What is Laboratory Refrigerators and Freezers?

- Laboratory Refrigerators and Freezers are special equipment used for keeping samples, reagents, and chemicals at low temperature to stop deterioration or decomposition.

- They can define as a storage unit that maintain precise cooling environment for biological / chemical materials etc.

- The temperature is controlled usually between 2–8°C for refrigerators and –20°C to –80°C for freezers, but sometimes more lower for special specimen.

- In these devices, cooling is performed by compressor system (like household fridge), but designed with more stability and safety controls.

- They are commonly used by laboratories of microbiology, biochemistry, hospitals, and research centers where sensitive samples are preserved for long time.

- A thermostatic controller is provided for regulation of temp, which may fluctuate slightly due to frequent door opening or power supply issue.

- The inside chamber are mostly made of stainless-steel, which resist corrosion and easy for cleaning purpose.

- Shelves and racks are adjustable so that bottles, vials, or culture media can be placed properly and safely.

- Alarm systems are often fitted, it gives indication when temperature goes beyond the preset limit, this help to prevail damage of stored items.

- In some model, auto defrosting mechanism is installed which remove excess ice formation automatically – maintaining uniform cooling inside.

- For laboratory freezers, the insulation thickness is more sturdy and hardy, helps to maintain low temp even during power interruption for short time.

- As energy saving is also considered, many new and fresh models use CFC-free refrigerants and digital displays for monitoring.

- The samples like enzymes, blood plasma, vaccines, bacterial cultures are stored for long-term experimentations.

- Maintenance must be done regularly (cleaning condenser, checking door gasket, etc.), otherwise cooling efficiency get reduced.

- It’s very important that temperature mapping is carried out, by which the uniform distribution of cold air can be ensured through chamber.

- After installation, calibration and validation are required, it ensure that the refrigerator/freezer meet standard lab conditions.

- Backup power supply or UPS are sometimes used, because during power cut the samples may spoil quickly.

- Such instruments are not used for domestic purpose, they are designed specifically for scientific applications, with strict accuracy and safety features.

- Thus, laboratory refrigerators and freezers act as core storage units for preserving integrity and viability of biological specimens.

- Without these, the stability of chemical reagents, tissues, and cultures can’t be maintained properly for longer duration.

Definition of Laboratory Refrigerators and Freezers

Laboratory refrigerators and freezers are specialized equipment used in scientific and medical settings to store and preserve samples, specimens, vaccines, pharmaceuticals, and biological materials at specific temperatures. They ensure hygienic conditions, precise temperature control, and reliable performance to maintain the integrity and viability of the stored items.

