Positive displacement pipettes are characterised by piston-driven displacement. The piston in a positive displacement pipette makes direct contact with the sample, which allows the aspiration force to remain constant.

Air displacement pipettes accurately dispense the majority of liquids. However, the precision may be affected negatively by the solution’s viscosity, volatility, surface tension, and temperature.

For instance, a liquid with a high viscosity can adhere to the pipette tip. A rapid withdrawal of the pipette can cause an air bubble to form in the tip, so reducing the volume of liquid administered. Similarly, surfactants lower surface tension, causing a very thin liquid coating to stay on the walls of the tip. Leakage of volatile solvents include acetone, hexane, and methanol. Warm liquids are frequently under-delivered, whereas cold liquids are frequently over-delivered.

When pipetting liquids with differing properties, some researchers employ workarounds, such as reverse pipetting, pre-wetting tips, or cutting the tips’ ends, because water at room temperature produces the most trustworthy findings. However, these can also introduce mistake.

Positive displacement satisfies the needs of pipette users who frequently manipulate viscous, thick, surfactant, volatile, hot, or cold liquids. With disposable Capillary Pistons, the positive displacement pipette MICROMAN E from Gilson addresses this issue.

To comprehend this, we will examine the internal mechanics of liquid handling instruments and the forces at play:

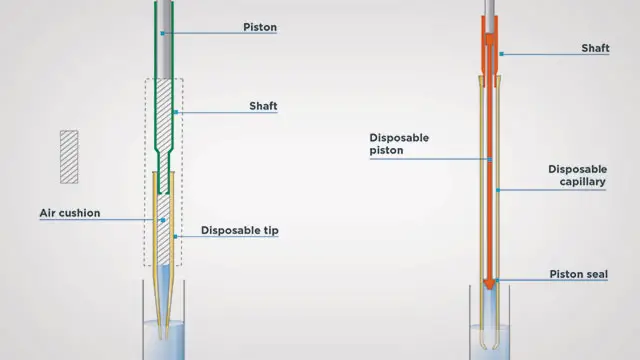

Pipettes for laboratory use can operate using either air displacement or positive displacement principles. A cushion of air separates the liquid in the plastic tip of an air displacement pipette from the piston inside the pipette. As with any gas, the air cushion changes based on the properties of the liquid, as well as lab or protocol settings (temperature variation, or humidity). The air cushion’s elasticity is affected by the various characteristics of volatile solvents. Evaporation is a continuous process, and liquids such as acetone, hexane, and methanol evaporate so rapidly that they cause leaks by expanding the air column inside the pipette. Leaks introduce inaccuracy and contaminate the work surface, whereas evaporation may contaminate the pipette’s interior components. Pipette users are also at risk, particularly when working with hazardous volatile liquids like radioactive solutions. In addition, corrosive substances, such as acids, may evaporate due to the air cushion within the pipette tips, resulting in pipette shaft, seal, and piston corrosion after several pipetting cycles.

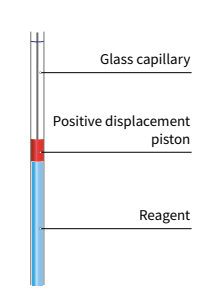

With a positive displacement pipette, there is no air cushion and the inhaled volume is not affected by the physical qualities of the sample. For easy pipetting of viscous, thick, and surfactant solutions, a piston substitutes the air cushion and glides along the internal surfaces of the capillary. Direct contact between the piston and the wall of the Capillary Piston guarantees precise dispensing. Similarly, volatile liquids and hot or cold solutions are aliquoted and supplied precisely and leak-free.

