What is Working Distance?

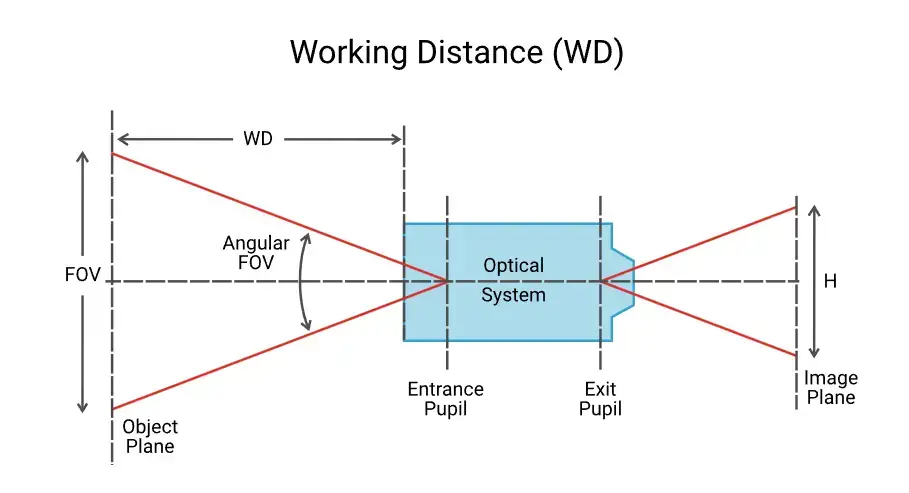

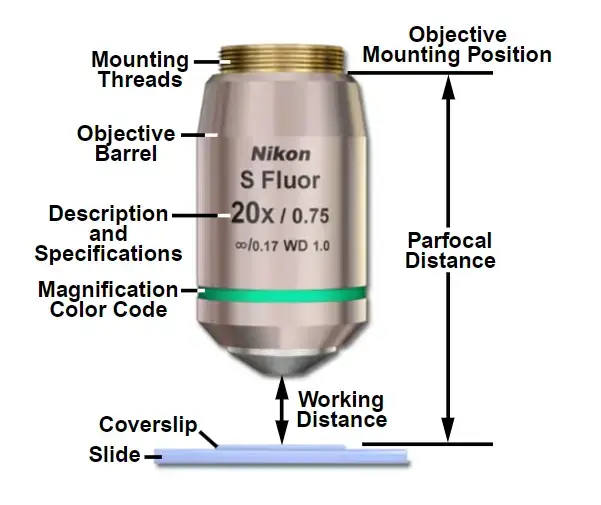

Working distance is defined as the distance that is maintained between the “objective lens” and the specimen, during focusing; it is measured along the optical axis of the microscope.

It is considered critical, because it determines the space available for manipulating the specimen, adding reagents, or using tools; a short working distance may limit handling.

Working distance is usually inversely related to the “magnification” of the objective; higher magnification objectives have shorter working distances, whereas lower magnification objectives provide longer working distances.

It should be noted, that incorrect estimation of working distance can result in the “objective lens” touching the specimen, which may damage both the lens and the sample.

It is typically provided by the manufacturer of the objective lens and can also be roughly estimated during microscopic adjustment; care is taken to avoid collisions.25

How Does Working Distance Work?

It is defined that “working distance” is the physical space between the “objective lens” and the specimen, and focusing is achieved along the optical axis.

- Light from the illumination system passes through the lens and converges on the specimen; correct distance ensures the focal point aligns with the sample plane.

- The objective lens is moved along the optical axis using coarse and fine focus knobs; precise focusing is achieved without contacting the specimen.

- It is observed that as magnification increases, focal length decreases, and “working distance” is reduced; careful adjustment is required.

- Proper distance allows safe placement of tools, reagents, or manipulations; collisions with the lens are prevented.

- Maintaining correct “working distance” ensures light converges properly, and sharp, clear images are produced; observations remain precise.

- It is noted that microscopes are operated efficiently when “working distance” is considered; experiment safety and accuracy are maintained.36

How to Find the Working Distance for an Objective Lens

Check Manufacturer Specs – It is first recommended that the “working distance” is obtained from the objective lens datasheet; distance values are usually provided in millimeters.

Mount the Lens – Then, the objective lens is securely attached to the microscope nosepiece; care is taken to avoid cross-threading or misalignment.

Prepare Specimen – A specimen slide is placed on the stage, and it is ensured that it is flat and stable; sample integrity is maintained.15

Initial Focus – Next, the coarse focus knob is used to bring the specimen into approximate focus; lens is moved closer cautiously.

