- Cotton Plug can define as a small piece of absorbent cotton that used to close the opening of glass tubes, culture flasks, test tubes, pipettes, etc., mainly during sterilization or culture works.

- It made from absorbent cotton wool rolled tightly so that it fit in the mouth of container, sometimes wrapped with gauze or muslin cloth for more firmness.

- The main purpose of cotton plug is to prevent entry of microorganisms, dust or spores from air while still allowing exchange of air or gases.

- The plug must not be too tight because it block the air movement, nor too loose because it may fall or allow contamination, so proper fitting is essential.

- Temporary Cotton Plug refers as the plug which used for short period of time like during autoclaving, transferring, or short incubation.

- These plugs usually made loosely, can be discarded after one or few uses.

- They often used in lab works when material frequently changed or heated.

- Permanent Cotton Plug used when the same vessel or culture maintained for longer time or repeatedly used.

- It made more tightly and sometimes covered by cheese cloth/muslin to hold shape after repeated sterilizations.

- Such plug cleaned, dried, and reused after each cycle if kept in good condition.

- Importance of cotton plug seen in microbiology, tissue culture, and pharmaceutical labs, because they keep environment sterile, yet permit slow diffusion of gases needed by culture.

- They also stop condensation water or droplets from entering media during heating, so contamination chances reduced.

- Historically, cotton plug was first used widely in 19th century microbiology, after the development of aseptic techniques by Louis Pasteur and others, who used cotton-stoppered flasks in their experiments to demonstrate microbial contamination came from air.

- After that, cotton plugs became standard practice in all sterilization and culture procedures, even before invention of modern air filters or membrane filters.

- Even today, though synthetic caps and filters available, cotton plugs still used in educational and basic research labs because they are cheap, easy to prepare and biodegradable.

Preparation Of Temporary Cotton Plugs

- Temporary cotton plug can define as a small cotton mass used for short period to close the mouth of test tube or flask during experiment.

- It is mostly used during sterilization, inoculation, or incubation to prevent entry of microorganisms from air.

- The plug is usually made by absorbent cotton wool, sometimes little pressed or rolled to fit tightly (but not too tight).

- It allows air exchange yet stops dust particles or contaminants — thus, maintaining sterility of culture medium.

- After sterilization the plug becomes dry and may little shrink, so sometimes replacement or moistening is needed before use again.

- Temporary plugs are used only for short-term culture or transfer process, while permanent plugs are prepared differently (by non-absorbent cotton, gauze, etc.).

- The cotton plug is usually sterilized by autoclaving (121°C, 15 psi, 15–20 min) before using in any microbiological work.

- Such plugs are essential to avoid contamination in microbial culture tubes, especially for Bacillus sp., E. coli, etc.

Requirements

- Absorbent cotton wool – clean and free from oil or dirt is required, because it used as main plugging material.

- Forceps or sterilized rod are used to handle cotton during plugging so contamination can avoid.

- Glass test tubes / flasks which already cleaned and dried are needed before plug preparation.

- Scissors (or blade) for cutting of cotton pieces in proper size, mostly small enough to roll easily.

- Spirit lamp or Bunsen burner kept nearby to maintain aseptic condition while inserting cotton in tube mouth.

- Autoclave or hot air oven used for sterilization of prepared plugs at about 121°C / 15 psi pressure.

- Sometimes sterile gloves or tissue paper used for handling after sterilization to avoid recontamination.

- For labeling, marker pen / tag may be used to identify the tube after plugging, though it not always compulsory.

Temporary Cotton Plugs Preparation Procedure

- Non-absorbent cotton roll is taken first and outer packing is removed carefully (dust or fiber parts are discarded).

- Cotton roll is spread and small pieces are separated depending on number, size, and type of flask / culture tube.

- Scissors are used to cut the cotton piece according to the diameter of mouth — slightly larger than the tube opening.

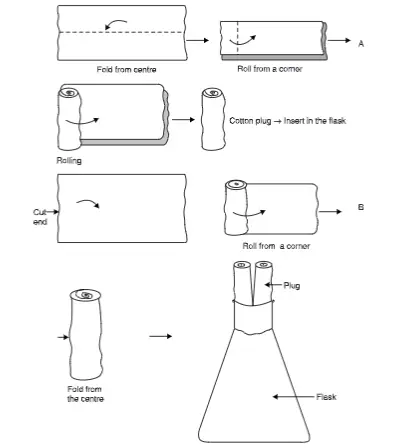

- Two methods are usually applied for preparing temporary plugs depending on requirement.

- Cut, fold and rolled plug

- A small portion of cotton sheet is cut by scissors, size based on tube mouth (like test tube or flask).

- The cut piece is folded from the center, keeping the fibers loose on one side.

- The folding is continued from one of its ends till it forms a short roll (a compact side and a free fibrous side).

- The rolled and folded side is inserted gently into the neck of culture tube, while the loose fibrous side remains outward to act as air filter.

