- The discovery of microorganisms and the explanation of fermentation chemistry in the 19th century allowed us to comprehend fermented products. Possibilities have broadened with the development of technology; the journey towards a healthier and conventional technique of producing fermented products by controlling spontaneous production has begun.

- Using the fermentation method, huge commercial organisations create fermented foods such as dairy goods, meat products, cereal products, fruit and vegetable products, alcoholic drinks, and soy-based products today.

- In this context, Louis Pasteur’s (1822-1895) research from approximately 150 years ago is considered a milestone in fermented food technology.

- Pasteur, who gave his name to the dairy industry’s key “pasteurisation” method, explained that this shift in fermented foods is caused by microbes and set the groundwork for the starter culture and fermented food manufacturing technology.

- In the 1860s, as a result of these experiments, scientists such as Storch, Weigman, and Cohn employed sour whey and buttermilk to produce fresh butter and cheese of higher quality.

- Lister produced the first pure culture of lactic acid bacteria in 1873, almost ten years after Pasteur’s fermentation investigations. In 1890, the first commercial enterprise offering starter cultures for dairy products was founded in Denmark.

- As a result of the invention of the lyophilization process in the 1950s, the usage of starting culture spread to numerous regions.

Starter Culture Definition

A starter culture is a microbial preparation containing a very high number of cells (such as 1012 g-1) of one or more microbe species that is given to raw material to produce fermented food by accelerating and directing fermentation.

- A starter culture is a culture of microorganisms that performs fermentation. In the preparation of fermented foods and beverages, starter preparations facilitate the beginning of the fermentation procedure.

- Several bacterial and other microbial strains have been utilised individually or in combination to achieve the desired impact in the final product.

- Pure or mixed bacterial or fungal strains are employed as starter cultures to kickstart the fermentation process.

- Starter culture refers to food-grade microorganisms with recognised and stable metabolic activities that are utilised to generate fermented foods with the desired look, body, texture, and flavour.

- Starter culture refers to the microorganisms chosen for their capacity to produce lactic acid for curd creation and a low pH to prevent spoilage, produce metabolites that impart desirable flavours, or produce enzymes that mature the dairy product.

Functions of Starter Cultures

The fundamental function of lactic starters is to convert lactose into lactic acid. In addition to producing lactic acid, starting cultures are also beneficial in the methods described below.

Functions of starter cultures

| Function | Result |

| Acid production | Gel formationExpulsion (syneresis) of whey for texturingPreservation of milkHelps in the development of flavour |

| Flavour | Formation of flavour compounds like diacetyl and acetaldehyde |

| Preservation | Lowering of pH and redox potentialProduction of lactic acidProduction of antibioticsProduction of H2O2Production of acetate |

| Gas formation | Eye formation in certain cheesesProduction of open texture Ex. blue veined cheese |

| Stabilizer formation | Development of body and viscosityEx. Polysaccharide materials |

| Lactose utilization | Reduces the development of gas and off flavoursSuitable for lactose intolerant people |

| Lowering of redox potential | Helps in preservationHelps in development of flavour |

| Proteolysis and lipolysis | Helpful in the ripening/maturation of cheeses |

| Miscellaneous compounds | Production of alcohol in kefir and kumis |

Characteristics of a good starter culture

When selecting a particular LAB starter culture, either alone or in combination with others, for the production of fermented milk products, the following desirable qualities must be considered in order to fully exploit their fermentation potential. These features consist of:

- The lactic starter culture must produce enough lactic acid at a desirable rate to accommodate the plant’s production schedule and provide a high-quality output.

- A healthy LAB culture must continue to produce acid over the temperature range in which it is likely to be utilised in the manufacturing of fermented dairy products from milk.

- The LAB starters must be antibiotic and bacteriophage resistant.

- The LAB starter must be active in the presence of inhibitory compounds including chemical, sanitizer, and detergent residues in milk.

- A good beginning culture should not create bacteriocins, bacteriocin-like chemicals, or antibiotic-like substances that inhibit other strains in the mixed culture.

