- An Incinerator can be define as a device/machine used for burning of waste materials at high temperature (around 870°C–1200 °C).

- It is mostly used by hospitals, industries, and municipal areas for disposing solid, liquid or gaseous wastes in safe way.

- The process by which wastes are burned is called Incineration, and it convert wastes into ash, flue gas, and heat energy.

- In the incinerator, the combustion occurs in presence of air (O₂), which helps complete oxidation of organic matters.

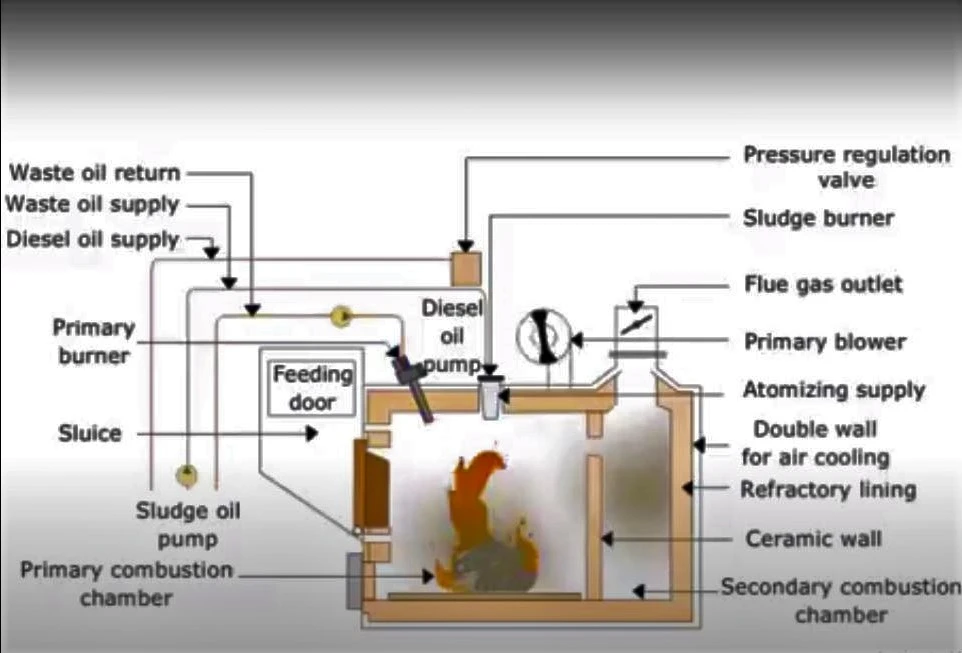

- Some systems are designed with two chambers, primary chamber where waste burned, and secondary chamber where gases are further oxidized for pollution control.

- It’s used for reducing the volume and weight of waste – sometimes up to 90 %, which make disposal easier by landfills etc.

- The ash that remains after burning, it contains inorganic residues, sometimes toxic metals also found.

- The flue gases are passed by filters or scrubbers to remove harmful gases, although some particles still escape, that’s a major environmental concern.

- Incinerators are classified by types like rotary kiln, fluidized bed, or multiple hearth depending by design and waste category.

