy during operation.

- The electromagnetic force restoration principle used in these balances ensures linear and reproducible readings even with repetitive measurements.

- It require very small amount of sample to obtain precise results, therefore material loss during weighing is minimum.

- The balance offer user-friendly digital interface with tare, calibration, and mode functions which simplify analytical procedure.

- It helps in minimizing environmental influence, since internal sensors compensate for small temperature and pressure changes automatically.

- Analytical balances are suitable for a wide range of applications like gravimetric analysis, standard solution preparation, formulation and micro-sample weighing etc.

- They are highly reliable and produce traceable results, which are essential for validation and quality control in laboratories.

- Maintenance is relatively easy because internal parts are enclosed and protected from dust and moisture, increasing instrument life.

- Due to high precision and stability, analytical balance reduce experimental variation and help achieve reproducible data between multiple trials.

Limitations of Analytical Balance

- The analytical balance is very sensitive to external disturbances like vibration, air flow, or temperature change, which cause unstable readings and error in measurement.

- It cannot used in open or dusty environment because dust particles and air currents interfere with the weighing chamber, affecting accuracy.

- The balance requires a controlled environment, with constant temperature and humidity; even small fluctuation can change mass readings.

- Handling error easily occur since touching the sample or weights transfer oil/moisture that alter true mass, hence operator skill is necessary.

- The maximum capacity of analytical balance is limited, usually up to 200–300 g, so it not suitable for weighing larger or bulky samples.

- It is very expensive instrument, and maintenance or repair require professional calibration which increase operational cost.

- Analytical balance cannot used for weighing volatile or reactive chemicals directly, because vapors or reaction heat disturb measurement stability.

- Static electricity cause major problem especially with fine powders or plastic containers, leading to erratic or drifting readings.

- The balance takes time to stabilize and needs warm-up before accurate use, which slow down weighing process when large number of samples analyzed.

- Exposure to magnetic or electric field near equipment like centrifuge, stirrer or refrigerator can interfere with electromagnetic mechanism of balance.

- Regular calibration is mandatory, otherwise small drift accumulate over time and affect accuracy of results.

- Frequent cleaning required since even tiny dust or fingerprint on weighing pan can introduce measurable error in ultra-sensitive measurement.

- It is not portable instrument and need fixed position setup with anti-vibration table, so field application or on-site weighing cannot performed.

Video guide of Analytical Balance

FAQ

What is the minimum load weighed on analytical balance?

A basic rule of thumb states that to weigh 1 milligramme of sample, at least a 0.0001 g (Four Place) balance is required. This may still not be sufficient. We propose a minimum load of 10 milligrammes for our four-position balances (mg). Or 0.0100 g to ensure accurate measurements.

What Is Mass?

Mass is a constant measure of how much matter something has. No matter where you measure it, it’s always the same. The kilogramme and the gramme are the most common ways to measure mass.

What Is Weight?

The heaviness of an item is its weight. It is proportional to the item’s gravity multiplied by its constant mass. Due to differences in gravity, the weight of an object at the summit of a mountain will be less than the weight of the same object at the base. The newton is a unit of measurement for weight. A newton accounts for an object’s mass and relative gravity to determine its total force, which is weight.

Although mass and weight are distinct concepts, the process of ascertaining both is referred to as weighing.

What is Accuracy?

The capacity of a scale to produce results that are as close to the actual value as possible. When comparing masses of one kilogramme, the accuracy of the best current balances exceeds one part in one hundred million.

What is Calibration?

The comparison between a scale or balance’s output and a standard value. Typically performed with a known reference weight and adjusted so the device delivers a consistent reading.

What is Capacity?

The maximum load that the equipment can measure.

What is Precision?

Repeatability is the degree of agreement between repeated measurements of the same quantity. A scale may be exceptionally precise but not necessarily accurate.

What is Readability?

This is the smallest division that can be read on the scale or balance. It might range from 0.1g to 0.0000001g. The readability of a scale refers to the number of places following the decimal point that can be read.