- If the plug doesn’t fit properly or becomes loose, it is removed and readjusted — some cotton is taken out or pressed slightly until tightness is proper.

- Cut, rolled and fold plug

- A piece of cotton is cut and rolled tightly from one end to another till a cylinder shape formed.

- The rolled cotton is then folded lightly at the middle to create a short bend (for easier fitting).

- The folded end of cotton is placed into the mouth / neck of flask or tube, while the opposite end (with loose fibers) remains exposed to air.

- It should not be inserted too tightly — air must pass freely for proper aeration of culture medium.

- After all plugs are prepared, they are kept for sterilization by autoclaving at 121°C (15 psi, 15–20 min) before use.

Preparation Of Permanent Cotton Plugs

- Permanent cotton plug can define as a plug made for long-term closing of flask or culture tube during microbial or tissue culture experiments.

- It is usually prepared from non-absorbent cotton wool (sometimes mixed with gauze or muslin cloth) which not stick to glass even after sterilization.

- The plug is made little tighter and more compact than temporary one, to provide better mechanical support and prevent contamination for long period.

- In permanent plugs, the cotton is rolled and pressed firmly, sometimes stitched with gauze cover so that shape remain same after repeated sterilization cycles.

- These plugs are designed to withstand autoclaving many times (121°C / 15 psi) without losing their shape or air permeability.

- Permanent plugs are used in stock cultures, long-term incubation, or storage of sterile media, where frequent opening is not needed.

- Air can still pass slowly through fibers, maintaining aseptic but aerated environment for microbial growth.

- Such plugs reduce risk of loosening, falling, or contamination—so they are more reliable for repeated use.

Requirements

- Non-absorbent cotton roll – used as main material for making durable plug, it should be clean and dry type.

- Scissors / sterile blade – required to cut the cotton pieces according to flask or tube mouth size.

- Gauze bandage – wrapped around cotton plug to give extra durability & firmness during repeated sterilization.

- Thread – used to tie or fasten the gauze properly so plug shape not lost in handling.

- Culture tubes / flasks – clean, sterilized glassware in which prepared plug is to be inserted and fitted securely.

Permanent Cotton Plugs Preparation Procedure

- Cotton is cut into a square or strip of suitable size to fit the flask or tube neck (measure roughly by mouth diameter).

- The cut piece is pinched at one edge and then rolled tightly from that edge to form a firm neck so the plug will seat securely.

- Rolling is continued until a compact cylindrical shape is obtained, while fibers at the free end are left loose for gas exchange.

- The rolled piece is folded at its middle, to make it more robust, and the folded/rolled end is inserted into the neck — the loose fibres remain outward.

- The plug is checked for fit; if loose, some cotton is removed or re-rolled until snugness is proper (not forced too deep).

- For permanent plug use, the shaped plug is wrapped with gauze / muslin (a bandage like wrap) to reinforce the body.

- The gauze is tied with a small piece of thread or stitch, so the shape is retained during repeated autoclaving and handling.

- The reinforced plug is placed so that about two-thirds of its length sit inside neck and one-third remain outside for easy removal/handling.

- Care is taken that the plug is firm enough to prevent accidental dislodgement, but not so tight that removal becomes difficult or aeration is blocked.

- All plugged tubes/flasks are wrapped in autoclave bags or thick paper and then sterilized (Autoclave at 121°C, 15 psi, 15–20 min) before use.

- After sterilization, plugs are inspected (some shrinkage may occur) and re-adjusted if needed, do not reuse visibly contaminated plugs.

- Records/labels are applied to vessels if required, and workspace is cleaned after procedure, burners turned off etc.

Methods to test contamination risk from cotton plugs

The risk of contamination from cotton plugs can be evaluated using simple but controlled laboratory tests that directly assess microbial ingress into sterilized media.

- Sterile Media Exposure Test –

- Sterile nutrient broth is filled in several clean culture tubes or flasks (volume according to vessel size).

- Each vessel is sealed with cotton plug prepared in the same way as normally used.

- Both medium and plug are autoclaved together at 121°C / 15 psi for 15–20 min.

- After cooling, plugs are exposed to normal laboratory handling — removed & reinserted few times, under both aseptic and non-aseptic conditions.

- The tubes/flasks are incubated at about 37°C for several days.

- Media are observed daily for turbidity / growth, which indicates contamination entry through plug fibres.

- Comparative Closure Study –

- Cotton plugs are compared with other closures like screw caps, rubber stoppers, glass lids etc.

- All vessels contain same sterile media and are treated in identical condition (autoclaved and handled equally).

- Incubation is done and results are noted by counting how many tubes show contamination.

- This comparison show which closure type gives better aseptic performance or more contamination.

- Air Exposure Challenge –

- Plugged, sterilized culture media are kept openly in areas with circulating air or near working benches where microbes may float.

- These vessels are not opened, only left exposed to air contact for certain time periods (like 24–72 hrs).

- Growth is monitored over days to see contamination frequency — higher growth mean plug not performing well under real lab environment.

