What is pasteurisation?

Pasteurisation was developed by an French Scientist known as Louis Pasteur during the nineteenth century. Pasteur realized that warming milk up to a high temperature , then cooling it quickly prior to packaging or bottling could preserve it for a longer time.

Nowadays, pasteurisation is commonly used in the food and beverage industry. It is the most commonly used form of heat treatment applied to milk in Northern Ireland. Pasteurisation assures that the milk is safe for consumption (by getting rid of any bacteria) and can also help prolong the shelf-life of milk.

Pasteurisation is the process of warming milk until 71.7degC for minimum 15 seconds (and not longer than). Due to the nature of the heat treatment, it is sometimes called the ‘High Temperature Short Time’ (HTST) process. After the milk is heated, it is rapidly cooled to less than 3 degrees Celsius. The machine used to cool and heat the milk is referred to as”heat exchanger”.

Once the milk is pasteurised, it’s either stored in bottles or packages for sale to consumers.

What is Milk Pasteurization?

- Milk pasteurization is a crucial process employed in the dairy industry to ensure food safety and extend the shelf life of milk. It is a form of thermal processing that involves treating milk with mild heat to eliminate harmful pathogens and destroy or inactivate microorganisms that contribute to spoilage. The process is named after the renowned French scientist Louis Pasteur, who conducted pioneering research in the 1880s, demonstrating that thermal processing could effectively deactivate unwanted microorganisms in wine.

- During pasteurization, both packaged and non-packaged milk undergoes heat treatment at temperatures usually below 100 °C (212 °F). This temperature range is considered mild, as it is below the boiling point of water. The purpose of using lower temperatures is to ensure that the milk’s nutritional quality and taste are preserved while effectively eliminating harmful bacteria.

- The primary goal of pasteurization is to enhance food safety by destroying or inactivating pathogenic organisms present in milk. While the process can eliminate vegetative bacteria, it is important to note that bacterial spores are not always destroyed. These spores have a protective outer layer, which allows them to survive heat treatment. However, they are usually not a significant concern in terms of food safety because their growth and multiplication are inhibited by the pasteurization process.

- Pasteurization plays a vital role in preserving milk and ensuring its safety for consumption. By eliminating harmful microorganisms, the process helps prevent foodborne illnesses that can result from consuming contaminated milk. Additionally, pasteurization extends the shelf life of milk by inhibiting the growth of spoilage-causing bacteria, yeasts, and molds.

- Beyond milk, pasteurization is widely utilized in various food processing industries. Fruit juices and other packaged foods also undergo pasteurization to enhance food safety and increase their shelf life. This process is essential in meeting the general and urgent need for rapid procedures in process control to monitor and maintain food safety and quality standards.

- In conclusion, milk pasteurization is a critical process in the dairy industry and other food processing sectors. By subjecting milk to mild heat, it effectively eliminates pathogens, destroys or inactivates spoilage-causing organisms, and extends the shelf life of the product. This method, named after Louis Pasteur, has become a cornerstone of food preservation and food safety, ensuring that consumers can enjoy milk without the risk of harmful microbial contamination.

Definition of Milk Pasteurization

Milk pasteurization can be defined as a carefully controlled process that involves heating milk or milk products to a specific temperature for a set duration, while maintaining strict measures to prevent re-contamination throughout the entire process.

The temperature at which milk is heated during pasteurization is determined based on the heat resistance of the microorganisms that the pasteurization program aims to eliminate. Different microorganisms have varying levels of heat resistance, and the chosen temperature is intended to ensure the destruction of targeted spoilage microorganisms while preserving the quality of the milk.

During the pasteurization process, it is crucial to prevent any re-contamination to maintain the safety and integrity of the milk. Stringent measures are implemented to ensure that the milk remains free from any additional microorganisms or contaminants during and after pasteurization.

By subjecting milk to controlled heat treatment, pasteurization aims to reduce the microbial load in the milk, eliminating or reducing the presence of harmful bacteria that can cause foodborne illnesses or contribute to spoilage. This process helps to enhance the safety and shelf life of milk, making it suitable for consumption while maintaining its nutritional value.

Overall, milk pasteurization is a defined process that involves heating milk to a predetermined temperature and duration, considering the heat resistance of specific spoilage microorganisms. The goal is to eliminate harmful bacteria while preventing re-contamination, ensuring that the milk remains safe and of high quality for consumers.

The Purpose of Pasteurization

- Increase the safety of milk for consumers by eliminating microorganisms responsible for causing disease (pathogens) that could be found in milk.

- To improve high-quality milk products by eliminating spoilage microorganisms and enzymes which cause a decrease in the quality and shelf-life of milk.

Types of Thermal Processing Methods

Thermal processing methods are essential in the food industry to ensure the safety and preservation of various products, including milk. Here are some types of thermal processing methods commonly used:

- Thermization: Thermization involves heating milk to temperatures ranging between 57°C to 68°C and holding it at that temperature for 15 minutes. This method is designed to target pathogenic bacteria while preserving the beneficial bacteria present in the milk. The relatively low temperatures used in thermization do not significantly alter the milk’s structure and taste.