What is Tare?

The process of removing a known weight of an object, often the weighing container, from a scale in order to zero it. This indicates that the final reading will reflect the weight of the material being weighed and not the weight of the container. The majority of balances permit tagging to capacity.

What is the difference between accuracy and precision?

Accuracy indicates how well a scale approximates the actual value. A faulty scale provides a reading that is not near to the actual value. Precision and accuracy are distinct concepts. Repeatedly weighing the same object on a precise scale will get the same result. A precise scale can be unreliable if it consistently returns values that are far from the actual value. For instance, a scale that reads 5.2g for the same item three times in a row is quite exact, but if the item truly weighs 6.0g, the scale is not accurate.

What is the use of analytical balance?

Analytical balances are precision measuring instruments used in quantitative chemical analysis, to determine the mass of solid objects, liquids, powders and granular substances.

What are the various parts of an analytical balance?

The various parts of an analytical balance are Balance plate (pan), Weights, Water pass, Power button (on / off button), ‘Re-zero’ or ‘Tare’ button, ‘Mode’ button

- Proper Use of Balances. (2022, August 17). California State University Dominguez Hills.

- https://chem.libretexts.org/@go/page/74518

- https://www.axis.pl/en/k-analytical-balances-1.html

- https://www.nextdayscience.com/blog/analytical-balances.htm

- https://www.sigmaaldrich.com/IN/en/search/analytical-balance?focus=products&page=1&perpage=30&sort=relevance&term=analytical%20balance&type=product_name

- https://www.precisa.co.uk/product_category/analytical-balances/

- https://www.labsalescorporation.com/electronic-analytical-balance.html

- https://www.scalepeople.com/blog/four-types-of-laboratory-balances/

- http://chemed.chem.purdue.edu/genchem/lab/equipment/analytical/instructions.html

- https://www.laboratory-supply.net/blog/difference-between-analytical-balance-and-precision-balance/

- https://www.chemicool.com/definition/analytical_balance.html

- https://www.cerritos.edu/chemistry/_includes/docs/Chem_111/Lab/Exp%203%20Laboratory%20Weighing%20Fall%2008.pdf

- https://scalesu.com/products/analytical-balances/

- https://www.mt.com/in/en/home/products/Laboratory_Weighing_Solutions/analytical-balances.html

- https://ussolid.com/blog/how-to-calibrate-analytical-balance/

- https://microbenotes.com/analytical-balance-principle-parts-types-examples/

- https://ussolid.com/blog/how-to-properly-use-an-analytical-balance/

- https://www.precisa.com/blog/what-is-an-analytical-balance/

- https://www.pharmaguideline.com/2014/11/drift-and-its-importance-in-analytical-balances.html

- https://www.labmanager.com/laboratory-technology/analytical-balances-and-proper-weighing-practices-1805

- https://www.grainger.com/know-how/equipment-information/kh-laboratory-balance-scale-types-care-terms

- https://owlcation.com/stem/A-Quick-Look-at-Mass-Volume-and-Density

- https://hyprowira.com/en/blog/analytical-balance-sections

- https://radwag.com/en/analytical-balances,4,101-101

- https://www.sartorius.com/en/products/weighing/laboratory-balances/analytical-lab-balance

- https://in.vwr.com/assetsvc/asset/en_IN/id/26952326/contents/manual-top-loading-balances.pdf

- https://us.ohaus.com/en-US/Products/Balances-Scales/Analytical-Balances

- https://www.depts.ttu.edu/meatscience/docs/The-Analytical-Balance-7-23-20.pdf

- Text Highlighting: Select any text in the post content to highlight it

- Text Annotation: Select text and add comments with annotations

- Comment Management: Edit or delete your own comments

- Highlight Management: Remove your own highlights

How to use: Simply select any text in the post content above, and you'll see annotation options. Login here or create an account to get started.