Working Principle of Laboratory Refrigerators and Freezers

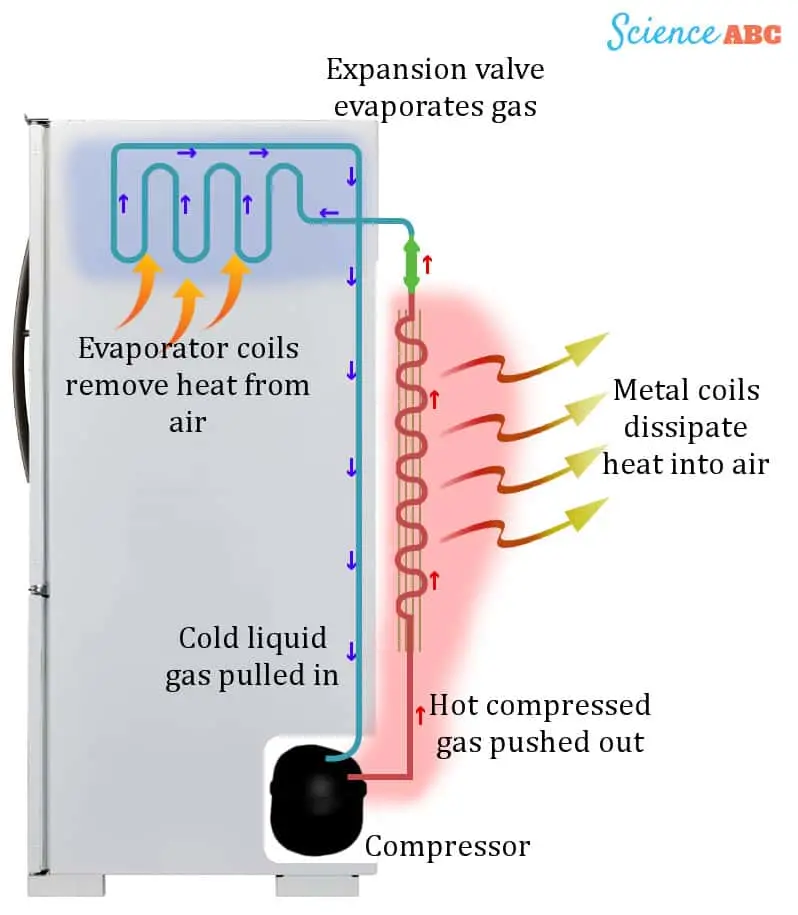

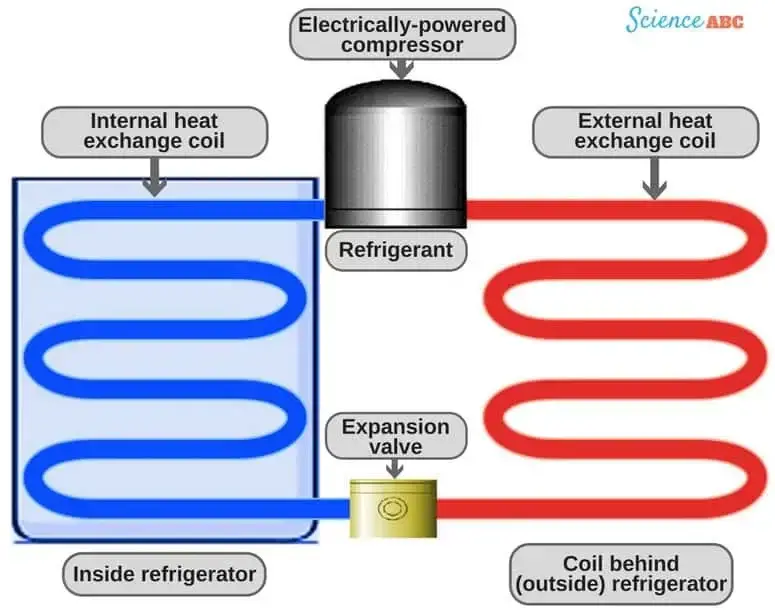

- The core working principle is essentially the same. It is based on a refrigeration cycle, which is basically a process where heat is removed from a chamber to keep it cold.

- The heat that results from the materials that are stored is taken by the refrigerant gas (such as Freon, R-134a etc.), which moves through the closed loop system.

- The refrigerant gas in the evaporator coil changes to a liquid and absorbs heat from the immediate surroundings, thus the air and the surfaces of the chamber get cooled.

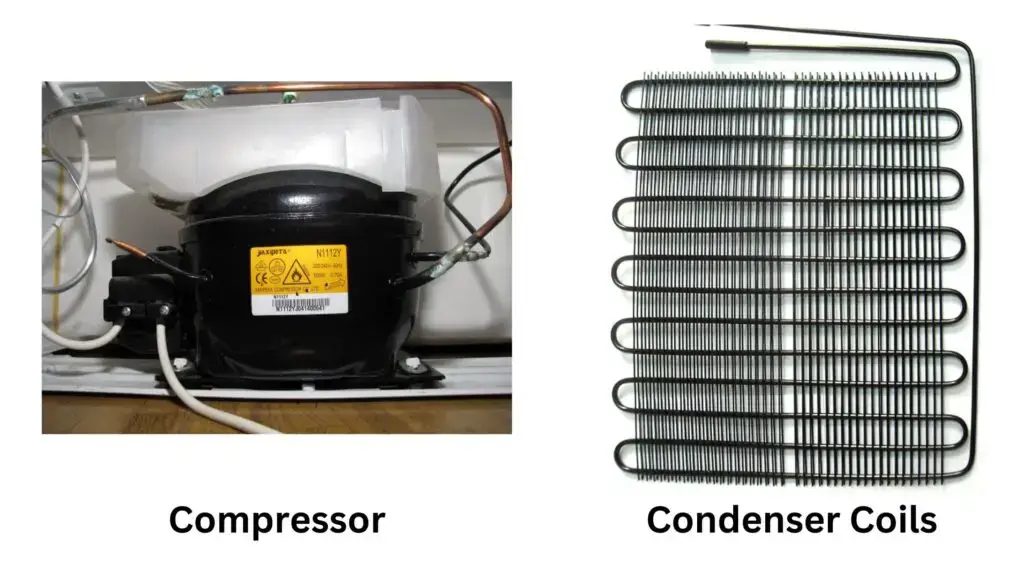

- After that, the compressor compresses the refrigerant vapor, increasing both the pressure and the temperature of the vapor.

- This hot gas is directed to the condenser coil, which is generally at the back or at the bottom, where the heat is given out to the surrounding air and the gas turns back into liquid.