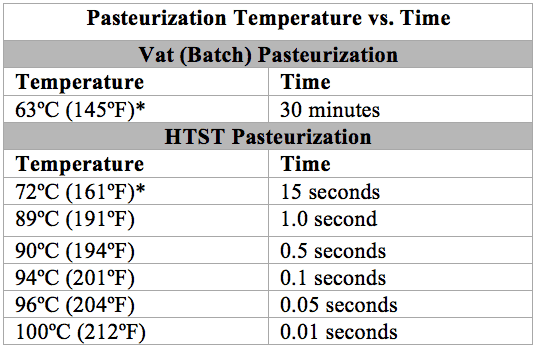

- Batch pasteurization (LTLT): Also known as low-temperature long time pasteurization, this method involves heating milk to 63°C and maintaining that temperature for 30 minutes. The extended holding time during batch pasteurization can lead to some changes in the milk’s protein structure and taste.

- Flash pasteurization (HTST): Flash pasteurization, also referred to as high-temperature short time pasteurization, requires heating the milk to temperatures between 72°C to 74°C for a duration of 15 to 20 seconds. The rapid heating and short duration of this method effectively eliminate pathogens while minimizing alterations to the milk’s taste and structure.

- Ultra-high temperature (UHT) pasteurization: UHT pasteurization involves subjecting the milk to very high temperatures ranging between 135°C to 140°C for a brief period of 2 to 4 seconds. This extreme heat treatment is effective in targeting heat-resistant organisms such as Coxiella burnetii, the bacterium responsible for causing Q-fever. UHT pasteurization kills all vegetative forms of bacteria and allows the milk to have an extended shelf life of up to 9 months.

- Canned sterilization: Canned sterilization is a wet treatment method applied to canned milk products using specialized treatment chambers or autoclaves. The milk is heated to temperatures ranging from 115°C to 121°C for a duration of 10 to 20 minutes. This process ensures the destruction of harmful bacteria and extends the shelf life of the canned milk.

These various thermal processing methods offer different levels of heat treatment to eliminate pathogens and extend the shelf life of milk and other dairy products. The specific method chosen depends on factors such as the desired shelf life, product characteristics, and the targeted microorganisms to ensure both food safety and quality.

Methods Used in Milk Pasteurization

1. High-Temperature Short Time (HTST) Pasteurization

High-Temperature Short Time (HTST) pasteurization, also known as flash pasteurization, is a specific method of pasteurization used in the dairy industry. Here’s what you need to know about HTST pasteurization:

- Flash pasteurization: HTST pasteurization is commonly referred to as flash pasteurization due to the short duration of the process. The milk is rapidly heated to a specific temperature to effectively eliminate pathogens.

- Temperature and time: Flash pasteurization involves heating the milk to a temperature of 71.7°C (161°F) for a duration of 15 seconds. The objective is to target and kill Coxiella burnetii, a heat-resistant pathogen that can be present in raw milk.

- Temperature range: Achieving an exact temperature of 71.7°C can be technically challenging in practice. Therefore, it is considered safe to work within a temperature range. Heating the milk to between 72°C to 74°C (162°F to 165°F) for 15 to 20 seconds ensures that the milk is uniformly heated to the required temperature for effective pasteurization.

- Uniform heating: The HTST pasteurization method aims to heat the milk uniformly to the desired temperature. This helps to ensure that all parts of the milk are adequately treated and that the target pathogen is effectively destroyed.

- Continuous pasteurization systems: Flash pasteurization is particularly suitable for continuous pasteurization systems commonly used in large-scale production. The process can be seamlessly integrated into the production line, allowing for efficient and continuous processing of milk.

- Shelf life: Milk that undergoes flash pasteurization typically has a shelf life ranging between 16 and 21 days. However, it is worth noting that for commercial reasons, some manufacturers intentionally reduce the number of days to move the products off the shelves promptly.

In summary, HTST or flash pasteurization involves rapidly heating milk to a specific temperature for a short duration to eliminate Coxiella burnetii, a heat-resistant pathogen. By working within a temperature range of 72°C to 74°C, the milk can be uniformly heated, ensuring effective pasteurization. This method is commonly employed in continuous pasteurization systems and results in milk with a shelf life of around 16 to 21 days, although manufacturers may intentionally reduce this timeframe for commercial reasons.

2. Low-Temperature Long Time (LTLT) pasteurization

Low-Temperature Long Time (LTLT) pasteurization, also known as batch pasteurization, is a method of pasteurizing milk at lower temperatures for an extended period. Here’s what you need to know about LTLT pasteurization:

- Temperature and time: LTLT pasteurization involves heating the milk to a reduced temperature of 63°C (145°F) and maintaining this temperature for a prolonged period of 30 minutes. The lower temperature and longer holding time ensure the effective elimination of pathogens.

- Alteration of milk proteins: The extended holding period during LTLT pasteurization leads to changes in the structure of milk proteins. These altered proteins are better suited for the production of yogurt, as they provide desirable texture and consistency.

