Heat Treatment as a Food Preservation

- Heat treatment is a widely used method in food preservation, aimed at ensuring the safety and extending the shelf life of various food products. By subjecting food to high temperatures for a specific duration, heat treatment effectively kills or reduces the load of microorganisms that can cause food spoilage.

- One of the primary reasons for employing heat treatment in food preservation is its ability to destroy or inactivate enzymes, toxins, and microorganisms. Enzymes are biological catalysts that can cause undesirable changes in food, such as browning or softening. By subjecting the food to heat, these enzymes are denatured and rendered inactive, preventing or slowing down the natural enzymatic reactions that lead to spoilage. Heat treatment also destroys or reduces the viability of microorganisms, including bacteria, yeast, and molds, which are responsible for foodborne illnesses and spoilage.

- In addition to its preservative effects, heat treatment plays a crucial role in food processing by enhancing the quality of food. When food is subjected to heat, it undergoes various chemical and physical changes that can improve its texture, color, aroma, and flavor. For example, heat treatment can soften meat, making it more tender and easier to chew. It can also enhance the color of certain fruits and vegetables, giving them an appetizing appearance. Furthermore, heat treatment can release and enhance the aroma and flavor compounds present in food, making it more enjoyable and appealing to consumers.

- Consumer choice is an important aspect of food processing, and heat treatment plays a vital role in meeting consumer preferences. By employing different heat treatment techniques, food manufacturers can create a wide range of products with diverse textures, colors, aromas, and flavors. This allows consumers to choose from a variety of options that suit their taste and preferences, ultimately enhancing their overall dining experience.

- In conclusion, heat treatment is an essential method in food preservation due to its ability to kill or reduce microorganisms and inactivate enzymes and toxins. It not only ensures the safety and extends the shelf life of food but also enhances its quality, making it more tender, palatable, and visually appealing. The diverse effects of heat treatment on textures, colors, aromas, and flavors provide consumers with a wide range of choices, catering to their individual preferences and improving their satisfaction with the food they consume.

What is the Role of heat treatment in food preservation?

Heat treatment plays a vital role in food preservation by offering various benefits that help ensure food safety, extend shelf life, and improve the overall quality of food products. The following points highlight the key roles of heat treatment in food preservation:

- Inactivate Enzymes: Enzymes naturally present in food can lead to spoilage and deterioration. Heat treatment, such as blanching or pasteurization, can inactivate enzymes, slowing down the enzymatic activity and preventing undesirable changes in color, flavor, and texture.

- Lower Microbial Load: Heat treatment effectively reduces the microbial load in food by destroying or inhibiting the growth of bacteria, yeast, and molds. Proper heat treatment methods, such as canning, retorting, or cooking at high temperatures, help eliminate harmful microorganisms and minimize the risk of foodborne illnesses.

- Destroy or Inactivate Spores and Toxins: Some heat-resistant microorganisms, such as certain bacterial spores, can survive normal heat treatments. However, by employing specific heat treatment techniques like autoclaving or high-pressure processing, these spores can be destroyed or rendered inactive. Additionally, heat treatment can also neutralize certain heat-labile toxins produced by bacteria, enhancing food safety.

- Aids Aroma, Flavor, and Texture of Foods: Heat treatment can enhance the aroma, flavor, and texture of foods. For example, roasting, baking, or grilling can create desirable flavors and aromas through the Maillard reaction. Appropriate heat treatment can also improve the tenderness and palatability of certain food items.

- Makes Food More Tender and Palatable: Heat treatment methods like boiling, steaming, or braising are commonly used to tenderize tough cuts of meat and make them more enjoyable to eat. By applying heat over an extended period, collagen in meat breaks down into gelatin, resulting in tender and succulent dishes.

- Aids in Peeling: Heat treatment, such as blanching or steam treatment, is often employed to facilitate the peeling of fruits and vegetables. The application of heat softens the outer layers, making them easier to remove.

- Aids in Packaging: Heat treatment is an integral part of food packaging processes, especially for perishable products. Methods like hot filling or aseptic processing involve subjecting food or beverages to high temperatures to ensure sterility and extend shelf life. Heat treatment is crucial in eliminating spoilage organisms and maintaining product quality during storage.

Key Considerations for Heat Treatment Preservation

When selecting a safe and proper heat preservation treatment for food products, it is essential to consider several factors. The following points should be taken into account:

- Heat Resistance of Pathogens: Different microorganisms have varying heat resistance levels. It is crucial to determine the time and temperature combination required to effectively inactivate the most heat-resistant pathogens that may be present in the food. This information can be obtained through scientific research, reference materials, or expert guidance.

- Food Composition: The composition of the food plays a significant role in heat penetration and preservation. Different food matrices have different heat transfer characteristics, which affect the effectiveness of heat treatment. Factors such as moisture content, pH level, fat content, and the presence of particulates or additives can impact heat penetration. Understanding the composition of the food will help in selecting the appropriate heat treatment process.

- Heat Penetration Characteristics: Each food product has its unique heat penetration characteristics, influenced by its size, shape, density, and packaging. It is important to consider the heat transfer properties of the food and how heat will be distributed throughout the product during the preservation process. This knowledge helps determine the appropriate time and temperature parameters to ensure uniform heat treatment.