- A good LAB starting culture should generate fermented products with appropriate flavour, aroma, consistency, and body.

- The usage of starter cultures that produce defects such as ropy body, malty or any other unwanted flavour, as well as related problems, should be ceased promptly.

- In the case of mixed cultures, the constituent cultures must be capable of maximising aroma and flavour generation without inhibiting acid formation.

- Even after multiple subcultures, the associative effect of mixed cultures must be relatively stable and contribute to the formation of a good starting culture.

Classification /Taxonomic Groups as Per Bergey’s Manual

As illustrated in Fig. 1, starter cultures are typically categorised according to their ability to consume lactose.

1. Bacteria

a. Genus lactococcus

Bergey’s Manual of Systematic Bacteriology (1986) classified all mesophilic lactic acid bacteria (LAB) and Lactococcus lactis as a single species due to their shared characteristics.

- Isoprenoid quinines and enzymes are identical Beta-phosphate.

- Undifferentiated lactic dehydrogenase.

- Equal proportion of guanine and cytosine.

- High DNA similarity.

Examples include

- Lactococcus lactis subsp. cremoris : Acid producer but non-flavour producer

- Lactococcus lactis subsp. cremoris : Acid producer but non-flavour producer

- Lactococcus lactis subsp. lactis biovar. diacetylactis: Both acid and flavour producer

All of these Lactococcus species are mesophilic, and their optimal growth temperature ranges between 25 and 30 degrees Celsius. All organisms are homogeneously fermentative.

b. Genus streptococcus

- Streptococcus members are Gram-positive organisms that typically form pairs or chains.

- In 1937, Sherman separated the genus based on physiological and growth characteristics, in particular temperature limitations on growth.

- Sherman identifies four categories of bacteria: (1) pyogenic, (2) viridans, (3) enterococcus, and (4) lactic.

- Relationships between species have been shown to overlap, rendering this classification somewhat obsolete.

- Streptococcus salivarius subsp. thermophilus is the only species used as a culture starter.

- This yoghurt culture is thermophilic, with an optimal growth temperature between 38 and 42 degrees Celsius. All organisms are homogeneously fermentative.

c. Genus leuconostoc

- All are heterofermentative organisms that can convert glucose into lactic acid, carbon dioxide, and aromatic compounds (ethanol and acetic acid).

- Typically, these microorganisms are combined with lactic acid bacteria (LAB) in multiple or mixed strain cheese starter cultures to produce flavour compounds. Leuconostoc cremoris, Leuconostoc citrovorum, Leuconostoc dextranicum.

d. Genus lactobacillus

- Along with Streptococcus salivarius subsp. thermophilus, Lactobacillus delbruekii subsp. bulgaricus is utilised in the production of yoghurt.

- These two organisms have a symbiotic relationship with one another. Lactobacillus acidophilus is a probiotic culture that is used to make acidophilus milk and other probiotic milk products such as Bifigyurt and Bioghurt, etc.

- The members of lactobacillus are divided into three groups based on their ability to ferment glucose, as depicted in Figure.

e. Genus bifid bacterium

- Found in the intestines of newborns, humans, numerous animals, and honeybees.

- These organisms are typically employed in conjunction with yoghurt, acidophilus milk, or yakult starting cultures to prepare fermented milk products for therapeutic purposes.

- Bifidobacterium breve, Bifidobacterium longum, Bifidobacterium inf antis, etc.

- The optimal growing temperature range is 37 to 41 degrees Celsius. For optimal growth, anaerobic conditions are required.

- Milk fermented with bifidobacteria has a unique vinegar flavour due to the breakdown of carbohydrates producing acetate and lactate.

f. Genus propionibacterium

- Swiss cheese contains Propionibacterium freudenreichii and Propionibacterium shermanii.

- During the ripening / maturation process, it is able to develop big gas holes in the cheese. There are also P. jensenii, P. thoenii, and P. acidipropionici among these taxa.

g. Genus brevebacterium

- Brevebacterium linens is used as a starter culture for bacterial surface-ripened cheeses.