- Batch pasteurization: LTLT pasteurization is typically conducted in batch processes, where the milk is held in a jacketed vat or container for the required duration. This allows for effective pasteurization of a specific batch of milk at a time.

- Batch pasteurizer designs: There are various designs of batch pasteurizers available in the market, catering to both domestic and commercial use. These pasteurizers are specifically designed to provide controlled heating and holding conditions to ensure proper pasteurization of the milk.

LTLT pasteurization is suitable for applications where a longer holding time at lower temperatures is preferred, such as in the production of yogurt. By heating the milk at 63°C for 30 minutes, this method achieves the desired pasteurization effect while ensuring the milk retains its desired properties for specific applications.

Overall, LTLT or batch pasteurization offers an alternative approach to milk pasteurization, utilizing lower temperatures and longer holding times. This method is particularly beneficial for applications where specific changes in milk proteins are desired, as well as for batch processing in both domestic and commercial settings.

3. Ultra-High Temperature (UHT) Pasteurization

Ultra-High Temperature (UHT) pasteurization is a highly effective method used for milk preservation. Here’s what you need to know about UHT pasteurization:

- Closed pasteurization method: UHT pasteurization is conducted using a completely closed system. The milk or cream being processed is never exposed to the external environment, even for a fraction of a second, throughout the entire pasteurization process. This ensures maximum hygiene and minimizes the risk of contamination.

- Temperature and duration: UHT pasteurization involves heating milk or cream to extremely high temperatures, typically ranging between 135°C to 150°C (275°F to 302°F). The heating duration is very short, lasting only for approximately one to two seconds.

- Immediate chilling and aseptic packaging: Following the brief exposure to high temperatures, the milk or cream is rapidly chilled. This rapid cooling is crucial to halt any further heat-related processes that could affect the quality of the product. The milk is then aseptically packaged in hermetic (air-tight) containers to maintain its sterility during storage.

- Benefits and popularity: UHT pasteurization is a highly popular method for milk preservation due to its numerous benefits. It ensures that the milk is safe and stable, preventing the growth of harmful microorganisms. UHT-treated milk does not require refrigeration until the package is opened, which is advantageous for distribution and storage. Despite the risk of Millard browning, a non-enzymatic browning reaction that can occur during UHT treatment, this method remains widely used due to its effectiveness in preserving milk quality and safety.

Overall, Ultra-High Temperature (UHT) pasteurization is a closed pasteurization method that involves rapidly heating milk or cream to extremely high temperatures for a very short duration. The product is then immediately chilled and aseptically packaged for storage. Despite the potential risk of Millard browning, UHT pasteurization is a popular method for milk preservation, ensuring safe and stable milk that can be stored without refrigeration until opened.

4. Ultra Pasteurized

Not to be mistaken for UHT, Ultra Pasteurized (UP) milk is heated with industrially-grade sterile equipment, however, it isn’t considered to be as sterile since it isn’t hermetically sealed. The milk is heated up to 280 degrees Fahrenheit (138 degrees Celsius) for minimum two seconds, after which it is rapidly cooled down. Because the milk isn’t completely sealed off, it needs to be refrigerated, with an average shelf-life of 30 to 90 days.

Steps of Pasteurization

The general procedure of mil Pasteurization are;

1. Milk chilling

Milk chilling is an essential step in milk processing, although it is not a pasteurization process itself. Here are some key points about milk chilling:

- Purpose of chilling: When dealing with large volumes of milk, chilling becomes necessary to control bacterial growth and preserve the quality of the milk. Milk is naturally produced at temperatures above the ambient, and these warmer temperatures create favorable conditions for rapid bacterial multiplication, leading to accelerated spoilage.

- Temperature reduction: The primary objective of milk chilling is to reduce the temperature of the milk to a range between 2°C to 5°C. By lowering the temperature, bacterial growth and metabolism are significantly slowed down. Chilling arrests the growth of bacteria and other microorganisms present in the milk, helping to maintain its freshness and quality.

- Preserving quality: Chilling milk before pasteurization provides a head start in maintaining its quality. By inhibiting bacterial growth and slowing down metabolic processes, chilling helps to delay spoilage and maintain the integrity of the milk until it undergoes proper pasteurization.

Chilling is a crucial step in milk processing, particularly for large-scale operations. By lowering the temperature of milk to a range that hinders bacterial growth and metabolism, it serves as a preventive measure to preserve the quality of the milk before it undergoes subsequent processes such as pasteurization.

2. Pre-heating (regeneration) and Standardization Stage

The pre-heating (regeneration) and standardization stage is an important step in milk processing that involves heating the chilled milk and adjusting the butterfat content to achieve uniformity. Here are some key points about this stage:

- Pre-heating: After the chilled milk is bulked or collected, it undergoes a pre-heating process. The purpose of pre-heating is to raise the temperature of the milk to approximately 40°C. This temperature facilitates the separation of butterfat during the subsequent standardization process.

- Regenerative heating: The pre-heating stage typically utilizes regenerative heating, which involves utilizing the heat energy from the already pasteurized milk to heat the incoming chilled milk. The two milk streams, pasteurized and chilled, flow in a counter-current direction, allowing for efficient heat transfer. As the chilled milk is heated, it cools down the pasteurized milk, creating a regenerative heat exchange process.