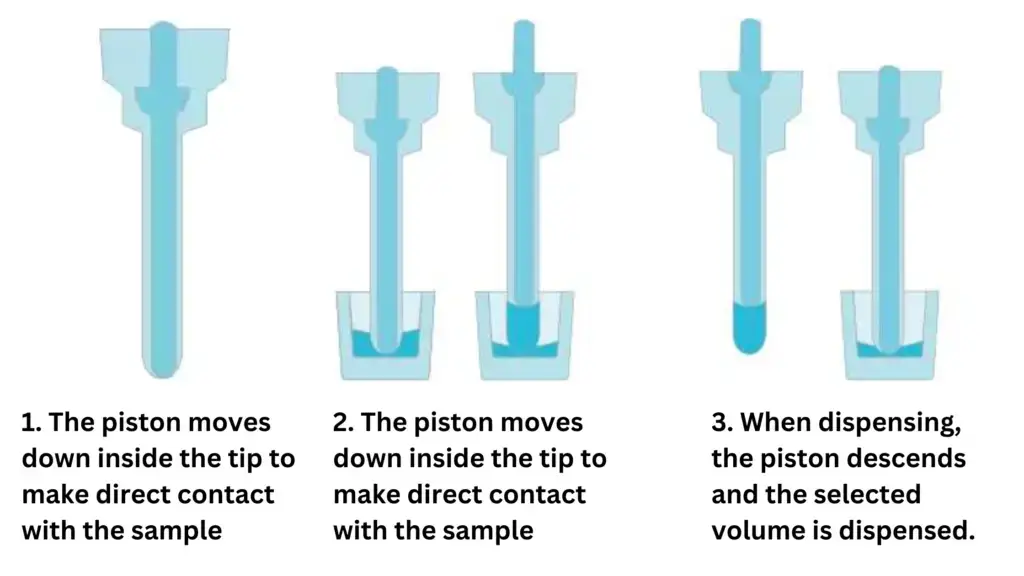

The MICROMAN E’s pipetting movement is easy for users accustomed to the usual mode of air displacement pipetting. The user presses the button to the first stop, releases the plunger to the home position to aspirate the liquid, and presses the button to the first stop once more to expel the liquid.

In contrast to air displacement pipetting, no purge or “blow-out” phase is required to remove any remaining sample from the tip. Instead, pressing the button to the second and final stop on a MICROMAN E ejects the capillary and piston without hand contact, thereby simplifying the pipetting procedure and eliminating the separate button for tip ejection.

Positive displacement pipettes, such as MICROMAN E, can maximise sample preparation for HPLC, qPCR/PCR, pharmaceutical formulations, and the manipulation of biological fluids. Due to the piston’s direct contact with the capillary, volatile liquids can be aliquoted and dispensed correctly and without leaking. These innovative pipettes protect users from harmful liquid spills on the bench and prevent liquid corrosion caused by fumes.

Principle of Positive Displacement Pipetting

The principle of positive displacement is frequently applied to repeated or specialised positive displacement pipettes. The piston of a positive displacement pipette is in direct touch with the liquid to be pipetted, in contrast to air displacement systems. During dispensing, the piston aspirates the liquid through a vacuum and cleans the walls of the tip, right down to the last drop, which leaves the tip. This principle ensures very reproducible outcomes regardless of the liquid or air cushion influence. In order to guarantee contamination-free functioning, the piston, which is integral to the device in air displacement models, must constantly be replaced in positive displacement models. Depending on the model, this may increase the time required to change the tip and the cost of consumables.

Positive Displacement Pipetting technique

Positive displacement pipettes act very similarly to air displacement pipettes.

Operation of a positive displacement pipette

- Adjust the pipette volume.

- Attach a CP tip to the pipette’s nozzle.

- Vertically hold the pipette and press the plunger to the first stop.

- Insert the CP tip into the sample and slowly release it while returning the button to its initial position.

- To dispense the sample, depress the plunger to the first stop position once more.

- To eject the CP tip, depress the plunger to the second stop position.

When to Use Air Displacement vs. Positive Displacement Pipettes?

Air displacement pipettes provide highly accurate performance for many ordinary liquid handling tasks; they are ideal for handling aqueous solutions and other non-viscous liquids at room temperature. Compared to the sophisticated capillary piston tips used for positive displacement, the tips used for air displacement are more affordable and simpler to replace. Therefore, air displacement is both time- and cost-efficient for applications requiring liquids that are not “complex.”