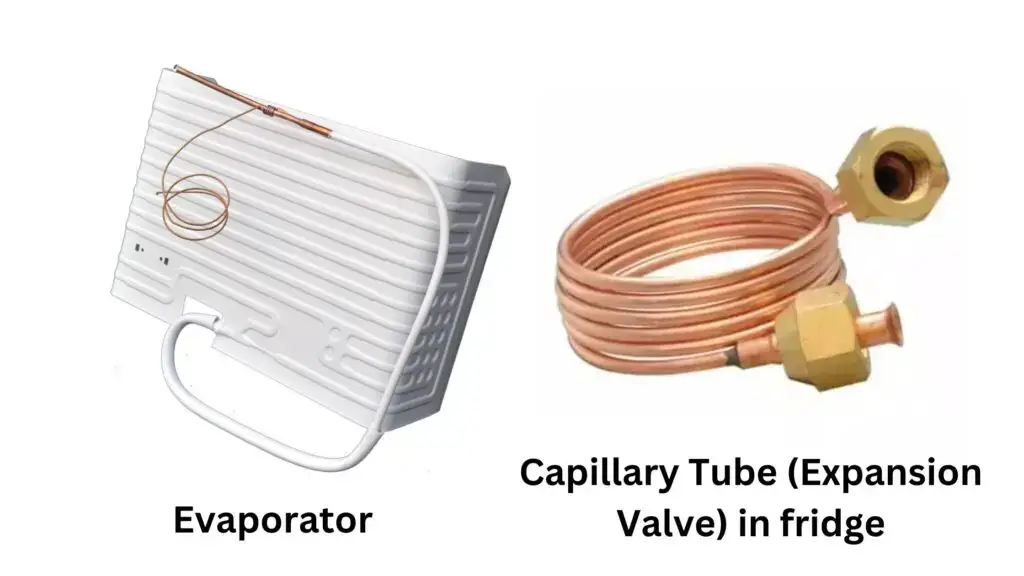

- The capillary tube or expansion valve is there to lessen the pressure of the refrigerant before it is allowed to enter the evaporator again, thus the continuous cycle is completed.

- Therefore, the continuous heat exchange that takes place between the evaporator and the condenser is what really keeps the temperature constant inside the cabinet.

- The temperature regulating mechanism performs its functions without human intervention—it detects increasing or falling temperatures and changes the compressor operations accordingly by switching it ON/OFF.

- At times, the fan motor is used for circulating the chilled air uniformly so that there would be no hot–cold spots, which could result from uneven cooling.

- The insulation material (such as polyurethane foam) is doing the work of lowering heat exchange with the outer environment, thus energy efficiency remains at a high level.

- The same principle is behind the working of freezers; however, laboratory freezers have more powerful compressors and thicker insulation to achieve ultra-low temperature (–20°C to –80 °C).

- The defrosting could be manual or auto. In the auto-defrost system, the ice that forms on the evaporator is melted regularly by the heating coil.

- The fluctuations in the power supply could be a reason for the malfunction of the compressor, thus a voltage stabilizer or UPS is usually used in laboratory setups.

- It is noticed that the efficiency largely depends on the proper sealing of the door gasket because even a small leakage can lead to an increase in temperature and the appearance of moisture.

- Some modern appliances are equipped with digital microprocessor controllers that continuously monitor the parameters for safety and accuracy.

- Both laboratory refrigerators and freezers use the same working principle. The only differences are the temperature range and the compressor–evaporator assembly design.

- As the system is cyclic, energy is conserved and temperature maintained without major fluctuation for longer duration.

- The refrigeration cycle is essentially the main heart of the system that is responsible for keeping the samples safe, fresh, and viable for the upcoming experiments.

Parts/Components of Laboratory Refrigerators and Freezers

- Compressor– It is main part that compresses refrigerant gas and circulate it by the cooling system.

- Condenser– Heat produced from compressor are removed here, usually located at back side or bottom.

- Evaporator – The refrigerant gets evaporated here and absorb heat from inner chamber making it cold.

- Refrigerant – It refers as cooling chemical (like R134a, ammonia, freon etc.) which flow inside coil for heat transfer.

- Thermostat – It controls temperature automatically; when preset temperature reach it cut off power to compressor.

- Cabinet– The main body made of stainless steel or polymer, insulated for maintaining constant low temperature.

- Insulation material – Foam or fiber used between walls to prevail temperature fluctuation and increase efficiency.

- Door – Usually double walled and fitted with rubber gasket to avoid leakage of cold air / entry of moisture.

- Shelves / Racks– Adjustable shelves provided for placing samples, reagents, chemicals, culture plates etc.

- Temperature display panel – It shows real-time temperature (°C or °F) by sensor inside the chamber.

- Temperature sensor / probe– Used to detect actual internal temperature and send data to thermostat.

- Fan or blower– Circulates cool air uniformly inside chamber so temperature remain same in all space.

- Drain system– Melted frost water passes by this outlet to collecting tray below unit.

- Defrost system – Some models have automatic or manual switch to remove ice formed on evaporator coils.

- Control buttons / Switches – These are provided for adjusting settings, alarm reset, or turning on/off.

- Indicator lights – Small bulbs/LEDs used for showing status like power on, cooling, alarm etc.