- It lends an unique reddish orange hue to the rind of Brick and Limburger cheeses, as well as Camembert cheese.

2. Moulds

Molds are utilised in the production of certain semi-soft cheese kinds and fermented milk products. Molds increase the flavour and slightly alter the consistency of curd.

a. White mould

- It is utilised in the production of surface-ripened cheeses like as Camembert and Brie.

- Eg: Penicillium camemberti, Penicillium caseicolum, Penicillium candidum.

b. Blue mould

- It is utilised in the production of cheeses such as Roquefort, Blue Stilton, Danish blue, Gorgonzola, and mycella.

- Eg: Penicillium roquefortii.

c. Other moulds

- Mucor rasmusen is utilised in the production of ripened skim milk cheese in Norway.

- Aspergillus oryzae is used to produce Soya milk cheese in Japan.

- Geotricum candidum is utilised in the production of Villi, a Finnish cultivated product.

- The white velvety covering on the surface of the milk is caused by mould growth.

3. Yeasts

Yeasts are used in the manufacture of Kefir and Kumiss

a. Kefir grains

- Kefir grains contain many bacteria, including Candida kefir, Kluyeromyces marxianus, Saccharomyces kefir, and Torulopsis kefir.

b. Kumiss

- Torulopsis spp. are significant starting microflora of kumiss. Saccharomyces cervisiae, Kluyeromyces marxianus var lactis.

Types of Starters

On the basis of microflora makeup, growth temperature, product type, flavour generation, and kind of fermentation, starters are classified into the following categories:

Types of Starters Based on the composition of micro flora/ organisms

- Single: In the manufacture of dahi or cheese, a single organism is always employed. Due to a bacteriophage attack, there will be a rapid failure of the starter, resulting in significant losses for the industry.

- Paired compatible strain: Two strains of cultures with known proportions of complementary activity are utilised to create a paired compatible strain. This will lessen the likelihood of cultural failures. In the event of a bacteriophage attack, only one type of organism will be harmed, while the other will continue to ferment normally.

- Mixed Strain: Multiple organisms with diverse characteristics, such as acid generation, flavour production, slime production, etc., are utilised in an undetermined proportion.

- Multiple mixedstrain: The use of more than two strains in proportions that are known. These strains’ quality and behaviour are predictable.

Types of Starters Based on the growth temperature

Organisms can be classified as mesophilic or thermophilic based on their growth temperatures.

1. Mesophilic starter cultures

- The ideal growth temperature for these cultures is 30°C, and their growth temperature range is between 22 and 40°C.

- The mesophilic starting cultures typically contain Lactococci germs.

- Examples of Dahi cultures: Lactococcus spp.

- Lactococcus lactis subsp. cremoris

- L. delbrueckii subsp. lactis

- L. lactis subsp. lactis biovar diacetylactis

- Leuconostoc mesenteroides subsp. Cremoris

2. Thermophilic starter cultures

- These cultures have an optimal growth temperature of 40°C and a growth temperature range of 32-45°C.

- Examples include:

- Streptococcus salivarius subsp. thermophilus (S.thermophilus)

- Lactobacillus delbrueckii subsp. bulgaricus

- L. delbrueckii subsp. lactis

- L. casei

- L. helveticus

- L. plantarum

Types of Starters Based on the flavour production

The types of starters include B, D, BD, and N based on their ability to produce flavour.

- B (L) type: Leuconostocs as taste producer (old name is Betacocccus).

- D type: L. lactis subsp. lactis biovar diacetylactis is the type D organism.

- Type BD (LD): Mixture of the two preceding cultures.

- N or O type: Lack of a flavor-producing organism

Types of Starters Based on the type of fermentation

Based on the end metabolites generated from glucose metabolism, starters are classed as homogeneously or hetero fermenter.

- homogeneously fermentative cultures: example. Lactococcus lactis subsp lactis.