- Standardization: After pre-heating, the milk undergoes standardization. The primary objective of standardization is to adjust the butterfat content of the milk to achieve uniformity. This process ensures that the final product, such as milk or dairy products, has a consistent and desired butterfat content. Standardization is essential for maintaining quality and meeting regulatory requirements.

In summary, the pre-heating (regeneration) and standardization stage in milk processing involves heating the chilled milk to around 40°C and utilizing regenerative heating to achieve efficient heat transfer. The purpose is to facilitate the separation of butterfat during standardization. The standardization process aims to achieve uniformity in the butterfat content of the milk, ensuring consistent quality in the final product.

3. Clarification stage

The clarification stage in milk processing is a crucial step aimed at removing foreign matter and impurities from the milk. Here are the key points about the clarification stage:

- Removal of large solid particles: The initial step in clarification involves the removal of large solid particles from the milk. This is achieved by passing the milk through tubular metallic filters. These filters have fine pores that strain out larger particles, such as debris or foreign matter, effectively cleansing the milk.

- Centrifugal clarifier: In addition to the filtration process, a centrifugal clarifier is employed to separate soil and sediments from the milk. Unlike the centrifuge used for standardization, this clarifier is dedicated to the clarification stage. It utilizes centrifugal force to separate heavier particles from the milk, resulting in a cleaner product.

- Twin filter setup: To enable continuous processing, the filters used in the clarification stage are typically fitted in parallel twins. This means that there are two filters operating in tandem. While one filter is in use, the other can be cleaned or maintained, ensuring uninterrupted processing.

- Regular filter cleaning: It is essential to clean the filters regularly to prevent the growth of bacteria and maintain optimal filtration efficiency. The cleaning frequency depends on the level of dirt and can range from every 2 to 10 operational hours. Regular cleaning helps ensure the filters remain effective in removing impurities from the milk.

In summary, the clarification stage in milk processing involves the removal of foreign matter and impurities from the milk. This is achieved through filtration using tubular metallic filters and the use of a centrifugal clarifier. The twin filter setup enables continuous processing, while regular cleaning of the filters is necessary to prevent bacterial growth and maintain filtration efficiency. The clarification stage plays a critical role in ensuring the cleanliness and quality of the final milk product.

4. Standardization stage

The standardization stage in milk processing is a critical step that ensures consistent quality and meets the diverse preferences of consumers. Here are the key points about the standardization stage:

- Consistent quality: Standardization is necessary to achieve a consistent quality of the milk product. Different consumers have varying preferences, ranging from skim milk to low-fat milk, standardized milk, or high-fat milk. By standardizing the milk, producers can cater to the preferences of all consumers, ensuring they receive the desired milk product.

- Meeting consumer preferences: Standardization allows for the production of milk products with different levels of fat content to cater to varying consumer demands. Some consumers prefer skim milk, which has little to no fat content, while others opt for low-fat milk. There are also those who prefer standardized milk with a moderate fat content, as well as consumers who prefer high-fat milk. Standardization enables producers to meet these diverse preferences in the market.

- Separation of butterfat: Another important aspect of the standardization stage is the separation of butterfat from the milk. During this process, the desired amount of butterfat is removed from the milk to be used for producing cream and other fat-based products such as butter and ghee. This separation allows for the creation of specific dairy products with different fat concentrations.

By standardizing the milk, producers can offer a range of products that cater to different consumer preferences while also ensuring the extraction of butterfat for the production of specific dairy products. This stage is crucial in achieving consistent quality, meeting consumer demands, and maximizing the utility of butterfat for various dairy products.

5. Homogenization stage

The homogenization stage in milk processing is a process that breaks down milk fat globules into smaller droplets, ensuring a uniform distribution of fat throughout the milk. Here are the key points about the homogenization stage:

- Purpose of homogenization: The primary purpose of homogenization is to prevent cream separation in milk. Milk naturally contains fat globules that have a tendency to rise and form a cream layer. Homogenization disrupts these larger fat globules, breaking them down into smaller droplets, which helps to discourage cream separation.

- Prevention of fat rising: By reducing the size of the fat globules, homogenization increases their density within the milk. The smaller droplets of fat do not rise to the top of the milk column, as their reduced sizes result in increased integration and suspension throughout the milk.

- Homogenization process: The homogenization process involves passing the milk through a milk homogenizer, typically operating at pressures between 100 to 170 bars. The high pressure exerted by the homogenizer effectively breaks down the fat globules into very tiny droplets. This process ensures that the fat is uniformly distributed and integrated into the milk, preventing cream separation.

- Uniform distribution of milk fat: As a result of homogenization, the milk fat remains uniformly dispersed and distributed throughout the milk. This creates a consistent texture and appearance in the milk, as the smaller fat droplets are evenly dispersed and do not form a separate cream layer.

In summary, homogenization is a physical process used to break down milk fat globules into smaller droplets, preventing cream separation in milk. By reducing the size of the fat droplets and ensuring their uniform distribution, homogenization creates a more consistent and integrated milk product.