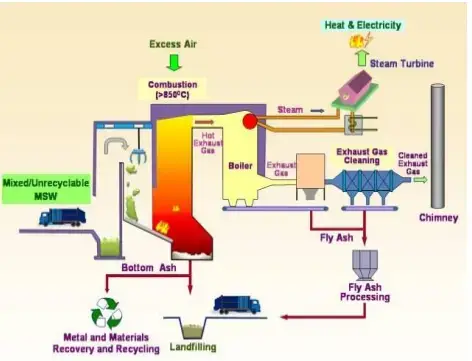

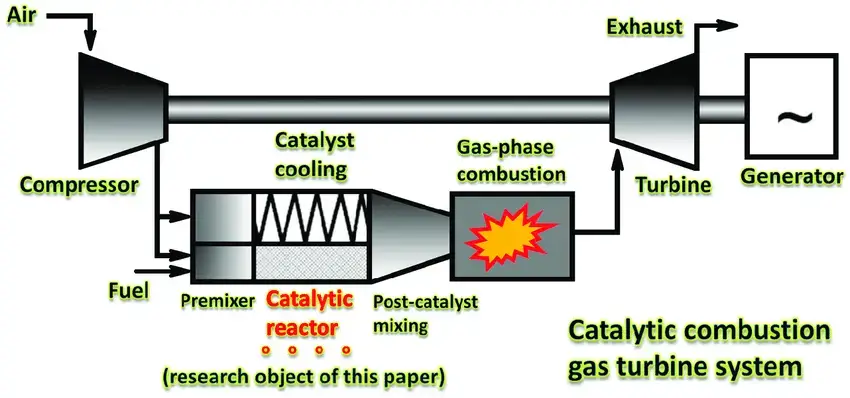

- The heat generated by this process can be recovered by heat exchangers / boilers for generating steam or electricity, that’s energy recovery system.

- However, by improper operation, the dioxins and furans may be produced which are very harmful pollutants to atmosphere and health.

- Thus, regular monitoring and maintenance are required, else the system efficiency and safety are reduced.

- It’s a important device for modern waste management, though it’s sometimes criticized for air pollution and high running cost.

- Overall, an Incinerator is considered a controlled and efficient (but not perfect) way of treating waste which can’t be recycled or reused.

Definition of Incinerator

An incinerator is a specialized furnace designed for burning potentially dangerous materials in a controlled manner, typically at high temperatures, to eliminate pollutants and safely dispose of waste.

Working principle of Incinerator

- The working principle of Incinerator can define as the controlled combustion of waste materials to convert them into ash, flue gas, and heat energy.

- The process is mainly based on the oxidation of organic substances present in waste by supply of adequate air (O₂) at high temperature (usually 850°C–1200 °C).

- Inside the primary chamber, the waste materials are ignited and partial combustion occurs under controlled air ratio.

- In next stage, the gases generated from first chamber are moved to secondary chamber where complete combustion occurs due to extra air and high temp (about 1100°C).

- The reaction can represent as: C + O₂ → CO₂ + heat, which release huge amount of thermal energy used for further burning or energy recovery.

- After that, the hot gases are cooled and passed by scrubbers / filters / electrostatic precipitators to remove dust, acidic gases and harmful compounds.

- The remaining solid residue or ash is collected at bottom of chamber; it mainly contain non-combustible inorganic materials.

- The temperature and oxygen supply are continuously controlled by sensors and regulators to ensure complete oxidation and to prevail formation of toxic gases.

- The generated heat energy can be used in waste-to-energy system, like for producing steam or electricity by boiler units.

- Finally, the cleaned flue gases are released by chimney into atmosphere under emission control norms, though sometimes few pollutants still escape.

- The efficiency of incineration depends by waste type, moisture content, air supply and design of combustion chamber, etc.

- Thus, in simple way it’s a thermo-chemical process where waste is transformed into harmless products (mainly gases and ash) by applying high temperature under controlled condition.

Operating procedure of Incinerator

- The incinerator chamber is checked for leftover ash or waste that has not been burned before fresh loading and if necessary, it is cleaned properly.

- It is also ensured that the air blowers/burners are in proper working condition and the sensors are sometimes calibrated.

- Then the primary chamber is heated up to 200–300°C approximately with the help of the auxiliary burners until the target temperature is reached.

- The first chamber is filled with segregated and dried waste materials gradually; air circulation is kept by not overloading the chamber.

- When the fire is started, the air/oxygen is given in enough quantity through the forced draft fans so that the organic matter is completely oxidized.

- The carbon monoxide is converted into carbon dioxide by reaction with oxygen in the air (generally 98% or more of CO is oxidized), as well as other tars and unburned gases are burned in the afterburner.

- The gases generated in the first chamber are passed into the secondary chamber where they are burnt again at a very high temperature (about1100–1200°C) to destroy the toxic gases and odor.

- The digital control panel is used to monitor the temperature, air pressure, and residence time constantly (sometimes these parameters are automatically adjusted too).

- The burners are closed down and the system left to cool naturally before the ash is removed, after the incineration cycle is finished.

- The ash that is left over from the bottom is taken out and disposed of properly, mostly it is dumped in landfill sites that are safe and designed for such purposes.