- Packaging and Container Considerations: The choice of packaging material and container can affect the heat transfer and preservation process. Different packaging materials have varying thermal properties, such as thermal conductivity and insulation capabilities. Additionally, the type of container used may influence heat distribution and the ability to achieve the desired temperature throughout the food product. Understanding the packaging and container characteristics is crucial for selecting an appropriate heat preservation method.

- Regulatory Guidelines and Standards: It is essential to be aware of the regulatory guidelines and standards specific to heat preservation treatments for food products. Different countries or regions may have specific requirements and regulations concerning the processing and preservation of food. Adhering to these guidelines ensures compliance with safety standards and helps maintain the quality and integrity of the food products.

- Process Validation and Monitoring: Validation and monitoring of the heat preservation process are critical to ensure its effectiveness and safety. Regular monitoring of critical control points, such as temperature and time, helps verify that the desired heat treatment parameters are achieved consistently. Process validation involves conducting tests and studies to confirm the efficacy of the chosen heat preservation method for the specific food product.

- Expertise and Training: Proper training and expertise in heat preservation techniques are crucial for ensuring safe and effective treatment. It is advisable to seek guidance from professionals with knowledge and experience in food processing and preservation. Engaging experts or consultants in the field can provide valuable insights and assistance in selecting and implementing the appropriate heat preservation treatment.

Popular Heat Treatment Methods for Food Preservation

1. Blanching

Blanching serves as a crucial preliminary process in food preservation, specifically in fruits and vegetables, aiming to eliminate enzyme activity. While not intended as a standalone preservation method, blanching is employed as a pre-treatment before freezing, drying, or canning. Its primary purpose is to accomplish the following objectives:

- Destroying Enzyme Activity: The main goal of blanching is to deactivate enzymes present in fruits and vegetables. Enzymes, which can lead to quality deterioration, are proteins that lose their activity when exposed to high temperatures. Notable enzymes include Lipoxygenase, Polyphenoloxidase, Polygaacturonase, and Chlorophyllase.

In addition to enzyme deactivation, blanching offers several secondary benefits that contribute to the overall preservation process:

- Reducing Surface Microbial Contamination: Blanching helps minimize surface microbial contamination on the produce, enhancing food safety and extending shelf life.

- Softening Vegetable Tissues: By subjecting vegetables to blanching, their tissues are softened, making it easier to fill them into containers during subsequent preservation methods.

- Removing Air from Intercellular Spaces: Prior to canning, blanching aids in eliminating air trapped in the intercellular spaces of the food, ensuring better preservation outcomes.

Blanching is particularly essential in situations where freezing or dehydration alone are insufficient to inactivate enzymes. While freezing and dehydration methods may not adequately deactivate enzymes, the conditions encountered in canning processes may allow sufficient time for enzyme activity to be eliminated.

It is important to note that certain enzymes, such as Catalase and Peroxidase, exhibit heat resistance and may require more rigorous treatment for inactivation.

In conclusion, blanching plays a vital role in the preservation of fruits and vegetables. By deactivating enzymes and offering additional benefits such as reduced microbial contamination, softened tissues, and removal of trapped air, blanching prepares the produce for subsequent preservation methods, ensuring optimal quality and extended shelf life.

Methods of Blanching

Blanching, a vital pre-treatment step in food preservation, can be carried out using various methods. The commonly used methods of blanching include:

- Hot Water Blanching: Hot water blanching involves immersing the food product in hot water at temperatures up to 100°C. The food is typically submerged in a container or conveyed through a blanching system where it comes into direct contact with the heated water. Hot water blanching is conducted at or near atmospheric pressure and is a widely used and cost-effective method.

- Steam Blanching: Steam blanching utilizes steam to heat the food product. The food is exposed to steam either by direct contact or through a steam chamber. Steam blanching is also conducted at or near atmospheric pressure and is effective for heat transfer, especially in larger food processing operations.

- Fluidized Bed Blanching: Fluidized bed blanching is a relatively newer technique that involves the use of a mixture of air and steam. This method offers advantages such as faster and more uniform heating, better mixing of the product, reduced effluent, shorter processing time, and minimized loss of soluble and heat-sensitive components. Fluidized bed blanching is particularly beneficial for products that require precise temperature control and gentle treatment.

- Microwave Blanching: Microwave blanching involves exposing the food product to microwave radiation for a short period. This method offers the advantage of rapid heating and reduced loss of water-soluble components. However, microwave blanching may require higher capital costs due to specialized equipment and can pose challenges in achieving uniform heating throughout the food product.

Each blanching method has its advantages and considerations. Hot water and steam blanching are widely used due to their simplicity and cost-effectiveness. Fluidized bed blanching offers benefits such as improved heating efficiency and reduced loss of components. Microwave blanching provides rapid heating but may require additional investments in equipment and ensuring uniform heating.

Steam Blanchers

- Steam blanchers are a preferred method for foods with large cut surface areas, as they result in lower leaching losses compared to other blanching methods. This technique involves conveying the food material on a mesh belt or a rotating cylinder through a steam atmosphere. The residence time is controlled by adjusting the speed of the conveyor or rotation.

- One of the challenges with steam blanchers is achieving uniform heating throughout the multiple layers of food. It can be difficult to attain the required time-temperature at the center of the food without overheating the outside layers. This non-uniform heating can result in variations in the quality and texture of the blanched product.