Pipettes that rely on the displacement of air for precise liquid aspiration and dispensing can encounter difficulties in a number of circumstances. First, the temperature of the liquid might affect the volume of the air cushion, leading to the inaccuracy of liquid aspiration. When the liquid is colder than the ambient temperature, the air cushion can contract, resulting in unintended over-delivery of the solution; when the liquid is warmer than the ambient temperature, the air cushion can expand, leading to unintentional under-delivery. Positive displacement-based pipettes can provide more precise pipetting for samples that require freezing temperatures, such as restriction enzymes, or higher temperatures, such as mammalian cell cultures or polymerase chain reaction (PCR) solutions.

Highly viscous liquids are an additional application for which positive displacement pipettes are optimal. Viscous liquids such as glycerol, fats, oils, resins, and protein solutions may adhere to the pipette tip and not be delivered completely; same liquids may also create air bubbles when aspirated too quickly in an air cushion pipette, resulting in under-delivery. With direct contact between the piston and solution, exact volumes of viscous solutions can be drawn up, and the entire volume is displaced by the piston sliding against the walls of the capillary cylinder.

Due to evaporation and leakage, volatile liquids such as acetone and methanol can be difficult to pipette using air displacement methods.

Evaporation into the air cushion is problematic not only because of inaccuracy in liquid volume dispensing, but also because of contamination of the pipetting device, particularly when caustic or hazardous solutions are involved. Positive displacement pipettes limit evaporation and leakage and avoid contamination or damage to the pipetting instrument by utilising a disposable, sealed piston.

Applications Positive Displacement Pipette

Since the piston makes direct contact with the sample, the physical qualities of the sample have no effect on the aspiration force in a positive displacement pipette. Several liquid handling companies assert that positive displacement pipettes can be utilised to accurately pipette samples that are extremely viscous, volatile, hot or cold, or caustic.

- Viscous liquids: Very slowly do viscous liquids, such as glycerol, flow. Glycerol has a high dynamic viscosity, thus if a researcher aspirates a sample of glycerol using an air displacement pipette too quickly, air bubbles will be drawn into the sample. When a researcher tries to distribute the liquid, a portion of it will adhere to the pipette tip wall, dispense very slowly, and remain in the tip. This effect is similarly produced by surfactants, although the resulting liquid layer is thinner. In a pipette with positive displacement, the aspiration force remains constant, thus the tip is filled evenly. Additionally, the piston moves along the inside surfaces of the pipette tip and expels the entire volume, leaving no liquid behind.

- Volatile liquids: In air displacement pipettes, volatile liquids such as acetone, hexane, and methanol evaporate constantly. Certain volatile liquids expand so rapidly that they cause the air column in the pipette to expand, resulting in leakage: the pipette will lose drops and dispense liquid imprecisely. As drips escape, they can contaminate the bench, resulting in sample-to-sample cross-contamination. These droplets might potentially be hazardous to one’s health. Because positive displacement pipettes lack an air cushion, liquids do not evaporate or leak. No drops will fall from the tip, and no vapours will contaminate the pipette’s interior. Additionally, the disposable capillary/piston (CP) tips used for positive displacement pipetting.

- Hot or cold liquids: The ambient temperature in an air displacement pipette correlates with the volume of the air cushion and influences the aspiration volume. Cold liquids, such as a suspension of restriction enzymes, which are typically handled at 0°C, cause the air cushion to contract and the pipette to aspirate more liquid than anticipated, resulting in over-delivery. Warm samples, such as mammalian cell cultures at body temperature or polymerase chain reaction solutions at 60°C or higher, will cause the air cushion to expand, leading the pipette to aspirate and provide less liquid than planned. Positive displacement pipettes lack an air cushion and are less sensitive to liquid temperature, resulting in improved pipetting precision.

- Corrosive and hazardous liquids: In an air displacement pipette, corrosive and radioactive liquids can damage the piston, seal, and tip holder. Positive displacement pipettes feature a disposable capillary/piston (CP) tip, preventing corrosive samples from affecting the pipette over its lifetime. As there is no contact between the sample and the pipette, the danger of contamination is minimal.

Advantages of Positive Displacement Pipetting

Positive displacement pipettes are highly precise and accurate liquid handling tools that are commonly used in a variety of laboratory settings. Some advantages of using positive displacement pipettes include:

- High accuracy and precision: Positive displacement pipettes use a piston or other mechanism to physically displace a specific volume of liquid, which allows for very precise and accurate measurements.