- The flue gas is passed through the scrubbers / filters / ESP (electrostatic precipitators) to remove the dust that is contained in the flue gas along with other pollutants before they are released into the atmosphere.

- The next batch of waste can be loaded once the cooling is completed but the temperature sensors and fans should be checked to ensure that they are working properly.

- In order to prevent a malfunction lubricating, cleaning the burners, and checking the refractory lining need to be done on a regular basis weekly.

- The safety measures such as using gloves, mask, and heat-resistant apron are strictly followed by the operators throughout the process.

- No wet waste, explosive, or pressurized containers must be added by mistake because it can cause sudden increase of pressure or destruction, and this is very important.

- The incinerator stays in good working condition for a long time by means of proper operation and periodic checking.

Parts of Incinerator

Primary Chamber – It is the main combustion chamber where the waste materials are burned at high temperature (about 850–1000°C). The walls are made of refractory bricks to resist heat and corrosion.

Secondary Chamber – In this chamber, the gases coming from the primary chamber are further oxidized, to remove unburned hydrocarbons and toxic gases, by extra supply of air.

Burners – They are installed in both chambers, used for ignition and for maintaining the temperature during whole combustion process. Sometimes they work automatically when temp. fall below set point.

Air Supply System – It provide controlled quantity of air / oxygen, required for proper combustion. It usually includes blowers, dampers and air nozzles.

Waste Feeding Door – Through this door, solid waste is fed into the chamber manually or by mechanical feeder. It must be closed tightly to avoid leakage of smoke.

Ash Collection Pit – After burning, the residual ash is collected at bottom part, which can be removed manually after cooling.

Flue Gas Cleaning System – It is used for cleaning the gases before releasing to atmosphere, consist of scrubber, filter, ESP (electrostatic precipitator) etc.

Chimney / Stack – This part allows the exhaust gases to go into atmosphere at safe height, minimizing air pollution by proper dispersion.

Control Panel – It contains temperature indicators, pressure gauges, alarms, timers and switches for regulating whole operation safely.

Refractory Lining – A layer of heat resistant material that protect the steel structure of chamber from high temperature and chemical attack.

Grate System – Some incinerators use grates on which the waste rests during burning, allowing air circulation from below for efficient combustion.

Fuel Supply Unit – Supplies diesel, gas or other fuel for operating burners, sometimes integrated with auto-start system for continuous running.

Types of Incinerator

There are various categories of commercial combustion technologies:

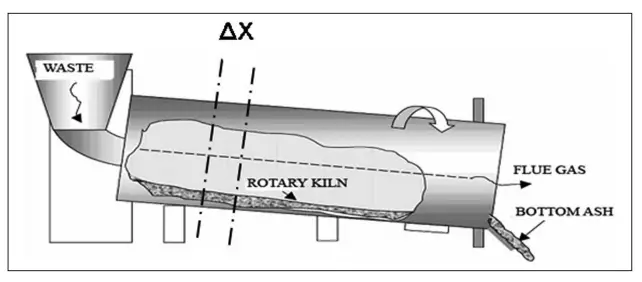

1. Rotary Kiln Incinerator – It is widely used type for burning hazardous and medical wastes. The chamber is a rotating cylindrical kiln, lined with refractory material, where waste is continuously mixed during combustion for complete burning.