6. Heating section

The heating section is a crucial part of milk processing that utilizes steam heat to raise the temperature of the milk. Here are the key points about the heating section:

- Temperature increase: The purpose of the heating section is to increase the temperature of the milk from around 60°C to the required temperature of 72°C. This temperature is necessary to effectively kill Clostridium botulinum spores, which can be present in the milk.

- Heat exchange process: The heating section employs a plate heat exchanger (PHE) system where steam and milk flow in a counter-current motion. The steam transfers its heat to the milk as they pass through the PHE plates. This heat exchange process rapidly raises the temperature of the milk.

- Flow diversion valve: At the end of the heating section, there is a temperature sensor that monitors the temperature of the milk. This sensor controls a flow diversion valve. If any portion of the milk does not reach the required temperature of 72°C, it is diverted back to the heating section. This ensures that all milk passes through the heating section until it attains the necessary temperature for effective pasteurization.

The heating section plays a vital role in milk processing by utilizing steam heat to raise the temperature of the milk to the required level. Through the plate heat exchanger system, steam and milk interact in a counter-current flow, enabling efficient heat transfer. The temperature sensor and flow diversion valve help ensure that all milk reaches the desired temperature for proper pasteurization, enhancing food safety and quality.

7. Holding section

The holding section is an integral part of milk processing that follows the heating section. Here are the key points about the holding section:

- Function: The holding section allows the milk to stay at the required pasteurization temperature for a specific duration to ensure effective microbial inactivation. This holding time is crucial for achieving proper pasteurization.

- Holding tubes: After the milk is heated in the heating section, it flows into the holding tubes. The lengths of these tubes are calibrated according to the milk flow rate, ensuring that the milk spends at least 16 seconds in the tubes. This controlled holding time is necessary for thermal treatment and microbial reduction.

- Temperature maintenance: Throughout the holding tubes, it is essential to maintain the required pasteurization temperature. If a breach in temperature is detected, a sensor triggers a flow diversion valve. This valve redirects the milk back to the heating section to bring it back to the required temperature, ensuring consistent and effective pasteurization.

- Regeneration section: Once the milk has completed the holding time and maintained the required temperature at the end of the holding tubes, it flows back to the regeneration section. In the regeneration section, the milk exchanges heat with incoming chilled milk, serving to heat the incoming milk while cooling down the pasteurized milk to approximately 30°C.

The holding section ensures that the milk remains at the necessary pasteurization temperature for the specified duration, enabling effective microbial inactivation. The calibration of holding tube lengths, temperature sensors, and flow diversion valves contribute to maintaining the required temperature and providing a robust pasteurization process. Finally, the regeneration section facilitates the heat exchange between pasteurized milk and incoming chilled milk, optimizing the overall thermal efficiency of the system.

8. Cooling/chilling section

The cooling/chilling section in milk processing is a crucial step that follows the regenerative cooling of pasteurized milk. Here are the key points about the cooling/chilling section:

- Cooling process: After the regenerative cooling process, the pasteurized milk enters the cooling section of the plate heat exchanger (PHE) system. In this section, chilled water or PHE coolant is used to lower the temperature of the pasteurized milk.

- Temperature reduction: The cooling section aims to reduce the temperature of the milk to approximately 4°C. This chilled temperature is ideal for ensuring the freshness and preservation of the milk while maintaining its quality.

- Packaging transition: Once the milk has been sufficiently cooled, it is pumped to the packaging machines for aseptic packaging. The packaging process involves filling the milk into containers or cartons, ensuring proper sealing to maintain its sterility.

- Cold room storage: After packaging, the milk is transferred to a cold room for storage. The cold room provides a controlled environment with low temperatures to maintain the freshness and quality of the milk throughout its shelf life.

The cooling/chilling section plays a vital role in milk processing by effectively lowering the temperature of pasteurized milk to the desired level for preservation. The use of chilled water or PHE coolant ensures the milk is adequately cooled before it undergoes aseptic packaging and subsequent storage in a cold room. This ensures the milk remains fresh and maintains its quality until it reaches the consumer.

Significance of Pasteurization

The significance of pasteurization lies in its ability to ensure the safety, quality, and extended shelf life of milk. Here are the key points about the significance of pasteurization:

- Public health safety: The primary objective of milk pasteurization is to destroy pathogenic bacteria that may pose a public health concern. By subjecting milk to heat treatment, harmful microorganisms that can cause foodborne illnesses, such as Salmonella and E. coli, are effectively eliminated. This makes the milk safe for consumption, reducing the risk of foodborne diseases.

- Spoilage prevention: Pasteurization also eliminates destructive bacteria and enzymes that can contribute to the spoilage of milk. By removing these microorganisms, the process extends the shelf life of the milk. This allows for longer storage and distribution without the need for expensive equipment, helping to reduce food waste.

- Prolonged shelf life: Proper pasteurization helps to ensure that milk can be stored for longer periods without compromising its safety or quality. By eliminating spoilage bacteria and enzymes, pasteurized milk can maintain its freshness and nutritional content for an extended period, reducing the need for frequent restocking and minimizing product waste.