- Low error rates: Because the liquid is physically displaced, rather than drawn in through the tip, positive displacement pipettes are less susceptible to errors that can occur due to variations in liquid viscosity or surface tension.

- Ability to handle viscous liquids: Positive displacement pipettes can handle liquids with high viscosities or particles suspended in them that would clog a traditional air displacement pipette.

- Versatility: Positive displacement pipettes are available in a wide range of volume sizes and can be used with different types of liquids, including viscous liquids and liquids with high surface tension.

- Quality assurance: Positive Displacement pipettes are sealed systems, reducing the potential for contamination which increase the chances for the quliaty of the results.

- Easy to operate: Positive displacement pipettes are relatively easy to operate, and many models are designed to be ergonomic and comfortable to use for extended periods of time.

It’s worth noting that Positive displacement pipettes are generally more expensive than traditional air displacement pipettes, but they are a preferred option when working with highly viscous samples, high precision volume measurements, or in regulated environemnts such as Pharmaceuticals and food industries.

Positive displacement pipettes limit volatile solvent evaporation and prevent cross contamination because there is no liquid-to-pipette contact.

Therefore, they are ideally suited for working with tough and volatile compounds, for which an air displacement pipette would require saturation of the air cushion to prevent evaporation. They are also less impacted by atmospheric pressure and laboratory temperature because there is no air cushion between them and the environment.

Perfect for use with:

- High density solutions

- Viscous solutions (like resins, fats, protein solutions and oils)

- Dense solutions

- Foaming liquids

- Volatile liquids

- Problematic liquids

Ideal for use in:

- Food and beverage production

- Cosmetic manufacturing

- The Molecular Biology of Forensic Science

- Performing environmental

- DNA sample work and PCR

Tips & Techniques

- Select the appropriate pipette for your needs

- Practice, practise, practise! Improve your technique with the aid of a comprehensive pipetting instruction. Your chosen brand probably has one (try this one from Gilson)

- Hold the pipette upright when drawing in liquid, immerse the tip slightly so as not to coat the exterior, and add more liquid than you want.

- Utilize a slow, cautious motion, and do not haste.

- When dispensing, hold the pipette vertically while holding the receiving vessel at a 45-degree angle.

- Examine yourself – Check the precision of your procedure by measuring the mass of the dispensed droplets on a fine balance and calculating the variation; if it’s less than 5%, you’re in the clear. If not, continue practising until your skill improves and your confidence grows!

- Look after your pipette: Regularly have your pipette serviced by a “pipette doctor” who will repair worn parts and recalibrate it for you.

- Always store your pipette vertically in a pipette holder, as opposed to on its side.

- Before beginning work each day, clean your pipette with 70% ethanol and examine it for any broken pieces.

References

- https://www.thermofisher.com/in/en/home/life-science/lab-plasticware-supplies/lab-plasticware-supplies-learning-center/lab-plasticware-supplies-resource-library/fundamentals-of-pipetting/liquid-handling-selection/air-vs-positive-displacement-pipettes.html

- https://www.mt.com/in/en/home/products/pipettes/rainin-pipettes/specialty-pipettes/posd-positive-displacement-pipette.html

- https://www.gilson.com/default/shop-products/pipettes/positive-displacement.html

- https://www.labmanager.com/how-it-works/how-positive-displacement-pipettes-work-3041

- https://www.analox.com/blog/positive-displacement-pipettes/

- https://www.pipettes.com/pipettes/positive-displacement-pipette/

- https://pipette.com/pipettes/positive-displacement-pipettes.html

- https://blog.btlabsystems.com/blog/positive-displacement-pipettes

- https://www.eppendorf.com/IN-en/liquid-guide/

- https://shop.brand.de/en/liquid-handling/positive-displacement-pipettes.html

- https://www.labcompare.com/10-Featured-Articles/591341-Tech-Compare-Air-vs-Positive-Displacement-Pipetting/

- https://www.fishersci.com/us/en/products/I9C8L3DY/positive-displacement-pipetter-tips.html