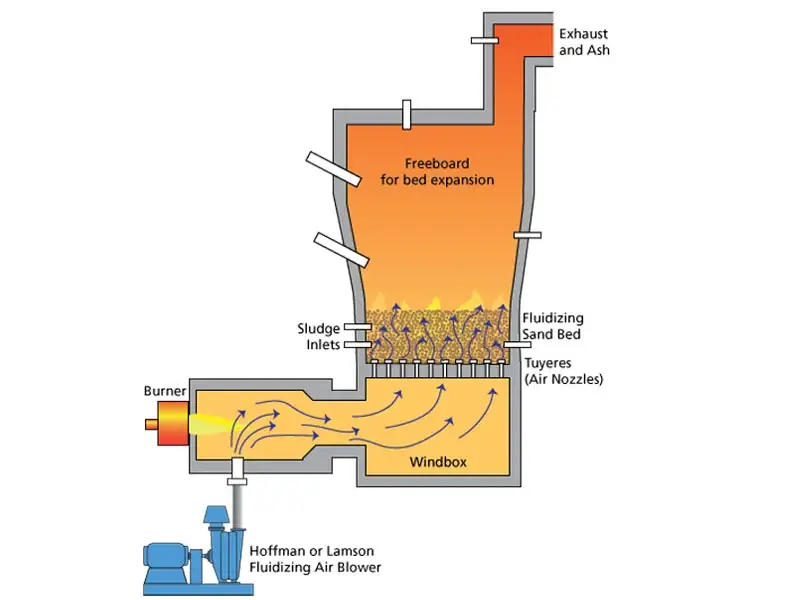

2. Fluidized Bed Incinerator – In this type, waste is burned on a bed of hot inert material (like sand) which is kept in suspension by air blown from below. It provide uniform temperature and better efficiency, but operation is complex.

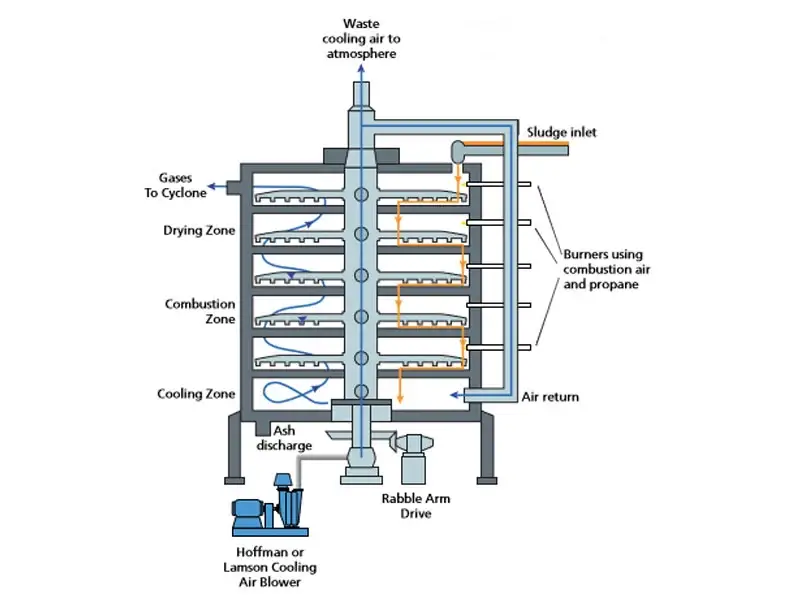

3. Multiple Hearth Incinerator – It consist of several hearths arranged in vertical series, with rotating arms that move waste downward, while hot gases move upward. Used mostly for sludge or wet wastes.

4. Controlled Air Incinerator – Sometimes called starved-air type, where limited oxygen is supplied in primary chamber to make partial combustion, and then gases are burned fully in secondary chamber. It reduce smoke and odors effectively.

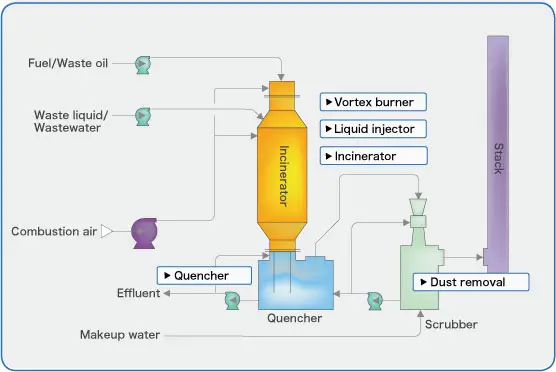

5. Liquid Injection Incinerator – This one is designed mainly for liquid / slurry wastes, where the waste is sprayed into a high-temp combustion chamber (about 1000°C) by special nozzles for atomization.