Fine Adjustment – Then, the fine focus knob is slowly turned to achieve sharp focus on the specimen; attention is paid to avoid collisions.

Measure Distance – It is observed that the distance from the tip of the “objective lens” to the top of the specimen surface is measured using a calibrated scale or microscope ruler; this is recorded as the working distance.

Verify with Other Objectives – Finally, the same procedure can be repeated for other objective lenses; comparative values are noted, and safe handling is ensured.

Practical Note – Care is taken throughout the process to prevent touching or damaging the specimen or lens; proper lighting and alignment are maintained.27

Why is Working Distance Important?

For various practical purposes, particularly in microscopy and other optical instruments, working distance is crucial. These are some main reasons it matters:

- Safety of Lens and Specimen – It is considered that “working distance” is important, because collisions between the “objective lens” and specimen are avoided; damage is minimized.

- Specimen Manipulation – Then, it is ensured that enough space is available for handling the sample, adding reagents, or using tools; experiments are conducted without obstruction.

- Image Quality – It is observed that proper “working distance” allows light to focus correctly, and clear images are produced; observations are precise.

- Compatibility with Objectives – Next, it is noted that high magnification lenses have shorter distances, whereas low magnification lenses provide longer distances; adjustments are required for each.

- Operational Efficiency – Then, it is recognized that correct distance improves workflow, reduces errors, and maintains precision and safety; careless handling may disrupt experiments.

- Sample Integrity – It is ensured that delicate or fragile specimens are not crushed or disturbed; structural preservation is maintained.

- Ease of Observation – Next, it is observed that proper distance allows smooth focusing, and repeated adjustments are minimized; efficiency is enhanced.

- Contamination Prevention – Then, it is considered that accidental contact is reduced, and contamination of the lens or specimen is avoided.4

- Instrument Longevity – It is noted that collisions are avoided, and lifespan of the “objective lens” and microscope is prolonged; maintenance needs are reduced.

- Reproducibility – Finally, it is ensured that consistent “working distances” allow experiments to be repeated reliably; results remain trustworthy.

Long Working Distance Objective Lenses

- “Long working distance” (LWD) objective lenses are designed so that a greater distance is maintained between the “objective lens” and the specimen; focusing is achieved without risking contact.

- They are used when extra space is required for manipulating samples, adding reagents, or using tools; experiments are conducted safely.

- LWD lenses are usually low to medium magnification; higher magnification versions exist, but working distance is still longer than standard lenses.

- They are commonly applied in live specimen observation, industrial inspection, and material testing; fragile or bulky samples are handled without damage.

- It is observed that collisions are minimized, specimen accessibility is improved, and workflow is more efficient; light focusing remains precise.

- LWD lenses often have longer focal lengths and specialized optics; image clarity is maintained despite increased distance.

- When using LWD lenses, care must be taken that “working distance” is adjusted properly; proper illumination and focus are ensured.810

| Objective Type | Magnification | Working Distance (mm) |

|---|---|---|

| Achromatic | 4X | 37.4 |

| Achromatic | 10X | 6.6 |

| Achromatic | 40X | 0.64 |

| Achromatic | 100X (Oil) | 0.19 |

| LWD Plan Achromatic | 4X | 11.98 |

| LWD Plan Achromatic | 10X | 11 |

| LWD Plan Achromatic | 40X | 2.9 |

| LWD Plan Achromatic | 100X (Oil) | 0.12 |

Shortest Working Distance Objective Lens

- The “shortest working distance” objective lens is designed to have minimal space between the “objective lens” and the specimen; focusing is achieved very close to the sample.

- It is used for high magnification observations where detail is critical; fine structures are resolved with precision.

- These lenses are usually high magnification, often 40x, 60x, or 100x; working distance is extremely short compared to lower magnification lenses.

- They are commonly applied in cellular biology, microbiology, and materials science; fine details of specimens are studied, often under immersion.

- It is noted that some shortest working distance lenses require immersion (oil or water) to maintain image clarity; optical efficiency is improved.

- Extreme care is required to avoid collisions; even minor stage movements can damage the “objective lens” or specimen.