- An alternative approach to steam blanching is Individual Quick Blanching (IQB). This method involves a two-stage process. In the first stage, a single layer of food is heated to a sufficient temperature to inactivate enzymes. In the second stage, a deep bed of the product is held for a specific time to allow the temperature at the center of each piece to increase to the desired level for enzyme inactivation. IQB helps to ensure more consistent heat treatment throughout the food product, reducing the risk of overcooking the outer layers.

- One of the major advantages of steam blanching, especially IQB, is the reduced heating time. Compared to conventional blanching methods, the shorter processing time in steam blanchers results in higher energy efficiency. For example, for 10 mm diced carrots, steam blanching may require 25 seconds of heating and 50 seconds of holding, whereas conventional blanching can take up to 3 minutes. This improved efficiency translates to higher energy savings and reduced operational costs.

- In addition to energy efficiency, steam blanchers, particularly IQB, allow for higher throughput. With small-sized products like peas, sliced or diced carrots, the mass of produce blanched per kilogram of steam increases significantly with IQB. While conventional steam blanchers typically handle around 0.5 kg of produce per kilogram of steam, IQB can process 6-7 kg of produce per kilogram of steam. This higher productivity makes IQB an attractive option for large-scale food processing operations.

- In conclusion, steam blanchers, including IQB, offer an efficient method for blanching foods with large cut surface areas. While there may be challenges in achieving uniform heating, the reduced processing time, higher energy efficiency, and increased throughput make steam blanchers a valuable tool in the food processing industry.

Hot Water Blanchers

Hot water blanchers are a commonly used method for heat treatment in food processing. They involve various designs that hold the food in hot water, typically ranging from 70 to 100°C, for a specified period. The blanching process is followed by moving the food to a dewatering and cooling section.

There are different types of hot water blanchers:

- Drum Blanchers: In this design, the food enters a slowly rotating drum that is partially submerged in hot water. The food is carried along by internal flights within the drum, and the residence time is controlled by adjusting the speed of rotation. Drum blanchers are effective for blanching a wide range of food products.

- Pipe Blanchers: Pipe blanchers consist of insulated tubes through which hot water is circulated. The food is metered into the stream of hot water, and the residence time is controlled by the length of the pipe and the velocity of the water. Pipe blanchers offer flexibility in terms of capacity and can be suitable for continuous processing operations.

- Blancher-Cooker: The blancher-cooker consists of three sections: a preheating stage, a blanching stage, and a cooling stage. The food remains on a single belt throughout the process, reducing the risk of physical damage to the product. Heat recovery systems are often incorporated in blancher-cookers, allowing for more efficient energy usage. Compared to conventional hot water blanchers, blancher-cookers can achieve higher throughput, with 16 to 20 kg of product blanched for every kilogram of steam, as opposed to 0.25 to 0.5 kg per kilogram of steam.

Hot water blanchers offer several advantages in food processing. They provide effective heat treatment to inactivate enzymes, reduce microbial load, and enhance the overall quality and safety of the preserved food. The use of hot water ensures uniform heating, and the flexibility in design allows for customization according to processing requirements and food product characteristics.

Testing of the Effectiveness of Blanching

- The effectiveness of blanching can be evaluated through testing to ensure optimal enzyme inactivation without causing excessive quality loss. Both over blanching and under blanching can lead to undesirable outcomes.

- Over blanching occurs when the food is subjected to excessive heat, resulting in quality deterioration such as texture changes, color loss, and flavor degradation. On the other hand, under blanching refers to insufficient heat treatment, leading to increased enzyme activity due to the activation of enzymes and the release of substrates.

- To assess the effectiveness of blanching, the Peroxidase test is often conducted in vegetables. Peroxidase is an enzyme that is relatively heat resistant and easily detectable. While it is not directly involved in degradation, its presence indicates incomplete enzyme inactivation. The test involves adding a guaiacol solution and a hydrogen peroxide solution to the blanched vegetables and observing the development of a brown color. The appearance of the brown color indicates peroxidase activity.

- Complete inactivation of peroxidase may not always be essential for all vegetables. Some vegetables, such as green beans, peas, and carrots, have shown adequate storage quality at -20°C even with some residual peroxidase activity. However, in certain vegetables like Brussels sprouts, zero peroxidase activity is crucial for maintaining the desired storage quality.

- Testing the effectiveness of blanching, particularly through the Peroxidase test, helps determine the appropriate blanching time and temperature needed to achieve enzyme inactivation while minimizing quality loss. By striking the right balance, blanching can effectively preserve the quality, color, texture, and flavor of the food while ensuring enzyme activity is sufficiently reduced to prevent degradation during storage.

- Overall, careful testing and monitoring of blanching effectiveness are essential to achieve optimal results and maintain the desired quality of blanched vegetables. This enables processors to establish appropriate blanching parameters and ensure the successful preservation of the food’s quality attributes.

2. Pasteurization

Pasteurization is a widely used heat treatment method in the food industry, aimed at reducing the microbial load and extending the shelf life of various food products. It involves heating the food to temperatures below 100°C, making it a relatively mild process compared to more intense heat treatments.

The primary purposes of pasteurization are the destruction of enzymes and the inactivation of relatively heat-sensitive microorganisms, such as non-spore-forming bacteria, yeast, and molds. The specific severity of the pasteurization treatment and the resulting extension of shelf life depend largely on the pH of the food. In low-acid foods (pH<4.5), the primary focus is on the destruction of pathogenic bacteria. Below pH 4.5, the main objective is to eliminate spoilage microorganisms or deactivate enzymes that could compromise product quality.