- Hetero fermentative cultures: example. Leuconostoc dextranicum.

Starter Culture Preparation

- Using the fundamental instructions for producing a beginning culture, a superior product can be produced. The nutrient requirements vary depending on the organism utilised.

- The nutritional medium often consists of beet molasses or sugar cane as a carbon source, ammonium salt, urea, malt sprouts as a nitrogen source, vitamin precursor, inorganic salts, and growth stimulants.

- Temperature and pH can vary based on the organism utilised. Unquestionably, starter culture microorganisms are selected according on the product and its qualities.

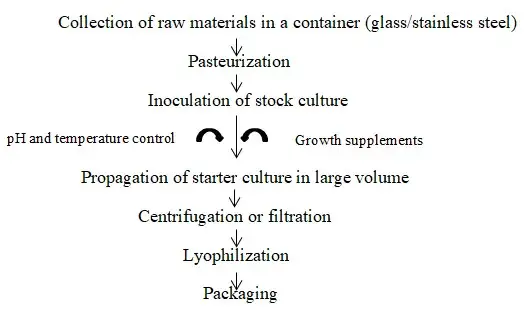

The flowchart that follows provides an overview of the preparation of starting culture.

Preservation of Starter Culture

Preserving starter cultures in liquid, frozen, or dry forms. The following methods can be used to maintain the starting culture:

- Sub-culturing: The starter culture can be maintained by transferring organisms to sterile fresh media at intervals of two to three months. Contamination during cell transfer and mutation during cell multiplication are the key problems associated with this technique.

- Storage at reduced temperature: The cultures are seeded onto agar slopes and stored at -20°C covered with sterile mineral oil or at -196°C in liquid nitrogen and re-suspended in cryo-protectant (10% glycerol) to prevent cell damage caused by the formation of ice crystals. These cells can be stored for six to twelve months.

- Storage in the dehydrated form: The inoculation culture in sterile, moist soil is allowed to grow for a few days before being dried at room temperature for approximately two weeks. This technique has been utilised extensively to store and preserve fungi and actinomycetes.

- Lyophilization: This approach requires cultivating the culture to its maximum stationary phase before lyophilization. Using a protective medium such as milk, serum, or sodium glutamate, cells are resuspended. A little amount of the suspension is then placed in an ampoule and frozen until the sublimation process is complete. The ampoule is then sealed. The cells in the ampoules can be preserved for up to 10 years if kept in a refrigerator.

Application of Starter Culture

There are numerous applications for starter culture in various industries. Listed below are some applications of starting culture.

- Adapted to the substrate, starter cultures allow us to govern the fermentation process and deliver predictable results.

- Currently, the use of starter culture as a probiotic is given equal weight.

- Starter cultures are utilised in numerous food industries, including the dairy industries for the manufacturing of cheese and other fermented dairy products, as well as the meat and alcoholic beverage industries for the production of sausage and beer and wine, respectively.

- It contributes to the enhancement of flavour, texture, and lactose digestion.

- It can be employed as a preservative.

References

- Durso, L., & Hutkins, R. (2003). STARTER CULTURES. Encyclopedia of Food Sciences and Nutrition, 5583–5593. doi:10.1016/b0-12-227055-x/01146-9

- Hansen, E. B. (2014). STARTER CULTURES | Uses in the Food Industry. Encyclopedia of Food Microbiology, 529–534. doi:10.1016/b978-0-12-384730-0.00320-7

- http://ecoursesonline.iasri.res.in/mod/resource/view.php?id=103033

- https://culturesforhealth.com/collections/cultured-favorites

- https://www.basu.org.in/wp-content/uploads/2020/04/Starter-Culture.pdf.pdf

- Sulieman, Abdel Moneim. (2017). Microbial Starter Cultures.

- http://dairy-technology.blogspot.com/2014/01/types-of-starters.html

- https://microbeonline.com/starter-culture-types-examples-and-uses/

- https://link.springer.com/book/10.1007/978-3-319-17915-5