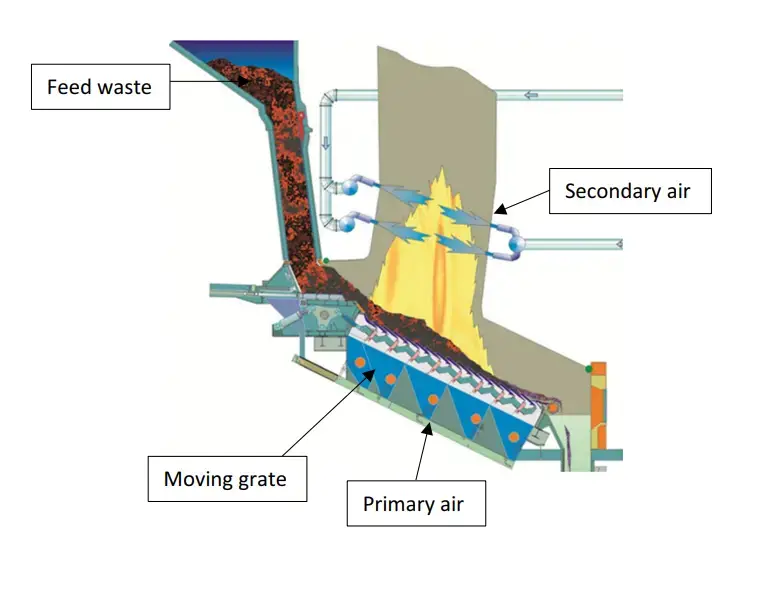

6. Fixed Grate Incinerator – Waste is fed on a stationary or moving grate, where air is supplied from below for burning. It is simple design, used for municipal solid wastes.

7. Waste Gas Incinerator – Used to destroy volatile organic compounds (VOC) and gaseous wastes from industrial exhausts, by oxidizing them at high temperature before releasing to atmosphere.

8. Modular Incinerator – These are compact, prefabricated units which can be easily installed and transported. Mostly used in small hospitals or remote areas for onsite disposal.

9. Pyrolytic Incinerator – It works on two-stage process, first stage involves thermal decomposition of waste without oxygen (pyrolysis), second stage burns the gases with air. Efficient and less smoke producing.

Applications of Incinerator

- In hospitals / clinics the incinerator is used to destroy medical waste (infectious gowns, sharps, pathological materials) so that pathogens cannot spread.

- In animal-care / veterinary settings it is used for disposal of carcasses, animal bedding and related materials, thereby reducing risk of disease transmission.

- For municipal solid waste (household trash, paper, cardboard, plastics) the incinerator is used to reduce volume and mass of waste; ash, flue-gas and heat are by-products.

- In industrial plants the apparatus is used for hazardous waste treatment (chemical sludges, solvents, sludge from pharma & chemical industry) where high temperatures are required.

- The incinerator is used in remote / camp / military or disaster-zones locations where conventional waste‐handling is difficult, allowing on-site disposal of bulky or mixed waste.

- Within a waste-to-energy context the incinerator is used to generate heat or steam which can be converted into electricity (thus recovering energy) from waste which otherwise would go to landfill.

- For special wastes like nanomaterials, animal by-products, expired pharmaceuticals the incinerator is used when normal disposal is inappropriate, because such wastes demand secure destruction.

- The incinerator is used for sludge from municipal / industrial operations (sewage sludge, paper-mill sludge) particularly via incineration technologies like fluidised bed, to reduce volume and treat organic content.

Advantages of Incinerator

- Waste volume can be reduced upto 85–90 %, which help in saving space in landfill area.

- Energy is recovered from waste combustion, the produced heat/electricity used for power generation or heating.

- Hazardous / infectious waste from hospitals and industries are completely destroyed, thus disease spreading is prevented.

- After burning, only small amount of ash residue remain which is easier for handling/disposal.

- Odor and pest problem are mostly eliminated because waste not left to decompose like in open dump.

- It is considered as more environmentally safe when compared to uncontrolled dumping of solid wastes.

- Volume reduction by incineration help in prolonging life of existing landfill sites, that already are filling fast.

- Combustion process also destroy harmful organic compounds and pathogens, which can cause contamination of soil/water.

- Location of incinerator near waste source reduce need of long transportation, saving fuel and cost both.