The extent of heat treatment required during pasteurization is determined by the D value, which represents the decimal reduction time or the time required to reduce the microbial population by a factor of 10 or 90% of the initial load. The D value is specific to each heat-resistant enzyme or microorganism present in the food. To ensure the effectiveness of the pasteurization process, the presence of alkaline phosphatase, a naturally occurring enzyme in raw milk, is commonly checked. Since alkaline phosphatase has a similar D value to heat-resistant pathogens, its absence is considered an indicator of adequate pasteurization.

The temperatures and times used for milk pasteurization are as follows:

- 63°C for 30 minutes (low-temperature, long-time method, LTLT)

- 72°C for 15 seconds (primary high-temperature, short-time method, HTST)

- 89°C for 1.0 second

- 90°C for 0.5 second

- 94°C for 0.1 second

- 100°C for 0.01 second

These temperatures and times are sufficient to destroy most heat-sensitive non-spore-forming pathogens present in milk. They also eliminate yeasts, molds, gram-negative bacteria, and many gram-positive bacteria. The microorganisms that can survive pasteurization temperatures used in milk are categorized into two groups:

- Thermoduric organisms: These organisms can withstand exposure to relatively high temperatures but do not necessarily grow at these temperatures. Examples include Streptococcus and Lactobacillus.

- Thermophilic organisms: These organisms not only survive high temperatures but require elevated temperatures for growth.

In conclusion, pasteurization is an effective method for reducing microbial load and extending the shelf life of various foods. By using mild heat treatment, pasteurization destroys or reduces the number of pathogenic and spoilage microorganisms, ensuring the safety and quality of the food.

Types of pasteurization

Pasteurization is a crucial heat treatment process employed in the food industry to eliminate harmful microorganisms, extend shelf life, and ensure the safety of various products. There are different types of pasteurization methods used, depending on the specific requirements of the food product. Let’s explore some of these methods:

- Before Packaging (Pre-packaging) Pasteurization: In this method, the product is pasteurized first, ensuring its safety and reducing microbial load. After pasteurization, the product is then filled into sterile containers, minimizing the risk of contamination during packaging. This approach is commonly used for liquid foods like milk, fruit juices, and beverages.

- In-Package Pasteurization: In this method, the product is first filled into a sterile container, which is then sealed. The sealed container with the product inside undergoes pasteurization, effectively eliminating any harmful microorganisms present. This method is often used for products that are sensitive to heat or require a specific packaging format.

- Batch Pasteurization or LTLT (Low-Temperature-Long-Time): Batch pasteurization involves heating the product to temperatures between 68°C to 71°C and holding it at this temperature for a duration of 30 minutes. This method ensures thorough heat penetration and microbial inactivation. It is commonly used for certain liquid products, such as dairy milk.

- Continuous Pasteurization or HTST (High-Temperature-Short-Time, Flash Pasteurization): Continuous pasteurization is a rapid heat treatment method where the product is heated to higher temperatures than traditional pasteurization for a shorter duration. For example, fruit juice can be rapidly heated for about 1 minute at a temperature approximately 50°C higher than the regular pasteurization temperature. This process effectively reduces microbial load while minimizing heat-induced changes in the product’s quality.

- Ultra-High-Temperature (UHT) Pasteurization: UHT pasteurization is an intensive heat treatment method that operates at high temperatures for an extremely short holding time. The product is exposed to temperatures typically above 135°C for approximately 3 seconds. UHT pasteurization ensures the destruction of heat-resistant microorganisms, allowing for an extended shelf life without the need for refrigeration. It is commonly used for products like long-life milk, cream, and some beverages.

The choice of pasteurization method depends on factors such as the product characteristics, desired shelf life, packaging format, and regulatory requirements. Each method offers distinct advantages in terms of microbial safety, product quality preservation, and shelf life extension.

In summary, pasteurization is an essential process in the food industry, and different types of pasteurization methods are employed to ensure the safety and quality of food products. Whether it’s pre-packaging or in-package pasteurization, batch or continuous processing, or utilizing high-temperature-short-time or ultra-high-temperature approaches, these methods play a crucial role in reducing microbial load, extending shelf life, and maintaining the integrity of various food items.

Method for Pasteurizing

a. Batch (holding) Method

- The batch (holding) method is a traditional heat treatment approach that involves heating every particle of a product, such as milk, to a specific temperature and holding it at that temperature for a designated period. In this method, the minimum temperature requirement is 63°C, and the holding time is at least 30 minutes. However, it is important to note that this method is not commonly used in commercial food processing practices today.

- The batch method was historically employed as a means to ensure the destruction of harmful microorganisms and enhance the safety of the product. By heating every particle of the food to a specific temperature and maintaining it for a prolonged duration, the batch method aimed to achieve thorough heat penetration and complete microbial inactivation.

- Although the batch method was effective in providing an adequate level of safety, it had limitations in terms of commercial viability. The long processing time required for each batch and the large-scale equipment needed to accommodate the entire product volume made it impractical for most commercial food processing operations. As a result, more efficient and time-effective heat treatment methods, such as continuous flow pasteurization, have become the industry standard.

- Continuous flow pasteurization methods, such as the High-Temperature Short-Time (HTST) method, have largely replaced the batch method in commercial food processing. These methods involve rapid heating to a specific temperature for a shorter duration, providing effective microbial inactivation while allowing for higher production throughput.