Overall, pasteurization is of significant importance as it ensures the safety of milk by eliminating harmful pathogens. It also prevents spoilage, extending the shelf life of the milk and reducing food waste. These benefits contribute to the overall quality, availability, and accessibility of milk as a safe and nutritious food product for consumers.

Pasteurization conditions used for milk products

| Pasteurization Type | Typical Product | Typical Storage | Temperature | Holding Time |

|---|---|---|---|---|

| Batch, vat | Milk | Refrigerated | 145°F (62.8°C) | 30 min |

| “ | Viscous products, or products with more than 10% fat or added sweetener | “ | 150°F (65.6°C) | 30 min |

| “ | Egg nog, frozen dessert mixes | “ | 155°F (68.3°C) | 30 min |

| Continuous, high temperature short time (HTST) | Milk | “ | 161°F (71.7°C) | 15 sec |

| “ | Viscous products, or products with more than 10% fat or added sweetener | “ | 166°F (74.4°C) | 15 sec |

| “ | Egg nog, frozen dessert mixes | “ | 175°F (79.4°C) | 25 sec |

| “ | “ | “ | 180°F (82.2°C) | 15 sec |

| Continuous, higher heat shorter time (HHST) | Milk | “ | 191°F (88.3°C) | 1 sec |

| “ | “ | “ | 194°F (90°C) | 0.5 sec |

| “ | “ | “ | 201°F (93.8°C) | 0.1 sec |

| “ | “ | “ | 204°F (96.2°C) | 0.05 sec |

| “ | “ | “ | 212°F (100°C) | 0.01 sec |

| Continuous, Ultrapasteurization | Milk and cream | Refrigerated, extended storage | 280°F (137.8°C) | 2 sec |

| Aseptic, ultra high temperature (UHT) | Milk | Room temperature | 275-302°F (135-150°C) | 4-15 sec |

| Sterilization | Canned products | “ | 240°F (115.6°C) | 20 min |

High temperature short-time (HTST) Pasteurization Process of milk

The first time this was developed by A. P. V. Co. in the United Kingdom in 1922. The HTST pasteurizer provides an uninterrupted stream of milk. The process of HTST involves heating milk to 72 to 750 C and a 15 second waiting time, before cooling.

One of the primary benefits of batch and continuous system is the fact that it can be reclaimed by means of regeneration. Regeneration efficiency of up to 95% are possible this means that a pasteurized item that requires heating to 720C could be heated to more than 680C via regeneration when the milk’s initial temperature is 4 degrees C. Even though high regeneration efficiency results in significant savings in energy however, they require the use of greater areas due to the less force driving temperature and there is a more expensive capital cost to heating exchangers.

The following functions and parts are utilized when milk goes across these HTST system of pasteurization:

- Float-Controlled Balance Tank (FCBT): The Float Controlled Balance Tank (FCBT) maintains an even amount of milk to feed the milk pump that is raw; it also gets any milk that is sub-temperature that is diverted through the an flow diverter valve (FDV).

- Pump: A rotating positive pump that is connected to the heater and regenerator or a centrifugal pump that has a flow control mechanism to ensure that the output is constant following FCBT is utilized.

- Plates: The Plate Heat Exchanger is often utilized for the HTST system, specifically to heat to temperatures that are lower than that of the milk’s boiling point. Plate heat exchangers are compact easy to clean and examined unit. The plates can be employed for cooling, heating and regeneration as well as holding. A distance of about 3 millimeters is maintained between the plates through the use of a rubber gasket that is non-absorbing or a seal.

- Regeneration (Heating): The cold milk that is incoming is partially and in turn heated by hot milk that is outgoing (milk-to-milk renewal). This increases the efficiency and efficiency of HTST process as the milk coming in requires less heat from hot water to increase the temperature to hold.

- Filter: Differently designed filter units that connect straight to the HTST systems are put in the pre-heater or the regeneration (heating) segment. These units, made up of 40 to 90 mesh fabric, are typically cylindrical in design. The majority of the time, two filters are used however they can be used simultaneously.

- Holding: The tubes or plates assure that milk is stored for a certain amount of period of time, not more than 15 seconds and at a temperature of 720C or higher.

- Flow diversion valve (FDV): The valve is used to route the milk following the heat treatment. If the milk is adequately pasteurized, the milk flows through the unit. For milk remains unpasteurized flows ahead through the unit. The milk unpasteurized milk is automatically returned to FCBT to process it. It is typically operated with the force of air against a spring that is strong.

- Regeneration (cooling): The hot milk that is pasteurized is cooled in part and indirectly by the cold milk that is incoming. This further enhances the efficiency that is a result of this HTST process.

- Control panel: It contains controls, instruments FDV mechanism, as well as a holding system, all inside a single moisture-proof panel.

- Hot water set: circulates heated water throughout the section that heats the unit in order to keep the proper temperature of milk within extremely precise parameters.

- Automatic control devices: Automated control devices include steam pressure controllers as well as control of water temp.

