- Chocolate, sugar confectionery (non-chocolate), liquid sugars, sugar syrups, and honey are the high-sugar items.

- Sugar confectionery products include of hard candy, soft/gummy candy, caramel, toffee, licorice, marzipan, creams, jellies, and nougats.

- Low water activity (aw) is a frequent intrinsic feature associated with high-sugar goods, which is known to prevent the growth of most spoilage and harmful bacteria. Nonetheless, deterioration can develop due to the presence of osmophilic yeasts and xerophilic moulds.

- The range of aw for high-sugar goods is 0.20 to 0.80. Due to the presence of yeasts in the liquid sugar brine or the cherry, products, such as chocolate-covered cherries, get spoiled.

- Typically, ruined merchandise will develop leaks. It is unlikely that the chocolate covering the cherry would be a source of yeast contamination.

- In addition to aw, pH, processing and storage temperatures, and the presence of preservatives all influence the durability of high-sugar goods.

- Consumers typically identify the term sugar with sucrose, which is abundantly dispersed in nature and heavily utilised across the food business.

- Additionally, dextrose, lactose, and fructose are utilised. Recently, polyols such as sorbitol, mannitol, xylitol, and maltitol have replaced sugar in sugar-free candies, chocolate, and other food products.

Contamination Of Sugars And Sugar Products

Sucrose

- The raw juice extracted from sugarcane may get contaminated with microorganisms if not processed immediately.

- Relevant microorganisms include slime makers, such as species of Leuconostoc and Bacillus; representatives of the genera Micrococcus, Flavobacterium, Alcaligenes, Xanthomonas, Pseudomonas, Pseudoalteromonas, Pseudoalteromonas, Pseudoalteromonas, Erwinia, and Enterobacter; a variety

- Debris or small particles on the sides or seams of the plant’s troughs could be a major source of contamination.

- It is possible for organisms to convert sucrose into glucose or even destroy sugar as they grow.

- From the cutting of the cane through the extraction and clarifying of the juice, yeasts and bacterial vegetative cells are killed by the organisms.

- Through sedimentation, filtration, evaporation, crystallisation, and centrifugation, bacterial spores may be reduced in number, however thermophilic spores may be introduced via equipment. The packaging of raw sugar may also introduce bacteria.

- Equipment contamination may occur during the refining of raw sugar, and organisms are added during bagging.

- During the production of beet sugar, beets are sliced into thin slices and the sugar is extracted by a diffusion process at 60 to 85 degrees Celsius. Flume waters and diffusion-battery waters are the contamination sources.

- Thermophiles can develop at temperatures as low as 70 C. Sugar may also become contaminated during refining and packaging.

- Currently available granulated sugar has a very low microbial concentration, ranging from a few to several hundred organisms per gramme, the majority of which are bacterial spores.

Maple Syrup

- In the vascular bundles of the sugar maple, the sap is sterile or almost so, but becomes contaminated by external sources in the tapholes, spout, plastic tubing, and buckets or other collection vessels.

- If an unusually warm period occurs prior to sap collection, significant yeast and bacterial development may occur in the sap.

- The majority of microorganisms entering sap between its flow from the tree and boiling and concentration are psychrotrophic, gram-negative rods of Pseudomonas, Alcaligenes, and Flavobacterium, as well as yeasts and moulds.

- Taphole pellets containing paraformaldehyde are put into the drilled hole to prevent microbial growth from obstructing the flow.

- The collection of sap through a series of plastic tubes reduces bacterial contamination in sugarcane fields that are subjected to exceptional levels of dust and air pollution.

- In a well-managed sugarcane field, however, the microbiological composition of sap collected via tubing is not considerably different from that obtained with individual pails.

- Typically mobile sap-collecting tanks must be routinely cleansed to prevent the growth of a large number of germs in the sap before it reaches the evaporator.

- Bacterial counts in sap are typically less than 10,000 per millilitre, although greater levels can emerge near the end of the season due to warmer temperatures and poor sanitation.

Honey

- The primary sources of microorganisms in honey are floral nectar and honeybees.

- It has been demonstrated that yeasts originate from nectar and the bee’s digestive material; bacteria also originate from the latter source. Honey includes staphylococci and enteric bacteria seldom.

- Typical isolates consist of acidophilic and glycolytic yeasts, which can cause product damage. Lysozyme, an enzyme with a bacteriostatic and lytic action on most gram-positive bacteria, has been identified in honey.

- Antibiotics like as neomycin and streptomycin are frequently used in beekeeping, and these antibiotics have been detected in honey produced from treated larvae and bees.