- In summary, the batch (holding) method was a traditional heat treatment approach that aimed to ensure the safety of food products by subjecting every particle to a specific temperature for a prolonged period. While it was effective in microbial inactivation, this method is no longer widely used in commercial food processing due to its impracticality and the development of more efficient continuous flow pasteurization methods.

b. High-Temperature-Short-Time (HTST)

The High-Temperature-Short-Time (HTST) method is a widely used heat treatment approach in the dairy industry for the pasteurization of milk. This method involves heating every particle of milk to a minimum temperature of 72°C and holding it at that temperature for at least 15 seconds. The HTST process is carried out continuously, allowing for efficient and high-volume milk processing.

In addition to standard pasteurization, the HTST method can also be utilized for Ultra Heat Treatment (UHT), which is a sterilization treatment. UHT involves subjecting milk to even higher temperatures for shorter times, such as 1 second at 135°C. This process ensures an extended shelf life for the milk, allowing it to be stored at room temperature without the need for refrigeration.

The typical equipment employed for the HTST method includes:

- Plate Heat Exchanger (PHE): The plate heat exchanger is used for rapid and efficient heat transfer. It consists of a series of plates that allow the milk to flow on one side while hot water or steam flows on the other side, facilitating heat exchange.

- Holding Tube: The holding tube is sized to ensure the correct treatment time is achieved. It provides the necessary residence time for the milk at the specified temperature to achieve proper pasteurization or UHT treatment.

- Holding Tanks: Holding tanks are used for the storage of raw milk and pasteurized milk. They serve as temporary storage before the milk is further processed or packaged.

- Balance Tank: The balance tank helps maintain a continuous flow of milk and assists in ensuring full flow throughout the process. It also allows for the collection of returned milk if the desired temperature is not achieved, ensuring proper treatment.

- Control and Monitoring System: A control and monitoring system is employed to record and monitor the temperature throughout the process. It ensures that the milk reaches and maintains the required temperature, diverting flow back to the balance tank if the correct temperature is not achieved.

The HTST method offers a balance between effective heat treatment to ensure microbial safety and the preservation of milk quality attributes. By employing rapid heating and short holding times, the HTST method minimizes heat-induced quality changes while ensuring the destruction of pathogenic microorganisms. This process allows for efficient and high-volume milk processing, meeting industry and regulatory requirements for milk pasteurization.

In summary, the High-Temperature-Short-Time (HTST) method is a continuous heat treatment approach used for the pasteurization of milk. It involves heating every particle of milk to a minimum temperature of 72°C and holding it for at least 15 seconds. By utilizing appropriate equipment such as plate heat exchangers, holding tubes, tanks, and monitoring systems, the HTST method ensures effective and efficient milk processing while maintaining quality and safety standards.

c. Pasteurization of packaged foods

- In the food industry, some liquid foods like beer and fruit juices undergo pasteurization after they are filled into containers. The process of pasteurizing packaged foods aims to eliminate harmful microorganisms, extend shelf life, and ensure product safety. The specific methods and temperatures used for pasteurization depend on the type of packaging and the characteristics of the food product.

- When packaging foods into glass containers, hot water is typically used for pasteurization to minimize the risk of breakage due to thermal shock. The maximum temperature difference between the container and the liquid during heating is usually kept within 20°C, while for cooling, it is around 10°C. Metal and plastic containers, on the other hand, can be pasteurized using steam-air mixtures or hot water.

- The pasteurization process for packaged foods can be carried out in both batch and continuous systems. In a batch system, the food containers, often placed in crates, are heated to a pre-set temperature in a water bath. The containers are then cooled by draining the hot water and adding cold water. Continuous pasteurization systems involve conveying the containers through a hot water bath followed by a cold water bath.

- Alternatively, steam tunnels can be used for pasteurization, offering the advantage of faster heating, shorter residence time, and smaller equipment requirements. The temperatures in the heating zones of steam tunnels can be controlled based on the amount of air present.

- For certain acidic products like fruit or acidified vegetables such as beetroot, pasteurization can be carried out in a retort. A retort is a pressure vessel that allows for the pasteurization or sterilization of packaged foods through the use of high temperatures and pressure.

- The specific temperatures and times used for pasteurization depend on the type of food product, its pH level, and regulatory requirements. These parameters are carefully monitored and controlled to ensure the destruction of harmful microorganisms while preserving the sensory and nutritional qualities of the packaged food.

- In conclusion, pasteurization of packaged foods is a critical step in ensuring product safety and extending shelf life. The process can involve hot water, steam-air mixtures, or retorts, depending on the packaging material and the characteristics of the food. Whether using batch or continuous systems, maintaining precise temperature control is essential to achieve effective pasteurization while preserving the quality of the packaged food.

3. Heat Sterilization

- Heat sterilization is a crucial process in food preservation and processing that involves the destruction of vegetative microbial cells, spores, and the inactivation of enzymes through the application of heat. It is one of the two main methods of food sterilization, the other being non-thermal processes.

- Heat sterilization plays a vital role in ensuring the safety and extended shelf life of various food products. By subjecting the food to elevated temperatures, heat sterilization effectively destroys yeasts, molds, vegetative bacteria, and spore formers that can cause spoilage and pose health risks to consumers.