Steam pressure controller: Steam pressure controller keeps an unchanging hot water temperature for heating milk at the temperature required for pasteurization.

Water temperature controller: Controls the quantity of milk that leaves the tube or plate that holds the milk. This is an electronic contact instrument that can operate either an FDV or a milk pump, which prevents that milk is not leaving the storage area at the temperature that is required. The frequency and the duration of the flow divert and temperatures of milk that leaves the holding section are documented by the thermograph (recording chart) with the help of two distinct pen (De 2001).

Advantages of HTST pasteurization of milk

- Large quantities of milk could be processed in a continuous manner.

- Automatic precision controls assure positive pasteurization.

- The equipment needs a minimal amount of floor and space for the plant.

- The system can easily adapt for CIP cleaning.

- The filling operation may start almost at the same time.

- It is the HTST method is cost-effective because it makes use of regenerators.

- The whole process is straightforward and requires only a little supervision.

- The capacity can increase by increasing the amount of plates, without the need to sacrifice the floor space.

- It is well-suited to the use of regenerative cooling and heating.

- The closed unit reduces processing loss to a minimal.

Disadvantages of HTST system

- The system isn’t adequate for handling small amounts of various milk-based liquid products.

- Gaskets need to be monitored to ensure leakage is not occurring and for the proper use of sanitation.

- It requires precise instruments for control.

- It is impossible to drain the entire reservoir without loss.

- Long-term pasteurisers could create serious bacterial issues; the plant must be thoroughly cleaned every six to eight hours in order to keep these from happening.

Tunnel (Spray) Pasteurizers for beverage

Tunnel (Spray) Pasteurizers are extensively utilized in the beverage sector to provide continuous cooling and heating of food items within sealed container. They are ideal for large volume throughput. Examples of these products include carbonated and soft beverages, juices, beers and sauces. With this technique the post-processing contamination will be greatly reduced with the primary cause being poor seams on the container. There are three primary steps within the tunnel that are heating, holding and cooling. In each of these stages, water at the correct temperature is sprayed on the container. Because the heating rate isn’t as high as those of tubes or plates and tubular heat exchangers, these methods are better suitable for longer-term or processes with lower temperatures. The average transit time can be as short as 1 h with temperatures that range between 60 to 700C for around 20 min (Brennan and Grandison 2008).

What is Batch/ Holding Pasteurization?

This process is also called the Low -Temperature-Long-Time (LTLT) method. The process has not gained much popularity for the milk industry after the HTST method was implemented. The milk and the milk products are heated or cooled in batches, either in three, two and three tank. This involves heating milk until temperatures of between 62.8 and 65.60C and maintaining it at this temperature for about 30 mins and then quickly cooling it down to less than 100C. Batch processing involves filling up the vessel with milk, heating and cooling, holding and emptying the vessel, filling into containers, as well as washing the containers (Lewis and Jun 2012).

The cooling and heating of the product are done via a wall of steel. It is heated steam or hot water. The product is then either cooled or heated, and gentle stirring is used to ensure quick heat exchange. Pasteurizers can be found in three kinds:

- Water-jacketed vat: These are double-walled around the sides and bottom, in which steam or hot water in partial vacuum flows to heat and cold water is used to cool. The wall on the outside (lining) is typically lined with insulation to prevent the loss of heat. The heat exchange occurs through the wall of the lining. The temperature difference of the water used to heat it and that of the milk has to be held to an absolute minimal. The milk is stirred by gradually shifting (revolving) propellers. In the event of heating, the cover of the vat is opened to let out of flavours that are not desired; while holding the milk, the cover is shut. During the time of holding it is recommended to use an air space/foam heater (steam or electric heated) hinders the cooling of the surface of milk.

- Water-spray type: A layer consisting of water is spray through an aperforated pipe onto the tank’s surface that holds the product. The product is then agitated as described previously described. A continuously moving, continuous layer of water allows for quick heat exchange.

- Coil-vat type: The cooling or heating medium is pumped through a tube that is placed in vertical or horizontal position and then turned around the product. The rotating coil is causes the product to be agitated (but additional agitation might be required).

The batch pasteurizers can be inexpensive, easy to use and designed for small-scale plants and for small-volume products (De 2001).

Alkaline Phosphatase Test for Checking Efficiency of Pasteurization in Liquid Milk

Alkaline Phosphatase, a native milk enzyme. Its activity decreases at the point of pasteurization and is used as a measure of the effectiveness of pasteurization. Because milk is a known vector for several pathogenic bacteria, such as Salmonella, Compylobactor and Listeria This test has great importance for dairy producers in order to check the efficacy of heat treatment. In the method below the solution of disodium P-nitrophenyl phosphate within buffer with pH 10.2 can be used to serve as a a substrate. This colorless compound when in the solution hydrolyzed by alkaline milk phosphate to release p-nitrophenol. This in alkaline conditions imparts an intense yellow coloration of the liquid. The liberated p nitrophenol is determined directly by comparison to conventional colour discs within the Lovibond comparator. The test is not applicable to milk that is sour or preserved using chemical preservatives (FSSA 2012).