- Modern incinerator equipped with air pollution control devices (APCDs) – which minimize emission of SO₂, NOx, and particulate matters, though not totally avoided.

- Incinerator operation is continuous and not affected by weather (unlike landfills that face rain issues etc.).

- Some countries even recover metals from ash for recycling – giving economic plus environmental benefit.

- The process can be automated easily, maintenance is not much complicated if proper system follow.

- Energy efficiency of new type plants is improved, so they contribute also to renewable energy generation sector.

- The overall sanitation of area is improved due to less waste accumulation in streets or open spaces.

Disadvantages of Incinerator

- Large amount of air pollutants like dioxins, furans, and heavy metals are released during burning process which affect environment badly.

- High installation and maintenance cost make incinerator operation very expensive, especially for small municipalities or local area.

- Residue ash (bottom and fly ash) from combustion contains toxic materials that need special handling/disposal.

- Operation of incinerator consumes much energy, sometimes more than what it produce back.

- Toxic gases and particulates emitted can prevail respiratory issues in nearby population if control system fail.

- Incineration may discourage recycling activities since waste are directly burned instead of reuse/recover.

- The equipment need continuous monitoring for temperature and emission, otherwise incomplete combustion occurs causing smoke and odor.

- Greenhouse gases like CO₂ and NOx are produced, which contribute for climate change problems.

- Land is still required for disposal of residual ash (approx 10–25 % of original waste weight).

- During rainy or humid condition, moisture content of waste reduces combustion efficiency a lot.

- Highly skilled personnel are required to operate and maintain the plant, otherwise breakdown happen frequently.

- Public opposition is often observed, because of fear of toxic emission and health hazard nearby residential zones.

- The incinerator lifespan decreases quickly due to corrosion caused by high temperature flue gases.

- Waste with low calorific value cannot be burned efficiently, sometimes auxiliary fuel (like diesel/gas) needed.

- Odor and noise pollution during loading/unloading of waste materials also disturb surrounding people.

Precautions

- Waste must be properly segregated before loading, as plastic/PVC material release toxic gas when burned.

- Temperature inside primary chamber should be maintained between 850–1100°C to assure complete combustion.

- Operators must wear PPE (Personal Protective Equipments) like gloves, mask, apron, goggles etc. to avoid contact of ash or smoke.

- Wet or high-moisture waste shall not be feeded, because it reduce heat efficiency and cause incomplete burning.

- Air pollution control system (like scrubber, filter, cyclone) should be installed for controlling emission of NOx, SO₂, and particulate matters.

- Proper monitoring of flue gas outlet is needed; as leakage can prevail environmental contamination.

- Ash generated from incinerator must be collected carefully and disposed in secured landfill area.

- The door of incinerator chamber must remain tightly closed during operation to prevent smoke leakage.

- Routine inspection and cleaning of burner and chimney is required to maintain smooth operation.

- Electrical and mechanical parts should be checked regularly to avoid any short circuit or malfunction.

- Combustion air supply should be sufficient, otherwise incomplete oxidation of waste may occur.

- Only trained personnel should operate incinerator, since unskilled handling can cause accident/fire hazard.

- Secondary combustion chamber is to be used for ensuring full destruction of volatile organic compounds.

- During maintenance, the unit must be completely cooled and isolated from power supply.

- Record of temperature, emission data, and maintenance activity need to be kept for official verification.

- Safety signs and emergency fire extinguishers should be available nearby incinerator site.

- Location of incinerator must be far from residential or food preparation areas to avoid exposure.

- Stack height should be designed properly (usually 20–30 m) to disperse emission effectively.

FAQ

What incinerator means?

An incinerator is a device used to burn waste materials, typically as a method of disposal. Incineration is a process of thermally oxidizing waste materials in the presence of oxygen to convert them into ash, flue gas, and heat. Incineration is used to dispose of a wide variety of waste materials, including municipal solid waste, medical waste, hazardous waste, and sewage sludge. It is also used to generate electricity in some cases.

What is incinerator in hospital?

An incinerator in a hospital is a device used to burn medical waste, which is defined as any waste materials that have been contaminated with blood, body fluids, or other potentially infectious materials. Medical waste can include sharps (such as needles, scalpels, and syringes), pathological waste (such as tissue samples), and biohazardous waste (such as lab cultures and animal carcasses).