- In practice, complete sterilization is not always preferred, as it can lead to a deterioration in product quality and nutritional value. Instead, the goal is to achieve commercial sterilization, which refers to the degree of sterilization where all pathogenic microorganisms and toxin-forming bacteria are destroyed. Although heat-resistant spores may still be present in the product after commercial sterilization, they typically do not multiply and pose a risk.

- Many canned and bottled food products undergo commercial sterilization, resulting in commercially sterile goods with a shelf life of more than two years. This extended shelf life is achieved by ensuring that the product is free from viable microorganisms that could cause spoilage or pose a health hazard.

- Of particular concern in food preservation is the destruction of two types of bacteria: Clostridium botulinum and C. sporogenes. These bacteria produce toxins that can cause severe illness, including botulism. Heat sterilization processes effectively destroy these bacteria and their spores, ensuring the safety of the preserved food.

- Heat sterilization methods can vary depending on the product and packaging. They may include processes such as retorting, autoclaving, or the use of continuous systems with precise temperature control. The specific time and temperature parameters employed in heat sterilization depend on the characteristics of the food, the type of microorganisms targeted, and regulatory requirements.

- In conclusion, heat sterilization is a critical unit operation in food preservation and processing. By subjecting the food to elevated temperatures, heat sterilization effectively destroys vegetative microbial cells, spores, and enzymes, ensuring product safety and extending shelf life. Achieving commercial sterilization is the goal, where all pathogenic and toxin-forming microorganisms are destroyed, resulting in commercially sterile food products with extended shelf life.

Heat Sterilization Principle

- The principle of heat sterilization is based on the effective destruction of microorganisms and the prevention of spoilage or toxin release from the treated products. To ensure successful sterilization, specific temperature and time combinations are necessary.

- The minimum temperature required for heat sterilization is typically set at 121.1°C (250°F). This temperature is chosen because it achieves a 12D reduction in microorganisms, meaning it reduces the microbial population by a factor of 10^12. Achieving such a reduction is crucial to ensure the elimination of harmful microorganisms and prevent their growth during storage. To completely destroy bacterial spores, which are highly heat-resistant, the heat treatment may need to be extended up to 15 minutes.

- An important consideration during heat sterilization is the slowest heating point, also known as the cold point. This refers to the part of the product that takes the longest time to reach the desired sterilization temperature. It is crucial to ensure that the slowest heating point reaches the necessary temperature for the required duration to achieve sterilization. This careful consideration of time and temperature throughout the product ensures that all microorganisms, including heat-resistant spores, are effectively destroyed.

- Proper temperature and time combinations are determined based on the heat resistance of the target microorganisms and the desired degree of sterilization. The processing parameters are established through thorough research and experimentation to ensure the safety and quality of the treated products.

- It’s important to note that heat sterilization may affect the sensory qualities and nutritional value of the product. Therefore, finding the balance between achieving complete sterilization and maintaining product quality is crucial. The goal is to apply the necessary heat treatment to achieve microbial destruction while minimizing negative impacts on the product’s organoleptic properties and nutritional composition.

- In summary, the principle of heat sterilization revolves around the effective destruction of microorganisms and the prevention of spoilage or toxin release. By applying specific temperature and time combinations, heat sterilization can achieve a significant reduction in microbial populations and even complete destruction of bacterial spores. Proper consideration of the slowest heating point and appropriate time-temperature combinations is essential for successful sterilization while preserving the quality of the product.

Conditions Affecting the Growth of Microorganisms

The growth of microorganisms in food is influenced by several key factors that affect their ability to thrive and multiply. Understanding these conditions is crucial for food safety and preservation. Let’s explore the main factors that impact microbial growth:

- Water: The water content and availability of water activity (Aw) in food can significantly affect microbial growth. Microorganisms require water to survive and multiply. The availability of water can be measured using the Aw scale, ranging from 0 to 1, with 1 being pure water. Microbes have varying requirements for water activity, with some needing higher levels to grow, while others can thrive at lower levels.

- Temperature: Temperature plays a crucial role in the rate of microbial growth and determines the types of microbes that can flourish. Microorganisms have different temperature ranges at which they grow optimally. They can be categorized into groups based on their temperature requirements:

- Thermophiles: These microbes have a minimum growth temperature of around 40°C and an optimum temperature range of 55-75°C.

- Mesophiles: Mesophiles, including many common bacteria, grow best at moderate temperatures. Their minimum growth temperature is typically around 5°C, the optimum range is 37-45°C.

- Psychrotrophs: Psychrotrophic microorganisms can grow at low temperatures, with a minimum growth temperature around -3°C and an optimum range of 20-30°C. These organisms are responsible for spoilage in refrigerated foods.

- Oxygen Requirements: Microorganisms can be categorized into three groups based on their oxygen requirements:

- Aerobes: These microorganisms require oxygen to grow and thrive. They cannot grow in the absence of oxygen.

- Anaerobes: Anaerobes are microorganisms that cannot grow in the presence of oxygen. They thrive in oxygen-depleted environments.

- Facultative Anaerobes: Facultative anaerobes are adaptable microorganisms that can grow with or without oxygen. They prefer aerobic conditions but can switch to anaerobic growth if necessary.

- pH: The pH level of the environment is an important factor influencing microbial growth. Different microorganisms have different pH ranges within which they can grow optimally. The pH scale ranges from 0 to 14, with values below 7 considered acidic, 7 neutral, and above 7 alkaline. Microbes can be categorized into groups based on their preferred pH ranges:

- Low acid: Microorganisms that prefer a pH above 5.0 for optimal growth.