Procedure

- In an empty test tube pipette five milliliters of buffer substrate, Stopper and increase it to 37oC.

- Add 1 milliliter of test milk to it, shake it up and then replace the stopper.

- Let it incubate at 37oC for two hours.

- Incubate a blank made from boiling milk that is the exact kind like the sample being tested for each of the samples.

- Take the tubes off after 2 hours and the contents should be evenly mixed.

- Put the milk blank that has been boiled on the left edge of the Comparator stand and the test samples on top.

- The reading is taken in reflection light by rotating this disc till the sample matches.

- Note the readings that fall between two standards, by adding a minus or plus sign to the number to indicate the closest standard.

Interpretation

The test is deemed satisfactory If it shows a value of less than 10 ug of p-nitrophenyl for every ml milk. Pasteurized milk that is properly processed does not give visible hue.

Frequently Asked Questions

When was pasteurization invented?

Around 150 years ago, Louis Pasteur developed the pasteurization method while given the task of solving practical issues like keeping harmful bacteria away in various food items.

After a few decades, when the first time he came up with the idea in the 1960s, an New Jersey milk plant installed the first pasteurizer in the United States. From that point and until today with the exception of milk that’s advertised by the name of “raw” (milk that has not been pasteurized) milk, every milk sold in the United States has been pasteurized. This is just one of the many ways in which the U.S. dairy industry helps ensure that our milk is secure.

Why is it necessary?

Based on the Centers for Disease Control and Prevention (CDC) the raw milk may contain harmful bacteria that be a serious health risk to yourself and the rest of your household. Pasteurization eliminates the bacteria.

Does pasteurization change milk?

No. According to CDC the pasteurization process does not alter what milk’s nutritional values are. Indeed, it is possible that you could reap all the benefits of pasteurized milk without the danger of getting sick that comes from drinking raw milk.

In terms of milk’s nutritional value and minerals, all the minerals found in milk remain the same, however there’s a slight variation in the vitamins. Raw milk has a tiny volume (<10 percentage of recommended daily allowance which is why it’s not considered to be a great supply) of Vitamin C which isn’t enough to withstand the process of pasteurization.

Additionally According to the CDC the CDC, if you’re contemplating drinking raw milk since you believe it’s a beneficial food source for beneficial bacteria such as probiotics, be aware that it’s not. It’s potentially hazardous and can cause illness. If you’re planning to have drinks or food that contain probiotics, experts like registered dietitians advise purchasing one that’s clearly labeled as probiotics, rather than trying to guess.

When you’re done with your day, you’ll be able to rest assured that the milk you drink is not only healthy for your health, but it’s safe also. All those who work in the dairy business all the way from farms to the grocery store, are aware of the importance of these qualities and strive to ensure that your family is getting the highest quality milk you can get.

What are the risks of drinking raw milk?

According to an US Centre for Disease Control and Prevention study the frequency of outbreaks caused by nonpasteurized milk and products made of it was more than 150 times higher than those caused by pasteurized milk. Younger adults and children were more affected by illness. Raw milk can contain pathogens that may cause illness or disease.

Some claim to have grown as children drinking raw milk but never got sick due to it. But public health authorities have a number of instances of people getting sick due to drinking raw milk.

The requirement for the pasteurization process of milk halted large-scale outbreaks of milk-borne diseases in Canada. However, the possibility of outbreaks from raw milk continue to occur and warn us about the risks of drinking milk that is raw.

What is the process of pasteurizing milk?

In the majority of milk processing facilities the chilled milk can be heated up by passing it through the plates of stainless steel until it is at 161 degrees F. It’s kept at this temperature for a minimum of 15 seconds before being swiftly chilled back to the original temperature of 39 degrees F.

The “cool” part: One method that dairy companies save energy is to use the heat generated by heated pasteurized milk to heat the next batch of raw cold milk. The chilled milk then is used as a cooling agent for the pasteurized milk. This way the industry can use heat and refrigeration energy more effectively in the process of milk pasteurization.

How is pasteurized milk different from raw milk?

Pasteurized milk is a raw dairy that is heated at a specific temperature and length of time to kill pathogens that could be present in the milk. Pathogens are microorganisms like bacteria that can cause illness. Raw milk could contain pathogens, such as Campylobacter, E. coli O157:H7 Salmonella, Listeria and other bacteria. Raw milk is made up of milk from goats, cows, sheep and dairy animals.

The law requires that every milk sold to the public must be pasteurized before being packaged at a dairy plant that is licensed. Vitamins A and D are the only vitamins that can be added to milk. No other preservatives or additives can be added legally to milk. Vitamin A enhances your eyesight, assists you in seeing clearly when you are sleeping or in dim lighting, and assists in distinguishing the different shades. Vitamin D aids your body absorb calcium and decreases the risk of developing osteoporosis.

Who is at risk of getting sick?

Anyone can be sick due to pathogens found in milk that is raw.

Children, infants elderly women, pregnant women and people suffering from chronic illnesses are more susceptible to infection and are at greater chance of becoming sick due to consumption of raw milk. Children and infants are the most vulnerable because they typically drink a lot of milk.