Incineration is considered one of the most effective ways to destroy medical waste, as it uses high temperatures to sterilize the waste and reduce its volume. Incinerators used in hospitals typically have advanced filtration systems in place to capture any pollutants that may be released during the burning process. These systems may include scrubbers and filters that remove pollutants such as dioxins, furans, and particulate matter.

Hospital incinerators are regulated by local authorities and are required to meet specific emission standards. They are also typically subject to regular inspections to ensure they are operating safely and effectively.

What is the principle of incinerator?

An incinerator is a device that burns waste materials in the presence of oxygen to convert them into ash, flue gas, and heat. The basic principle of an incinerator is thermally oxidizing the waste materials to reduce the volume of the waste and eliminate the need for landfills. The process of incineration is typically divided into three main stages: drying, combustion, and post-combustion. The drying stage removes moisture from the waste, the combustion stage burns the waste at high temperatures, and the post-combustion stage treats the flue gases to remove pollutants before they are released into the atmosphere. Incinerators are equipped with advanced filtration systems to capture pollutants, including scrubbers and filters, to remove pollutants such as dioxins, furans, and particulate matter. This ensures that the incineration process is safe and environmentally friendly.

Do incinerators pollute air?

Incinerators can release pollutants into the air if not properly controlled. Incineration process produces flue gases that contain pollutants such as particulate matter, dioxins, furans, and heavy metals. These pollutants can be harmful to human health and the environment. Therefore, it is important that incinerators are equipped with advanced filtration systems, such as scrubbers and filters, to remove these pollutants before they are released into the atmosphere.

Additionally, the emissions from incinerators are regulated by local authorities and are required to meet specific emission standards, which vary by location. Regular inspections are also conducted to ensure that the incinerators are operating safely and effectively.

However, with proper control and management, modern incineration facilities are designed to minimize the release of pollutants into the air and meet the stringent emission standards set by the authorities.

Can plastic be incinerated?

Plastic can be incinerated, but it’s not considered a recommended method of disposal due to the potential negative environmental and health effects. Plastic releases pollutants such as hydrochloric acid, sulfur dioxide, and dioxins when burned, which can harm human health and the environment. Additionally, burning plastic can also damage the incinerator itself.

Plastic is not considered a suitable waste for incineration since it is not a good source of energy, it has low calorific value, and it produces toxic pollutants when burned. Instead, plastic waste should be recycled or processed in a facility specifically designed to handle plastic waste, such as a pyrolysis or gasification plant.

It’s important to note that regulations vary by location and the specific type of incinerator being used. Always check with local authorities for specific regulations regarding what can and cannot be burned in an incinerator.

- Zjup, Wdse & Bourtsalas, Athanasios & Huang, Qunxing & Zhang, Hanwei & Themelis, Nickolas. (2020). Energy recovery in China from solid wastes by the moving grate and circulating fluidized bed technologies https://rdcu.be/b3jg1. 2. 27-36.

- Lombardi, F., Lategano, E., Cordiner, S., & Torretta, V. (2013). Waste incineration in rotary kilns: a new simulation combustion tool to support design and technical change. Waste Management & Research, 31(7), 739–750. doi:10.1177/0734242×13484187

- https://microbenotes.com/incinerator-principle-procedure-parts-types-uses-examples/

- https://www.rpi.edu/dept/chem-eng/Biotech-Environ/incinerator.html

- https://slideplayer.com/slide/10814404/

- https://www.inciner8.com/blog/waste-management/what-are-incinerator-machines-an-idiots-guide

- https://www.inciner8.com/how-an-incinerator-works

- https://www.irjet.net/archives/V4/i12/IRJET-V4I1270.pdf

- https://www.conserve-energy-future.com/advantages-and-disadvantages-incineration.php

- https://www.marineengineersknowledge.com/2021/06/incinerator.html

- https://www.epa.gov/sites/default/files/2015-04/documents/a_citizens_guide_to_incineration.pdf

- https://frtr.gov/matrix2/health_safety/chapter_24.html