- Medium acid: Microbes with an optimal pH range of 4.5-5.0.

- Acid: These microorganisms thrive in acidic conditions, with an optimal pH range of 3.7-4.5.

- High acid: Microbes that can grow in highly acidic environments, with an optimal pH below 3.7.

Sterilisation Process and Equipment

The sterilization process in the canning industry involves several phases to ensure the effective elimination of microorganisms and the preservation of food products. Different types of autoclaves or retorts are used to carry out the thermal treatment under pressure, reaching temperatures above 100°C for sterilization. Let’s explore the sterilization process and the equipment involved:

Sterilization Process Phases:

- Heating Phase: The product temperature is increased from ambient to the required sterilization temperature using a heating medium, such as water or steam.

- Holding Phase: The product is maintained at the sterilization temperature for a defined time to ensure complete microbial destruction.

- Cooling Phase: Cold water is introduced into the autoclave to rapidly reduce the temperature inside the cans.

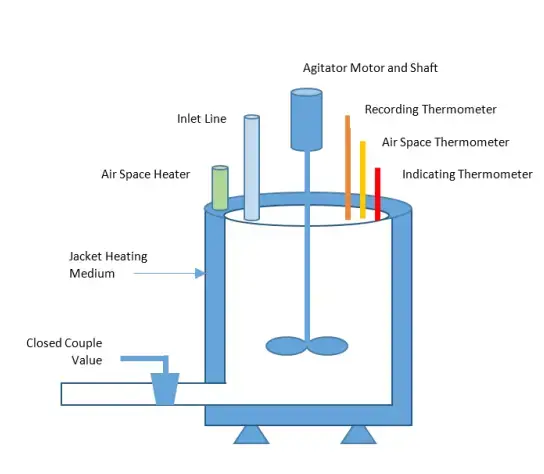

Autoclaves or Retorts: Autoclaves or retorts are pressure cookers designed to reach temperatures above 100°C for sterilization. They generate high temperatures using direct steam injection, heating water to temperatures over 100°C, or combined steam and water heating. The autoclave is equipped with various components, including a thermometer, pressure gauge, pressure relief valve, vent for manual pressure release, safety relief valve, water supply valve, and steam supply valve.

Types of Autoclaves:

- Simple Small Autoclaves: These vertical autoclaves have a lid on top. Cans are loaded into the autoclave through the opened lid, often placed in metal baskets. The lid is firmly locked before the sterilization process begins. These autoclaves are suitable for smaller operations and offer ease of use and affordability.

- Larger Autoclaves: These horizontal autoclaves have a front lid for loading. They can be single or double vessel systems. Double vessel systems heat water in the upper vessel to sterilization temperature and release it into the lower processing vessel when loaded and sealed. This allows for immediate heat treatment without a lengthy heating process and enables recycling of hot water for subsequent sterilization cycles.

- Rotary Autoclaves: Rotary autoclaves involve rotating the basket containing cans during sterilization. This technique is particularly useful for cans with liquid or semi-liquid content as it promotes accelerated heat penetration and ensures better sensory quality of the products.

Cooling and Pressure Stabilization: After the sterilization process, it is crucial to cool the products quickly. Introducing cold water into the autoclave causes steam to condense, resulting in a rapid pressure drop. However, the pressure difference between the autoclave and the high temperature inside the containers can potentially deform the containers. To avoid this, a blast of compressed air may be introduced into the autoclave during the initial cooling phase. Alternatively, sufficient hydrostatic pressure from the cooling water can provide counterpressure, eliminating the need for compressed air. Stabilization rims can also be incorporated into the lids, bottoms, and bodies of metallic cans to ensure container stability.

The sterilization process and equipment used in the canning industry are designed to achieve effective sterilization and maintain the quality and safety of canned products. By following proper procedures and using appropriate equipment, microorganisms are destroyed, and the products can have an extended shelf life while retaining their sensory characteristics.

Advantages of heat treatment

Heat treatment offers several advantages in the preservation of food, providing simplicity, control, and improved nutritional qualities. Some of the key advantages include:

- Simplicity and Controllability: Heat treatment methods are relatively straightforward and can be easily controlled to achieve desired outcomes. By adjusting factors such as temperature and duration, the process can be customized to meet specific preservation requirements.

- Shelf Stability: One of the significant benefits of heat treatment is the ability to produce shelf-stable food products. Heat-treated foods are less susceptible to spoilage, microbial growth, and enzymatic activity, thereby extending their shelf life. This eliminates the need for refrigeration, allowing for easier storage, transportation, and distribution.

- Destruction of Anti-nutritional Factors (ANF): Heat treatment plays a crucial role in eliminating anti-nutritional factors present in food. Substances like tannins, phytates, oxalates, and enzyme inhibitors, which can hinder nutrient absorption or have adverse effects on health, are effectively destroyed during the heating process. By reducing these factors, the nutritional quality and bioavailability of the food are improved.

- Improved Nutrient Availability: Heat treatment can enhance the availability of nutrients in food. It helps to break down complex structures such as proteins and complex carbohydrates, making them more accessible for digestion and nutrient absorption. By improving the release and availability of essential nutrients, heat treatment enhances the overall nutritional value of the preserved food.

- Enhanced Digestibility: The breakdown of proteins, complex carbohydrates, and other components during heat treatment improves the digestibility of food. This makes it easier for the human digestive system to break down and absorb nutrients, promoting better digestion and utilization of the food’s nutritional content.