- Alarm system – Warns if temperature rise above safe limit or door remain open for long time.

- Power cord and plug – Supply electric power (usually 220V / 50Hz) to the whole refrigeration unit.

- Freezer compartment – Separate lower chamber (in combined model) used for storing samples below -20°C.

- Gasket seal– Soft rubber lining fitted around door for airtight closing, preventing cold loss.

- Safety lock– Installed on door to protect valuable or biohazard samples from unauthorized access.

- Interior lighting– LED or fluorescent lamp inside help to view samples clearly even when door closed partly.

- Wheels /Legs– Castor wheels or adjustable legs attached at base for easy movement and stability.

- Data logger port – Provided in advanced model for recording temperature variation during operation.

- Outer paint coating– Applied for corrosion resistance and also give aesthetic appearance to instrument.

Types of Laboratory Refrigerators

Types of Refrigerator

- Domestic Type – This type mostly used for normal lab purpose / small sample storage. They operate usually at 4°C but sometimes temperature fluctuates slightly. Cooling is done by compressor and refrigerant gas, which circulate by copper tubes.

- Explosion-Proof Refrigerator – Designed for storage of flammable or volatile chemicals, so no spark or ignition can occur inside chamber. They are specially insulated and sealed from electric sparks, though sometimes they cost higher and heavy too.

- Flammable Material Refrigerator – It used where chemical vapors can mix with air forming explosive mixture. The compressor motor placed outside the cabinet (so vapors not contact with electric part), and interior light also shielded.

- Ultra–Low Temperature Freezer (ULT) – Temperature maintained between −40°C to −86 °C (sometimes even −90°C in few model). It used for long-term preservation of enzymes, bacteria, DNA, tissues etc. Cooling achieved by cascade system or multiple compressors working sequentially.

- Cryogenic Freezer – It works at extremely low temp, often below −150°C using liquid nitrogen (LN₂) or other cryogens. Such units mostly used for storage of cells / genetic samples. Safety measure must follow strictly.

- Pharmaceutical Refrigerator – These are made for vaccines, drugs, and biological reagents which required constant +2°C to +8°C range. Air circulation fan used for uniform temperature distribution; some have data logger and alarm system.

- Blood Bank Refrigerator – Constructed specially for storing whole blood and plasma at +4°C (±1°C). Internal trays and digital temperature monitoring provided, after that automatic alarm triggers if temp deviate.

- Chromatography Refrigerator – Mainly used to store reagents / chromatography solvents under controlled low temperature to reduce evaporation or degradation. They usually equipped with glass door for easy visibility but still insulated properly.

- Laboratory Freezer – It generally operates at −20°C or −40°C, sometimes used to store reagents, enzymes, and short-term biological sample. Frost-free or manual defrost both type available depending by user need.

- Explosion-Safe / Spark-Free Freezer – Similar like explosion-proof but also designed that internal electric components are replaced by mechanical switch or sealed relay to avoid any possible spark.

- Walk-in Cold Room – Large scale cold chamber, often modular built. It’s used for bulk storage of samples, vaccines, or culture media. Temperature and humidity both can be adjusted by control panel.

- Flake Ice / Chest Freezer – Some labs used them for temporary cooling of materials or to preserve specimen on ice bath, these have deeper chamber and top lid opening which retain cold air efficiently.

- Combination Refrigerator-Freezer – It contain both compartment, one for refrigeration (4°C) and another for freezing (−20°C). Very handy for multi-purpose lab use, though temperature stability sometimes less accurate compare to separate unit.

- Under–Counter Refrigerator – Smaller size units designed to fit under laboratory benches. Used when space limited but frequent access of sample needed. They are often frost-free type for convenience.

- Medical Grade Refrigerator – Specially certified for clinical and diagnostic use. They are tested for temperature uniformity, door-open recovery, and alarm accuracy etc., which ensure sample integrity.

Types of Freezer

- Low Temperature Freezer – Usually operates at −20°C or −40 °C; used for temporary storage of reagents, enzymes, or culture samples. Cooling is done by mechanical compression cycle, and temperature is controlled by digital thermostat though sometimes it fluctuate little.

- Ultra–Low Temperature Freezer – This type maintain between −40°C to −86°C range, commonly called ULT freezer. Two stage cascade refrigeration system applied, so temperature stability is quite better but energy consumption high.

- Cryogenic Freezer – Operates at extremely low temperature (below −150 °C) by using liquid nitrogen (LN₂) or sometimes liquid helium. It used for preservation of biological specimen, DNA, stem cells etc., they must be handled with insulated gloves otherwise frost bite occur easily.

- Deep Freezer – A common type in laboratory, capable to reach up to −80°C in few model, though many work at −20°C for daily use. These are vertical or chest type, with thick insulation walls to reduce heat transfer from outside environment.