- Obviously, traces of these antibiotics in honey would have an effect on its microflora. Honey is one of the dietary vehicles considered to be the source of C. botulinum spores in newborn botulism infections.

- Approximately 10% of the honey samples had live spores. According to a 1975 study by Ruiz-Argueso and Rodriguez-Navarro, Gluconobacter and Lactobacillus are the two predominant types of bacteria present during the transformation of nectar into honey.

Candy

- Retail candies contain between 0 and 2 million bacteria each piece, however the vast majority have fewer than a few hundred.

- There are few coliform bacteria found. The majority of the candy’s contamination comes from its ingredients, although unwrapped portions may be contaminated by air, dust, and handling.

- For microbiological considerations, the many thousand types of sweets and confections can be separated into two categories: (1) cold-processed and (2) hot-processed confections.

- In the first category are moulded chocolate and chocolate coatings for creamed centres. During processing, temperatures may only reach the pasteurisation temperature.

- The second group includes candies such as hard candy, jellies, caramels, and fudges. The processing temperatures for these products vary, but they are all subjected to a more intense heat treatment than those in the first group.

- Rarely are candies involved with food-poisoning outbreaks, however chocolate candies have been implicated with salmonellosis cases.

- Cross-contamination between raw and roasted cocoa beans appears to be the cause of the problem, with the raw beans or environmental isolates serving as the source of contamination.

- Although temperatures of 60 degrees Celsius for ten hours are not uncommon during the processing and mixing of milk chocolate, the low moisture content or dryness of the chocolate shields the salmonellae from the heat.

Preservation

- Similar to cereals, sugars have aw levels so low that bacteria cannot live on them. Only when moisture has been absorbed is microbial deterioration a possibility.

- The sugar should be stored in such a way that pests are excluded and it remains dry. Similar to the recommended storage temperature for grains.

- Cane or sugar beets may be stored in a climate-controlled environment. The combination of 6 percent carbon dioxide and 5 percent oxygen inhibits fungal development.

- During the production of raw sugar and its subsequent refining, most subsequent processes, such as clarification, evaporation, crystallisation, centrifugation, and filtration, reduce the number of microorganisms that may have been present in large numbers during extraction from sugar cane or sugar beets.

- During sugar refining, chemical preservatives are helpful at reducing the quantity of microorganisms.

- Sugar that will be used for a specific purpose, such as soft drinks or canning, may be subjected to additional treatments during refining to limit the number and types of organisms.

- During processing, care is made to prevent the accumulation of organisms and their spores, and their numbers may be reduced by ultraviolet irradiation or the combined action of heat and hydrogen peroxide.

- Due to their high sugar content and low aw, most candies are not susceptible to microbial decomposition; nevertheless, the soft contents of chocolate-covered candies may enable microbial development.

- A consistent and relatively thick chocolate coating and the use of a fondant or other filling that does not let the formation of gas formers prevent the explosion of chocolates.

- Sirups and molasses have typically been heated sufficiently to kill most germs, but they must be maintained at cool temperatures to avoid or limit chemical changes and microbial growth.

- Some molasses may contain enough sulphur dioxide to limit microbial development, although the high osmotic pressure of sugar solutions in the majority of sirups and molasses prevents microbial growth.

- In proportion to the degree of inversion (hydrolysis) of the sucrose, the osmotic pressure rises. Mold formation on the surface of the syrup or molasses is prevented by a full container and minimised by periodic mixing.

- When maple sap is evaporated into maple syrup, the boiling process eliminates harmful organisms.

- This syrup, when bottled hot and in a container that is totally full, typically keeps well. Locally distributed honey on a small scale is typically not pasteurised and hence susceptible to crystallisation and probable spoiling by osmophilic yeasts over time.

- Honey sold commercially is typically heated between 71 and 77 degrees Celsius for a few minutes. The recommended therapy is to rapidly heat to at least 71 degrees Celsius, maintain that temperature for five minutes, and then fast cool to between 32.2 and 38 degrees Celsius.

Spoilage

- The deterioration of sugars or concentrated sugar solutions is restricted to microorganisms that are osmophilic or xerotolerant.

- Certain yeasts, particularly those of the genus Saccharomyces, and particular fungi would be the most prevalent spoiling organisms.

- Some species of bacteria, such as Bacillus and Leuconostoc, have been considered as potential spoiling agents.

- As sugar concentrations decline, a greater variety of organisms can proliferate, hence maple sap would exhibit sorts of deterioration that maple syrup would not.