- Maximum resolution is achieved, and fine structural details are visualized; however, sample manipulation is limited due to short distance.9

Shortest Working Distance (SWD) Lens vs Long Working Distance (LWD) Lens

| Feature | Shortest Working Distance (SWD) Lens | Long Working Distance (LWD) Lens |

|---|---|---|

| Definition | Minimal distance between “objective lens” and specimen; focusing is very close | Greater distance between “objective lens” and specimen; focusing occurs safely away from sample |

| Magnification | High magnification (40x, 60x, 100x) | Low to medium magnification; some higher magnifications exist |

| Applications | Cellular biology, microbiology, materials science; fine structures observed | Live specimens, industrial inspection, material testing; bulky or fragile samples handled |

| Immersion | Often requires oil/water immersion for clarity | Usually does not require immersion; air lens is common |

| Sample Handling | Care required to avoid collisions; manipulation is limited | Easy manipulation; space available for tools or reagents |

| Advantages | Maximum resolution; fine structural details visualized | Safe handling; improved workflow; collisions minimized |

| Focal Length | Very short focal length | Longer focal length |

| Image Quality | High resolution; precise detail | Clear images; sometimes slightly lower resolution than SWD |

Working distance in the work place – real life examples.

- Microscope Labs – “Working distance” is used to handle samples safely; pipettes or probes are applied without touching the lens, and manipulation is precise.

- Surgical Procedures – In microscopic surgeries, distance between the “surgical microscope” and tissue is maintained; accuracy is ensured and tissue damage is avoided.

- Electronics Inspection – Small components are examined under microscopes, and “working distance” allows tools to be used without contact; components remain intact.

- Industrial Quality Control – Materials are inspected for defects; proper distance keeps fragile items safe, and measurements are reliable.14

- Forensic Analysis – Evidence is observed under microscopes, and “working distance” prevents contamination; samples are preserved.

- Education / Training – Students are taught to maintain “working distance”; safety and handling skills are developed.

- Pharmaceutical Research – Reagents are added under the microscope using correct distance; experimental accuracy is maintained.

- Material Science – Small defects or particles are measured under microscopes, and “working distance” ensures precise readings; samples are undamaged.11

Relationship Between Magnification and Working Distance

- The connection between magnification and working distance is quite interesting. It’s like a seesaw – when one goes up, the other goes down.

- When you’re using lower magnification, you can keep the lens a bit far from the object you’re looking at. This is called a long working distance. But as you want to zoom in more and make things bigger, you have to move the lens closer to the object. This makes the working distance much shorter.

- For example, if you’re using really powerful lenses, like the 100x ones, they need to be very, very close to the object. They’re so close that sometimes they need oil to help them see better. But being this close can be tricky – you might accidentally touch and damage the object you’re studying. It’s like getting super close to something delicate. So, it’s important to be careful when using these lenses.

- Remember, it’s a trade-off: the more you magnify, the closer you need to be to the object. So, when you’re using a microscope, you’re not just looking at tiny things – you’re also figuring out how to balance magnification and distance to see things clearly and without causing any harm. It’s a neat lesson in science and patience!1213

FAQ

What is working distance in a microscope?

Working distance in a microscope is the space between the objective lens and the object you’re observing. It’s important because it affects how close you need to be to the object to see it clearly.

How does working distance relate to magnification?

Working distance and magnification are inversely related. As you increase magnification, you need to move the lens closer to the object for a clear view.

Why do some objective lenses require oil immersion for optimal working distance?

Oil-immersion lenses, like the 100x objective, need oil between the lens and the slide to achieve maximum clarity. The oil helps capture more details and improve the image quality.

Why is longer working distance preferred for some observations?

Longer working distance is preferred when observing specimens that are not flat or emit harmful substances. It provides more space and reduces the risk of damaging the object or the lens.

What happens if the working distance is too short?

A short working distance can make it challenging to manipulate tools and might lead to accidental contact between the lens and the specimen, potentially causing damage.

How is working distance measured and indicated on an objective lens?

Working distance is usually indicated on the objective lens barrel using the letters “WD,” followed by the distance in millimeters (e.g., “WD: 0.5” or “0.5 EL WD”).

Can working distance affect the cost of a microscope lens?

Yes, lenses with longer working distances might cost more due to their specialized design and ability to reduce the risk of damage, potentially saving money in the long run.

Are there alternatives to oil immersion lenses for achieving short working distances?

Yes, some dry objective lenses can provide short working distances without the need for oil immersion, but they may have slightly different characteristics.

Why is it important to balance working distance and magnification?

Balancing working distance and magnification ensures clear and accurate observations without damaging the specimen or the lens. It’s about finding the right distance for the best results.

Can you measure working distance using a digital caliper?

While it’s possible to measure working distance using a digital caliper, it’s not recommended as it could potentially damage the lens or compromise your microscope’s performance. It’s safer to rely on manufacturer specifications or inscriptions on the lens barrel.