- Flammable Material Freezer – Designed specifically for chemicals that can emit volatile vapors, so all electrical components sealed and located externally. Internal light and thermostat are explosion proof to prevail fire hazard.

- Explosion–Proof Freezer – Similar to flammable freezer but more safety feature, such as spark-free switches and hermetically sealed compressors. It used for high-risk storage in chemical laboratories and pharmaceutical industries.

- Medical / Pharmaceutical Freezer – Intended for storage of drugs, vaccines, serum, plasma etc., which require constant −20°C or −40°C. They come with alarm system, temperature recorder and sometimes backup battery to ensure safety during power failure.

- Blood Plasma Freezer – Maintained strictly between −30°C to −40°C, used to preserve plasma, blood products and related biological fluids. After that if temperature rises, automatic alert activated to protect stored content.

- Chest Freezer – Opens from top side; cold air retained better when door open. Mostly used for long-term storage of sample packs or bulk frozen materials. However, finding small vials sometimes difficult due to stacking.

- Upright Freezer – Similar to domestic refrigerator type, but designed for laboratory use. It has multiple shelves, easier to organize samples though more heat loss occur during door opening.

- Walk–in Freezer Room – Large cold storage chamber (temperature −20°C to −80°C range), usually constructed modular. Used where bulk materials or research samples needed to be stored for long term. Temperature uniformity achieved by continuous air circulation fans.

- Compact / Under–Counter Freezer – Small-sized unit fitted below bench, helpful in labs having limited space. Mostly frost-free type and used for short time specimen preservation etc.

- Combination Refrigerator–Freezer – Dual compartment unit, one acts as refrigerator (4°C) and another as freezer (−20°C). Ideal for multipurpose laboratory but temperature recovery sometimes slower than dedicated one.

- Industrial Freezer – Very sturdy and hardy design, used in production or pilot-scale laboratories. They often have larger capacity (>1000 L) and heavy-duty compressors for continuous operation cycles.

- Frost–Free Freezer – Equipped with automatic defrost mechanism by periodic heating coils, so frost build-up not happen. Although they save maintenance time, but sometimes sensitive biological samples dry out due to airflow.

Laboratory Refrigerators and Freezers Operating procedures

- Before using the equipment, it should be properly set on a sturdy and levelled surface so as to not vibrate or make an unnecessary noise during operation.

- One should also see to it that the power supply matches the rated voltage (230 V ±10 %) and is properly grounded. Incorrect power supply may result in the equipment malfunctioning or prevailing of electricity.

- Usually, the internal temperatures of the refrigerator/freezer are fixed by the factory. However, one can change the temperature by turning the control knob or using the digital controller depending on the need of the specimen.

- The door gasket must always be maintained in a clean condition. Dirt or frost may cause a bad sealing which will result in temperature fluctuation.

- Samples / chemicals (like enzymes, sera, media, etc.) have to be put in labeled containers. One must also refrain from overfilling the shelves as this restricts the air circulation inside.

- The air-vent or fan openings should always be free from any obstruction. The reason for this is that the cold air is distributed through these openings.

- Once the samples are loaded, the door has to be closed immediately. Do not keep the door open for a long time as this will allow warm air to enter and condensation will be formed in the walls.

- For long-term storage, the inner temperature is kept at about −20°C (freezer) and 2–8 °C (refrigerator). However, a slight variation is possible depending on the model.

- Temperature control is done by a built-in thermometer or an external data-logger; the temperature should be recorded daily in order to ensure stable conditions.

- The cleaning is mostly done once a month; before cleaning, the power should be turned off and the samples moved to another cold storage temporarily.

- While cleaning the inner parts, a mild detergent solution should be used (not a strong chemical) and then wiped dry thoroughly, to stop rust or bad-smelling from forming.

- Ice deposit (mostly on the evaporator coil or inner wall) has to be removed through the defrosting process. Some units are equipped with auto-defrost while others need a manual one.

- The condenser coils which are located behind the unit or on the back side need to be dusted with a soft brush or vacuumed every few months for proper working.

- Power can be turned on again and the temperature can be left to stabilize after cleaning or defrosting are done before putting the samples back (usually takes 30–60 min).

- If there is any abnormal noise, temperature increase, or ice build-up that is beyond the normal, you should inform the maintenance team about it. Do not try to handle it yourself.

- It is very important to take note of a power outage at the time it happens. In case of a short power failure, doors should be kept closed tightly in order to retain the coldness. However, if the power outage is for a long time, then the samples should be moved to the backup unit.

- The calibration of a thermometer or sensor is done from time to time (normally every 6 months) and is achieved by comparing it with a standard certified device to ensure precision.

- The alarm systems (for high/low temp or door open) should be checked from time to time, at times daily, to be sure that they work properly.

- A chemical or biological sample spillage inside should be cleaned quickly with a disinfectant (such as 70 % ethanol), since that contamination can spread quite fast.