Sucrose

During the production of sugar, the original cane or beet juice becomes increasingly purified toward sucrose and the concentration of sugar in solution increases until crystalline sugar and high-sugar molasses are produced. The more pure a product is, the less suitable it is as a microorganism culture medium; the more concentrated it becomes, the fewer types of organisms can grow in it.

Raw Juice

- Raw cane or beet juice is low in sugar and includes an abundance of microorganisms’ co-nutrients; consequently, if adequate time is allowed, it is easily degraded by the various organisms present.

- In the absence of clarity, gum and slime may be produced, such as dextran by Leuconostoc mesenteroides or L. dextranicum* and levan by Bacillus spp. or, less frequently, by yeasts and moulds.

Sugar in Storage

- Liquid sugar with a sugar level of 67 to 72 brix will stimulate the growth of airborne yeasts (Saccharomyces, Candida, and Rhodotorula) and moulds.

- The product may degrade as a result of the growth of microbes caused by the dilution caused by surface moisture absorption.

- This can be avoided by circulating sterile air across the top of the storage tank or by exposing the liquid to UV lamps.

Molasses and Syrups

- Molasses spoiling by microorganisms is uncommon, but difficult to sterilise by heat due to the protective effect of the sugar.

- osmophilic yeasts that survive the heating process may cause deterioration in canned molasses or syrup.

- Molasses or syrup exposed to air will mould on the surface over time, and this can also form on the surface of bottled or canned syrup if air is allowed on the surface and contamination occurs prior to sealing.

- Some types of molasses are sufficiently acidic to induce hydrogen to expand during long-term storage.

Maple Sap and Syrup

- As noted previously, when sugar maple sap is extracted, it becomes polluted. Although a small quantity of development can enhance flavour and colour, the sap is frequently exposed to conditions that promote excessive growth of germs and, consequently, deterioration.

- Five principal types of spoiling are identified:

- Typically caused by Enterobacter aerogenes, however Leuconostoc spp. may also be involved.

- Cloudy, occasionally greenish sap caused by the growth of Pseudomonas fluorescens, with occasional contributions from Alcaligenes and Flavobacterium species.

- Colored by the pigments of red bacteria, such as Micrococcus roseus, or yeasts or yeast-like fungi.

- Sour sap, a catch-all category for varieties of spoilage that do not exhibit a distinct change in colour but have a sour odour and are produced by a range of bacteria and yeasts.

- Moldy sap that has been ruined by mould.

- Maple syrup may be ropy due to the presence of Enterobacter aerogenes, yeasty due to the growth of species of Saccharomyces yeasts, pink due to the presence of Micrococcus roseus, or mouldy on the surface, where species of Aspergillus, Penicillium, or other genera may grow.

- Due to alkalinity caused by microorganisms growing in the sap and the inversion of sucrose, the syrup may become black. Molds can form on maple sugar if it becomes moist, unless it is kept dry.

Honey

- Honey’s composition is vary, but it must include no more than 25 percent moisture. Due to its high sugar content, 70 to 80 percent, primarily glucose and levulose, and its acidity, pH 3.2 to 4.2, the primary cause of its rotting is osmophilic yeasts: Zygosaccharomyces species, such as Z. mellis, richteri, or nussbaumeri, or Torula (Cryptococcus) mellis.

- The majority of moulds do not grow well on honey, but Penicillium and Mucor species have developed slowly.

- The majority of honey yeasts cannot thrive in the laboratory at sugar concentrations comparable to honey.

- Therefore, unique hypotheses for the commencement of yeast growth in honey have been proposed:

- Because honey is hygroscopic, it becomes diluted at the surface, where yeasts begin to proliferate and quickly adapt to the high sugar concentrations.

- Upon crystallisation of glucose hydrate from honey, the sugar content in solution decreases.

- Yeasts become gradually accustomed to high sugar concentrations with time.

- The essential moisture content for yeast growth has been determined to be 21 percent.

- The degree to which bees convert sucrose to glucose and levulose, as well as the amount of accessible nitrogen, are also included as factors influencing the chance of growth.

- The fermentation process often takes months and produces carbon dioxide, alcohol, and nonvolatile acids that provide an unpleasant flavour to the honey. Typically, fermentation is accompanied by a darkening and crystallisation of the liquid.

Candy

- Because of their relatively high sugar and low moisture content, most candies are not susceptible to microbial deterioration.

- Exceptions are chocolates with soft fondant or inverted sugar centres that, under certain conditions, burst or explode.