Disadvantages of heat treatment

While heat treatment is widely used and effective in food preservation, it does come with certain drawbacks. Some of the disadvantages of heat treatment include:

- Quality Loss: Excessive heat exposure can lead to the degradation of the organoleptic characteristics of food, including taste, texture, color, and aroma. Overheating or prolonged heating can result in undesirable changes in flavor and texture, compromising the overall quality of the preserved food.

- Nutrient Loss: Heat treatment can cause the destruction or degradation of heat-sensitive vitamins and other nutritional factors present in food. Certain vitamins, such as vitamin C and some B vitamins, are sensitive to heat and can be partially or completely lost during the heating process. This can result in a reduction of the overall nutritional value of the preserved food.

- Formation of Harmful Compounds: Improper heat treatment, such as high temperatures or prolonged cooking times, can lead to the formation of potentially carcinogenic compounds in food. For example, the Maillard reaction, which occurs between amino acids and reducing sugars during heating, can produce harmful compounds like acrylamide and polycyclic aromatic hydrocarbons (PAHs). These compounds pose health risks if consumed in excessive amounts.

- Ineffectiveness Against Heat-Resistant Microorganisms: While heat treatment is effective against many microorganisms, certain heat-resistant bacteria and spores can survive and grow under normal heat treatment conditions. This poses a challenge in eliminating all potential pathogens and spoilage microorganisms, as they may survive and cause food safety issues or reduce the shelf life of the preserved food.

- Limited Shelf Life: Although heat treatment can extend the shelf life of many food products, it is not a panacea for indefinite preservation. Heat-treated foods still have a limited shelf life due to factors such as oxidative reactions, enzymatic activity, and potential microbial recontamination during storage. Proper packaging, storage conditions, and handling practices are crucial to maximize the shelf life of heat-treated food products.

- Inapplicability to Heat-Sensitive Foods: Heat treatment may not be suitable for certain heat-sensitive foods that are highly prone to quality degradation or nutrient loss at elevated temperatures. Examples include delicate fruits, leafy greens, and some dairy products. Alternative preservation methods, such as cold processing or minimal processing, are often preferred for these types of food.

- Cost and Energy Consumption: Implementing heat treatment for preservation requires specialized equipment, such as pasteurization or canning systems, which can be expensive to acquire and maintain. Additionally, heat treatment processes often consume significant amounts of energy, contributing to higher operational costs and environmental impact.

In summary, while heat treatment is a widely used method in food preservation, it is important to be aware of its potential disadvantages. These include quality and nutrient loss, the formation of harmful compounds, ineffectiveness against heat-resistant microorganisms, limited shelf life, inapplicability to heat-sensitive foods, and the cost and energy consumption associated with specialized equipment. Understanding these drawbacks can help in selecting appropriate preservation methods and optimizing the overall quality and safety of preserved food products.

FAQ

What is heat treatment as a food preservation technique?

Heat treatment refers to the application of heat to food products to destroy microorganisms, enzymes, and other spoilage factors, thereby extending the shelf life of the food and ensuring its safety.

How does heat treatment preserve food?

Heat treatment works by subjecting food to high temperatures that are lethal to microorganisms, including bacteria, yeasts, and molds. The heat denatures enzymes and destroys the structure of microorganisms, preventing their growth and spoilage.

What are the main methods of heat treatment in food preservation?

The main methods of heat treatment in food preservation include pasteurization, sterilization, blanching, and canning.

What is the difference between pasteurization and sterilization?

Pasteurization is a milder form of heat treatment that aims to reduce the microbial population in food, while sterilization aims to eliminate all microorganisms, including spores, to achieve complete sterilization.

What foods are commonly pasteurized?

Commonly pasteurized foods include milk, fruit juices, canned beverages, and liquid egg products.

How does heat treatment affect the nutritional value of food?

Heat treatment can lead to some nutrient loss, particularly heat-sensitive vitamins. However, the impact on nutritional value varies depending on the specific food and the heat treatment process employed.

Can all foods be heat-treated for preservation?

Not all foods are suitable for heat treatment preservation. Heat-sensitive foods, such as certain fruits and vegetables, may undergo quality degradation or textural changes when subjected to high temperatures. Alternative preservation methods may be more appropriate for these foods.

Are there any risks associated with heat treatment?

Improper heat treatment or inadequate processing conditions can pose risks. If the required temperature and time parameters are not met, microorganisms may survive, increasing the risk of foodborne illnesses.

How can the effectiveness of heat treatment be ensured?

The effectiveness of heat treatment can be ensured through proper process monitoring, including temperature control, time validation, and quality testing of the treated products. This helps verify that the desired microbial reduction or sterilization has been achieved.

What are the advantages of heat treatment as a food preservation technique?

Heat treatment offers several advantages, including the destruction of harmful microorganisms, extended shelf life, improved food safety, reduced enzyme activity, and the preservation of flavor and texture in some cases. It is a widely used and effective method for food preservation.

References

- Potter NP (1987), Food Science, CBS Pub, India

- Rahman MS (1999), Handbook of Food Preservation, Marcel Dekker, Inc, NY

- http://www.tiselab.com/pdf/Thermal-Processing-of-Food.pdf

- https://www.ift.org/policy-and-advocacy/advocacy-toolkits/food-processing/thermal-preservation-process