- Volatile or explosive materials should not be stored in a freezer unless the unit is specifically made as an explosion-proof model. Otherwise, there is a risk of fire being caused by a spark from the compressor.

- A freezer is not the right place for the same sample if you are going to do the repeated thawing and freezing. The quality of the biologicals will be degraded.

- Subsequently, the user should make a record of all the maintenance activities in a log book / digital sheet with the aim of traceability.

- If the power is off, or the equipment is being moved, it should be kept upright (not tilted more than 45°). This is because, if the compressor is inverted, the oil may leak into the coil.

- As an additional safety measure, it would be good if the children and other unauthorized persons are kept away from the laboratory refrigerator and freezer compartments.

- Lastly, technical people should perform the performance verification (cooling rate, temperature uniformity, etc.) at least once a year in order to be able to comply with laboratory standards.

Applications of Laboratory Refrigerators and Freezers

- Laboratory refrigerators are mainly used for preservation of biological samples, like blood, serum, plasma etc. which are sensitive for temperature fluctuation.

- In most laboratories, the vaccines are stored between 2°C–8 °C; these temperature maintained to stop degradation of active ingredients.

- Reagents and chemicals are also preserved by cold storage to increase their shelf life, sometimes even minor warming can spoil them completely.

- The freezers are utilized for long-term storage of biological material (like DNA, RNA, enzymes, tissues) where ultra-low temp. up to −80°C are required.

- Samples for microbial cultures are stored frozen to prevent metabolic activity, this keeps them viable for months or even years.

- In clinical and hospital labs, refrigerators are used for blood products storage (whole blood, platelets, plasma) under separate compartment to avoid contamination.

- After analytical tests, some specimens are re-stored for rechecking purpose, especially when results are abnormal, thus re-test possible anytime.

- Certain pharmaceutical formulations (like insulin, hormones, antibiotics) are also kept inside refrigerator/freezer to prevail denaturation.

- Environmental samples from field (like soil or water) are temporarily stored in refrigerator before further chemical / microbial analysis.

- Cryopreservation of cell lines, embryos, and genetic material is done by ultra-low freezers, sometimes with liquid nitrogen (−196°C).

- In molecular biology work, the enzymes like Taq polymerase and restriction endonucleases are stored frozen for activity maintaining.

- Some refrigerator chambers are also used for media and buffer preparation components; especially those with volatile solvents which evaporate quickly.

- During clinical trials, sample integrity is ensured by continuous cold-chain using laboratory freezers, the deviation can affect whole study result.

- In research centers, archived specimens of microorganisms are stored for taxonomic / genetic studies and future reference.

- Refrigerators are also used for cooling of laboratory instruments (for example centrifuge rotors pre-cooling before sample spinning).

- Biological waste that need safe disposal are sometimes stored in freezer to prevent odor and infection spread until proper discarding.

- Laboratory freezers are also used in storage of standard reference materials, calibration samples etc., ensuring accuracy of future experimentations.

- In pathology sections, tissue blocks and slides are stored cold to maintain morphology for histological examinations.

- For diagnostic kits like ELISA, PCR reagents, etc. cold storage is mandatory to maintain sensitivity and specificity of assay.

Advantages of Laboratory Refrigerators and Freezers

- The sample integrity is maintained as stable low temperature stop chemical / biological reactions that degrade them.

- Because of precise temperature control, the storage of vaccines, blood, enzymes etc. are ensured safe for longer period.

- Contamination chances are highly reduced as samples are kept isolated and cooled, so microbial growth is restricted naturally.

- Laboratory freezers provides environment for long-term storage (even years), that’s helpful for research continuity.

- As the cooling system work automatically, less manual supervision needed which saves both time and human effort.

- The data recording function in some advanced models helps to monitor fluctuations, thus reliability of results is improved.

- After experiments, leftover reagents can be re-used when stored in refrigerator; this reduces wastage and cost.

- In medical & hospital labs, these equipment provide safe storage of blood components—ensuring life-saving materials are ready anytime.

- Enzymes and proteins (like DNA polymerase, albumin) retain their activity under low temperature; otherwise they denature quickly.

- Freezers can maintain ultra-low temperature (−20°C to −80 °C) that helps in cryopreservation of biological materials.

- The internal design often includes separate compartments, preventing cross-contamination between reagents / biological samples.

- By proper storage, reproducibility of experimental data is achieved, because the sample condition remains constant.

- They are energy efficient and sturdy–built with insulation materials that maintain stable cooling even during short power cuts.

- Laboratory refrigerators allow temporary storage of field-collected samples, avoiding decomposition before testing.

- In pharmaceutical studies, stability testing is possible under fixed temperature, which increase accuracy of analysis.

- The maintenance of sterile environment inside reduces odor, spills and accidental microbial spreading.