- Yeasts developing in these sweets generate a gas pressure that may destabilise the entire candy or, more frequently, will force some of the syrup or fondant through a crack in the chocolate coating.

- Typically, this weak place is the poorly covered bottom of the chocolate, from which a fondant cylinder squeezes out.

- Using a filling that does not support the growth of the gas-forming organisms and coating the candy with a uniformly thick and sturdy layer of chocolate prevents the fault.

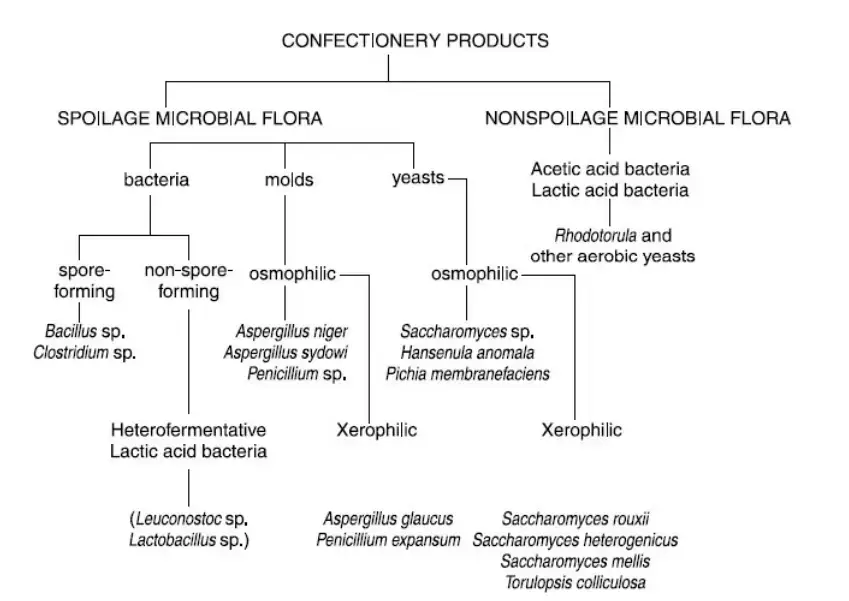

- Figure summarises the microbial deterioration flora of numerous confectionery goods.

References

- Jennifer J., P., & Maria C., F. (2020). A Comprehensive Review of Maple Sap Microbiota and Its Effect on Maple Syrup Quality. Food Reviews International, 1–20. doi:10.1080/87559129.2020.1788579

- CHAINE, A., LEVY, C., LACOUR, B., RIEDEL, C., & CARLIN, F. (2012). Decontamination of Sugar Syrup by Pulsed Light. Journal of Food Protection, 75(5), 913–917. doi:10.4315/0362-028x.jfp-11-342

- CHAINE, A., LEVY, C., LACOUR, B., RIEDEL, C., & CARLIN, F. (2012). Decontamination of Sugar Syrup by Pulsed Light. Journal of Food Protection, 75(5), 913–917. doi:10.4315/0362-028x.jfp-11-342

- Bogdanov, S., Jurendic, T., Sieber, R., & Gallmann, P. (2008). Honey for Nutrition and Health: A Review. Journal of the American College of Nutrition, 27(6), 677–689. doi:10.1080/07315724.2008.1071974

- Olaitan, P. B., Adeleke, O. E., & OOla, I. (2007). Honey: a reservoir for microorganisms and an inhibitory agent for microbes. In African Health Sciences (Vol. 7).

- Silva, M. S., Rabadzhiev, Y., Eller, M. R., Iliev, I., Ivanova, I., & Santana, W. C. (2017). Microorganisms in Honey. In Honey Analysis. https://doi.org/10.5772/67262

- Suman, S., Kirtiraj, G., & Omre, P. K. (2014). Spoilage of sugarcane juice a problem in sugarcane industry. International Journal of Agricultural Engineering, 7(1), 259–263. Retrieved from http://www.researchjournal.co.in/online/IJAE.htm

- William C. Frazier; Fourth Edition.pdf (1995). Food Microbiology.

- Wojtczak, M., Biernasiak, J., & Papiewska, A. (2012). Evaluation of microbiological purity of raw and refined white cane sugar. Food Control, 25(1), 136–139. https://doi.org/10.1016/j.foodcont.2011.10.031

- Text Highlighting: Select any text in the post content to highlight it

- Text Annotation: Select text and add comments with annotations

- Comment Management: Edit or delete your own comments

- Highlight Management: Remove your own highlights

How to use: Simply select any text in the post content above, and you'll see annotation options. Login here or create an account to get started.