Experimental Controls & Evaluation

- Negative control – Some tubes are kept completely sealed and untouched after sterilization to ensure that any contamination observed is truly due to air exposure or handling, not internal defect.

- Quantitative check – The number of contaminated tubes per total tested are recorded, and contamination rate (%) plotted against exposure time or handling frequency.

- Result interpretation – if no visible growth or turbidity occurs, cotton plug considered effective; if growth appear early, then plugging or sterilization process need improvement.

Differences between Permanent Cotton Plugs and Temporary Cotton Plugs

- Material Used – Temporary plug made from absorbent cotton wool, while Permanent plug prepared by non-absorbent cotton (sometimes wrapped with gauze).

- Tightness / Compactness – Temporary plug is loose & soft type to allow easy removal, Permanent one is rolled tight and firm for long-term fitting.

- Durability – Temporary plug used for short duration only, but Permanent plug remain stable even after many sterilization cycles.

- Air Permeability – Both allow air passage, but in Permanent plug air passes slowly due to dense packing and gauze wrapping.

- Reusability – Temporary plug is usually discarded after one use, while Permanent plug can reused many times after sterilization.

- Sterilization Resistance – Permanent plugs withstand repeated autoclaving at 121°C / 15 psi, Temporary plugs may deform or shrink after first sterilization.

- Use Purpose – Temporary plugs used in routine culture transfer or short incubation, Permanent plugs used in stock cultures or long storage.

- Construction Feature – Permanent plug often wrapped with muslin / gauze & tied by thread, Temporary plug kept simple without wrapping.

- Cost & Effort – Temporary plug easy & quick to prepare, Permanent plug takes more time and material but gives sturdy and hardy protection.

Uses of Cotton Plugs

- Used to prevent contamination– cotton plugs stop entry of microorganisms, dust and spores from air into sterile media or culture vessel.

- Provide aeration– allows exchange of gases like O₂ and CO₂ without letting particles enter, which helps growth of aerobic microbes.

- Used during sterilization – keeps the opening of tube or flask covered so medium not spill out or get infected during autoclaving.

- Maintain aseptic condition– after inoculation, plug helps to maintain sterile environment for culture till incubation period complete.

- Used for long-term storage– in permanent plugs, provide safe closure for stock cultures or preserved samples.

- Protect from moisture loss– reduces evaporation from media surface while still permitting small air diffusion.

- Used in tissue culture works – to close culture vessels containing explants and nutrient medium without sealing completely.

- Provide safety in handling – prevents accidental spillage or contact of culture material while transferring or transporting tubes.

Advantages of Cotton Plugs

- Simple & economical – cotton plugs are easily prepared from inexpensive materials, no complex tool or device needed.

- Reusable (in permanent type) – can withstand repeated sterilization cycles without losing shape, so long-term use possible.

- Provide effective filtration – fine cotton fibres trap dust particles, spores and airborne microbes preventing contamination.

- Allow air exchange – maintain aerobic condition for microbial and tissue cultures by letting air pass slowly through fibres.

- Heat resistant – can tolerate high temperature of autoclave (121°C / 15 psi) without melting or releasing toxic gas.

- Non-reactive – cotton is chemically inert with most media, reagents and glass surfaces, so no chemical interference occurs.

- Light weight & easy handling – plugs can be inserted or removed quickly during aseptic transfer or inoculation work.

- Environment friendly – made from natural fibre, can be disposed or burned safely after use, no plastic waste generated.

- Maintain sterile seal – when fitted properly, provide firm closure preventing external contamination but not blocking air.

Limitations of Cotton Plugs

- Contamination risk – during inoculation or transfer, cotton plugs get exposed to air and can catch microorganisms, especially when touched by hand or forceps improperly.

- Not flame sterilizable – because cotton is flammable, it cannot be sterilized directly by flame; only autoclaving is possible which sometimes not give 100 % surface sterility.

- Inhibitory effect – few microbes show poor growth as cotton fibres may adsorb growth factors or release traces of inhibitory material.

- Poor sealing property – plugs don’t make airtight closure, hence in long incubation more evaporation occur causing change in media concentration.

- Biological waste generation – after use, large quantity of used cotton become bio-waste which require careful disposal and increases maintenance cost.

- Variable oxygen diffusion – if plug packed very tight, air exchange reduced; if too loose, contamination chances increase, so balance often difficult.

- Unsuitable for some works – cotton plugs not recommended for chemical handling or anaerobic cultures where complete sealing is needed.

- Deformation after sterilization – after repeated autoclaving, plugs may shrink or lose shape which make fitting improper by time.

- Handling limitation – cotton plug can absorb moisture and become wet, sticky or break during long incubation, affecting aseptic condition.

- Text Highlighting: Select any text in the post content to highlight it

- Text Annotation: Select text and add comments with annotations

- Comment Management: Edit or delete your own comments

- Highlight Management: Remove your own highlights

How to use: Simply select any text in the post content above, and you'll see annotation options. Login here or create an account to get started.