- Certain volatile chemicals (like acetone, chloroform) are safely kept inside explosion-proof refrigerators preventing hazard risk.

- Research materials, patient specimens, and diagnostic kits are all protected by same cold-chain system, improving overall laboratory safety.

- As temperature alarms are installed, any deviation can be quickly noticed, minimizing sample loss.

Limitations of Laboratory Refrigerators and Freezers

- Sample integrity can be compromised when power failures occur, and backup systems are not present, causing thawing and spoilage.

- Temperature uniformity inside units is often limited, cold spots and warm spots are created, and sample placement is critical but sometimes ignored.

- High initial cost and maintenance expense are required, so small labs may find purchase and upkeep costly.

- Space is limited within refrigerator/freezer chamber, and overcrowding leads to poor air circulation, hence uneven cooling.

- Some reagents and kits are sensitive to repeated freeze-thaw cycles, their activity is reduced, and results are affected.

- Ultra-low freezers (−80°C) consume considerable electricity, the running costs are high and energy efficiency may be poor.

- Alarm systems are installed, but false alarms or alarm failures are reported occasionally, sample loss risk remains.

- Mechanical failures (compressor, thermostat, valves ) are possible, replacement parts may be delayed and downtime is experienced.

- Cross-contamination is possible when proper segregation is not done, aerosols and spills are not always prevented.

- Transport of samples requires cold-chain, and during transit temperature control is often lost, leading to degradation.

- Some volatile solvents cannot be stored in normal refrigerators, special explosion-proof models are needed, and they are costly.

- Size and footprint of ultra-low units are big, laboratory space planning is affected and bench area is lost.

- Noise and vibration are generated by compressors, they may disturb sensitive instruments nearby, and staff comfort is impacted.

- Monitoring systems are relied upon, but manual logs are still needed sometimes, digital records can be corrupted, so redundancy is required.

- Long-term storage at −80 °C or liquid nitrogen is required for cell banks, yet not all samples tolerate freezing, ice-crystal damage occurs.

- Cooling capacity is reduced in high ambient temperature, units are affected by room heat load and performance drops.

- Standardization across multiple units is difficult, different models are used and they are calibrated differently, reproducibility may suffer.

- Energy-saving modes are present but they can cause slow recovery after door opening, rapid temp. recovery cannot always be achieved.

- Some biological materials (like Escherichia coli stocks or primary cells) are badly affected by improper freezing, viability is lowered.

- Regulatory compliance and documentation burden are increased, audits are required and record-keeping is time-consuming.

- Accessibility issues are created when large number of samples are archived, retrieval time is increased, workflow is slowed down.

- Emergency plans are needed but sometimes they are not practiced, so when failures occur, samples are lost — this could have been prevailed (malapropism intended).

Precautions

- The refrigerator/freezer should always be kept clean, dust and spilled materials must be wiped immediately to avoid contamination.

- Temperature must be checked daily, because small fluctuation may cause big damage to sensitive biological samples.

- Samples should be properly labeled before storing, unlabeled tubes often get misplaced or mixed up later.

- It’s advised that chemicals and biological specimens not stored together, as vapors can react and spoil others.

- Overloading of chamber must be avoided; air circulation should not be blocked by too many boxes or bags.

- Doors should not be opened frequently or for long time, as this causes rise in temperature and condensation formation.

- In ultra-low freezers (−80°C), frost must be removed regularly, otherwise it reduces cooling efficiency and increases power use.

- Periodic calibration of thermometer / temperature sensor is required to ensure accuracy of reading.

- Samples with strong odor (like formalin-fixed tissues) should be sealed tightly in double containers to prevail smell diffusion (malapropism).

- Power backup systems (UPS or generator) must be connected for preventing loss during electricity failure.

- When defrosting is done, all samples must be transferred to another safe unit, not left at room temperature.

- Maintenance log book should be maintained and entries updated after cleaning or repair activities.

- The unit should not be placed directly near walls or sunlight windows; ventilation space of 10–15 cm required for compressor cooling.

- Periodic checking of door gasket (rubber seal) is essential, damaged ones cause leakage of cool air and ice buildup.

- Flammable or explosive materials are not stored in ordinary refrigerators, only explosion-proof ones are suitable.

- Gloves must be worn while handling frozen vials; frostbite risk is high when touching surfaces below −20°C.

- Liquids must not be filled up to the brim, as they expand on freezing and the containers may burst.

- Regularly check for ice block at drain hole, blockage cause water leakage on floor during defrosting cycle.

- Before storing, temperature should be stabilized for at least 24 hrs after installation or shifting of refrigerator.

- Inventory should be updated monthly, expired or unnecessary samples must be discarded following biohazard rules.

- While removing materials from freezer, door should be closed quickly; others must wait outside to minimize exposure time.

- Always unplug unit before cleaning or defrosting, electrical shocks can occur due to moisture presence.

- Safety instructions and warning stickers should be clearly visible on front door and near plug point.

- Alarm settings should not be silenced permanently, any deviation must be corrected immediately not postponed.

- Proper training of laboratory staff required, since mishandling of freezer samples can lead to data loss and contamination etc.

FAQ

What is the purpose of a laboratory refrigerator or freezer?

Laboratory refrigerators and freezers are designed to store and preserve various types of samples, specimens, reagents, vaccines, and other temperature-sensitive materials in a controlled environment.

How do laboratory refrigerators and freezers differ from domestic ones?

Laboratory refrigerators and freezers are specifically designed for the unique requirements of laboratory settings. They often provide precise temperature control, better temperature uniformity, and additional safety features compared to domestic units.

Can I store food or beverages in a laboratory refrigerator or freezer?

No, laboratory refrigerators and freezers should be strictly used for laboratory purposes only. Storing food or beverages in these units can lead to contamination and compromise the integrity of both the stored items and the laboratory environment.

What temperature range is typically maintained in laboratory refrigerators?

Laboratory refrigerators typically maintain a temperature range between 2°C and 8°C. This temperature range is suitable for storing samples, reagents, and medications that require refrigeration but not freezing.

What temperature range is typically maintained in laboratory freezers?

Laboratory freezers can maintain temperatures below 0°C, typically ranging from -20°C to as low as -86°C in ultra-low temperature freezers. The specific temperature range depends on the type and purpose of the freezer.

How often should laboratory refrigerators and freezers be cleaned and defrosted?

It is recommended to clean and defrost laboratory refrigerators and freezers at least once a year or as frequently as necessary. Regular cleaning helps maintain cleanliness, prevent contamination, and ensure optimal performance.

Can laboratory refrigerators and freezers store flammable substances?

Certain laboratory refrigerators are designed to be explosion-proof and can safely store flammable substances. However, it is important to use the appropriate type of refrigerator specifically designed for this purpose to ensure safety.

How can I monitor the temperature inside a laboratory refrigerator or freezer?

Laboratory refrigerators and freezers often come with built-in temperature monitoring systems, such as digital displays and alarms. These systems allow users to monitor and maintain the desired temperature range and receive alerts if there are any temperature deviations.

Are laboratory refrigerators and freezers energy-efficient?

Efficiency levels can vary among different models and types of laboratory refrigerators and freezers. However, modern units often come with energy-saving features, such as LED lighting and efficient insulation, to minimize power consumption and reduce energy costs.

What precautions should I take when handling samples in laboratory refrigerators and freezers?

It is important to follow proper handling procedures and precautions when working with samples in laboratory refrigerators and freezers. This includes using proper containment methods, labeling samples accurately, and ensuring secure sealing to prevent cross-contamination and maintain sample integrity.

- https://pdf.indiamart.com/impdf/15406183033/MY-2305501/thermo-scientific-tsx-series-high-performance-undercounter-lab-refrigerator.pdf

- https://www.escolifesciences.com/products/lab-refrigerators-and-freezers

- https://www.thermofisher.com/in/en/home/life-science/lab-equipment/cold-storage/lab-refrigerators.html

- https://www.laboratory-equipment.com/refrigerators-and-freezers.php

- https://www.coolmed.co.uk/knowledge/news/what-is-a-laboratory-fridge/

- https://www.biomall.in/category/lab-refrigerators-and-freezers

- https://ehs.oregonstate.edu/sites/ehs.oregonstate.edu/files/pdf/si/labrefrigerators_si.pdf

- https://www.globalspec.com/learnmore/labware_scientific_instruments/thermal_processing/laboratory_freezers_refrigerators

- https://americanbiotechsupply.com/blogs/american-biotech-supply/2020/10/08/types-of-lab-freezers-qualities-and-recommended-use

- https://lab-training.com/how-a-laboratory-refrigerator-is-different-from-a-household-refrigerator/

- https://medium.com/@ramilabworld/how-laboratory-refrigerators-and-freezers-are-used-in-the-lab-59ac561f8205

- https://medium.com/@ramilabworld/the-many-uses-of-the-laboratory-refrigerator-cd179e7233c3

- https://ezinearticles.com/?The-Many-Uses-of-the-Laboratory-Refrigerator&id=3425642

- https://www.danfoss.com/en/about-danfoss/our-businesses/cooling/the-fridge-how-it-works/

- https://byjus.com/question-answer/what-is-the-principle-of-freezing/

- https://www.tampaapplianceparts.com/blog/what-are-the-main-working-parts-of-a-refrigerator/

- https://www.scienceabc.com/innovation/how-does-a-refrigerator-work-working-principle.html

- https://www.newfane.wnyric.org/cms/lib/NY01001283/Centricity/Domain/95/How%20a%20Refrigerator%20Works.pdf